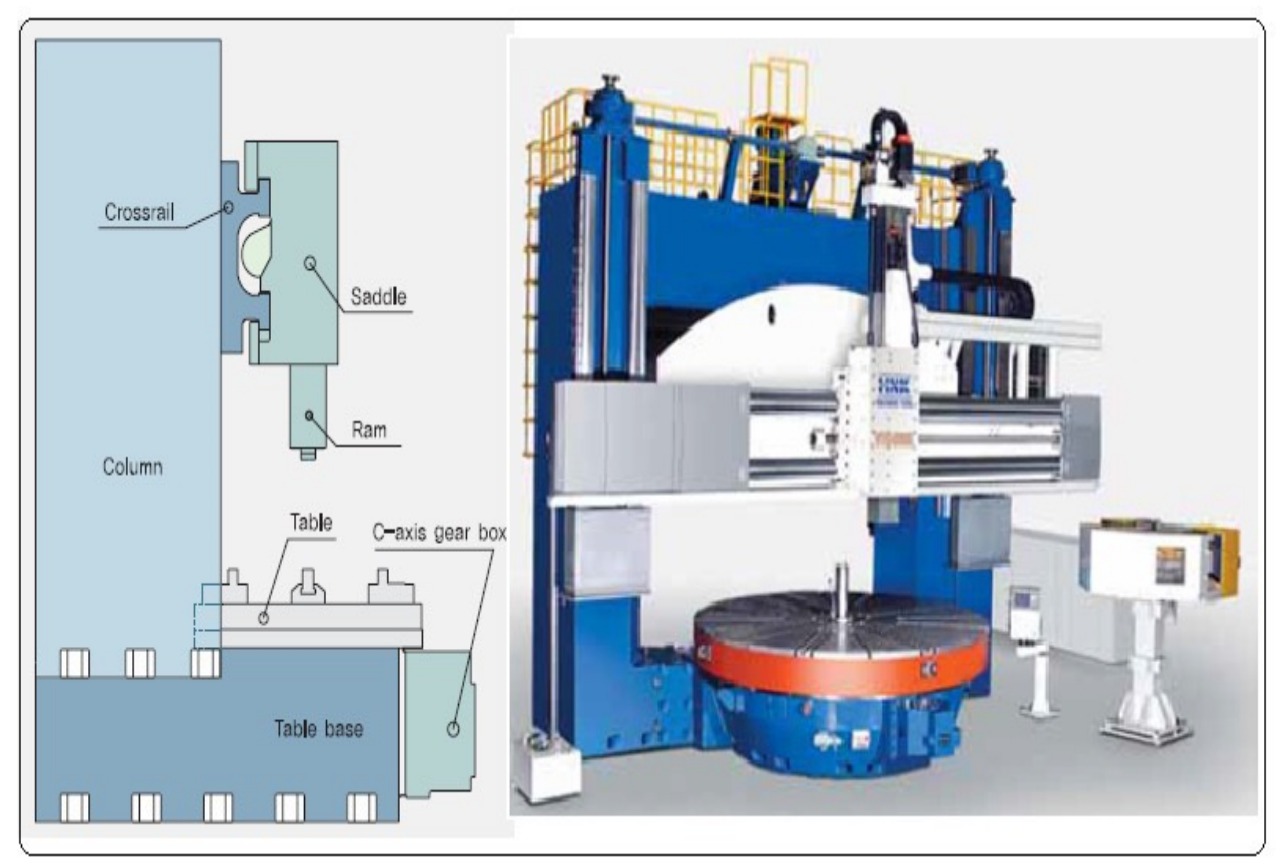

Dual-column dynamic beam structure: High-strength cast iron components (HT250/MTCrCu300); super-audio quenched guide rails (HRC48-55) ensure decades-long durability.

Drive system: High-power dual/triple/quadruple spindle servo motors (2×55kW to 4×75kW); equipped with Siemens 808D CNC system (dual controls for larger models).

Maximum turning diameter: 2500–10000mm; worktable diameter: 2000–7100mm.

Maximum workpiece height: 1500–2500mm; maximum workpiece weight: 20–80t.

Worktable torque: 20–100 kN·m; stepless speed range: 0.42–63 r/min.

Ram system: Square ram (200×200mm) with zinc-aluminum alloy wear-resistant plates.

Tool post system:

Maximum cutting force: 35 kN (vertical tool post).

Rapid traverse speed: 1560 mm/min; tool shank section: 40×40mm or 60×60mm.

