Dual independent spindles: Simultaneous drilling with 2×BT40 taper spindles; optimized for flanges, rings, and discs (φ100–500mm).

Rotary C-axis: 360° CNC rotary table with hydraulic auto-clamping; enables precision circular hole patterns.

Control system: Dual PLC control units (not full CNC); dedicated hydraulic/pneumatic logic for high-speed drilling.

Workpiece capacity:Diameter range: φ100–350mm (TDS350/2) / φ100–500mm (TDS500/2).Max. thickness: 50mm (uniform)

Axis system:C-axis (rotary table): 360° CNC rotation.Y-axis (head transverse): 180–260mm travel.Z-axis (spindle vertical): 230mm travel

Speed & feed:Rapid traverse: 8 m/min (Y-axis); 6 m/min (Z-axis)

Dimensions: 2.4×1.8×2.35m to 2.7×2.0×2.35m

| Deep Hole Drilling Machine Specifications | ||

|---|---|---|

| Parameter Name | Item/Model | Specification |

| Processing Range | ||

| Workpiece Size | mm | φ100-350 φ100-500 |

| Worktable | ||

| Clamping Method | Hydraulic Auto-Clamp Hydraulic Auto-Clamp | |

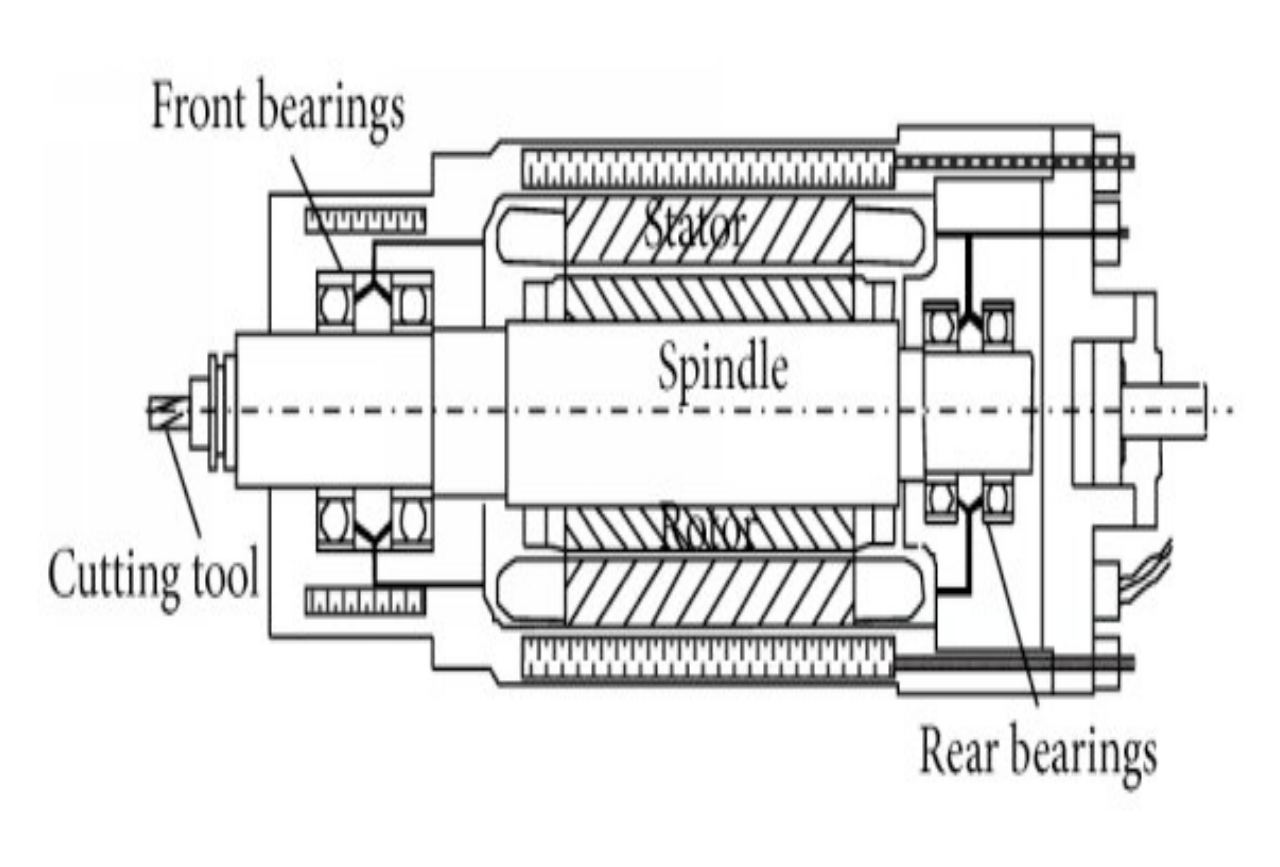

| Spindle Head | ||

| Quantity | 2 2 | |

| Spindle Taper | BT40 (with Torque Overload Protection) BT40 (with Torque Overload Protection) | |

| Max. Drilling Diameter | mm | Φ30 Φ30 |

| Max. Thickness | mm | 50 (Depth/Diameter Ratio ≤12) 50 (Depth/Diameter Ratio ≤12) |

| Spindle Speed | rpm | 10-4500 10-4500 |

| Spindle Motor Power | kW | 5.5 5.5 |

| Worktable Rotation (X-axis) | ||

| Angle | 360° 360° | |

| Max. Circular Positioning Accuracy | mm | 0.1 0.1 |

| Motor Power | kW | 1.3 1.3 |

| Spindle Head Movement (Y-axis) | ||

| Travel | mm | 180 260 |

| Positioning Accuracy | mm | 0.05 0.05 |

| Motor Power | kW | 1 1 |

| Spindle Vertical Feed (Z-axis) | ||

