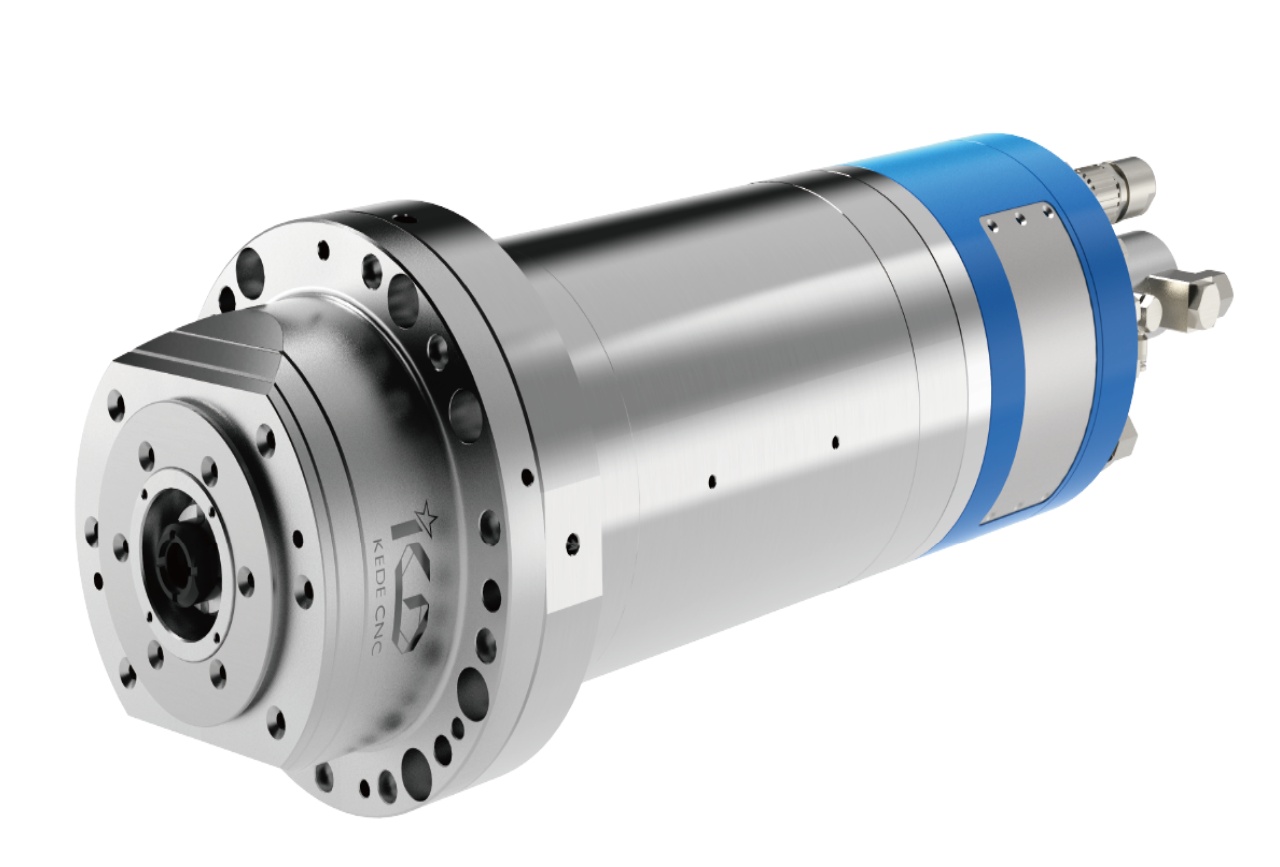

What is electrical spindle?

The electrical spindles are the shortened name of embedded motor spindles, the main property of which is to out the motor inside the spindle, and to run by driving power. Thus to fulfill the motor and spindle compounding.NeeBee Transmission have design and manufacture 4 series of eletrical spindles for ginding and 3 series for drilling and milling machines,as well as electrical spindle for high speed centrifugal machine.

