What is CNC Vertical Lathe?

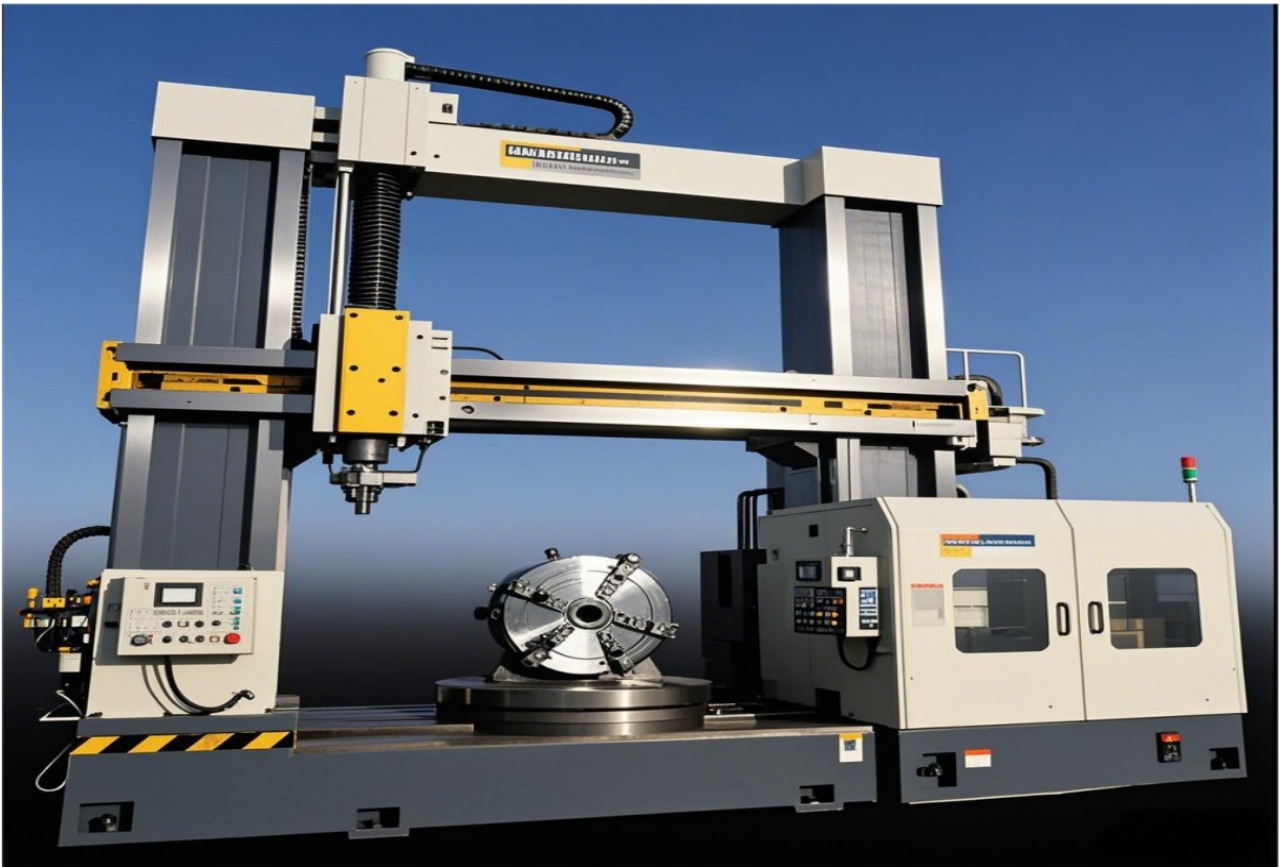

The CNC Vertical Lathe is a high-performance machine tool developed by Luoyang Newbee Transmission Technology Co., Ltd. It is designed for high-efficiency, multi-functional turning operations, combining the strengths of vertical lathe technology with advanced CNC features.

This machine is ideal for precision turning of large and heavy workpieces, widely used in industries such as aerospace, automotive, energy, and heavy machinery.

The machine is capable of performing a variety of operations, including turning, facing, grooving, and drilling. Its robust design and advanced features ensure high precision, efficiency, and reliability, making it a top choice for demanding industrial applications.

