An SX crossed roller bearing is a high-precision, compact bearing with a split outer ring and an integral inner ring, featuring cylindrical rollers arranged in an 'X' pattern (90° to each other) to support heavy radial, axial, and moment loads simultaneously, offering superior rigidity and accuracy for robotics, machine tools, and medical equipment where space saving is crucial.

Features:

Inner Ring: Split structure;

Outer Ring: Split structure;

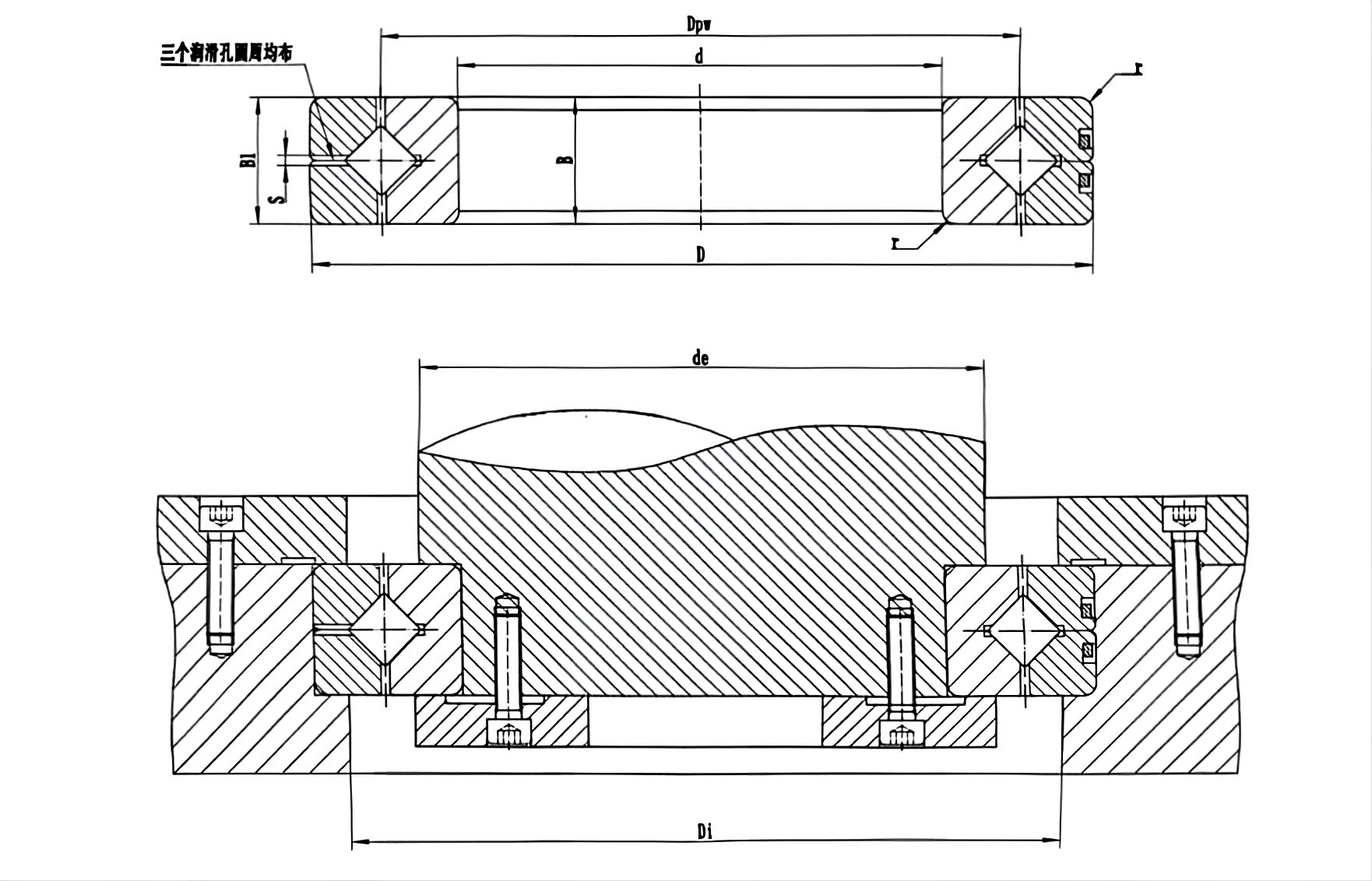

Shoulder: Precision-machined with standard positioning surfaces (equipped with greasing holes); Roller Arrangement: 90° orthogonal "X"-shaped cylindrical rollers

Accuracy: P5, P4, P2

Metric Series:

Inner Diameter: 70–500 mm;

Outer Diameter: 90–620 mm;

Cross-section Height: 10–56 mm;

Materials:

Bearing Rings & Rollers: GCr15 high-carbon chromium steel,SUS440C stainless steel ;

Cages: Brass , reinforced Nylon 66 , or custom high-load dedicated composite materials

Sealing Options:

Open Type: Requires regular external lubrication, suitable for clean, high-load medium-low speed working conditions;

Contact Rubber Seals (UU/U): Dustproof and splash-proof, suitable for complex high-load industrial environments with dust and humidity