Free Design Services

We provide free design and engineering services for custom non - standard machinery parts. Our goal is to meet your precise requirements.

Using advanced CAD/CAE software, our experienced engineers create detailed 3D models and simulations for optimal functionality.

We collaborate closely with you during the design process, incorporating your feedback to perfect the design.

Customization and Innovation

Our design team can handle complex geometries, unique materials, or specific tolerances. We tailor solutions to your exact specs.

We emphasize innovation and efficiency, ensuring the final design is both functional and cost - effective.

High Precision Machining

Our expertise lies in turning, milling, grinding, and drilling, enabling us to craft high-precision components with unwavering consistency.

Adhering strictly to ISO 9001 standards, our manufacturing processes are geared towards meeting the most exacting international quality requirements.

Low Minimum Order Quantities (MOQ)

Whether you need a single prototype or a small batch of custom parts, our team is equipped to meet your requirements precisely.

Material Expertise

Our team has the ability to source and process special or custom materials according to your specific needs.

Precision Assembly

Our skilled technicians and engineers precisely assemble non - standard parts for perfect fit and function. Advanced tools ensure high accuracy in the process.

Quality Assurance

Parts are rigorously checked during and after assembly to meet high standards. Functional testing verifies they match your specs.

Custom Integration

We provide custom assembly, integrating extra features or components as you need. Our team can also incorporate third - party systems like sensors for fully customized solutions.

Efficient Supply Chain Management

We have established a comprehensive supply chain network that ensures the timely procurement of high - quality raw materials and components. The logistics team collaborates closely with suppliers to strive to shorten lead times and maintain the smooth operation of the production process.

Global Shipping and Delivery

We offer a full - range of logistics solutions, covering packaging, shipping, and customs clearance, to ensure that your parts are delivered safely and on time all over the world. We use sturdy crates and shock - absorbing materials for packaging to prevent parts from being damaged during transit. We cooperate with reputable shipping partners to provide cost - effective and reliable air, sea, and land freight options.

Short Lead Times

Our efficient production process and well - organized supply chain enable us to achieve short lead times even for customized orders. For urgent projects, we have expedited production and shipping options to ensure the on - time delivery of your parts.

