✅Core Design Advantages

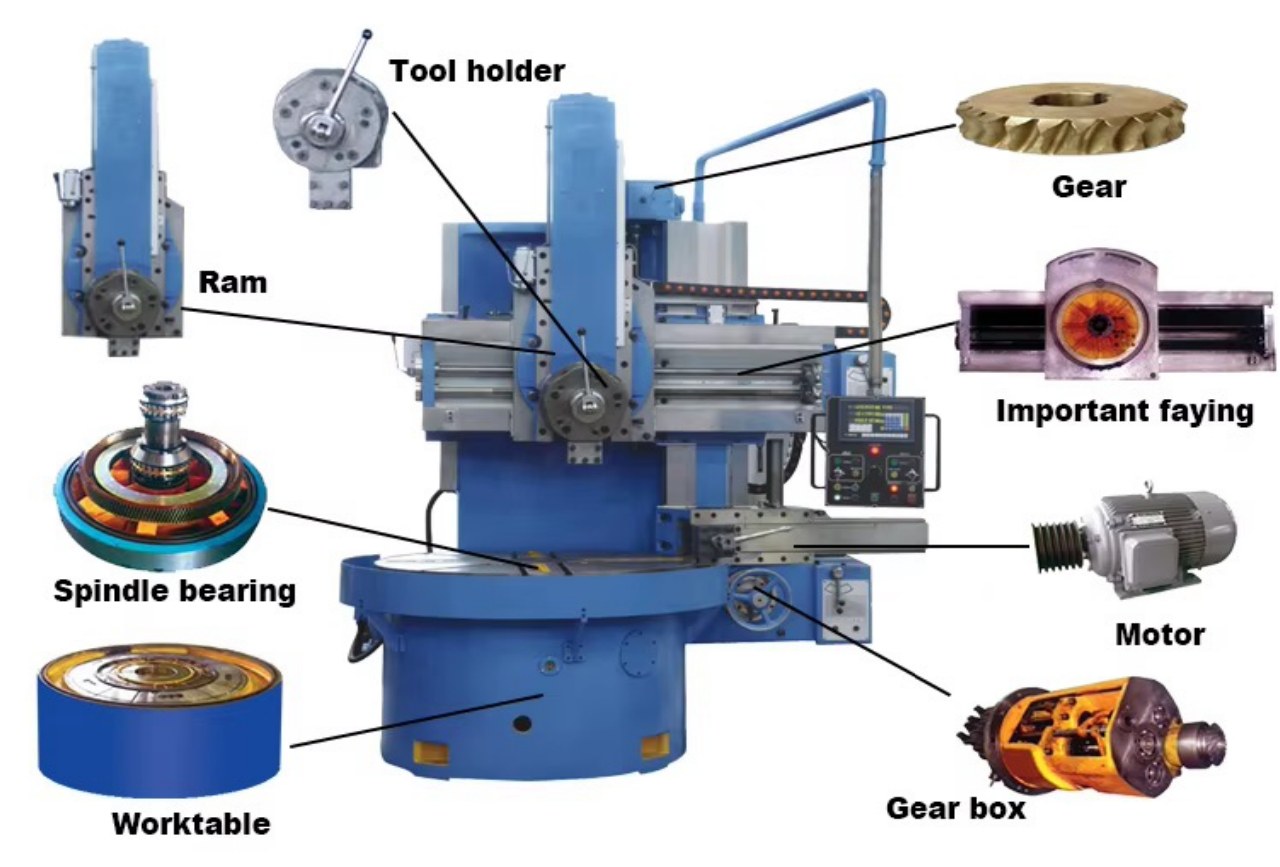

Single-column vertical lathe: High-strength cast iron bed and crossbeam (HT250/MTCrCu300); super-audio quenched guide rails (HRC48-55) ensure long-term accuracy.

Driven by high-power spindle servo motor (45kW); equipped with GSK980Ti CNC system.

✅Key Performance Parameters

Maximum turning diameter: 1600mm/2000mm; worktable diameter: 1400mm/1800mm.

Maximum workpiece height: 1400mm; maximum workpiece weight: 5t/8t.

