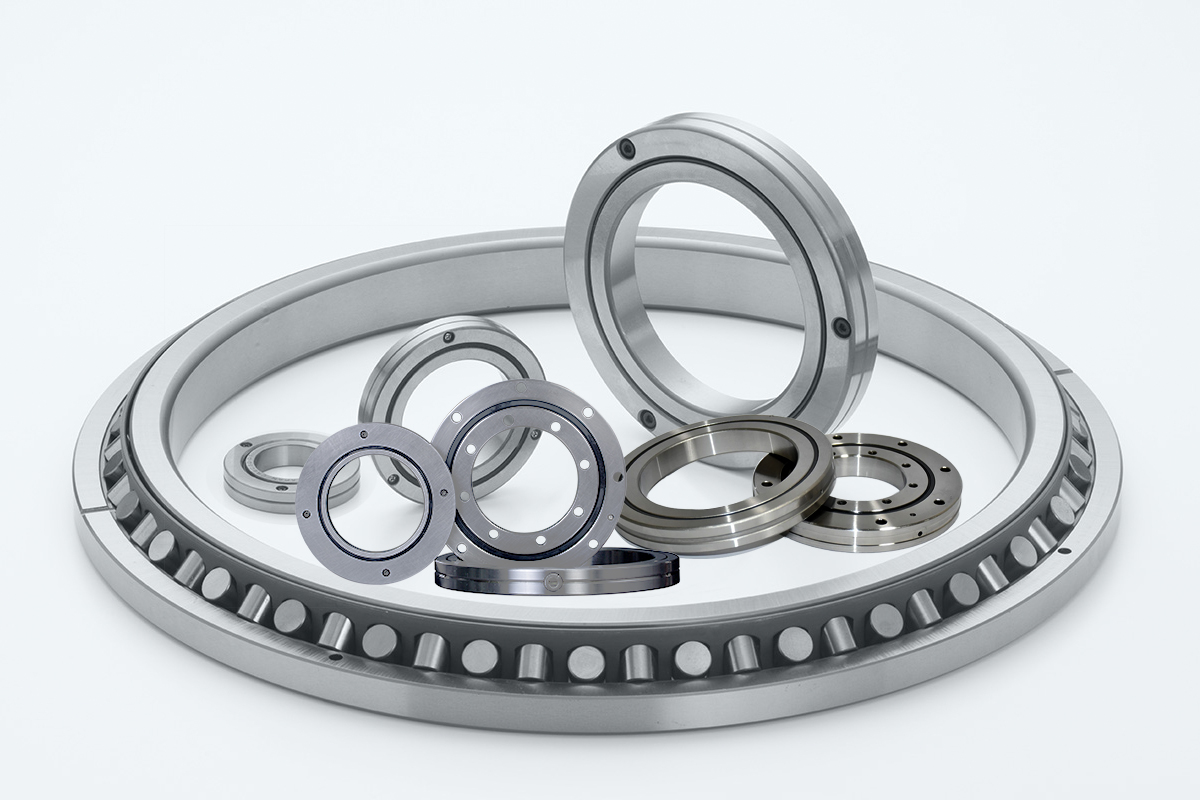

What is Cross Roller Bearing?

Cross Roller Bearing is also known as the Cross-Roller Bearing. Generally, cylindrical rollers or conical rollers are used as the rolling elements, which are arranged Crosswise with each other on a single raceway. The rollers are spaced by retainers or spacers. It has relatively high rotational precision, large load-carrying capacity, small external dimensions, high rotational speed and rigidity. It has a wide range of applications and advantages that other Bearing can't match.

RA Crossed Roller Bearings are a type of roller bearing that are designed to handle high axial,radial, and moment loads simultaneously, making them ideal for applications where precision andstability are critical....

RB crossed roller bearings are single-row roller bearings that use cylindrical rollers arranged in acrossed configuration. The rollers alternate in direction, which allows them to handle axial, radial, and moment loads simultaneously. ...

