What is Gantry Machining Center?

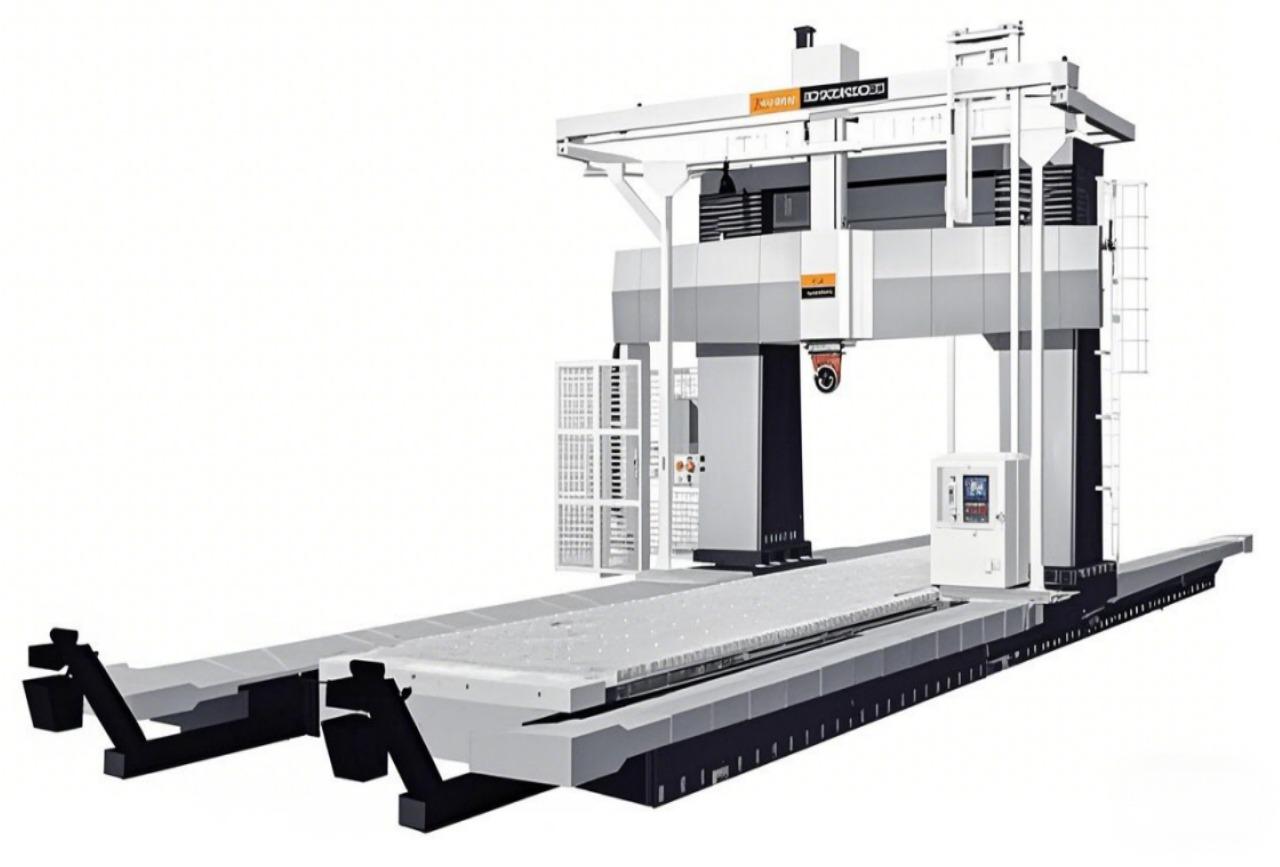

The Gantry Machining Center,developed by Luoyang NEWBEE Transmission Technology Co.,Ltd.,is a high - end CNC machine tool. Combining the high rigidity and wide machining range of traditional gantry - style machines with advanced tech,it's designed for high - efficiency,multi - functional machining. Ideal for aerospace,automotive,military,mold,metallurgy,and power generation industries,it can perform milling,drilling,boring,tapping,etc. Its robust design and advanced features guarantee high precision,efficiency,and reliability,making it a top pick for demanding industrial needs.

moving column gantry machining center is independently developed by Luoyang Newbee Transmission. It uses an HT300 high - strength cast iron bed and modular functional components, and is equipped with a Siemens 828D CNC system and imported spindle uni......

The moving table gantry machining center is independently developed by Luoyang Newbee Transmission. It uses an HT300 high - strength cast iron bed and modular functional components, and is equipped with a Siemens 828D CNC system and imported spindle ......

