A bearing cage is one of the core components of a bearing. It is used to fix the position of rolling elements,ensure their uniform distribution,and reduce friction. Its design directly affects the operating efficiency and service life of the bearing. NewBee Transmission provides various types of cages, including stamped steel cages,engineering plastic cages,and brass cages.These cages are suitable for deep groove ball bearings,tapered roller bearings, angular contact bearings,etc., and can meet the requirements of complex working conditions such as high speed,high temperature, and high load.

Our precision-engineered cages are designed to maximize deep groove ball bearing performance through optimal ball spacing and guidance. These components prevent ball-to-ball contact, reduce friction, and enhance operational stability across speed ran......

Our engineered cages optimize cylindrical roller bearing performance through advanced roller control and load distribution. Designed for demanding industrial applications including machine tool spindles, wind turbines, and heavy equipment, these comp......

Our sunflower-type bearing cages feature a patented petal-shaped design that revolutionizes bearing performance in extreme operating conditions. These precision components are engineered for aerospace, high-performance machinery, and precision instru......

Tapered roller bearing cages achieve precise roller guidance, combined load bearing, and improved lubrication efficiency through optimized structure and material selection, adapting to heavy-load working conditions in multiple fields and extending be......

The wind turbine bearing cage adopts a domestically innovative design and proprietary surface treatment technology. Through material innovation and precision manufacturing processes, it enables stable operation of wind turbine bearings under complex ......

CV joint bearing cages adopt a precision cavity structure, achieving uniform load distribution under constant velocity transmission by optimizing the ball contact trajectory. Their multi-directional adaptive design and high-precision machining proces......

Our spherical roller bearing cages are precision-engineered to automatically compensate for shaft misalignment while maintaining optimal roller positioning. Designed for the most demanding industrial applications including mining equipment, paper mac......

The E-type cage utilizes symmetrical spherical rollers and a two-piece hardened steel stamped design. A center guide ring ensures smooth roller movement, increasing dynamic load capacity (20%-35%) while reducing friction losses. Suitable for multi-di......

The micro bearing cage is engineered to maintain precise alignment of miniature rolling elements in extremely confined spaces. Its high-accuracy construction ensures smooth operation while minimizing mass and inertia—critical for micro-mechanical sys......

The needle roller bearing cage ensures proper alignment and spacing of needle rollers, preventing friction and wear while optimizing load distribution. Its lightweight and durable construction makes it suitable for high-load, high-speed applications ......

Offer free customized design and engineering services. Optimize the structure with CAD/CAE to reduce friction by 15% and enhance vibration resistance. Customize material solutions according to working conditions, covering steel, nylon, brass, etc. Support lightweight design, suitable for precision fields such as aerospace. Capable of designing complex geometries, like salt-fog-resistant pockets for wind turbines and low-friction profiles for automotive transmissions. Multiple innovative cases have passed stringent tests.

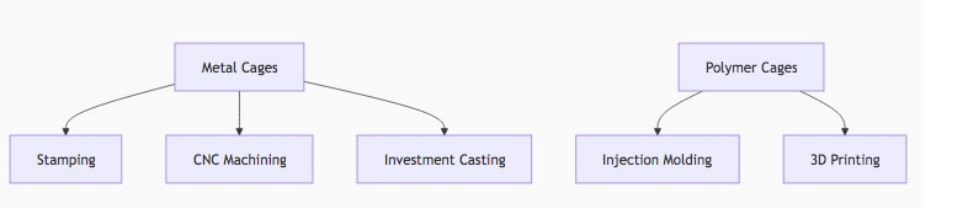

CNC precision machining ensures high precision of ±0.01mm. Cover processes such as stamping, injection molding, and turning to meet all batch requirements. Support single-piece to small and medium batch customization, with quick delivery of 7 days for standard parts and 15 - 30 days for customized parts. Treatments such as galvanizing and PTFE coating enhance corrosion resistance. Through multiple inspections like 3D scanning and salt spray tests, a service life of 5 - 10 years is guaranteed.

Achieve high-precision matching between rolling elements and cages. Support customized integration of sensors and third-party components. Conduct 100% dynamic testing to verify performance, simulating complex working conditions such as automotive impacts and corrosion environments of food machinery, ensuring stable operation in fields like rail transit and machine tool spindles.

Rely on a global raw material procurement network to ensure stable supply. Use layered shock-absorbing packaging and heavy-duty corner protectors to prevent damage during transportation. With rich experience in cross-border delivery, provide customs clearance and multimodal transport services (sea, air, land) to ensure products are safely delivered worldwide.

Features of Bearing Cages

1.Material Diversity Cages can be made of steel, nylon, brass, or special plastics, with different materials adapting to various environments. For example, engineering plastic cages are corrosion-resistant and lightweight, suitable for high-speed scenarios; brass cages are heat-resistant and ideal for heavy-duty industrial equipment.

2.Low-Friction Design Structural optimizations of cages (such as pocket shape and surface finish) reduce friction between rolling elements, minimizing energy consumption and noise while extending bearing service life.

3.Vibration and Impact Resistance High-precision cages effectively suppress rolling element vibration, preventing misalignment or wear caused by impacts and enhancing equipment operational stability.

4.Lightweight and Compact Structure Thin-walled stamped cages or lightweight plastic cages reduce the overall weight of bearings, making them suitable for weight-sensitive fields such as aerospace and precision instruments.

5. Corrosion Resistance Cages with special coatings or materials (such as PTFE plating or stainless steel) can operate stably for long periods in humid or chemically corrosive environments.

Applications of Bearing Cages

1. Automotive Drivetrain Systems

In gearboxes and wheel hub bearings, cages ensure uniform force distribution on rolling elements, withstand high rotational speeds and impact loads, and improve transmission efficiency and safety.

2. Wind Turbines Cages in main shaft bearings resist extreme wind loads and vibrations. Their corrosion-resistant designs adapt to high-humidity marine environments, ensuring long-term stable equipment operation.

3. High-Speed Machine Tool Spindles Lightweight nylon cages reduce centrifugal force effects, supporting ultra-high-speed spindle rotation while minimizing frictional heat and enhancing machining precision.

4. Food Machinery Food-grade engineering plastic cages meet hygiene standards and resist cleaning agent corrosion, suitable for wet and sanitary environments in mixers, filling equipment, and other applications.

5. Rail Transit High-strength steel cages are used in train wheel set bearings, withstanding frequent starts/stops and heavy-load impacts to ensure operational safety and low maintenance costs.

6. Medical Devices Precision cages provide smooth movement in CT machine rotating components. Their low-friction design reduces energy loss, ensuring imaging clarity and equipment longevity.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.