RU crossed roller bearing is a high-precision, compact bearing with cylindrical rollers set at 90-degree angles (crisscrossed) within integrated inner and outer rings that often feature mounting holes, allowing it to handle radial, axial, and moment ......

SXU crossed roller bearing is a type of high-precision, compact slewing ring (or turntable bearing) featuring rollers arranged at right angles, designed for supporting heavy radial, axial, and overturning loads with high rigidity, low friction, and e......

CRBH Cross Roller Bearing is a high-precision, compact bearing where cylindrical rollers are arranged in a crossed (90-degree) pattern within separate inner and outer rings, allowing it to handle heavy radial, axial, and moment loads simultaneously, ......

Crossed Tapered Roller Bearings are designed to handle high overturning moments and complex combined loads, making them the ideal solution for high-performance applications like robotics, precision rotary tables, and machine tools....

CRBC crossed roller bearings are a type of high-precision bearing (often from brands like IKO) featuring cylindrical rollers arranged perpendicularly (crossed) for high rigidity, compact size, and the ability to handle loads in all directions (radial......

A CRBF crossed roller bearing is a high-rigidity, compact bearing with rollers arranged at 90° angles, featuring integrated mounting holes in its inner and outer rings for easy bolting, enabling high accuracy and stiffness in small spaces for applic......

A CRBT crossed roller bearing is an ultra-compact, lightweight, and high-rigidity bearing with cylindrical rollers arranged perpendicularly (crossed) between inner and outer rings, designed for precision motion in space-constrained machines like robo......

A CRBS crossed roller bearing is a high-precision, compact bearing with rollers arranged at right angles, allowing it to handle radial, thrust, and moment loads simultaneously, making it ideal for robotics and precision machinery needing high rigidit......

An SX crossed roller bearing is a high-precision, compact bearing with a split outer ring and an integral inner ring, featuring cylindrical rollers arranged in an 'X' pattern (90° to each other) to support heavy radial, axial, and moment loads simult......

An XR/JXR Cross Tapered Roller Bearing is a high-precision, compact bearing using tapered rollers arranged perpendicularly (crossed at 90°) within inner and outer rings, allowing it to handle heavy radial, axial, and overturning moment loads simultan......

Professional Team: Comprising over 30 senior engineers, covering fields such as mechanical design, materials science, and industrial automation. They are well - versed in international standards like ISO, DIN, and JIS. By leveraging CAD/CAE assisted design, 3D models can be rapidly generated and simulated for analysis, ensuring the feasibility of the plan and performance optimization.Customization Process: Conduct in - depth communication regarding application scenarios such as high - temperature, high - speed, and heavy - load conditions. Design bearing structures, material selection, and lubrication solutions in a targeted manner. Complete the sample design within 15 days, support parameter adjustment and performance verification to shorten the development cycle. A strict confidentiality agreement is in place to safeguard the safety of clients' drawings and patents.

