Professional CNC Machinery refers to industrial equipment that adopts Computer Numerical Control (CNC) technology. It features high precision and high automation, and is commonly used for the precision Machinery of complex parts. It integrates mechanical engineering, computer programming, and automation technologies, and is suitable for manufacturing fields with extremely high requirements for efficiency and precision.

CNC movable beam double-column vertical lathe, developed by Luoyang Newbee Transmission, integrates international advanced design concepts. Equipped with the Siemens 808D CNC system and high-precision components, it ensures high-stability machining u......

CNC single - column vertical lathe, developed by Luoyang Newbee Transmission, adopts CAD - optimized design and advanced functional components at home and abroad. It features high rigidity, high stability, and a long service life. Its modular configu......

CNC movable beam double-column vertical lathe, developed by Luoyang Newbee Transmission, integrates international advanced design concepts. Equipped with the Siemens 808D CNC system and high-precision components, it ensures high-stability machining u......

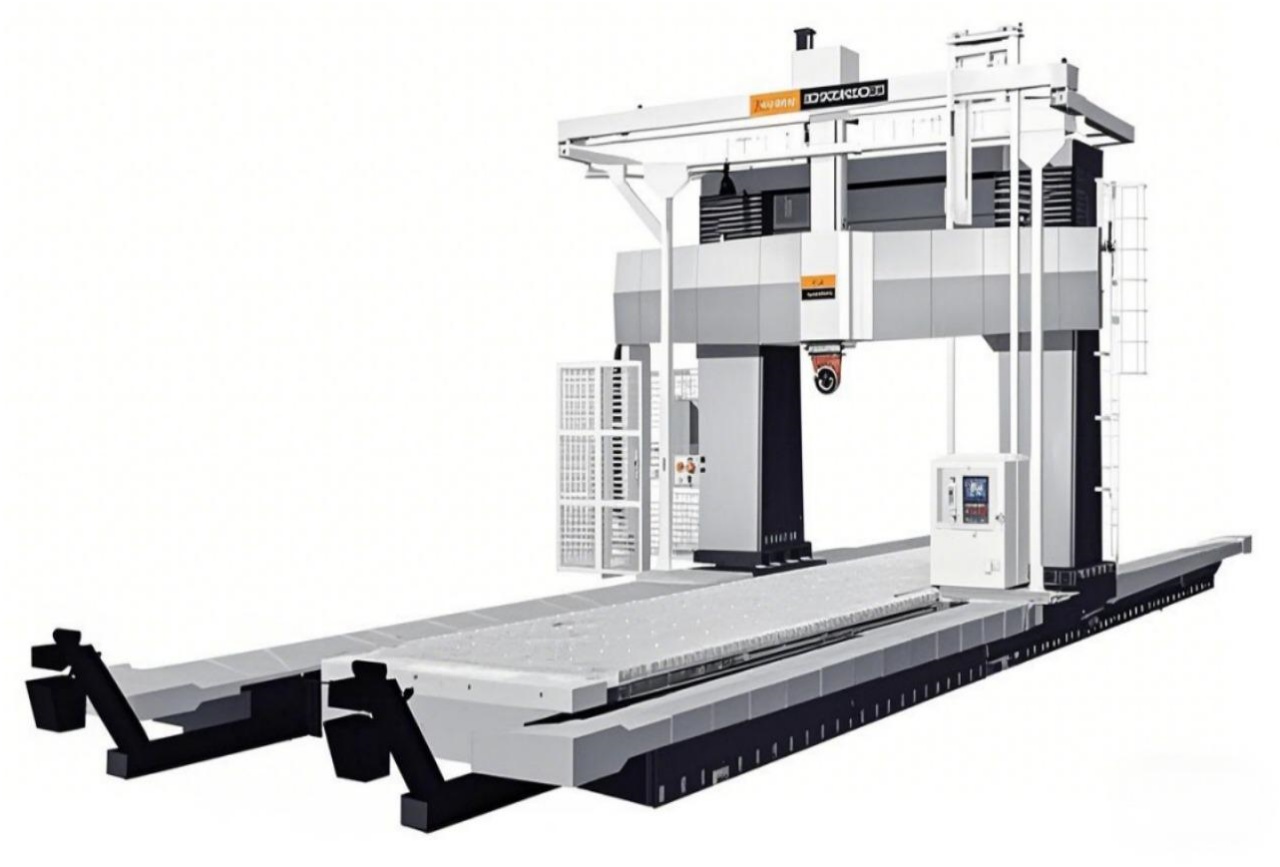

moving column gantry machining center is independently developed by Luoyang Newbee Transmission. It uses an HT300 high - strength cast iron bed and modular functional components, and is equipped with a Siemens 828D CNC system and imported spindle uni......

The moving table gantry machining center is independently developed by Luoyang Newbee Transmission. It uses an HT300 high - strength cast iron bed and modular functional components, and is equipped with a Siemens 828D CNC system and imported spindle ......

The horizontal dual-spindle CNC deep-hole drilling machine is developed by Luoyang Newbee Transmission. It adopts a modular design and a high-rigidity cast-iron structure, and is equipped with the Siemens 828D CNC system and imported functional compo......

The dual spindle flange - specific high - speed CNC drilling machine is developed by Luoyang Newbee Transmission. It adopts a dual - station independent power head design, is equipped with a PLC CNC system and high - pressure cooling technology, and ......

The worktable - mobile high - speed CNC flat drilling machine is developed by Luoyang Newbee Transmission. It adopts advanced international design concepts and high - precision components, and is equipped with the Siemens 808D CNC system to achieve h......

