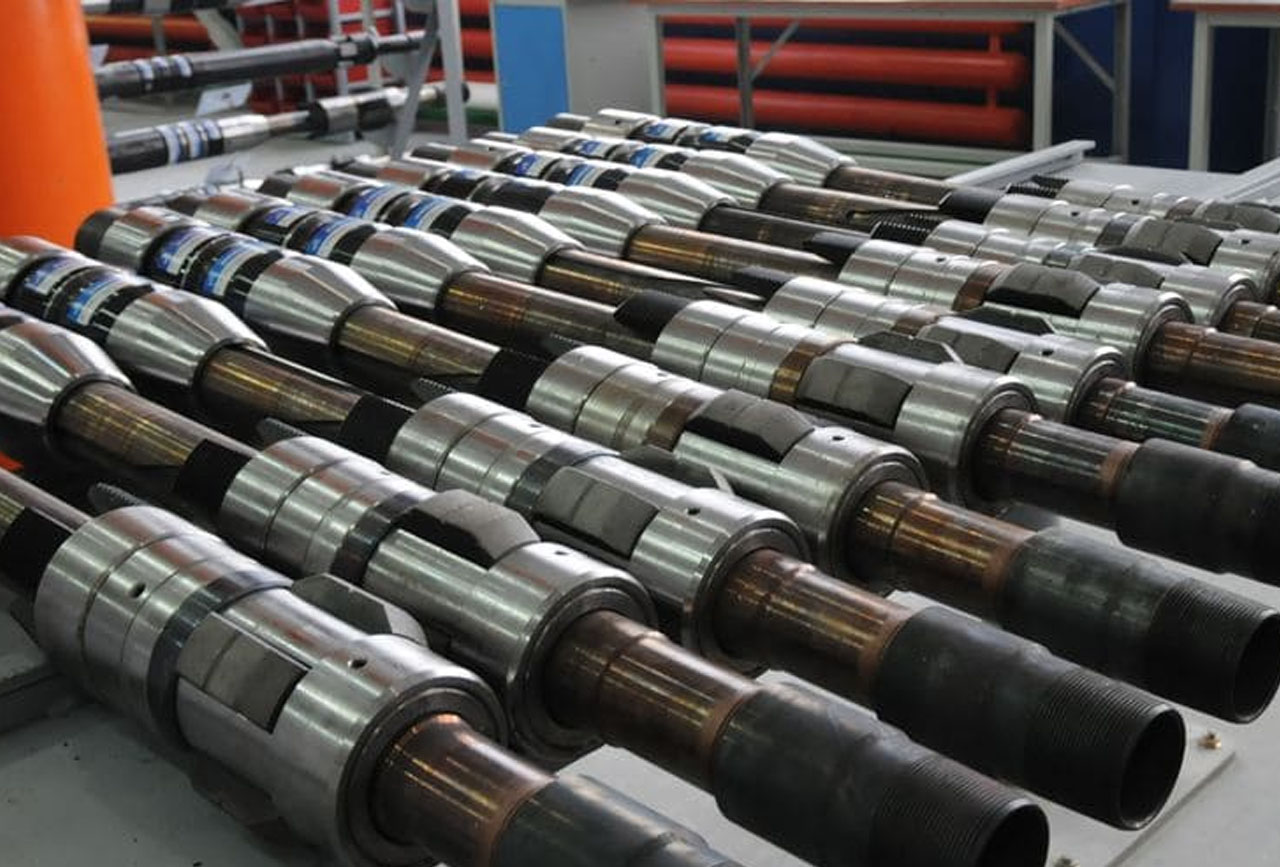

Precision machining parts refer to components that have been manufactured to meet stringent accuracy requirements, often at the micron or even nanometer level. These parts are essential in industries where precision, reliability, and performance are critical.

With the continuous advancement of technology, the demand for high-precision machining parts is increasing. Industries such as aerospace, automotive, medical equipment, and robotics rely heavily on these components to ensure the optimal performance and safety of their equipment.

Precision machining parts are widely used in various fields, including aerospace, automotive manufacturing, medical devices, robotics, and high-precision machinery.

Our company boasts a professional design team composed of senior CAD engineers, SolidWorks experts, and other specialists. We can seamlessly transition from 2D drawings to 3D model construction and virtual assembly, ensuring that our precision machining parts meet your exact specifications.

We operate state-of-the-art production facilities equipped with advanced machinery, including CNC machining centers, grinding machines, milling machines, and more. Our modern workshops and dust-free assembly rooms enable us to provide high-quality precision machining parts tailored to your needs.

Quality Control Capability

Our company specializes in providing high-precision, non-standard customized parts for global leaders in the semiconductor and aerospace industries. With years of industry experience and technical expertise, we offer end-to-end solutions from design and manufacturing to delivery, ensuring that our products meet the stringent requirements of our customers in terms of both quality and lead time.