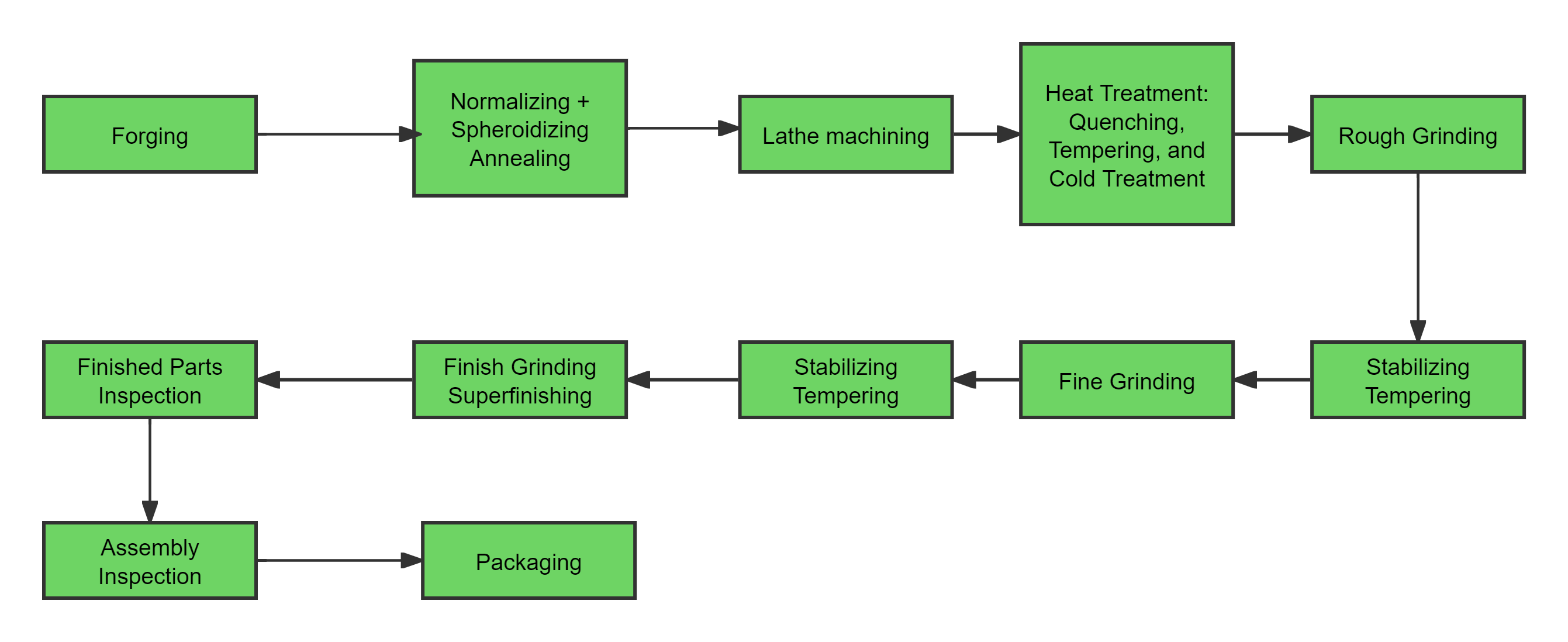

Advanced Manufacturing: Equipped with fully automatic CNC machine tools, high - precision grinding equipment, and heat - treatment production lines, capable of manufacturing all types of bearings. By adopting precision cold ring rolling and super - fine grinding processes, the tolerance can reach P5/P4 level, meeting high - precision requirements. The monthly production capacity exceeds 2 million sets, enabling flexible response to both small - batch trial production and large - volume orders. The regular delivery cycle is 30 days.Intelligent Management: The MES system monitors the production progress in real - time, and the entire order process is traceable. The modular production line can quickly change models to adapt to the production of multiple specifications and batches.

Full - process Quality Control: The raw materials are double - verified by a spectral analyzer and a metallographic microscope. Key dimensions are monitored online by a profilometer, a roundness tester, etc., with an automatic rejection rate of non - conforming products reaching 100%. The noise level, vibration value, and service life are fully inspected at a rate of 100%. Durability tests are carried out under simulated working conditions.

Authoritative Certifications: Passed ISO 9001 and GBT307.1 certifications. SGS third - party inspection reports can be provided along with the goods to meet the market access requirements worldwide.

Warehousing and Packaging The intelligent warehousing center dynamically manages inventory and supports the VMI (Vendor Managed Inventory) model. Customized anti - rust packaging with vacuum and shock - proof measures ensures zero damage during transportation. Global Network We cooperate with DHL, FedEx, etc., and offer trade terms such as FOB (Free on Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). With overseas warehouses established in Europe and North America, orders can be delivered within 7 - 10 days.

Cross Roller Bearing provide high - precision rotational support for the joint movements of industrial robots, effectively handling various forces in complex situations. They improve the movement prec...