Customized Design Solutions

Our seasoned R&D team, with over 20 years of expertise, works closely with clients to create bespoke machine designs that meet their unique needs.

Using advanced CAD/CAE/CAM software, we generate precise 3D models and simulations to ensure optimal performance.

Our design process focuses on innovation, efficiency, and reliability, integrating the latest tech to serve industries like aerospace, automotive, energy, and heavy machinery.

Prototyping and Testing

We offer rapid prototyping to validate designs before full - scale production, catching and fixing issues early.

Our state - of - the - art testing facilities ensure designs meet strict quality and performance standards, safeguarding product integrity.

Advanced Manufacturing Facilities

Our facilities feature the latest CNC machines, like lathes, milling and grinding equipment, ensuring high precision in production.

We use top - quality materials such as high - strength cast iron and alloy steels for durable machines.

Production follows ISO 9001 standards, guaranteeing components meet international quality norms.

Flexible Production Capacity

We can handle both small - batch and large - scale production, suiting clients' diverse needs.

Our flexible lines quickly adapt to design or production changes, ensuring on - time delivery.

Precision Assembly Process

Our skilled technicians and engineers precisely assemble machine components for perfect fit and function.

Advanced tools ensure high accuracy and consistency during assembly.

Machines are rigorously quality - checked both during and after assembly to meet high standards.

Customization and Integration

We provide customized assembly, integrating extra features or components as clients request.

Our team can also incorporate third - party systems like CNC controllers, tool changers, or cooling systems for fully customized machines.

Efficient Supply Chain Management

Our well - established network ensures timely procurement of top - quality raw materials and components.

The logistics team collaborates with suppliers to cut lead times and keep production flowing.

Global Shipping and Delivery

We offer all - in - one logistics, covering packaging, shipping, and customs clearance for worldwide, on - time delivery.

Durable crates and shock - absorbing materials protect machines during transit.

Reputable shipping partners provide cost - effective air, sea, and land freight options.

After - Sales Support

Our logistics team delivers spare parts for after - sales, minimizing machine downtime.

Real - time shipment tracking keeps clients informed at every order stage.

