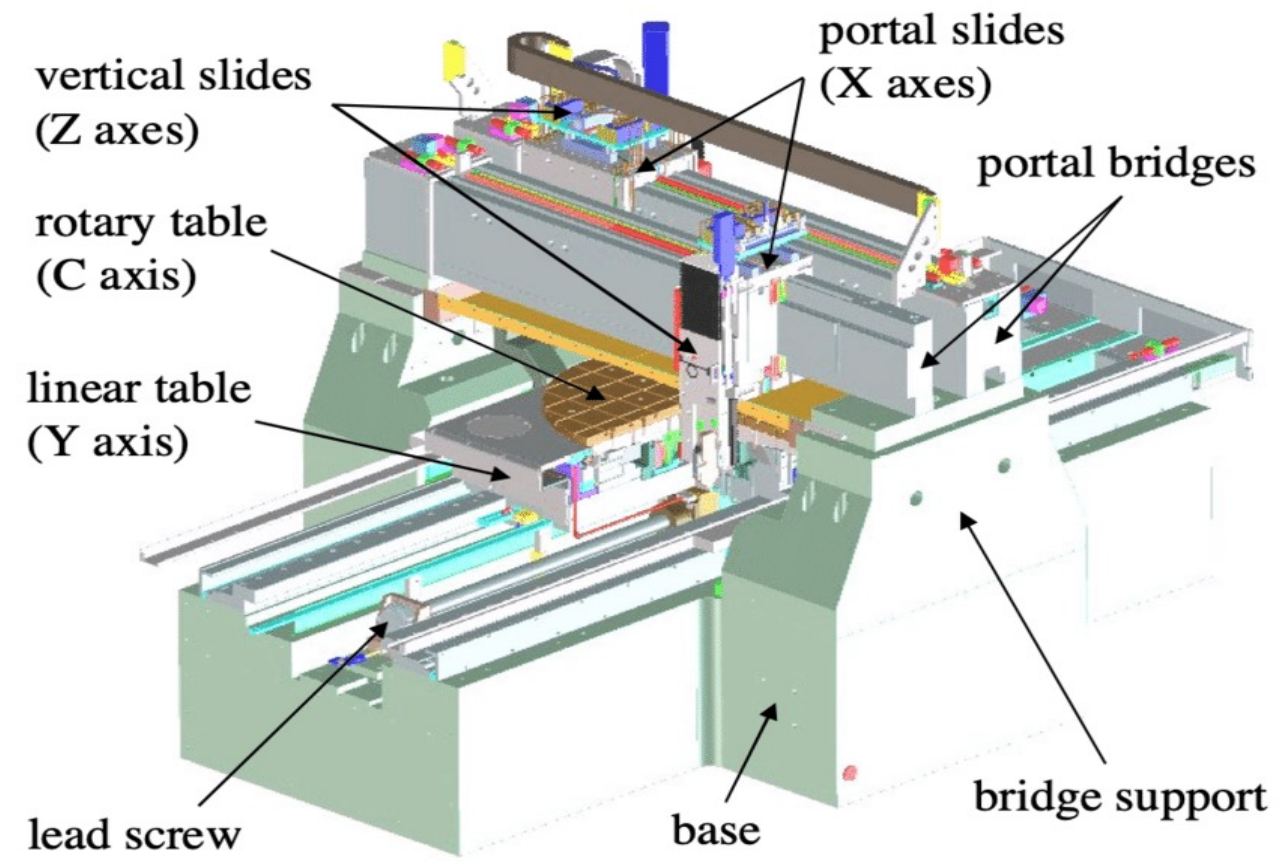

Moving table gantry structure: High-strength cast iron components (resin sand molding);

Ram system: Fully enclosed sliding guideways (cast iron + plastic friction pair) ensure smooth cutting stability.

Drive system: High-torque Taiwan spindle unit (30/37kW); equipped with Siemens 828D CNC system (standard).

Worktable size range: 1500×2000mm (TSUP1820) to 3000×8000mm (TSUP4080).

X-axis travel: 2200–8200mm; Y-axis travel: 1700–3200mm; Z-axis travel: 1250/1500mm (optional).

Max. load capacity: 3 t/m² uniformly across all models.

✅ Structural Configuration Features

Ram design: High-rigidity square ram (450×450mm) with hardened guideways and dual hydraulic balancing.

