What is thin-section bearing?

The thin-section bearing is a type of bearing that has achieved an extremely thin bearing cross-section as well as miniaturized and lightweight designs.Our company provides deep groove ball bearings, angular contact bearings and four-point contact ball bearings.

Thin-section four-point-contact ball bearings ( Type X ) are a specialstyle of precision bearing designed for applications where space, weight, and stiffness are critical....

The Thin Section Angular Contact Ball Bearings(A Type) are mainly applied to support radial and single direction axial loads. ...

Thin-section deep groove ball bearings are a specific type of deep groove ball bearing that features a smaller cross-section and larger bore diameter relative to its thickness....

A spindle bearing is a high-precision, specialized ball bearing designed for the central rotating shaft (spindle) in machine tools and other equipment, allowing it to spin at extremely high speeds with exceptional accuracy, rigidity, and smooth movem......

A thin section bearing is a high-precision ball bearing with a significantly smaller cross-section relative to its large bore diameter, allowing for compact, lightweight designs in space-constrained applications like robotics, aerospace, and medical ......

Professional Team: Comprising over 30 senior engineers, covering fields such as mechanical design, materials science, and industrial automation. They are well - versed in international standards like ISO, DIN, and JIS. By leveraging CAD/CAE assisted design, 3D models can be rapidly generated and simulated for analysis, ensuring the feasibility of the plan and performance optimization.Customization Process: Conduct in - depth communication regarding application scenarios such as high - temperature, high - speed, and heavy - load conditions. Design bearing structures, material selection, and lubrication solutions in a targeted manner. Complete the sample design within 15 days, support parameter adjustment and performance verification to shorten the development cycle. A strict confidentiality agreement is in place to safeguard the safety of clients' drawings and patents.

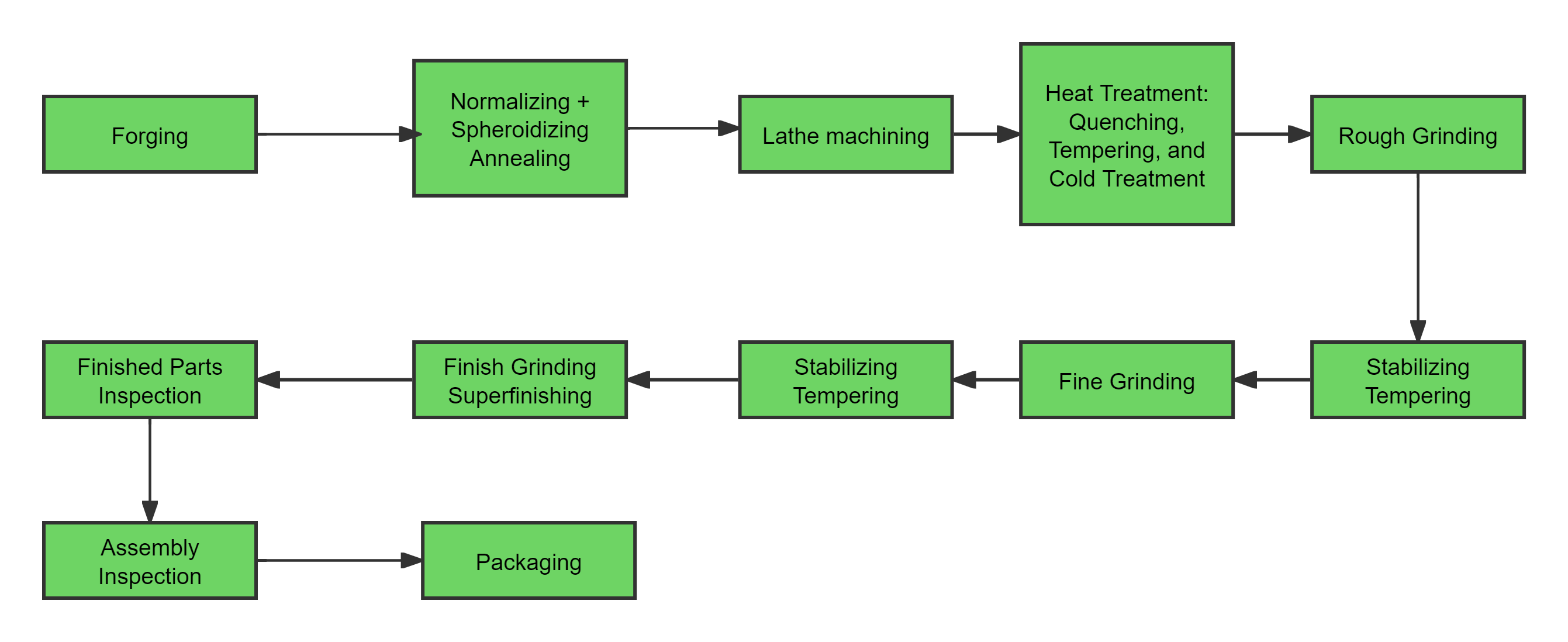

Advanced Manufacturing: Equipped with fully automatic CNC machine tools, high - precision grinding equipment, and heat - treatment production lines, capable of manufacturing all types of bearings. By adopting precision cold ring rolling and super - fine grinding processes, the tolerance can reach P5/P4 level, meeting high - precision requirements. The monthly production capacity exceeds 2 million sets, enabling flexible response to both small - batch trial production and large - volume orders. The regular delivery cycle is 30 days.Intelligent Management: The MES system monitors the production progress in real - time, and the entire order process is traceable. The modular production line can quickly change models to adapt to the production of multiple specifications and batches.