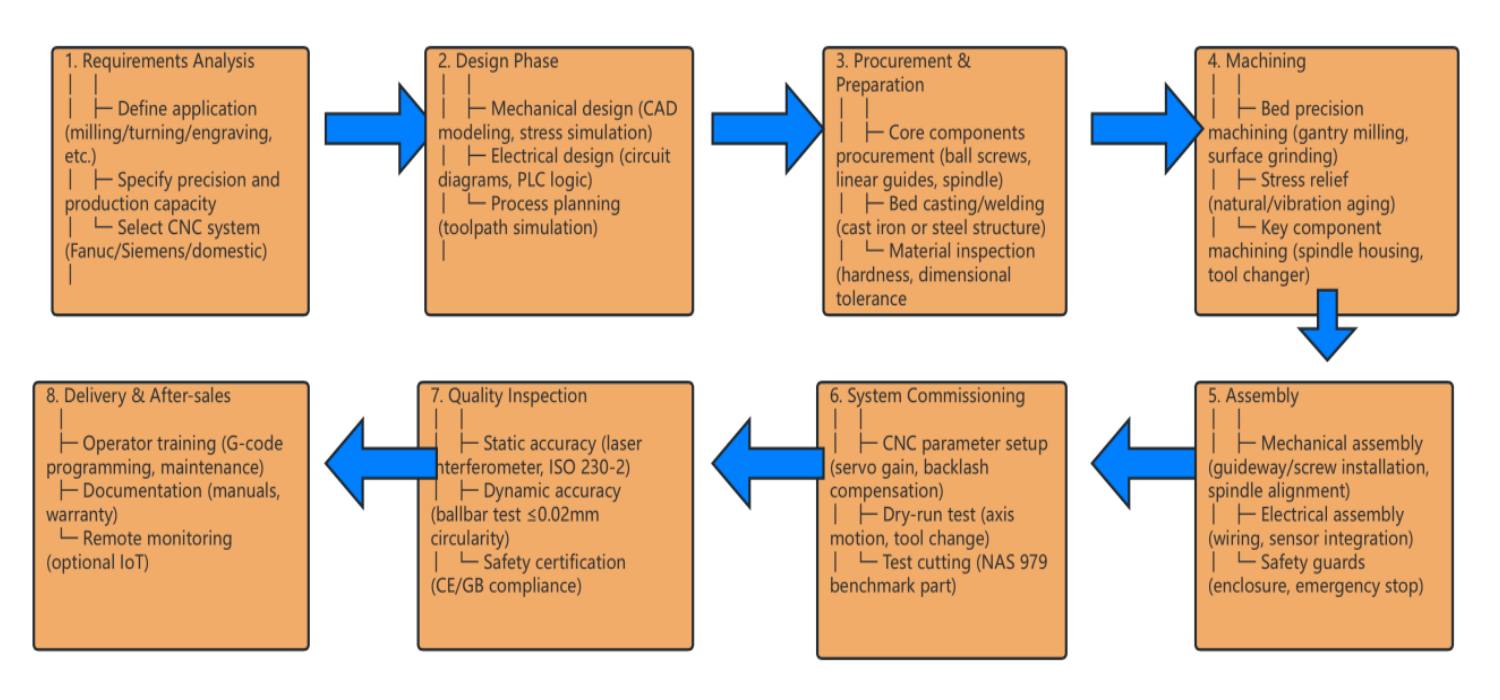

1.Customer Needs Analysis

Objective: Precisely define customer needs, covering key elements such as machine specifications, applicable materials, and delivery time schedules.

Output: A detailed requirements confirmation document.

2.Design & Engineering

Objective: Use computer - aided design (CAD)/computer - aided engineering (CAE) software to build 3D models and conduct simulations, aiming to deeply optimize the machine design.

Output: Precise 3D models and professional engineering drawings.

3.Manufacturing & Machining

Objective: Use CNC machines to perform high - precision machining on machine components, effectively ensuring that the components meet the design specifications.

Output: Processed components that meet the standards.

4.Quality Control & Inspection

Objective: Use precision measuring tools to carry out comprehensive dimensional and functional tests to ensure that the components meet the established quality standards.

Output: A standardized quality inspection report.

5.Assembly

Objective: Assemble machine components in an orderly manner, effectively integrate the CNC system and control devices, and conduct comprehensive functional tests.

Output: A fully assembled and functional machine.

6.Installation and Debugging of Electrical and PLC Control Devices

Objective: Properly install electrical wiring and programmable logic controller (PLC) control devices, and conduct detailed debugging of the system to ensure the normal operation of the system.

Output: Installed and debugged electrical and PLC control systems.

7.Surface Treatment

Objective: Implement surface treatment processes such as polishing, electroplating, and heat treatment to significantly improve the durability and appearance quality of machine components.

Output: Machine components with high - quality surface treatment.

8.Packaging & Logistics

Objective: Properly and safely package the machine and reasonably arrange transportation matters to ensure the safe delivery of the machine.

Output: A well - packaged machine and detailed transportation information.

9.Final Delivery

Objective: Deliver the machine to the customer strictly according to the scheduled time. - Output: A machine successfully delivered to the customer.

10.Customer Training & Support

Objective: Provide systematic machine operation training for customers and continuously provide technical support.

Output: Customers who are proficient in operation and complete support documentation.

11.Project Review and Documentation

Objective: Deeply analyze project performance and comprehensively record the experiences and lessons in the project process.

Output: A comprehensive and in - depth project review report.

12.Continuous Improvement

Objective: Continuously optimize processes and continuously improve product quality and production efficiency.

Output: More perfect processes and higher - standard quality specifications.

For machining large structural components, engine parts, and landing gear.

For producing molds, dies, and large automotive parts.

For machining wind turbine components, power generation equipment, and large gears.

For precision machining of defense equipment and components.

For producing large and complex molds with high precision.

For machining large structural parts and components used in construction and mining equipment.

1. What is CNC Machinery?

CNC (Computer Numerical Control) Machinery represents the cornerstone of modern manufacturing. It is a sophisticated manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology can control a range of complex machines, from grinders, lathes, and mills to routers and laser cutters. With CNC machining, a piece of material (metal, plastic, wood, ceramic, or composite) can be directed to cut, shape, and create parts with a level of precision, consistency, and complexity that is impossible to achieve through manual manipulation.

The heart of CNC machinery lies in its automation and digital template. Unlike manual control, which requires live operator input via levers or wheels, CNC systems operate through numerical control, where a software program is customized for an object. This digital instructions file dictates everything from the sequence of movements and the speed of the tool head (spindle) to the coordination of multiple axes of motion. This process enables the production of large volumes of identical components with minimal deviation, making it indispensable for industries like aerospace, automotive, medical device manufacturing, and robotics. The accuracy of these machines is heavily dependent on the quality of their core components, such as high-precision linear guides, ball screws, and especially, the robust bearings that support the entire motion system.