The XWFD series gantry - mobile high - speed CNC flat drilling machine is developed by Luoyang Newbee Transmission. It adopts a high - rigidity cast - iron structure and precision linear guides, and is equipped with the Siemens 808D CNC system to ach......

The XLMZ series gantry - mobile high - speed CNC flat drilling machine is developed by Luoyang Newbee Transmission. It adopts advanced international design concepts and high - precision components, and is equipped with the Siemens 828D CNC system to ......

Custom Design Solutions: We are proficient in creating CNC machinery and components according to your unique specifications. Our team utilizes advanced CAD/CAM software to generate high - precision 3D models and prototypes.

Application - Specific Designs: Whether your needs involve multi - axis machining, high - speed cutting, or specialized tooling, we can design applicable solutions for industries such as automotive, aerospace, medical, and electronics.

Collaborative Approach: We work closely with your team, deeply understand your needs, and incorporate your feedback throughout the design process.

Innovation and R & D: Our professional R & D team continuously explores new technologies and materials to provide cutting - edge design solutions.

Advanced Facilities: Our manufacturing facilities are equipped with advanced CNC machinery, including 3 - axis, 4 - axis, and 5 - axis machining centers.

Material Expertise: We are well - versed in handling a variety of materials, such as metals (aluminum, steel, titanium), plastics, and composites.

Automation and Robotics: We integrate automation and robotics technologies to improve production efficiency and maintain consistency.

Precision Machining: We maintain extremely tight tolerances (e.g., ±0.001 mm) to ensure the highest level of accuracy.

Quality Assurance Processes: Our quality control team conducts rigorous inspections at every stage of production, from raw materials to the final finished products.

Testing and Validation: We use advanced testing equipment to validate the performance and durability of our CNC machinery and components.

Global Supply Chain Management: We have extensive experience in managing international freight and handling customs clearance procedures.

Efficient Logistics Network: We cooperate with reliable freight suppliers to ensure the timely delivery of your orders.

Inventory Management: We maintain an organized inventory system to shorten lead times and ensure the availability of critical components.

After - Sales Support: We provide comprehensive support, including the delivery of spare parts and technical assistance, to minimize downtime.

