What is gear?

Gears are mechanical components with teeth that mesh together to transmit torque and rotation between machine parts. They are essential in various machinery and equipment,enabling speed reduction,torque amplification,and direction change. At NewBee Transmission,we offer a wide range of gears,including spur gears,helical gears,bevel gears,and worm gears,designed to meet the specific needs of different industries.

Free Design Services

We provide free design and engineering services for custom non - standard machinery parts. Our goal is to meet your precise requirements.

Using advanced CAD/CAE software, our experienced engineers create detailed 3D models and simulations for optimal functionality.

We collaborate closely with you during the design process, incorporating your feedback to perfect the design.

Customization and Innovation

Our design team can handle complex geometries, unique materials, or specific tolerances. We tailor solutions to your exact specs.

We emphasize innovation and efficiency, ensuring the final design is both functional and cost - effective.

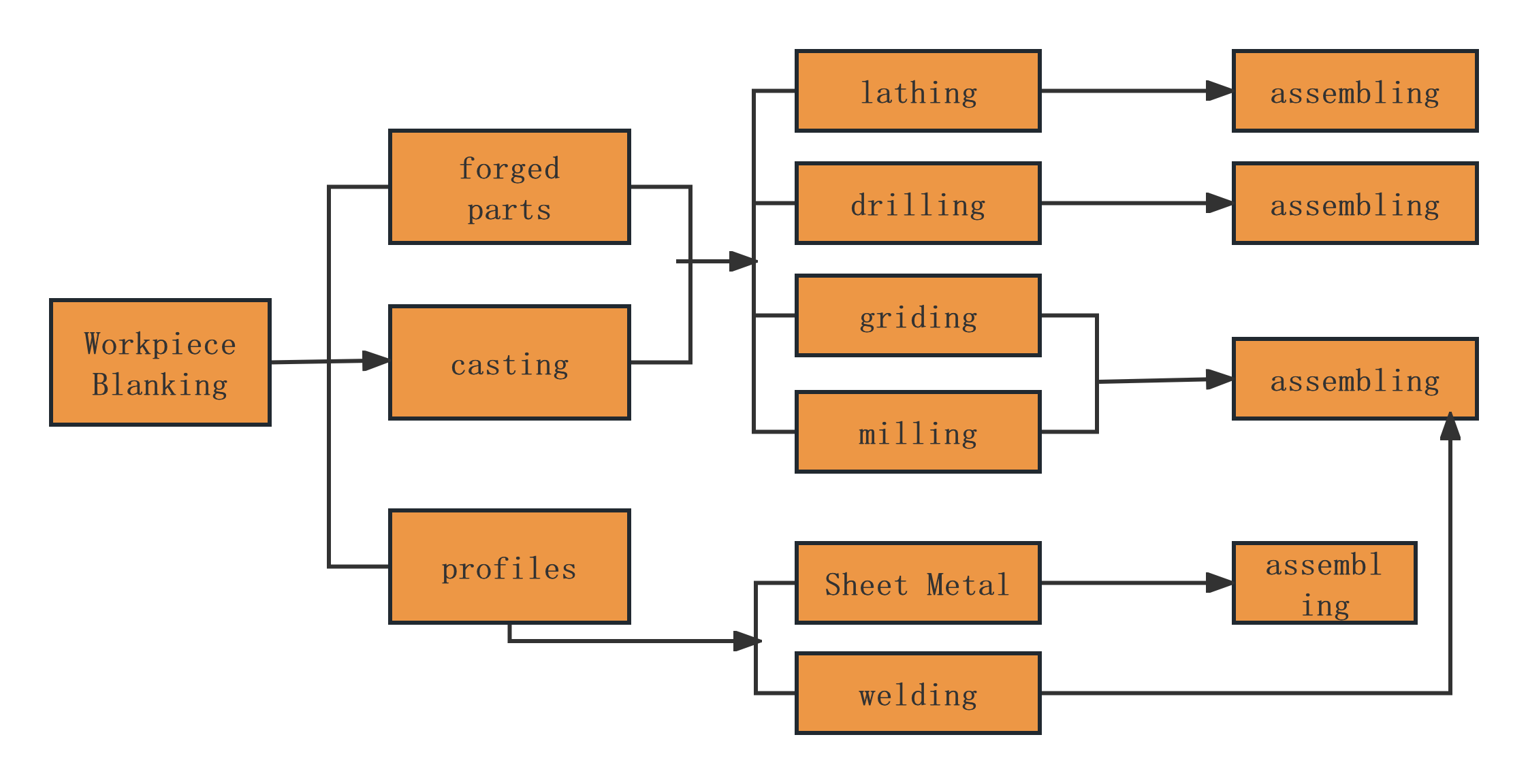

High Precision Machining

Our expertise lies in turning, milling, grinding, and drilling, enabling us to craft high-precision components with unwavering consistency.

Adhering strictly to ISO 9001 standards, our manufacturing processes are geared towards meeting the most exacting international quality requirements.

Low Minimum Order Quantities (MOQ)

Whether you need a single prototype or a small batch of custom parts, our team is equipped to meet your requirements precisely.

Material Expertise

Our team has the ability to source and process special or custom materials according to your specific needs.

Precision Assembly

Our skilled technicians and engineers precisely assemble non - standard parts for perfect fit and function. Advanced tools ensure high accuracy in the process.

Quality Assurance

Parts are rigorously checked during and after assembly to meet high standards. Functional testing verifies they match your specs.

Custom Integration

We provide custom assembly, integrating extra features or components as you need. Our team can also incorporate third - party systems like sensors for fully customized solutions.

Efficient Supply Chain Management

We have established a comprehensive supply chain network that ensures the timely procurement of high - quality raw materials and components. The logistics team collaborates closely with suppliers to strive to shorten lead times and maintain the smooth operation of the production process.