CNC movable beam double-column vertical lathe, developed by Luoyang Newbee Transmission, integrates international advanced design concepts. Equipped with the Siemens 808D CNC system and high-precision components, it ensures high-stability machining u......

CNC single - column vertical lathe, developed by Luoyang Newbee Transmission, adopts CAD - optimized design and advanced functional components at home and abroad. It features high rigidity, high stability, and a long service life. Its modular configu......

CNC movable beam double-column vertical lathe, developed by Luoyang Newbee Transmission, integrates international advanced design concepts. Equipped with the Siemens 808D CNC system and high-precision components, it ensures high-stability machining u......

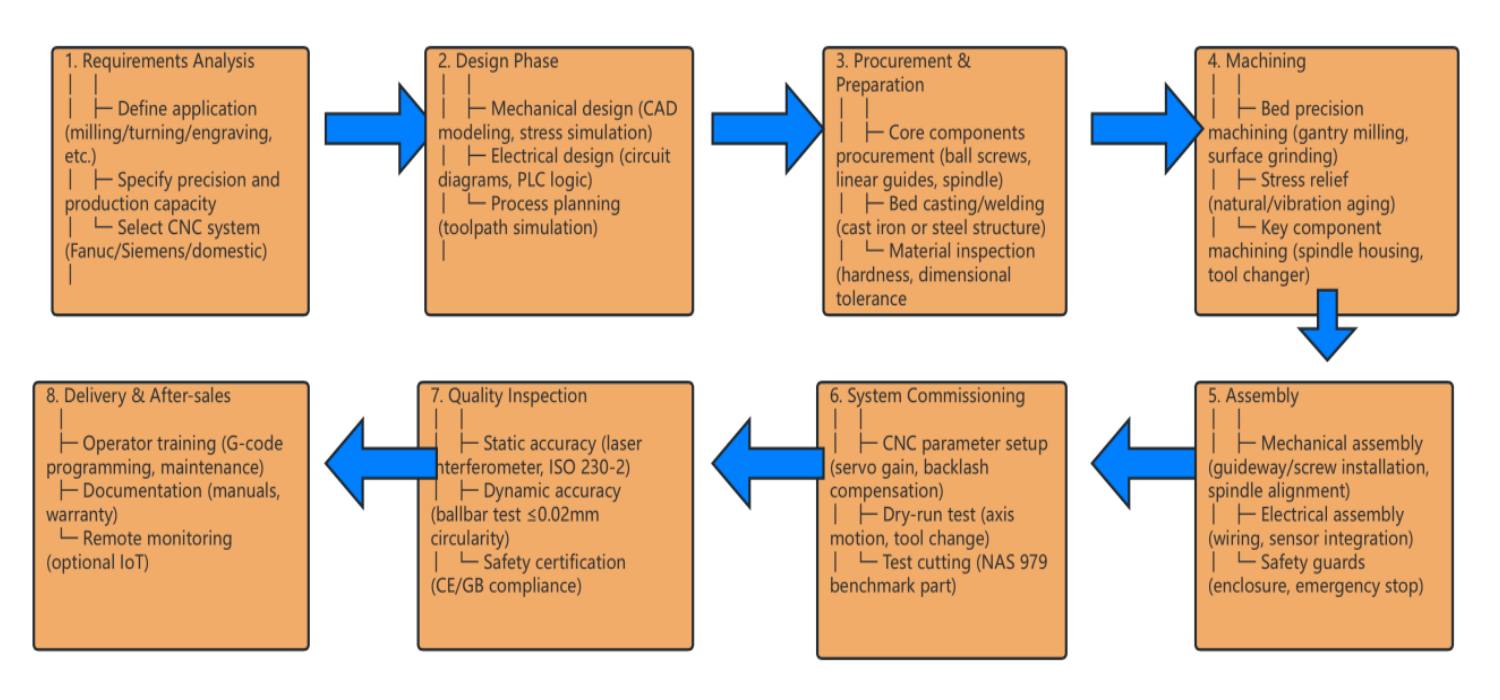

Customized Design Solutions

Our seasoned R&D team, with over 20 years of expertise, works closely with clients to create bespoke machine designs that meet their unique needs.