Full - process Quality Control: The raw materials are double - verified by a spectral analyzer and a metallographic microscope. Key dimensions are monitored online by a profilometer, a roundness tester, etc., with an automatic rejection rate of non - conforming products reaching 100%. The noise level, vibration value, and service life are fully inspected at a rate of 100%. Durability tests are carried out under simulated working conditions.

Authoritative Certifications: Passed ISO 9001 and GBT307.1 certifications. SGS third - party inspection reports can be provided along with the goods to meet the market access requirements worldwide.

Warehousing and Packaging The intelligent warehousing center dynamically manages inventory and supports the VMI (Vendor Managed Inventory) model. Customized anti - rust packaging with vacuum and shock - proof measures ensures zero damage during transportation. Global Network We cooperate with DHL, FedEx, etc., and offer trade terms such as FOB (Free on Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). With overseas warehouses established in Europe and North America, orders can be delivered within 7 - 10 days.

How to customize a thin-section bearig?

In industrial robotics, thin section bearings are crucial for joint parts, offering high precision and flexibility.Their compact design allows for reliable support in limited spaces, bearing radial an...

In aviation engines, thin section bearings support high - speed rotation, ensuring stable power output and flight safety. Landing gear benefits from thin section bearings' load - bearing capacity, red...

In medical centrifuges, thin section bearings provide precise and stable support during high - speed rotation, ensuring accurate sample separation. In imaging diagnostic equipment like X - ray machin...

Thin section bearings enable the precise rotation and positioning of radar antennas, ensuring accurate target detection. Their compact design allows them to be installed in space-constrained areas wit...

Thin section bearings provide precision positioning and stable support in optical devices, enhancing resolution and imaging quality.Their compact design enables them to fit into limited spaces, facili...

Thin-section bearings play a crucial role in the precision positioning of semiconductor manufacturing equipment, ensuring high-precision patterning. They enable high-speed and stable operation during ...

What is Thin Section Bearing?

Thin Section Bearings are specialized rolling element bearings characterized by their unique cross-sectional design where the radial thickness remains constant across various bearing diameters. Unlike conventional bearings that increase in thickness proportionally with diameter, thin section bearings maintain a consistent thin cross-section, enabling significant space and weight savings in compact mechanical designs.

These precision components are engineered to address the growing demand for lightweight, compact mechanical systems without compromising load capacity or performance. The fundamental principle behind thin section bearings is their ability to provide adequate load support while minimizing the envelope dimensions. Available in various configurations including deep groove, angular contact, and four-point contact designs, thin section bearings offer designers exceptional flexibility in addressing specific application requirements.

Manufactured to exacting tolerances, thin section bearings typically feature precision-ground raceways and optimized rolling element geometry to ensure smooth operation and precise rotational characteristics. The standardized cross-sections are categorized into specific series - C-type (light), X-type (extra light), and TX-type (ultra light) - allowing engineers to select the optimal balance between space constraints and performance requirements.

The Feature of Thin Section Bearings

Thin section bearings possess distinctive characteristics that make them indispensable in advanced mechanical systems:

Space Optimization: The primary advantage of thin section bearings is their ability to provide substantial space savings. With cross-sections up to 75% thinner than standard bearings of comparable diameter, they enable more compact and efficient mechanical designs.

Weight Reduction: By minimizing material usage while maintaining structural integrity, thin section bearings contribute significantly to overall system weight reduction, a critical factor in aerospace, robotics, and portable equipment applications.

High Precision Capability: Despite their reduced cross-section, thin section bearings maintain exceptional rotational accuracy and running precision, with many models achieving ABEC 5, 7, or higher precision grades.

Versatile Configuration Options: Available in multiple contact types including deep groove (for radial loads), angular contact (for combined loads), and four-point contact (for moment loads), providing design flexibility for various loading conditions.

Low Friction Operation: Advanced manufacturing techniques and optimized internal geometries ensure low torque and smooth operation, reducing power consumption and heat generation.

Material Diversity: Manufactured from various materials including chrome steel, stainless steel, and engineered polymers, allowing selection based on environmental conditions and performance requirements.