Global Shipping and Delivery

We offer a full - range of logistics solutions, covering packaging, shipping, and customs clearance, to ensure that your parts are delivered safely and on time all over the world. We use sturdy crates and shock - absorbing materials for packaging to prevent parts from being damaged during transit. We cooperate with reputable shipping partners to provide cost - effective and reliable air, sea, and land freight options.

Short Lead Times

Our efficient production process and well - organized supply chain enable us to achieve short lead times even for customized orders. For urgent projects, we have expedited production and shipping options to ensure the on - time delivery of your parts.

Gears are widely used in industrial machinery such as machine tools,conveyor systems,and packaging equipment,providing reliable power transmission and speed control.

In automotive transmissions,differentials,and engine systems,gears play a critical role in ensuring power transmission and vehicle performance.

In wind turbines,gearboxes are used to convert low-speed wind energy into high-speed electrical output. The high load-bearing capacity and durability of gears are crucial for efficient operation.

In aircraft engines and landing gear systems,gears are used for precise power transmission and mechanical motion control,ensuring flight safety.

Gears provide precise motion control in robotic joints and transmission systems,ensuring the flexibility and stability of robots.

In medical devices such as CT scanners and surgical robots,gears are used for precise mechanical motion control,ensuring the accuracy and reliability of the equipment.

Features of Gear

1.High Load-Bearing Capacity

Gears are designed to withstand high torque and heavy loads,making them suitable for heavy machinery and industrial equipment.

2.High Efficiency

Gear transmission is highly efficient,reducing energy loss and improving equipment performance.

3.Precision Transmission

The precise tooth profile of gears ensures smooth transmission and accurate motion control,making them ideal for high-precision equipment.

4.Durability

Made from high-strength materials,gears offer excellent wear resistance and long service life,suitable for continuous operation.

5.Diverse Designs

We provide various types of gears,including spur gears,helical gears,bevel gears,and worm gears,to meet different application requirements.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.