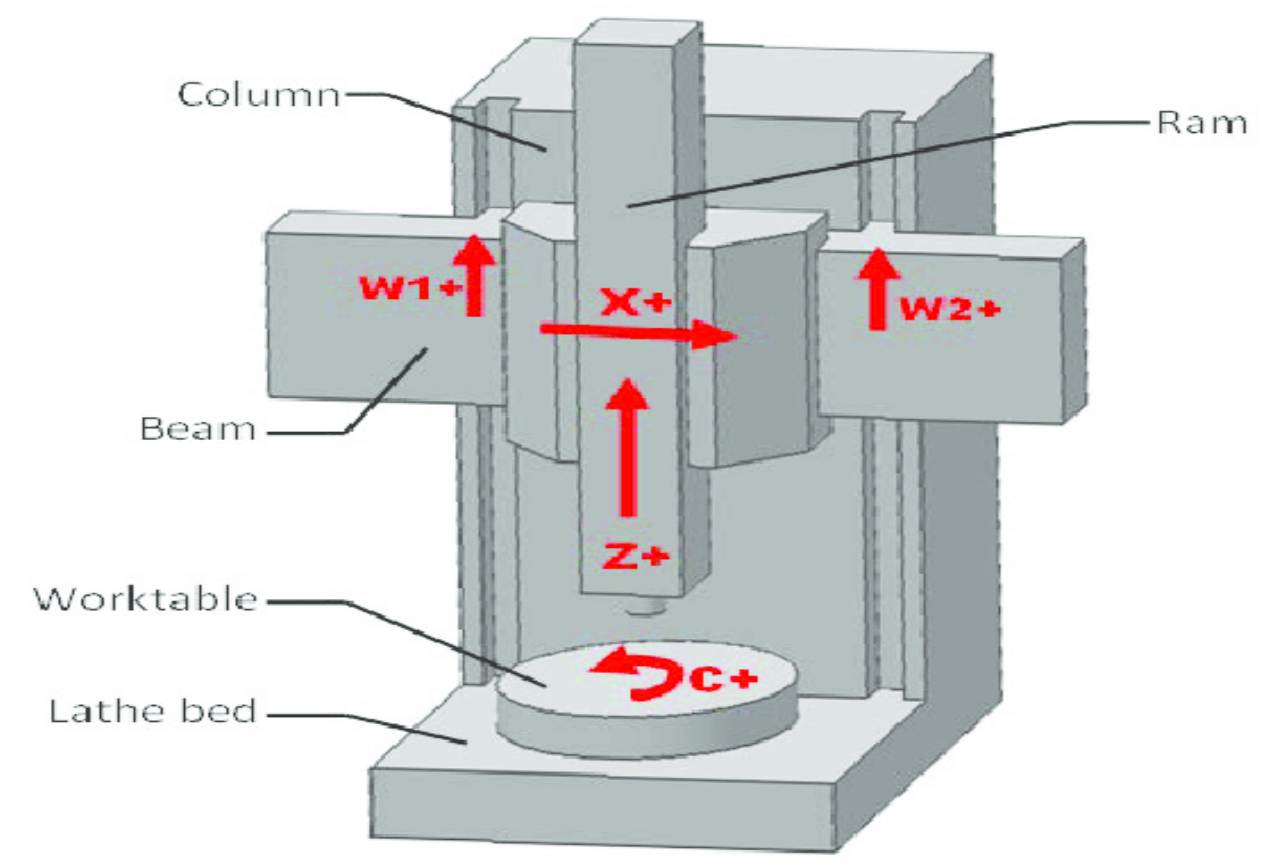

✅Structural Configuration Features

Cross-rail system: Square cross-rail (200×200mm) inlaid with zinc-aluminum alloy wear-resistant plate.

Tool post system: Maximum cutting force of vertical tool post: 22kN; rapid moving speed: 2000mm/min; tool shank section: 30×40mm.

✅Precision and Efficiency

Tool post feed rate: 0.1-500mm/min (stepless).

Horizontal stroke: -50~850mm / -50~1050mm; cross-rail stroke: 800mm.

Overall dimensions: 2400×2300×3100mm / 2800×2700×3100mm.

Machine weight: 14T/17.5T.

| Vertical Lathe Specifications | |||

|---|---|---|---|

| Parameter Name | Unit | TCK5116 | TCK5120 |

| Maximum Turning Diameter | mm | 1600 | 2000 |

| Worktable Diameter | mm | 1400 | 1800 |

| Maximum Workpiece Height | mm | 1400 | 1400 |

| Maximum Workpiece Weight | t | 5 | 8 |

| Maximum Worktable Torque | KN.m | 40 | 40 |

| Worktable Speed Range | r/min | 4-125 | 4-125 |

| Square Ram Section Size | mm | 200×200 | 200×200 |

| Maximum Cutting Force of Vertical Tool Post | KN | 22 | 22 |

| Tool Post Feed Rate Range (Stepless) | mm/min | 0.1-500 | 0.1-500 |

| Horizontal Stroke of Vertical Tool Post | mm | -50~850 | -50~1050 |

| Ram Stroke of Vertical Tool Post | mm | 800 | 800 |

| Rapid Moving Speed of Tool Post | mm/min | 2000 | 2000 |

| Tool Shank Cross-Sectional Size (Width×Height) | mm | 30×40 | 30×40 |

| Main Motor Power | KW | 45 | 45 |

| CNC System | - | Guangshu 980Ti | Guangshu 980Ti |

| Machine Overall Dimensions (L×W×H) | mm | 2400×2300×3100 | 2800×2700×3100 |

| Machine Tool Weight (Approx.) | T | 14 | 17.5 |

| Model: TCK5116 TCK5120 | |||

The high - rigidity structure: The bed and beam are made of HT250 cast iron, and the super - audio frequency quenched guide rails increase the dynamic and static stiffness by 40%.

Driven by a high - power spindle servo motor (45 kW), it supports heavy - duty cutting and increases the metal removal rate by 25%.

The guide rails are quenched to a hardness of HRC48 - 55 and, combined with zinc - aluminum alloy wear - resistant plates, have a service life of over 10 years.

The external lubrication system and one - click maintenance reminder reduce downtime.

Energy Industry: Finish machining of wind turbine hubs and flange end faces.

Automotive Manufacturing: High - precision turning of brake discs and drive shafts.

General Machinery: Machining the inner and outer circles of large gear discs and bearing seats.

Petrochemical Equipment: Turning the sealing surfaces of reactor flanges.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.