Linear motion: Imported precision guideways and ball screws (X/Y-axis protected).

Optional ATC: 24/30-tool disc magazine for automated tool change.

5-face machining: Supports manual/semi-auto/full-auto angular heads for complex geometries.

Positioning accuracy:

X-axis: 0.02–0.04mm; Y-axis: 0.016–0.025mm; Z-axis: 0.016mm.

Repeatability:

X-axis: 0.012–0.03mm; Y-axis: 0.01–0.016mm; Z-axis: 0.01mm.

Rapid traverse: 8 m/min (X/Y); 6 m/min (Z); Cutting feed: 6 m/min.

Machine weight: 25T (smallest) to 100T (largest model).

| Project | Unit | TSUP1820 | TSUP1830 | TSUP2540 | TSUP2560 | TSUP3060 | TSUP3080 | TSUP4080 |

|---|---|---|---|---|---|---|---|---|

| Worktable | ||||||||

| Worktable size | mm | 1500×2000 | 1500×3000 | 2000×4000 | 2000×6000 | 2500×6000 | 2500×8000 | 3000×8000 |

| Effective width of gantry | mm | 1800 | 1800 | 2500 | 2500 | 3000 | 3000 | 4000 |

| Maximum load - bearing capacity of worktable | t/㎡ | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Width of T - slot on worktable | mm | 22 | 22 | 22 | 22 | 22 | 22 | 22 |

| Machining Range | ||||||||

| X - axis travel | mm | 2200 | 3200 | 4200 | 6200 | 6200 | 8200 | 8200 |

| Y - axis travel | mm | 1700 | 1700 | 2200 | 2200 | 2700 | 2700 | 3200 |

| Z - axis travel (optional) | mm | 1250 (1500) | 1250 (1500) | 1250 (1500) | 1250 (1500) | 1250 (1500) | 1250 (1500) | 1250 (1500) |

| Distance from spindle end face to worktable surface | mm | 300-1550 | 300-1550 | 300-1550 | 300-1550 | 300-1550 | 300-1550 | 300-1550 |

| Spindle | ||||||||

| Spindle bore (7:24) | - | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Main motor power | kW | 30/37 | 30/37 | 30/37 | 30/37 | 30/37 | 30/37 | 30/37 |

| Maximum output torque | N·m | 1010/1250 | 1010/1250 | 1010/1250 | 1010/1250 | 1010/1250 | 1010/1250 | 1010/1250 |

| Maximum spindle speed | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Cross - sectional size of ram | mm | 450×450 | 450×450 | 450×450 | 450×450 | 450×450 | 450×450 | 450×450 |

| Feed | ||||||||

| Maximum cutting feed speed | m/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Rapid feed speed | m/min | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Positioning Accuracy | ||||||||

| X - axis | mm | 0.02 | 0.025 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 |

| Y - axis | mm | 0.016 | 0.016 | 0.02 | 0.02 | 0.025 | 0.025 | 0.025 |

| Z - axis | mm | 0.016 | 0.016 | 0.016 | 0.016 | 0.016 | 0.016 | 0.016 |

| Repeat Positioning Accuracy | ||||||||

| X - axis | mm | 0.012 | 0.015 | 0.016 | 0.025 | 0.025 | 0.03 | 0.03 |

| Y - axis | mm | 0.01 | 0.01 | 0.012 | 0.012 | 0.016 | 0.016 | 0.016 |

| Z - axis | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Equipment Weight | T | 25T | 35T | 45T | 60T | 70T | 80T | 100T |

Multi - process integration supports combined machining such as milling, boring and tapping, reducing the number of clamping operations and increasing efficiency by 40%.

The four - sided quenched guide rail of the square ram and the dual - hydraulic balance system improve vibration resistance by 60%.

The full - closed - loop detection system compensates for thermal deformation and mechanical errors in real - time, achieving a machining accuracy of ±0.01 mm.

Optional 24/30 - position disc tool magazines and automatic attachment milling heads can be selected to expand five - face machining capabilities.

Military Manufacturing: Five - face precision machining of aircraft engine casings and missile components.

Automotive Industry: Composite milling of body mold cavities and transmission housings.

Energy Equipment: Boring of nuclear reactor pressure vessel flanges and wind turbine hubs.

Mold Processing: High - precision surface machining of large die - casting molds.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.