| Travel | mm | 230 230 |

| Positioning Accuracy | mm | 0.05 0.05 |

| Motor Power | kW | 1 1 |

| Chip Removal System | ||

| Type | Chain Plate Type Chain Plate Type | |

| Quantity | 1 1 | |

| Chip Removal Speed | m/min | 1 1 |

| Motor Power | kW | 0.75 0.75 |

| High-Pressure Internal Coolant | ||

| Pressure/Flow/Power | MPa/L/min/kW | 2×1.5/40/2.2 2×1.5/40/2.2 |

| Hydraulic System | ||

| Pressure/Flow/Power | MPa/L/min/kW | 7/30/3 7/30/3 |

| Electrical System | ||

| CNC System | 2 Sets of PLC Control 2 Sets of PLC Control | |

| CNC Axes per Set | 3+1 3+1 | |

| Power & Weight | ||

| Total Power | kW | ~35 ~35 |

| Total Weight | T | ~4.8 ~7.5 |

| Dimensions | ||

| L×W×H | mm | ~2400×1800×2350 ~2700×2000×2350 |

| Model: XFS350/2 XFS500/2 | ||

The independent dual power heads perform synchronous processing, increasing the efficiency by 50% and meeting the requirements of mass production

With an internal cooling pressure of 2×1.5 MPa and in combination with BTA drills, the chip removal efficiency is increased by 40%.

PLC centralized control + CNC axis linkage ensures a hole position accuracy of ±0.1 mm and reduces manual intervention.

The machine tool has a small footprint (TDS500/2: 2700×2000 mm), which is suitable for limited workshop space.

Flange Manufacturing: Precision drilling of multiple workstations on flange sealing surfaces and bolt holes.

Petrochemical Equipment: Machining of positioning holes on valve flanges and tube sheets.

General Machinery: Synchronous machining of multiple holes on gear discs and bearing seats.

Mold Industry: Efficient machining of cooling holes and positioning pin holes on mold plates.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.