Cross Roller Bearing play a crucial role in the spindle systems of machine tools, bearing radial, axial loads and overturning moments during high - speed rotation to ensure high precision of machined ...

Cross Roller Bearing support rotating parts in precision measuring instruments and achieve precise movement by bearing radial and axial forces. They ensure the measurement accuracy of precision measur...

In medical imaging equipment like CT scanners and MRI machines, Cross Roller Bearing support rotating components to ensure high precision and stability for obtaining accurate images. For surgical and ...

Cross Roller Bearing play a critical role in aircraft landing gear systems, handling high impact forces and ensuring smooth operation during landing, takeoff, and taxiing. In aircraft engines componen...

In semiconductor manufacturing equipment like lithography machines and etching machines, Cross Roller Bearing support the worktables, enabling precise movement and positioning with high accuracy. Cros...

What is a Cross Roller Bearing?

A cross roller bearing is a special type of rolling bearing uniquely designed with cylindrical rollers arranged at 90 degrees to each other in V-shaped grooves between the inner and outer rings. This precision-engineered component can simultaneously withstand radial loads, axial loads, and overturning moments, making it an ideal choice for high-precision rotary applications. Unlike traditional solutions that require combinations of multiple standard bearings, a single cross roller bearing provides multi-directional load capacity, greatly simplifying mechanical design.

The rollers in the bearing are evenly spaced by precision cages or spacer blocks, ensuring optimal load distribution and smooth operation. The line contact between the cross-arranged rollers and raceways provides higher rigidity and load capacity compared to the point contact of ball bearings. This design makes cross roller bearings particularly suitable for applications requiring high rotationalaccuracy and compact designs, such as industrial robot joints, precision rotary tables, and medical equipment.

Based on structural characteristics, cross roller bearings are mainly divided into two types: non-separable (such as the RA series) and separable (such as the RB series). Non-separable bearings offer higher rigidity, while separable bearings facilitate installation and maintenance. Additionally, there is the RU series with mounting holes, which can be fixed directly with bolts, further simplifying the installation process.

Features of Cross Roller Bearings

Cross roller bearings possess several outstanding characteristics that make them indispensable in the field of precision machinery:

High Rigidity and High Load Capacity: The cross-arranged roller design enables the bearing to withstand loads in all directions, including radial, axial, and moment loads, while maintaining extremely high rigidity.

Excellent Rotational Accuracy: Precisely manufactured rollers and raceways ensure minimal runout during bearing operation, typically controlling radial and axial runout to micrometer levels, meeting the needs of high-precision applications.

Compact Design:Compared to multi-bearing combinations achieving the same function, a single cross roller bearing can save up to 50% of installation space, enabling equipment miniaturization.

Simplified Installation and Maintenance: Especially the separable design (such as the RB series), which allows the bearing to be installed on an already assembled shaft, greatly simplifying the installation process and maintenance work.

Low Friction and Smooth Operation: Optimized roller profiles and finely finished surfaces ensure smooth bearing operation and low friction torque, contributing to improved system efficiency and extended service life.

High Stiffness and Minimal Deformation:The cross roller arrangement minimizes bearing deformation under moment loads, ensuring the accuracy of precision positioning systems.

Applications of Cross Roller Bearings

Cross roller bearings are widely used in various high-precision equipment and mechanical systems:

Industrial Robots: Rotary joints, bases, and wrist joints of robots, especially critical parts of six-axis and SCARA robots, require high rigidity and precise positioning capability.

Precision Rotary Tables: Fourth and fifth-axis rotary tables for CNC machining centers, rotating platforms for precision measuring equipment, and wafer handling systems in semiconductor manufacturing.

Medical Equipment: Rotating gantries of CT scanners, MRI systems, surgical robot joints, and precision medical instruments, where smooth operation and precise control are extremely important.

Aerospace and Defense: Radar antenna bases, steering mechanisms for satellite communication systems, motion platforms for aviation simulators, and various navigation and targeting systems.