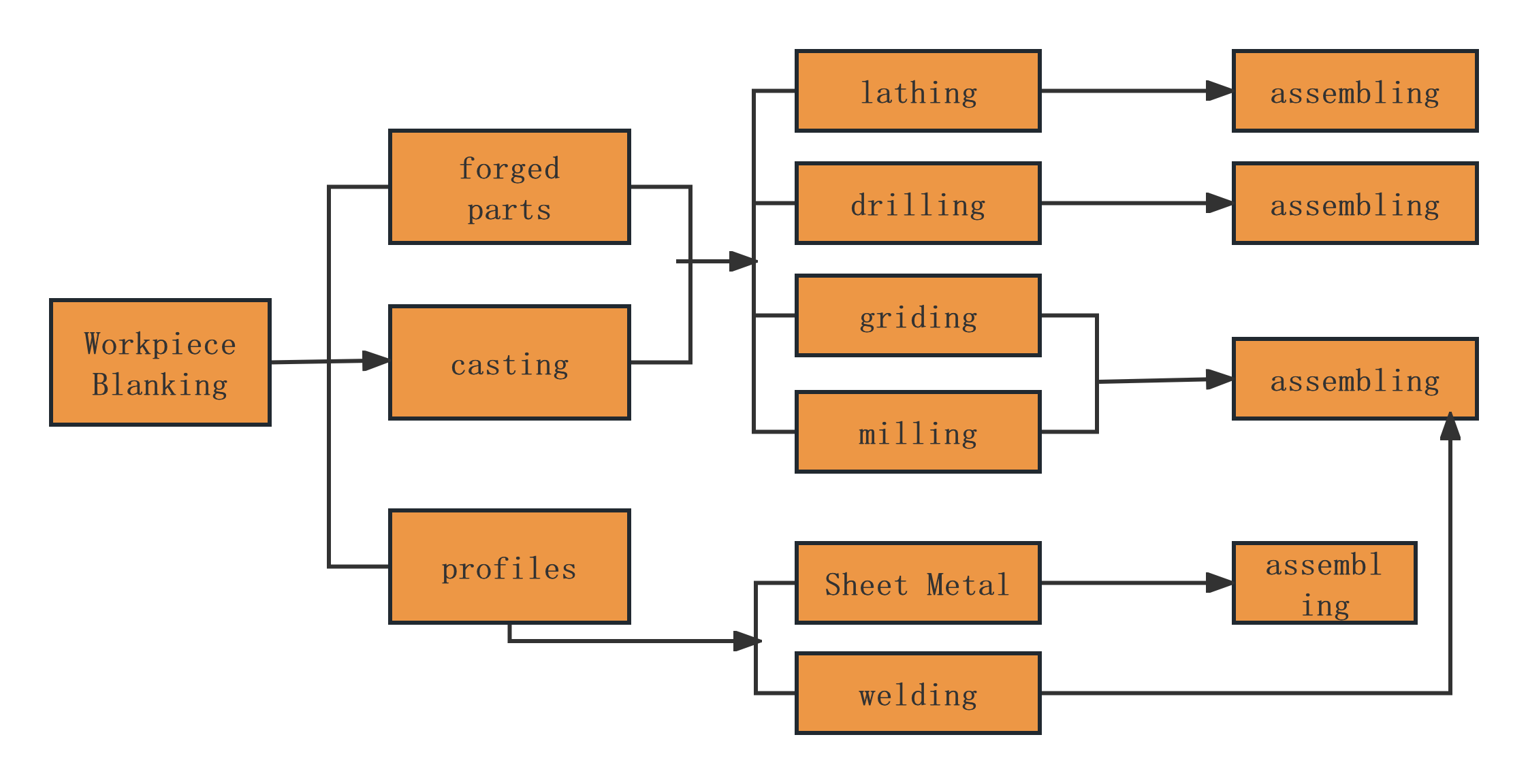

Flowchart Explanation

1. Customer Requirement Analysis

Objective: To precisely and comprehensively define customer requirements, meticulously covering key elements such as various specification parameters of parts, suitable material types, required quantities, and delivery time nodes.

Output: Generate a detailed and accurate requirement confirmation document, which serves as an important basis for subsequent work.

2. Design and Engineering

Objective: Make full use of advanced CAD/CAE software to construct precise 3D models and conduct in - depth simulation analysis, striving to achieve the optimization of the design scheme in multiple aspects such as functionality and structure.

Output: Produce high - precision 3D models and detailed and standardized engineering drawings, providing clear and definite guidance for the manufacturing and processing links.

3. Manufacturing and Processing

Objective: Rely on advanced CNC machine tools. With their excellent accuracy control capabilities, carry out high - precision part processing operations, strictly ensuring that the processed parts highly conform to the established design specifications.

Output: Obtain processed parts that meet the design requirements and have high precision, meeting the quality inspection needs of the next stage.

4. Quality Control and Inspection

Objective: Use professional and precise measuring tools to strictly inspect the dimensional accuracy and various functional characteristics of parts, thereby ensuring that the parts fully meet all the demand standards proposed by customers.

Output: Generate a detailed quality inspection report, clearly presenting the quality inspection results of parts and providing strong support for quality control.

5. Material Procurement

Objective: Actively search for and purchase materials that meet high - quality standards. At the same time, strictly screen according to design standards to ensure that the purchased materials are completely suitable for the design requirements in terms of performance and material.

Output: Successfully acquire high - quality materials that meet the design standards, laying a solid foundation for product manufacturing.

6. Surface Treatment

Objective: Implement diverse surface treatment processes such as fine polishing, professional electroplating, and precise heat treatment to significantly improve the durability and appearance quality of parts.