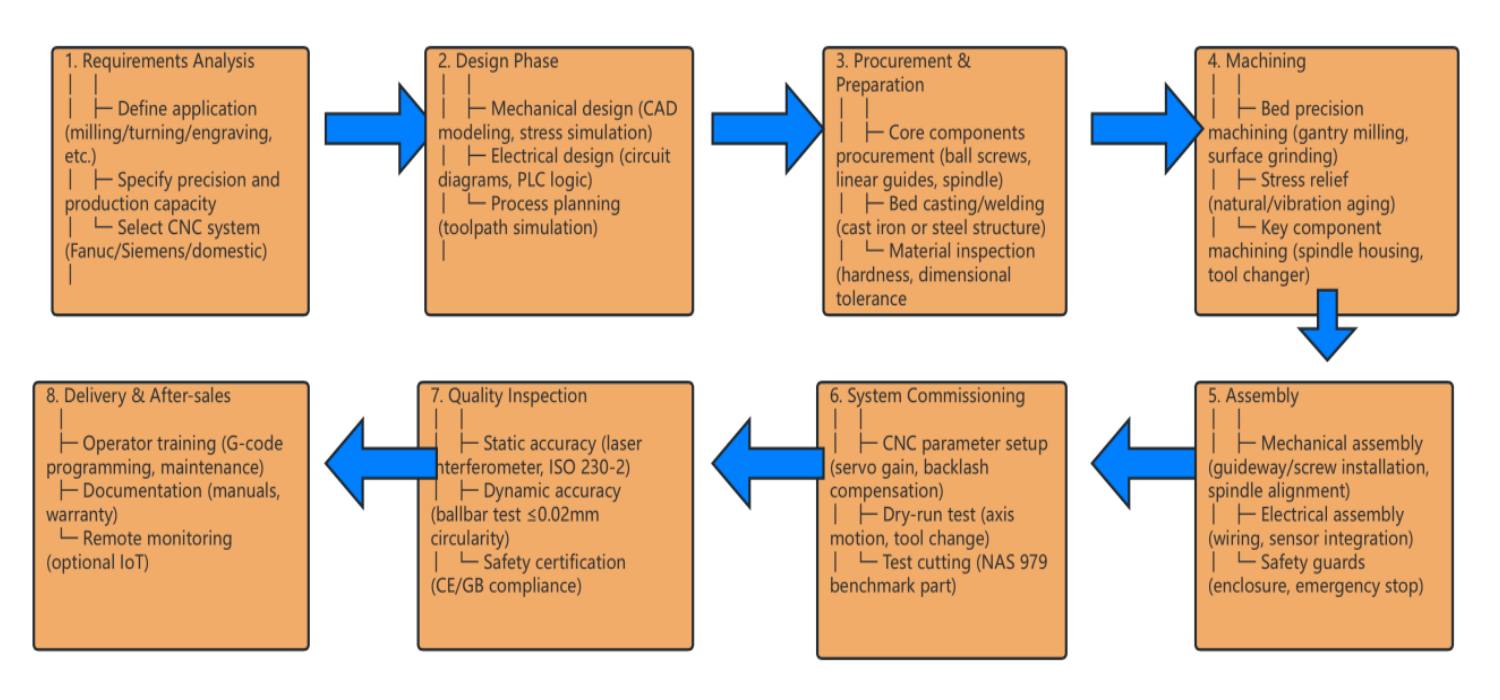

1.Customer Needs Analysis

1.Customer Needs Analysis

Objective: Precisely define customer needs, covering key elements such as machine specifications, applicable materials, and delivery time schedules.

Output: A detailed requirements confirmation document.

2.Design & Engineering

Objective: Use computer - aided design (CAD)/computer - aided engineering (CAE) software to build 3D models and conduct simulations, aiming to deeply optimize the machine design.

Output: Precise 3D models and professional engineering drawings.