2. How to choose CNC Machinery?

Selecting the appropriate CNC machinery is a critical decision that impacts productivity, quality, and cost-effectiveness. The choice should be guided by a thorough analysis of your specific manufacturing needs. Here are the key factors to consider:

Application and Material: The primary consideration is the type of work you will be performing. What materials will you be cutting (e.g., aluminum, titanium, hardened steel, composites)? Different materials require different levels of machine rigidity, spindle power, and torque. A machine for milling aerospace alloys will need to be far more robust than one for machining wood or plastics.

Work Envelope and Size: Evaluate the maximum part size you need to produce. The machine's work envelope—defined by its X, Y, and Z travel—must accommodate your largest components. Consider not just the raw size but also the need for multi-axis capabilities (e.g., 4-axis or 5-axis) for complex, contoured geometries.

Precision and Accuracy Requirements: The required tolerances and surface finish of your parts will dictate the machine's necessary precision grade. This is directly linked to the quality of its mechanical components. Look for machines built with high-grade linear motion guides, precision ball screws, and low-runout, high-rigidity bearings. The performance of these components, like the ZARN70130-TN support bearing for ball screws, ensures minimal deflection and vibration under load, which is essential for achieving micron-level accuracy.

Power and Speed: Spindle power (kW or HP) determines the machine's ability to remove material efficiently. Spindle speed (RPM) affects the surface finish and the ability to use smaller tools. A balance between power and speed is necessary for optimal performance.

Control System and Software: The CNC controller is the machine's brain. A user-friendly and powerful control system from a reputable brand can significantly reduce programming time and operator error.

Total Cost of Ownership: Look beyond the initial purchase price. Consider long-term costs, including maintenance, energy consumption, tooling, and the availability of spare parts and technical support.

3. What is the Price of CNC Machinery?

The price of CNC machinery is not a one-size-fits-all figure; it varies dramatically based on the factors mentioned above. Costs can range from tens of thousands of dollars for a basic 3-axis benchtop mill to several hundred thousand or even millions of dollars for a large-format, multi-axis, high-speed machining center.

The primary cost drivers include:

Machine Size and Configuration: Larger machines with more axes of motion command a higher price.

Precision and Performance: Machines designed for ultra-high-precision industries (e.g., medical, aerospace) use more expensive components, such as specialized P4-grade angular contact bearings for spindles and high-accuracy linear guides, which increase the cost.

Spindle and Tool Changer: A high-power, high-speed spindle and an automatic tool changer (ATC) with a large tool capacity add significant value and cost.

Control System: Advanced CNC controls from brands like Siemens, Heidenhain, or Fanuc are more costly than basic systems.

Brand and Support: Established brands with a global service and support network typically have higher prices, which is often justified by their reliability and after-sales service.

It's crucial to view a CNC machine as a long-term investment. A slightly more expensive machine with higher quality components often leads to lower downtime, better part quality, and higher resale value.

4. Why Choose NewBee Transmission?

At NewBee Transmission, we understand that the performance of your CNC machinery hinges on the quality and reliability of its core transmission components. We are not a machine tool builder, but a dedicated partner that ensures your machines operate at their peak potential. Here’s why leading manufacturers trust us:

Expertise in Precision Components: We specialize in supplying high-performance bearings and linear motion products specifically designed for the demanding CNC industry. From crossed roller bearings for rotary tables that provide exceptional moment rigidity to angular contact ball bearings for machine tool spindles that enable high-speed operation, we provide the critical components that define machine accuracy.

Proven Product Portfolio: We partner with and distribute world-renowned brands, offering components that meet the strictest tolerance standards (P4, P2). Our products, such as the K24820AP4DB and K20038AP4DB precision bearings, are engineered to deliver superior performance, extended service life, and unwavering reliability under heavy loads and high speeds.

Technical Support and Customization: We offer more than just products. Our team of experienced engineers provides unparalleled technical support, helping you select the right components for your application. We also offer customization services, including special bearing design and sealing solutions, to meet unique operational challenges.

Cost-Effective Solutions: By providing durable, long-lasting components, we help you minimize unplanned downtime and reduce the total cost of ownership. Our competitive pricing ensures you receive exceptional value without compromising on quality.

Commitment to Partnership: We build long-term relationships with our clients. From the initial sample testing phase to volume supply and after-sales support, we are committed to your success, ensuring your production lines keep running smoothly and efficiently.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.