Automation Equipment: Rotary units on automated assembly lines, precision indexing plates, and key rotating components of material handling systems.

Optical and Measuring Instruments: Azimuth and elevation axes of telescopes, optical mounts in laser processing equipment, rotary attachments for coordinate measuring machines, etc.

How to Choose Cross Roller Bearings?

Selecting the appropriate cross roller bearing requires comprehensive consideration of the following factors:

Load Condition Analysis: Evaluate the magnitude and direction of radial, axial, and moment loads present in the application, ensuring the selected bearing's rated load meets requirements and considering an appropriate safety factor.

Accuracy Requirements: Determine the necessary accuracy grade based on application needs. Standard grade is suitable for general industrial applications, precision grade (P5, P4) for high-precision equipment, and ultra-precision grade (P2, UP) for extremely precise instruments.

Size Constraints: Consider the limitations of the installation space on the bearing's inner/outer diameter and width. Cross roller bearings come in various series, from compact to heavy-duty types; the model most suitable for space constraints should be selected.

Operating Environment: Assess temperature, humidity, presence of contaminants, and lubrication conditions. Special environments may require stainless steel bearings, special coatings, or seal designs.

Installation Method: Choose between non-separable or separable bearings based on equipment structure. For situations where axial installation is difficult, separable bearings (such as the RB series) are a better choice.

Preload and Clearance: Determine whether preload (to eliminate clearance and increase rigidity) or retaining appropriate clearance (to compensate for thermal expansion) is needed based on application requirements.

Speed Capability: Consider the operating speed range of the bearing, ensure the selected bearing design is suitable for that speed condition, and select the appropriate lubrication method.

Price of Cross Roller Bearings

The price of cross roller bearings is influenced by various factors:

Accuracy Grade: Higher accuracy leads to higher manufacturing costs. Ultra-precision bearings (P4, P2 grade) can be 2-3 times more expensive than standard grade bearings.

Size and Series: Large-size bearings and special series (such as ultra-thin, heavy-duty types) are usually more expensive. Within the same series, prices increase non-linearly with size.

Materials and Processes: Bearings made from special materials like stainless steel, ceramics, or those undergoing special heat treatments (like cryogenic treatment) have significantly higher costs.

Brand and Origin: Bearings from well-known brands (such as INA, THK, IKO) typically carry a 20%-50% brand premium but offer more reliable quality and after-sales service.

Quantity and Delivery Time: Large quantity purchases can obtain more favorable unit prices, while rush orders may incur additional costs.

Special Requirements: Non-standard clearance, special lubricants, custom seals, or special packaging will increase costs.

Market Factors: Fluctuations in raw material prices, exchange rate changes, and market demand also affect the final price.

As a reference, the starting price for small standard cross roller bearings (inner diameter <100mm) is approximately $100-$200, while large precision bearings (inner diameter >500mm) can cost thousands or even tens of thousands of dollars.

Cross Roller Bearing Manufacturers

NewBee Transmission's Advantages: As a professional supplier in the field of precision transmission components, NewBee Transmission has established long-term cooperative relationships with several top manufacturers, providing comprehensive cross roller bearing solutions:

Comprehensive Product Range: From standard RA, RB, RU series to customized designs, meeting diverse customer needs.

Technical Support Capability: Possesses an experienced team of engineers providing full-process technical support from selection consultation to installation and maintenance.

Quality Control System: Strictly implements ISO quality management standards, ensuring the performance and reliability of each bearing.

Customization Services: Able to provide customized services such as size modifications, material replacements, and special heat treatments based on specific customer requirements.

Rapid Response Mechanism: Establishes an efficient supply chain system to ensure customers receive the required products in the shortest possible time.

When selecting a cross roller bearing manufacturer, comprehensive consideration should be given to their technical capability, product quality, service support, and price competitiveness. NewBee Transmission is committed to providing the most suitable bearing solution for each customer, ensuring optimal equipment performance and the longest service life.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.