✅ Design Advantages for Thin-Plates & Small Holes

Precision High-Speed Spindle: Single BT40 taper spindle optimized for drilling small holes (Max. Ø20mm) in thin plates/panels like needle plates, sieve plates, and face plates (Max. thickness: 12mm).

CAD/CAM Integration: Enables direct program conversion for automated, high-precision batch production.

Stable Control: Siemens 808D CNC system with LCD display ensures reliable operation and easy maintenance.

✅ Key Performance Parameters

Max. Drilling Diameter: Ø20mm.Max. Material Thickness: 12mm.Spindle Speed: 0–10,000 rpm.Spindle Power: 5.5 kW.

✅ Structural Configuration & Precision

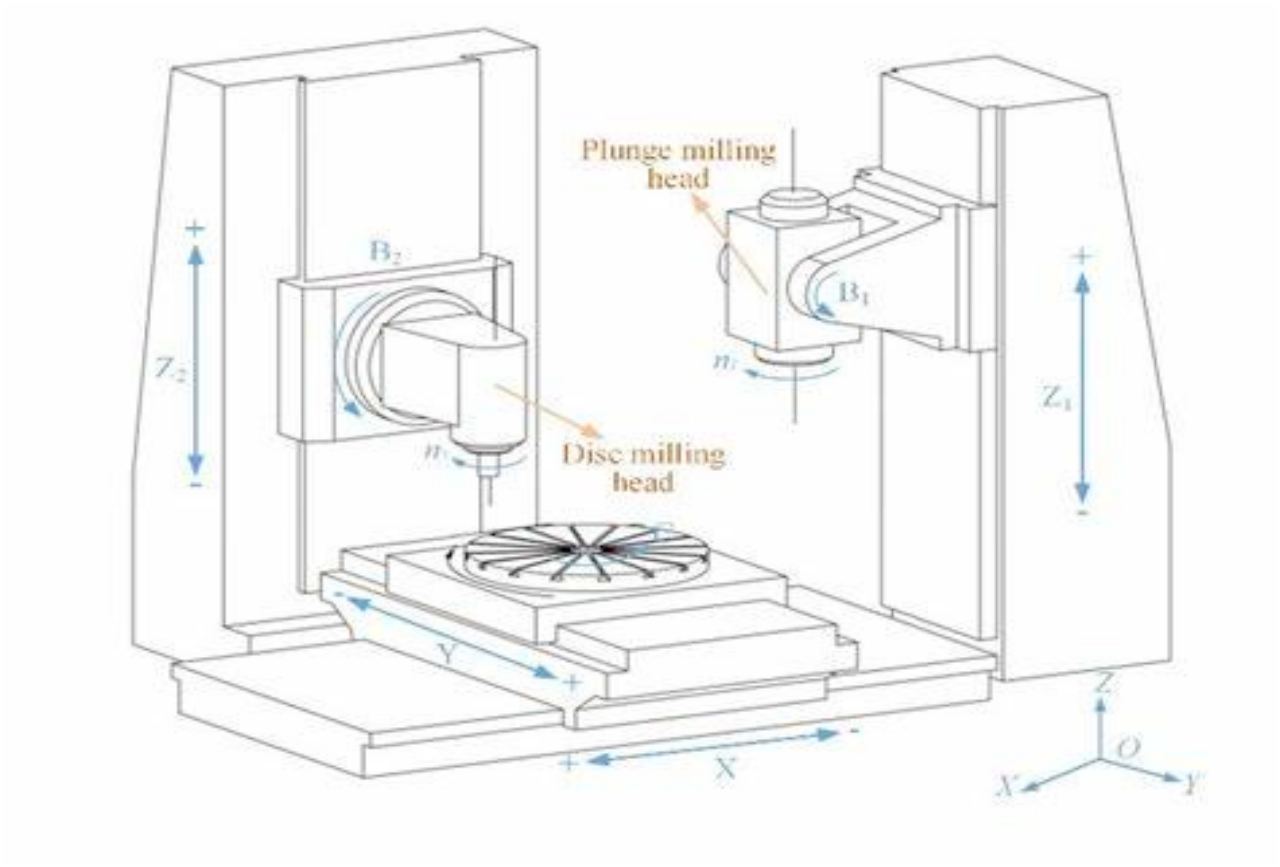

Axis System:

X-axis (Gantry Longitudinal): Travel 1000–8000mm (model dependent), Rapid traverse: 8 m/min, Precision: 0.05–0.12mm (full length, model dependent).

Y-axis (Head Transverse): Travel 1000mm, Rapid traverse: 8 m/min, Precision: 0.04–0.06mm (full length, model dependent).

Z-axis (Spindle Vertical): Travel 200mm, Max. feed: 6 m/min.