3.Manufacturing & Machining

Objective: Use CNC machines to perform high - precision machining on machine components, effectively ensuring that the components meet the design specifications.

Output: Processed components that meet the standards.

4.Quality Control & Inspection

Objective: Use precision measuring tools to carry out comprehensive dimensional and functional tests to ensure that the components meet the established quality standards.

Output: A standardized quality inspection report.

5.Assembly

Objective: Assemble machine components in an orderly manner, effectively integrate the CNC system and control devices, and conduct comprehensive functional tests.

Output: A fully assembled and functional machine.

6.Installation and Debugging of Electrical and PLC Control Devices

Objective: Properly install electrical wiring and programmable logic controller (PLC) control devices, and conduct detailed debugging of the system to ensure the normal operation of the system.

Output: Installed and debugged electrical and PLC control systems.

7.Surface Treatment

Objective: Implement surface treatment processes such as polishing, electroplating, and heat treatment to significantly improve the durability and appearance quality of machine components.

Output: Machine components with high - quality surface treatment.

8.Packaging & Logistics

Objective: Properly and safely package the machine and reasonably arrange transportation matters to ensure the safe delivery of the machine.

Output: A well - packaged machine and detailed transportation information.

9.Final Delivery

Objective: Deliver the machine to the customer strictly according to the scheduled time. - Output: A machine successfully delivered to the customer.

10.Customer Training & Support

Objective: Provide systematic machine operation training for customers and continuously provide technical support.

Output: Customers who are proficient in operation and complete support documentation.

11.Project Review and Documentation

Objective: Deeply analyze project performance and comprehensively record the experiences and lessons in the project process.

Output: A comprehensive and in - depth project review report.

12.Continuous Improvement

Objective: Continuously optimize processes and continuously improve product quality and production efficiency.

Output: More perfect processes and higher - standard quality specifications.

For machining large structural components, engine parts, and landing gear.

For producing molds, dies, and large automotive parts.

For machining wind turbine components, power generation equipment, and large gears.

For precision machining of defense equipment and components.

What is CNC Machinery?

CNC (Computer Numerical Control) Machinery represents the pinnacle of modern manufacturing technology, where pre-programmed computer software controls the movement of factory tools and machinery. This revolutionary technology has transformed traditional manufacturing processes by enabling unprecedented levels of precision, efficiency, and automation in material processing.

At its core, CNC machinery operates through a sophisticated digital control system that interprets computer-aided design (CAD) models and converts them into precise mechanical instructions. These instructions govern every aspect of the machining process, from the cutting tool paths and spindle speeds to coolant flow and auxiliary functions. Unlike conventional manual machining, CNC systems can maintain exceptional accuracy while operating continuously 24/7, making them indispensable in today's high-volume, high-precision manufacturing environments.

The typical CNC system encompasses several key components: the machine tool itself (such as mills, lathes, or routers), the CNC controller which serves as the system's brain, drive systems that convert digital commands into mechanical motion, and precision components like ball screws, linear guides, and high-rigidity bearings that ensure accurate movement and positioning.

The Feature of the CNC Machinery

CNC machinery offers several distinctive features that set it apart from conventional manufacturing equipment:

Precision and Accuracy: CNC machines can achieve tolerances within microns, ensuring part consistency that's impossible to maintain with manual operations. This exceptional accuracy stems from high-quality components like precision-ground ball screws and specialized bearings that minimize thermal expansion and mechanical deflection.

Automation and Efficiency: Once programmed, CNC machines can operate autonomously with minimal human intervention. This enables lights-out manufacturing, where machines continue production overnight and during weekends, dramatically increasing throughput and reducing labor costs.

Flexibility and Versatility: With simple program changes, the same CNC machine can produce completely different parts. This rapid changeover capability makes CNC ideal for both high-volume production and small-batch custom jobs.

Complex Geometry Capability: Modern 5-axis CNC machines can create intricate geometries that would be impossible to produce using conventional methods. This includes complex contours, undercuts, and compound angles in a single setup.