The Application of Thin Section Bearings

Thin section bearings find critical applications across numerous industries where space optimization and weight reduction are paramount:

Aerospace and Defense: Gimbal systems, satellite mechanisms, aircraft control surfaces, and radar positioning equipment where minimal weight and precise motion control are essential.

Robotics and Automation: Robotic joints, articulated arms, and end-effectors in industrial robots, collaborative robots, and automated manufacturing systems requiring compact, lightweight rotational components.

Medical Equipment: CT scanner gantries, MRI systems, surgical robots, and laboratory automation equipment where space constraints and precise positioning are critical.

Semiconductor Manufacturing: Wafer handling robots, precision stages, and positioning systems in cleanroom environments requiring minimal particle generation and precise motion control.

Optical and Instrumentation: Telescope mounts, laser scanning systems, measuring instruments, and surveillance equipment where vibration minimization and precise movement are crucial.

Aerospace Actuation Systems: Flight control mechanisms, landing gear systems, and auxiliary power units where reliability and weight savings directly impact performance.

How to Choose Thin Section Bearings?

Selecting the appropriate thin section bearing requires careful consideration of multiple technical factors:

Cross-Section Selection: Determine the optimal cross-section series (C, X, or TX) based on available space and load requirements. Consider both current design constraints and potential future modifications.

Bearing Type Configuration: Choose between deep groove (radial loads), angular contact (combined loads), or four-point contact (moment loads) configurations based on the primary loading conditions in your application.

Precision Requirements: Evaluate the necessary precision grade based on rotational accuracy needs. Standard applications may require ABEC 1 or 3, while high-precision systems typically need ABEC 5 or 7.

Material Compatibility: Select bearing materials appropriate for the operating environment. Chrome steel for general applications, stainless steel for corrosive environments, or special materials for extreme temperatures.

Load Capacity Analysis: Calculate both static and dynamic load requirements, considering the unique load distribution characteristics of thin section designs. Remember that thin section bearings have different load ratings compared to standard bearings of similar diameters.

Lubrication Requirements: Consider lubrication method and interval based on speed, temperature, and environmental conditions. Thin section bearings may require special lubricants due to their unique internal clearances.

Mounting Considerations: Evaluate installation methods, including proper fits and alignment procedures specific to thin section designs to prevent deformation during installation.

The Price of Thin Section Bearings

The cost structure of thin section bearings reflects their specialized nature and manufacturing complexity:

Manufacturing Complexity: The precision grinding and specialized heat treatment processes required for thin section bearings contribute significantly to their cost, often making them 2-3 times more expensive than standard bearings of comparable size.

Material Costs: Specialty materials like 440C stainless steel or corrosion-resistant coatings add premium costs but provide enhanced performance in specific environments.

Precision Grade: Higher precision grades (ABEC 5, 7, or 9) command substantial price premiums due to the extensive additional processing and quality control required.

Quantity Economics: While thin section bearings typically have higher unit costs than standard bearings, volume production can provide some cost reduction through manufacturing efficiency.

Customization Expenses: Special features including unique seals, specific internal clearances, or special packaging requirements add to the base cost but are often necessary for optimal application performance.

Quality Certification: Bearings manufactured under stringent quality systems (ISO 9001, AS9100) typically carry higher prices but provide assured reliability for critical applications.

Despite their higher initial cost, thin section bearings often provide superior value through extended service life, reduced maintenance requirements, and enabling more compact, efficient mechanical designs.

Thin Section Bearing Manufacturer

The manufacturing of thin section bearings requires specialized expertise and advanced production capabilities that distinguish qualified suppliers from standard bearing manufacturers. Leading thin section bearing manufacturers typically demonstrate:

Advanced Engineering Capabilities: Comprehensive design support including application engineering, load analysis, and custom solution development for unique application challenges.

Precision Manufacturing Expertise: State-of-the-art grinding equipment, specialized heat treatment facilities, and sophisticated quality control systems capable of maintaining micron-level tolerances.

Material Science Knowledge: Deep understanding of metallurgy and material performance characteristics to recommend optimal materials for specific application requirements.

Quality Assurance Systems: Robust quality management processes certified to international standards, ensuring consistent performance and reliability.

Technical Support Services: Application engineering support, installation guidance, and troubleshooting assistance throughout the product lifecycle.

NewBee Transmission has established itself as a trusted provider of thin section bearing solutions, combining extensive technical expertise with advanced manufacturing capabilities. Our engineering team works closely with clients to develop optimized bearing solutions that address specific space constraints and performance requirements.

When selecting a thin section bearing manufacturer, consider their technical capabilities, industry experience, quality certifications, and commitment to customer support. A reliable manufacturer should provide comprehensive technical documentation, application engineering support, and responsive customer service.

At NewBee Transmission, we understand that thin section bearings are often critical components in advanced mechanical systems. Our commitment extends beyond manufacturing to include technical consultation, design optimization, and ongoing support to ensure the success of your applications. Contact our engineering team to discuss how our thin section bearing solutions can address your specific design challenges.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.