Delivery:

Standard models: 7–15 days;

Customized models :Please contact the manufacturer.

| Cross Roller Bearing SX Series | |||||||||||||

| MODELS | BOUNDARY DIMENSIONS | SHOULDER HEIGHT | BASIC LOAD RATING (AXIAL) | BASIC LOAD RATING (RADIAL) | WEIGHT | ||||||||

| INNER RING | OUTER RING | ROLLER PITCH CIRCLE DIAMETER DP (MM) | WIDTH | GREASING HOLE | CHAMFER | DE | DI | CA | COA | CR | COR | KG | |

| d | D | B/B1 | R | KN | KN | KN | KN | ||||||

| (MM) | (MM) | (MM) | ∅ | (MIN) | |||||||||

| NB.SX011814 | 70 | 90 | 80 | 10 | 1.2 | 0.6 | 79.5 | 80.5 | 15.4 | 51 | 11 | 20 | 0.3 |

| NB.SX011818 | 90 | 115 | 102 | 13 | 1 | 101.5 | 102.5 | 26 | 91 | 18 | 37 | 0.4 | |

| NB.SX011820 | 100 | 125 | 112 | 13 | 1 | 111.5 | 112.5 | 28 | 102 | 19 | 41 | 0.5 | |

| NB.SX011824 | 120 | 150 | 135 | 16 | 1.5 | 1 | 134.4 | 135.6 | 41 | 146 | 27 | 59 | 0.8 |

| NB.SX011828 | 140 | 175 | 157 | 18 | 1.1 | 156.3 | 157.7 | 64 | 240 | 45 | 96 | 1.1 | |

| NB.SX011832 | 160 | 200 | 180 | 20 | 1.1 | 179.2 | 180.8 | 69 | 275 | 49 | 111 | 1.7 | |

| NB.SX011836 | 180 | 225 | 202 | 22 | 2 | 1.1 | 201.2 | 202.8 | 96 | 381 | 69 | 153 | 2.3 |

| NB.SX011840 | 200 | 250 | 225 | 24 | 1.5 | 224.2 | 225.8 | 102 | 425 | 72 | 170 | 3.1 | |

| NB.SX011848 | 240 | 300 | 270 | 28 | 2 | 269.2 | 270.8 | 148 | 640 | 105 | 255 | 5.3 | |

| NB.SX011860 | 300 | 380 | 340 | 38 | 2.5 | 2.1 | 339.2 | 340.8 | 243 | 1070 | 173 | 425 | 12 |

| NB.SX011868 | 340 | 420 | 380 | 38 | 2.1 | 379.2 | 380.8 | 260 | 1220 | 185 | 485 | 13.5 | |

| NB.SX011880 | 400 | 500 | 450 | 46 | 2.5 | 449 | 451 | 385 | 1800 | 275 | 720 | 24 | |

| NB.SX0118/500 | 500 | 620 | 560 | 56 | 3 | 558.8 | 561.2 | 560 | 2750 | 395 | 1100 | 44 | |

Maximum axial bearing capacity of 560 KN and radial bearing capacity of 395 KN, capable of stably withstanding ultra-heavy composite loads, adapting to the needs of high-load precision equipment.

Split inner and outer ring design supports refined preload settings, effectively improving system rigidity and positioning accuracy, meeting the precision operation requirements under high loads.

Precision shoulder structure provides standard positioning surfaces, combined with greasing hole design, simplifying installation process and lubrication maintenance, ensuring coaxiality under high loads.

Compatible with various high-load environments including clean, dusty, and humid conditions, supports non-standard customization, and adapts to high-load needs in multiple fields such as machine tools, semiconductors, and aerospace.

1. Industrial Robots & Collaborative Robots

Robot arm joints (wrist, elbow, shoulder)

Harmonic-drive output support

Compact rotary actuators

SX bearings provide high stiffness and moment resistance, improving robot positioning accuracy and repeatability.

2. Precision Rotary Tables

CNC indexing tables

Precision positioning rotaries

Laser processing rotary units

The bolt-on structure simplifies assembly and maintains high angular accuracy under load.

3. Automation & Handling Systems

Pick-and-place machines

Packaging automation

Precision assembly equipment

SX bearings handle combined radial, axial, and moment loads while reducing machine footprint.

4. Semiconductor Manufacturing Equipment

Wafer handling arms

Inspection and alignment stages

Lithography positioning systems

Stable torque and high rigidity support micron-level accuracy.

5. Medical Equipment

Surgical robots

Imaging system rotation units

Patient positioning mechanisms

Compact design, smooth motion, and reliability are key benefits.

6. Optical & Vision Systems

Camera gimbals

Beam steering platforms

Telescope and sensor mounts

SX bearings maintain optical alignment under dynamic loads.

7. Aerospace & Defense

UAV gimbal systems

Satellite antenna drives

Radar rotation units

Their lightweight and high-rigidity design suits mission-critical systems.

8. Compact Turntables & Slewing Mechanisms

Small industrial turntables

Pan-tilt units

Precision slewing drives

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.