✅ Efficiency & Dimensions

Dimensions (L×W×H): 3200×2000×2700mm to 10200×2000×2700mm .

| Drilling Machine Specifications | ||||||

|---|---|---|---|---|---|---|

| Items | Unit | Model | ||||

| XWFD1010 | XWFD1030 | XWFD1050 | XWFD1060 | XWFD1080 | ||

| Processing Range | ||||||

| T-slot Width | mm | 22 | 22 | 22 | 22 | 22 |

| Power Head | ||||||

| Quantity | unit | 1 | 1 | 1 | 1 | 1 |

| Spindle Taper Hole | - | BT40 | BT40 | BT40 | BT40 | BT40 |

| Maximum Drilling Diameter | mm | φ20 | φ20 | φ20 | φ20 | φ20 |

| Maximum Processing Thickness | mm | 12 | 12 | 12 | 12 | 12 |

| Spindle Speed Range | rpm/min | 0-10000 | 0-10000 | 0-10000 | 0-10000 | 0-10000 |

| Spindle Motor Power | KW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Distance from Spindle End Face to Worktable Surface | mm | 100-300 | 100-300 | 100-300 | 100-300 | 100-300 |

| Longitudinal Movement of Gantry (X-axis) | ||||||

| Stroke | mm | 1000 | 3000 | 5000 | 6000 | 8000 |

| Maximum Moving Speed | m/min | 8 | 8 | 8 | 8 | 8 |

| Motor Power/Torque | KW/N.m | 1.5/11 | 1.5/11 | 1.5/11 | 1.5/11 | 1.5/11 |

| Transverse Movement of Spindle (Y-axis) | ||||||

| Stroke | mm | 1000 | 1000 | 1000 | 1000 | 1000 |

| Maximum Moving Speed | m/min | 8 | 8 | 8 | 8 | 8 |

| Motor Power/Torque | KW/N.m | 1.0/11 | 1.0/11 | 1.0/11 | 1.0/11 | 1.0/11 |

| Vertical Feed of Spindle (Z-axis) | ||||||

| Stroke | mm | 200 | 200 | 200 | 200 | 200 |

| Maximum Feed Speed | m/min | 6 | 6 | 6 | 6 | 6 |

| Motor Power/Torque | KW/N.m | 1.5/11 | 1.5/11 | 1.5/11 | 1.5/11 | 1.5/11 |

| Positioning Accuracy | ||||||

| X-axis | mm | 0.05/Full Length | 0.06/Full Length | 0.08/Full Length | 0.10/Full Length | 0.12/Full Length |

| Y-axis | mm | 0.04/Full Length | 0.04/Full Length | 0.04/Full Length | 0.05/Full Length | 0.06/Full Length |

| Repeat Positioning Accuracy | ||||||

| X-axis | mm | 0.025/Full Length | 0.03/Full Length | 0.04/Full Length | 0.04/Full Length | 0.04/Full Length |

| Y-axis | mm | 0.02/Full Length | 0.02/Full Length | 0.02/Full Length | 0.02/Full Length | 0.02/Full Length |

| Chip Conveyor System | ||||||

| Chip Conveyor Type | - | Chain-type | Chain-type | Chain-type | Chain-type | Chain-type |

| Quantity | unit | 1 | 1 | 1 | 1 | 1 |

| Chip Conveyor Speed | m/min | 1 | 1 | 1 | 1 | 1 |

| Chip Conveyor Motor Power | KW | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Cooling System | ||||||

| High-pressure Internal Cooling | Mpa/L/min/KW | 1.5/40/2 | 1.5/40/2 | 1.5/40/2 | 1.5/40/2 | 1.5/40/2 |

| Low-pressure External Cooling | Mpa/L/min/KW | 0.2/30/0.2 | 0.2/30/0.2 | 0.2/30/0.2 | 0.2/30/0.2 | 0.2/30/0.2 |

| Automatic Lubrication System | ||||||

| Lubrication Pressure | MPa | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Lubrication Point Oil Injection Volume | mL/time | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 |

| Oil Injection Cycle | min | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 |

| Electrical System | ||||||

| CNC System | - | Siemens 808D | Siemens 808D | Siemens 808D | Siemens 808D | Siemens 808D |

| Number of CNC Axes | unit | 3+1 | 3+1 | 3+1 | 3+1 | 3+1 |

| Power and Weight | ||||||

| Total Power | KW | Approximately 12 | Approximately 12 | Approximately 12 | Approximately 12 | Approximately 12 |

| Total Weight | T | Approximately 7 | Approximately 10 | Approximately 14 | Approximately 16 | Approximately 20 |

| Overall Dimensions | ||||||

| Length×Width×Height (Reference) | mm | 3200×2000×2700 | 5200×2000×2700 | 7200×2000×2700 | 8200×2000×2700 | 10200×2000×2700 |

The spindle speed can reach 10000 rpm, suitable for processing small - diameter holes from φ0.5–20 mm, increasing the efficiency by 60%.

The Siemens 808D system integrates pitch error compensation, ensuring a hole pitch accuracy of ±0.1 mm.

With a total power of only 12 kW and a small footprint (TWFD1080: 10200×2000 mm), it is suitable for limited workshop space.

The automatic lubrication system and chain - type chip conveyor extend the maintenance cycle by 30%.

Electronics Industry: Machining high - density holes in PCB drilling templates and heat sinks.

Automotive Manufacturing: Machining positioning holes in engine cylinder heads and multiple holes in transmission cases.

Mold Industry: Precision drilling of cooling holes and ejector pin holes in injection molds.

Screening Equipment: Mass drilling of industrial sieve plates and filter plates.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.