Repeatability: CNC machines can produce thousands of identical parts with minimal variation, ensuring consistent quality throughout production runs.

The Application of the CNC Machinery

CNC machinery finds applications across virtually every manufacturing sector:

Aerospace Industry: Manufacturing complex components like turbine blades, engine parts, and structural elements that demand the highest precision and material integrity. The aerospace sector relies heavily on 5-axis CNC machining for creating complex aerodynamic surfaces.

Automotive Industry: Producing everything from engine blocks and transmission components to custom aftermarket parts. CNC machines handle both prototyping and mass production in automotive manufacturing.

Medical Device Manufacturing: Creating surgical instruments, orthopedic implants, and diagnostic equipment where precision and surface finish are critical for functionality and patient safety.

Electronics Industry: Manufacturing enclosures, heat sinks, connectors, and precision components for consumer electronics and industrial control systems.

Mold and Die Making: Producing injection molds, stamping dies, and casting patterns with the high precision and fine surface finishes required for mass production processes.

How to Choose the CNC Machinery?

Selecting the right CNC machinery requires careful consideration of several factors:

Application Requirements: Identify your primary materials (aluminum, steel, titanium, composites), part sizes, and complexity. Heavy-duty materials require machines with greater rigidity and power.

Work Envelope: Consider the maximum part size you'll produce. Ensure the machine's X, Y, and Z travels accommodate your largest components with additional space for tool clearance and fixturing.

Precision Needs: Determine the tolerances and surface finishes your applications require. High-precision applications demand machines with thermal stability compensation, vibration damping, and premium linear motion components.

Axis Configuration: 3-axis machines suit most prismatic parts, while 5-axis machines provide complete geometrical freedom for complex contours and simultaneous multi-side machining.

Control System: Choose a controller from established brands (Siemens, Fanuc, Heidenhain) that offers the features you need and an interface your operators can master.

Support and Service: Consider the manufacturer's reputation for technical support, training availability, and spare parts delivery to minimize potential downtime.

The Price of the CNC Machinery

CNC machinery pricing reflects its capabilities and construction quality. Entry-level 3-axis machines start around $50,000, while high-end 5-axis machining centers can exceed $500,000. Several factors influence the final cost:

Machine Size and Construction: Larger machines with more massive castings and reinforced structures command higher prices but offer greater stability and vibration damping.

Precision Components: Machines equipped with high-precision ballscrews, linear guides, and spindle systems from reputable manufacturers cost more but deliver superior accuracy and longevity.

Control System: Advanced controllers with more processing power, enhanced functionality, and sophisticated software options add significantly to the machine's cost.

Accessories and Automation: Additional features like automatic tool changers, pallet changers, probing systems, and integrated robotics increase the initial investment but enhance productivity.

Brand Reputation: Established manufacturers with proven track records typically price their machines higher, reflecting their research investment, quality standards, and comprehensive support networks.

CNC Machinery Manufacturer

The global CNC machinery market includes numerous established manufacturers, each with distinctive strengths and specializations. Leading companies like DMG MORI, Mazak, Haas, and Okuma have set industry standards for decades, offering comprehensive machine tool solutions backed by extensive research and development.

These manufacturers continuously innovate to improve machining accuracy, speed, and reliability. Many partner with component specialists like NewBee Transmission to integrate high-performance bearings, linear motion systems, and drive components that enhance machine performance and service life.

When selecting a CNC manufacturer, consider their experience in your specific industry, their technical support capabilities, training programs, and spare parts availability. A reliable manufacturer provides not just equipment but complete manufacturing solutions, helping you optimize your processes and maximize return on investment.

NewBee Transmission collaborates with leading CNC manufacturers to supply critical precision components that ensure optimal machine performance. Our expertise in high-precision bearings and linear motion systems helps manufacturers maintain the accuracy and reliability that modern manufacturing demands.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.