Customized Solutions for the Semiconductor and Aerospace Industries

Semiconductor Industry: We supply high-precision non-standard parts to leading semiconductor equipment manufacturers, including precision shafts, vacuum chamber components, wafer holders, and more. These parts require extreme precision and cleanliness to ensure the stability and reliability of semiconductor equipment. Our products are widely used in critical equipment such as lithography machines, etching machines, and thin-film deposition systems.

Aerospace Industry: We provide high-strength precision components for aerospace customers, including aircraft engine parts, flight control system compo...

Our logistics capabilities are second to none. We have established partnerships with reliable shipping companies for both domestic and international deliveries. Our in-house logistics team, supported by advanced software, ensures smooth and efficient operations. With a large, well-organized warehouse, we can handle large orders and provide real-time tracking for all shipments.

How to customize precision machining parts ?

Gears : Precision gears are crucial for transmitting power and motion in machinery. They are used in applications requiring high accuracy and durability, such as automotive transmissions, robotics, and industrial machinery.

Racks : Precision racks are used in conjunction with gears to convert rotational motion into linear motion. They are essential in CNC machines, automation systems, and precision positioning equipment.

Electric Spindles : Electric spindles are high-speed, precision components used in machining centers, grinding machines, and other high-precision equipment. They provide the necessary rotational force for cutting, grinding, and milling operations.

Electric spindles for milling include three series, which can carry through the high-speed milling and carving processing matched with numerical control milling machine, carving &milling machine ,and ...

In automotive transmissions,differentials,and engine systems,gears play a critical role in ensuring power transmission and vehicle performance.

In wind turbines,gearboxes are used to convert low-speed wind energy into high-speed electrical output. The high load-bearing capacity and durability of gears are crucial for efficient operation.

In marine applications,gear shafts are used in propulsion systems and steering mechanisms,offering reliable performance in harsh marine environments.

What is Non-Standard Machinery Part?

Non-Standard Machinery Parts refer to custom-engineered components specifically designed and manufactured to meet unique application requirements that cannot be satisfied by standard off-the-shelf parts. These specialized components are developed through close collaboration between manufacturers and clients to address specific technical challenges, space constraints, or performance demands that standard components cannot fulfill.

Unlike standard parts that follow established industry specifications and are mass-produced, non-standard parts are typically single-batch productions with customized dimensions, materials, tolerances, or performance characteristics. The development process involves comprehensive engineering analysis, including finite element analysis (FEA) for stress distribution, thermal analysis for temperature management, and dynamic simulation for moving components. This ensures the final product meets exact operational requirements while maintaining reliability and durability.

The manufacturing of non-standard parts requires advanced capabilities in precision machining, specialized heat treatment, and sophisticated quality control systems. Manufacturers must maintain strict adherence to customized specifications while ensuring the parts can withstand real-world operating conditions, including extreme temperatures, corrosive environments, high loads, and continuous operation demands.

The Feature of Non-Standard Machinery Parts

Non-standard machinery parts possess distinct characteristics that make them essential for specialized applications:

Customized Design Solutions: Each non-standard part is engineered to solve specific technical challenges, with designs optimized for particular applications, load conditions, and spatial constraints.

Precision Engineering: These components are manufactured to exceptionally tight tolerances, often exceeding standard industry specifications, ensuring perfect integration and optimal performance in complex mechanical systems.

Material Versatility: Non-standard parts can be fabricated from a wide range of materials selected for specific properties - including high-strength alloys, corrosion-resistant steels, specialized polymers, and advanced composites - to meet unique environmental and operational requirements.

Enhanced Performance Characteristics: Through custom engineering, these parts can achieve superior performance in areas such as load capacity, wear resistance, temperature tolerance, and service life compared to standard alternatives.

Technical Integration Capability: Non-standard parts are designed to seamlessly integrate with existing systems, often incorporating unique mounting features, special interfaces, or custom connection points that standard components cannot provide.

Quality Assurance: The manufacturing process typically involves rigorous testing and inspection protocols, including material certification, dimensional verification, performance testing, and sometimes prototype validation before full production.

The Application of Non-Standard Machinery Parts

Non-standard machinery parts serve critical functions across numerous industries where standard components prove inadequate:

Aerospace Industry: Custom brackets, specialized fasteners, and unique structural components for aircraft assemblies where weight optimization, specific material properties, and exact dimensional requirements are paramount.

Automotive Manufacturing: Prototype components, specialized fixturing elements, and custom tooling for vehicle assembly lines that require unique specifications not available in standard part catalogs.

Industrial Automation: Customized robotic end-effectors, specialized linear motion components, and unique conveyor system parts designed for specific manufacturing processes and space limitations.