Horizontal stroke range: -50 to 5050mm; ram stroke: 1000mm.

Feed rate range: 0.2–145 mm/min (stepless).

Crossbeam lift: 700–1500mm (adjustable for workpiece height).

Machine dimensions: 5400×4400×6200mm (smallest) to 13500×12000×6200mm (largest).

Machine weight: 34T (TCK5225) to 130T (TCK52100).

| Parameter Name | Unit | TCK5225 | TCK5230 | TCK5240 | TCK5250 | TCK5265 | TCK5280 | TCK52100 |

|---|---|---|---|---|---|---|---|---|

| Worktable - Maximum Turning Diameter | mm | 2500 | 3000 | 4000 | 5000 | 6500 | 8000 | 10000 |

| Worktable - Worktable Diameter | mm | 2000 | 2500 | 3600 | 4500 | 5500 | 6000 | 7100 |

| Worktable - Maximum Workpiece Height | mm | 1500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Worktable - Maximum Workpiece Weight | t | 20 | 30 | 40 | 40 | 40 | 60 | 80 |

| Worktable - Maximum Torque of Worktable | KN·m | 20 | 25 | 35 | 50 | 70 | 70 | 100 |

| Worktable - Rotation Speed Range (Stepless) | r/min | 2 - 63 (Stepless) | 2 - 63 (Stepless) | 2 - 63 (Stepless) | 0.42 - 42 (Stepless) | 0.42 - 42 (Stepless) | 0.42 - 42 (Stepless) | 0.42 - 42 (Stepless) |

| Cross - section of Square Slide | mm | 200×200 | 200×200 | 200×200 | 200×200 | 200×200 | 200×200 | 200×200 |

| Maximum Cutting Force of Vertical Tool Post | KN | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Feed Rate Range of Left Tool Post | mm/min | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 |

| Feed Rate Range of Right Tool Post | mm/min | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 | 0.2 - 145 |

| Lifting Stroke of Beam | mm | 700 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Horizontal Stroke of Vertical Tool Post | mm | - 50~1300 | - 50~1550 | - 50~2050 | - 50~2550 | - 50~3300 | - 50~4050 | - 50~5050 |

| Slide Stroke of Vertical Tool Post | mm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Rapid Traverse Speed of Tool Post | mm/min | 1560 | 1560 | 1560 | 1560 | 1560 | 1560 | 1560 |

| Power of Tool Post Rapid Motor | KW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Cross - section Size of Tool Shank (Width×Height) | mm | 40×40 | 40×40 | 60×60 | 60×60 | 60×60 | 60×60 | 60×60 |

| Main Motor Power | KW | 2×55 | 2×55 | 2×75 | 2×75 | 3×75 | 4×75 | 4×75 |

| Electrical Control | - | Siemens 808D Left Tool Post: Mechanical (Digital Display) | Siemens 808D Left Tool Post: Mechanical (Digital Display) | Right Tool Post: Siemens 808D Left Tool Post: Mechanical (Digital Display) | Right Tool Post: Siemens 808D Left Tool Post: Mechanical (Digital Display) | Right Tool Post: Siemens 808D Left Tool Post: Mechanical (Digital Display) | Right Tool Post: Siemens 808D | Right Tool Post: Siemens 808D |

| Overall Dimensions of Machine Tool (Length×Width×Height) | mm | 5400×4400×5590 | 5900×4900×6200 | 6900×5900×6200 | 7900×6900×6200 | 9500×8500×6200 | 11500×10000×6200 | 13500×12000×6200 |

| Machine Tool Weight (Approx.) | T | 34 | 43 | 60 | 70 | 90 | 105 | 130 |

Super - strong load - bearing capacity: The double - column movable beam structure can bear 80 - ton workpieces.

The super - audio frequency quenched (HRC50 - 55) guide rails of the beam, combined with hand scraping, ensure long - term accuracy stability.

Supports the optional configuration of multiple tool holders (left/right tool holders) and power milling heads, expanding the processing functions.

It has built - in vibration monitoring and temperature control systems that can provide real - time warnings of mechanical failures and reduce unplanned downtime.

Energy Equipment: Machining the main shafts of wind turbines and the flanges of nuclear power plant pressure vessels.

Heavy Machinery: Turning the end faces of ship propellers and the gear boxes of mining machinery.

Aerospace: High - precision machining of the inner and outer circles of rocket engine casings.

Metallurgical Industry: Turning the support seats of rolling mill roller tables and the segments of continuous casting machines.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.