Output: Obtain parts that have been carefully surface - treated and possess both durability and good appearance, enhancing the added value of the product.

7. Packaging and Logistics

Objective: Adopt a scientific and reasonable packaging method to properly package parts, and carefully plan the transportation scheme, fully ensuring the safe and complete delivery of parts during transportation.

Output: Parts that are packaged and accompanied by detailed transportation information, ensuring the smooth progress of the logistics link.

8. Final Delivery

Objective: Deliver parts to customers on time strictly in accordance with the scheduled time, fulfilling the delivery commitment to customers.

Output: Parts successfully delivered to customers, achieving a complete process loop from production to delivery.

Advantages of the Flowchart

Clear and Intuitive: Each step in the process is clearly marked and explained. Both professionals and ordinary readers can easily understand and accurately follow it.

Comprehensive Coverage: It completely and systematically covers the entire non - standard processing process from the initial design concept to the final delivery to customers, with no omissions in any link.

Efficient Collaboration: It greatly promotes effective communication and close collaboration within the team and between the team and customers, providing strong support for the efficient and smooth progress of the project.

If you need further adjustments or additional details, please feel free to let me know!

Electric spindles for milling include three series, which can carry through the high-speed milling and carving processing matched with numerical control milling machine, carving &milling machine ,and ...

Electric spindles for drilling include two series. They are mainly used to small holes drilling, micro-holes drilling in PCB and pumps&nuzzles. With the automatic power draw bar. the cutter fast and ...

Electric spindles for high-speed centrifugal devices are widely used in separation, amashing, fogging and testing etc. high speed centrifugal industry.

High speed lathe electric spindle makes it possible to get the fine processing accuracy and roughness, and are especially suitable for the aluminum, copper colored metal parts processing.

We al...

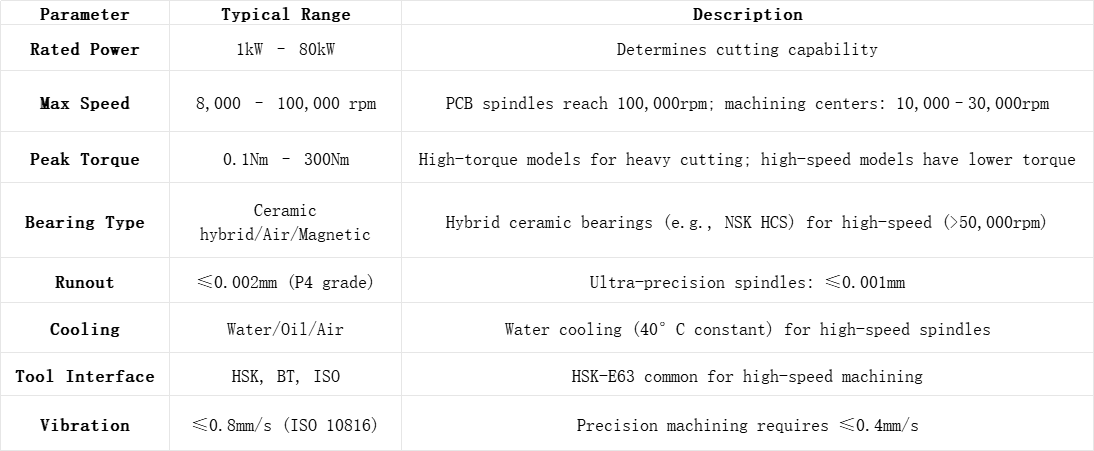

Features of electrical spindles

Electrical spindle realize the integration of spindle and motor.The quality of NewBee Transmission electrical spindle is guaranteed by National standard GJB/Z-9001 and ISO 9001.

We have design and developped more than 150 kinds of electrical spindles with following features:

1. Compact structure,high efficiency ,low noise and vibration and high precision;

2. Smooth operation and long life due to no impact;

3. Easy to gain high speed and stability under dynamc and static condition

4. Stepless speed change can be achieved within rated speed to adopt to various working condition and load.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.