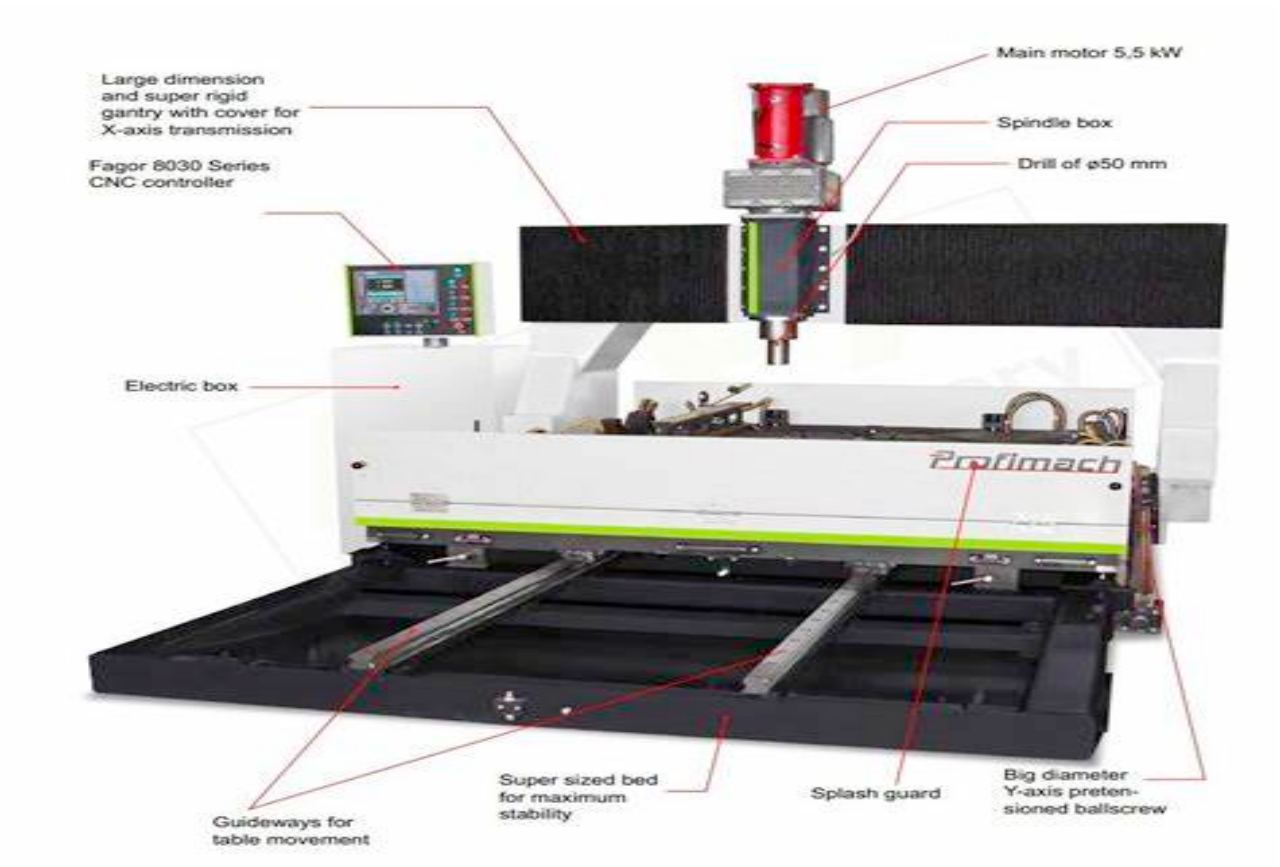

Fixed gantry & moving worktable structure:High-strength cast iron components (resin sand molding); optimized rigidity for precision drilling/milling.

✅ Key Performance Parameters

Worktable size:

TLMZ12: 1200×1200mm;TLMZ16: 1600×1600mm

Max. workpiece thickness: 300mm (uniform).

✅ Structural Configuration Features

X-axis (worktable longitudinal): Travel 1200/1600mm; rapid traverse: 8 m/min.

Y-axis (spindle transverse): Travel 1200/1600mm; rapid traverse: 8 m/min.