Using advanced CAD/CAE/CAM software, we generate precise 3D models and simulations to ensure optimal performance.

Our design process focuses on innovation, efficiency, and reliability, integrating the latest tech to serve industries like aerospace, automotive, energy, and heavy machinery.

Prototyping and Testing

We offer rapid prototyping to validate designs before full - scale production, catching and fixing issues early.

Our state - of - the - art testing facilities ensure designs meet strict quality and performance standards, safeguarding product integrity.

Advanced Manufacturing Facilities

Our facilities feature the latest CNC machines, like lathes, milling and grinding equipment, ensuring high precision in production.

We use top - quality materials such as high - strength cast iron and alloy steels for durable machines.

Production follows ISO 9001 standards, guaranteeing components meet international quality norms.

Flexible Production Capacity

We can handle both small - batch and large - scale production, suiting clients' diverse needs.

Our flexible lines quickly adapt to design or production changes, ensuring on - time delivery.

Precision Assembly Process

Our skilled technicians and engineers precisely assemble machine components for perfect fit and function.

Advanced tools ensure high accuracy and consistency during assembly.

Machines are rigorously quality - checked both during and after assembly to meet high standards.

Customization and Integration

We provide customized assembly, integrating extra features or components as clients request.

Our team can also incorporate third - party systems like CNC controllers, tool changers, or cooling systems for fully customized machines.

Efficient Supply Chain Management

Our well - established network ensures timely procurement of top - quality raw materials and components.

The logistics team collaborates with suppliers to cut lead times and keep production flowing.

Global Shipping and Delivery

We offer all - in - one logistics, covering packaging, shipping, and customs clearance for worldwide, on - time delivery.

Durable crates and shock - absorbing materials protect machines during transit.

Reputable shipping partners provide cost - effective air, sea, and land freight options.

After - Sales Support

Our logistics team delivers spare parts for after - sales, minimizing machine downtime.

Real - time shipment tracking keeps clients informed at every order stage.

For turning large structural components, engine parts, and landing gear.

For producing molds, flanges, and disc parts.

For machining wind turbine components, heat exchangers, and power generation equipment.

For turning large structural parts and complex components.

Features of CNC Vertical Lathe

1. High Rigidity and Stability

- The bed, worktable, and columns are made of high-strength cast iron using resin sand molding technology, ensuring excellent rigidity and stability.

- The machine features a fully enclosed sliding guideway system, providing smooth and vibration-free operation during machining.

2. Advanced Spindle System

- Equipped with a high-speed spindle unit from a renowned brand, offering high torque and reliability for heavy-duty turning operations.

- The spindle is designed for precision machining, ensuring stable performance even under high loads.

3. Imported Guideways and Ball Screws

- The machine uses wide-type heavy-duty linear guideways and high-precision ball screws, ensuring high accuracy, low friction, and smooth movement.

- The X, Y, and Z axes are equipped with full closed-loop detection systems, providing accurate positioning and repeatability.

4. Optional Configurations

- Tool Magazine: Available with a disc-type tool magazine (24/30 tools).

- Attachment Heads: Manual, semi-automatic, or fully automatic attachment heads can be added for multi-face machining, significantly improving efficiency and reducing costs.

- Cooling and Chip Removal System: Equipped with a cutting coolant system and chip conveyor for efficient chip removal and cooling.

5. Energy Efficiency and Environmental Friendliness

- The machine is designed with energy-saving features, including a constant-temperature cooling system and a spindle air-blow function.

- The electrical cabinet is equipped with a dust-proof and dehumidifying air conditioning system, ensuring stable operation in various environments.

Standard Configuration

1. Control System: Siemens 828D CNC system.

2. Spindle Unit: Imported high-speed spindle and gearbox.

3. Guideways and Ball Screws: Imported high-precision guideways and ball screws.

4. Cooling and Chip Removal: Cutting coolant system and chip conveyor.

5. Hydraulic System: Equipped with a hydraulic system for stable operation.

6. Safety Features: Area protection, emergency stop buttons, and three-color warning lights.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.