Heavy Equipment and Machinery: Large-diameter custom bearings, specialized seals, and unique gear components for mining equipment, construction machinery, and agricultural implements operating under extreme conditions.

Medical Device Manufacturing: Precision components for surgical robots, custom implants, and specialized instrumentation requiring biocompatible materials, unique geometries, and ultra-precise tolerances.

Energy Sector: Custom valve components, specialized turbine parts, and unique pipeline fittings for oil and gas applications, nuclear facilities, and renewable energy systems where standard solutions are unavailable or insufficient.

How to Choose Non-Standard Machinery Parts?

Selecting appropriate non-standard machinery parts requires careful consideration of multiple technical and operational factors:

Technical Requirements Analysis: Conduct comprehensive assessment of load conditions, operating speeds, temperature ranges, environmental exposure, and expected service life to establish precise performance specifications.

Material Selection: Choose materials based on mechanical properties, corrosion resistance, thermal characteristics, and compatibility with operating environment. Consider specialized treatments like surface hardening, corrosion-resistant coatings, or special heat treatments.

Manufacturing Capability Evaluation: Assess potential suppliers' technical capabilities, including their precision machining equipment, quality control systems, engineering expertise, and experience with similar custom projects.

Design for Manufacturing: Work closely with engineering teams to optimize designs for manufacturability, considering production methods, tooling requirements, and cost-effective manufacturing approaches without compromising performance.

Prototyping and Testing: Implement a thorough prototyping and testing process to validate design concepts, verify performance under simulated operating conditions, and identify potential improvements before full-scale production.

Lifecycle Considerations: Evaluate long-term factors including maintenance requirements, potential for future modifications, availability of replacement parts, and technical support throughout the product lifecycle.

The Price of Non-Standard Machinery Parts

The cost structure for non-standard machinery parts differs significantly from standard components due to various influencing factors:

Engineering Development Costs: Custom design work, engineering analysis, prototyping, and testing represent substantial initial investments that are distributed across the production quantity.

Tooling and Setup Expenses: Unique manufacturing requirements often necessitate custom tooling, specialized fixtures, and production line setup that contribute significantly to the overall cost.

Material Costs: Specialty materials required for specific applications typically carry premium prices compared to standard materials used in mass-produced components.

Manufacturing Complexity: The level of precision, specialized processes required, and manufacturing difficulty directly impact production costs. Complex geometries, tight tolerances, and special surface treatments increase manufacturing expenses.

Quantity and Economies of Scale: Unlike standard parts, non-standard components lack the cost advantages of mass production. Smaller production quantities result in higher per-unit costs due to fixed expenses being distributed across fewer units.

Quality Assurance Requirements: Comprehensive inspection protocols, material certification, and performance testing necessary for custom parts contribute to the overall cost structure.

Technical Support and Services: Engineering consultation, customization services, and ongoing technical support are typically included in the pricing of non-standard parts.

Non-Standard Machinery Part Manufacturer

The manufacturing of non-standard machinery parts requires specialized expertise and advanced capabilities that distinguish qualified suppliers from standard component manufacturers. Leading manufacturers in this sector typically possess:

Advanced Engineering Capabilities: Comprehensive design and engineering resources including CAD/CAM systems, simulation software, and experienced engineering teams capable of developing innovative solutions for complex challenges.

State-of-the-Art Manufacturing Facilities: Modern CNC machining centers, precision grinding equipment, advanced heat treatment facilities, and sophisticated quality control laboratories equipped with coordinate measuring machines (CMM) and other precision measurement instruments.

Material Expertise: In-depth knowledge of material science and engineering, enabling appropriate material selection and specialized processing for diverse application requirements.

Quality Management Systems: Robust quality assurance processes certified to international standards (ISO 9001, AS9100, etc.), ensuring consistent quality and reliability throughout the manufacturing process.

Technical Partnership Approach: Willingness to collaborate closely with clients throughout the entire process - from initial concept development through final production and ongoing technical support.

NewBee Transmission has established itself as a trusted provider of non-standard machinery parts, combining extensive engineering expertise with advanced manufacturing capabilities. Our team works closely with clients to develop customized solutions that address specific technical challenges while ensuring optimal performance and reliability.

When selecting a manufacturer for non-standard parts, consider their technical capabilities, industry experience, quality systems, and commitment to customer partnership. A reliable manufacturer should provide comprehensive support from initial concept through production and beyond, ensuring successful implementation of custom solutions.

At NewBee Transmission, we understand that non-standard parts often represent critical components in your systems. Our commitment extends beyond manufacturing to include technical consultation, design optimization, and ongoing support to ensure the success of your projects. Contact our engineering team to discuss how our custom manufacturing solutions can address your specific requirements.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.