Z-axis (spindle vertical): Travel 600mm; feed rate: 6 m/min.

Positioning accuracy: ±0.05mm (X/Y axes).Repeatability: ±0.025mm (X/Y axes).

Machine weight: 12T (TLMZ12) / 15T (TLMZ16).

Dimensions:

TLMZ12: 4900×3300×3700mm

TLMZ16: 5700×3800×3700mm

| Drilling Machine Specifications | |||

|---|---|---|---|

| Parameter | Unit | TLMZ12 | TLMZ16 |

| Processing Range | |||

| Length × Width | mm | 1200×1200 | 1600×1600 |

| Worktable | |||

| T-Slot Width | mm | 22 | 22 |

| Drilling Head | |||

| Quantity | pcs | 1 | 1 |

| Spindle Taper | BT50 | BT50 | |

| Max. Drilling Diameter | mm | Φ60 | Φ60 |

| Max. Thickness | mm | 300 | 300 |

| Spindle Speed Range | rpm | 5-4500 | 5-4500 |

| Spindle Motor Power | kW | 22 | 22 |

| Spindle-to-Table Distance | mm | 200-800 | 200-800 |

| X-axis (Worktable Longitudinal) | |||

| Travel | mm | 1200 | 1600 |

| Max. Speed | m/min | 8 | 8 |

| Motor Power/Torque | kW/N·m | 2.2/11 | 2.2/11 |

| Y-axis (Spindle Transverse) | |||

| Travel | mm | 1200 | 1600 |

| Max. Speed | m/min | 8 | 8 |

| Motor Power/Torque | kW/N·m | 2.2/11 | 2.2/11 |

| Z-axis (Spindle Vertical) | |||

| Travel | mm | 600 | 600 |

| Max. Feed Speed | m/min | 6 | 6 |

| Motor Power/Torque | kW/N·m | 3.0/16 | 3.0/16 |

| Positioning Accuracy | |||

| X-axis | mm | 0.05 | 0.05 |

| Y-axis | mm | 0.05 | 0.05 |

| Repeat Positioning Accuracy | |||

| X-axis | mm | 0.025 | 0.025 |

| Y-axis | mm | 0.025 | 0.025 |

| Chip Removal System | |||

| Type | Chain Plate | Chain Plate | |

| Quantity | pcs | 2 | 2 |

| Speed | m/min | 1 | 1 |

| Motor Power | kW | 0.75 | 0.75 |

| Cooling System | |||

| High-Pressure Internal Coolant | MPa/L/min/kW | 2/40/4 | 2/40/4 |

| Low-Pressure External Coolant | MPa/L/min/kW | 0.2/30/0.2 | 0.2/30/0.2 |

| Hydraulic System | |||

| Hydraulic System | MPa/L/min/kW | 7/30/4 | 7/30/4 |

| Automatic Lubrication | |||

| Lubrication Pressure | MPa | 2.5 | 2.5 |

| Lubrication Volume per Cycle | mL | 0.12 | 0.12 |

| Lubrication Interval | min | 3-10 | 3-10 |

| CNC System | |||

| CNC System | Siemens 808D | Siemens 808D | |

| Power & Weight | |||

| Total Power | kW | ~40 | ~40 |

| Total Weight | T | ~12 | ~15 |

| Dimensions | |||

| Dimensions (L×W×H) | mm | 4900×3300×3700 | 5700×3800×3700 |

| Model: TLMZ12 TLMZ16 | |||

The worktable - mobile design is suitable for quick positioning of small and medium - sized workpieces, increasing the processing efficiency by 40%.

The Siemens 808D system integrates pitch error compensation, ensuring a hole pitch accuracy of ±0.1 mm.

Driven by an AC servo motor, the energy consumption is reduced by 20%, supporting green production.

The external lubrication system and modular structure extend the maintenance cycle by 30%.

General Machinery: Precision drilling of flange sealing surfaces and gear discs.

Automotive Manufacturing: Machining multiple holes on brake discs and drive shafts.

Petrochemical Equipment: Drilling small tube sheets and valve flanges.

Mold Industry: Machining positioning holes and cooling holes on mold plates.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.