In the field of precision mechanical transmission, ball screw support bearings are core components that ensure high-precision positioning and stable transmission of equipment, widely used in machine tools, automated production lines, precision instruments, and other scenarios. The ZARN70130-TN ball screw support bearing produced by NewBee, with its optimized structural design, wide temperature adaptability, and excellent load-bearing performance, perfectly meets the high rigidity and high-precision support requirements of ball screws, providing reliable guarantee for various precision transmission systems. Its derivative model, ZARN70130-L-TN, features an extended structure design, further expanding the adaptability of application scenarios.

1. Wide Temperature Adaptability for Complex Working Conditions

Adopts special material and structural design, supporting continuous operation at 120°C and short-term use at 180°C. It can adapt to harsh working environments with alternating high and low temperatures without additional temperature control assistance.

The plastic cage (identified by the suffix TN) design combines lightweight and high-temperature resistance, avoiding deformation and failure under high-temperature conditions and ensuring stable operation of the bearing.

2. High Load-Bearing Capacity for Stable Transmission

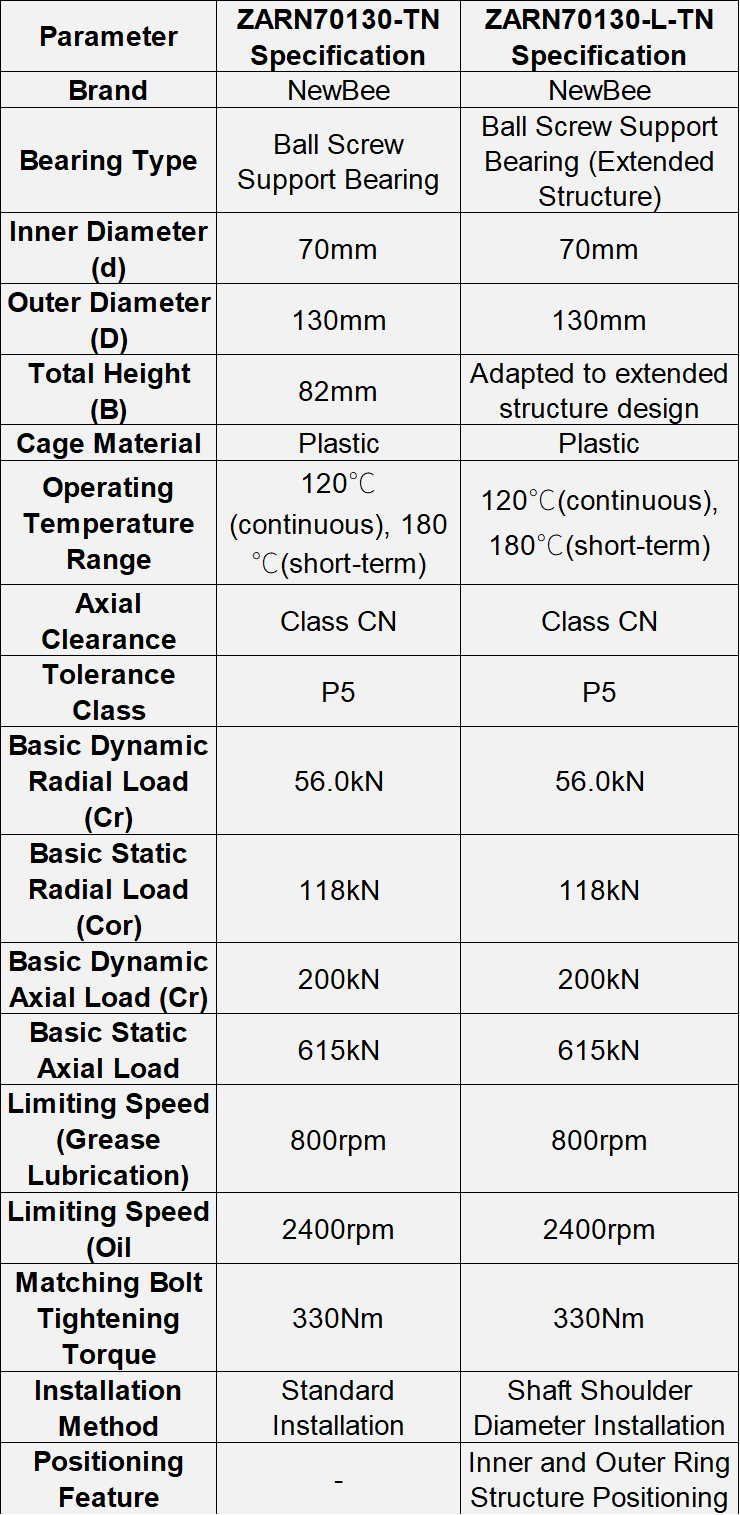

The basic dynamic radial load (Cr) reaches 56.0kN, the basic static radial load (Cor) is 118kN, the basic dynamic axial load (Cr) is 200kN, and the basic static axial load (Cor) is as high as 615kN. It can easily handle composite loads during ball screw transmission and reduce deformation risks.

The axial clearance is class CN, combined with high-precision processing technology, ensuring precise positioning during transmission and avoiding transmission errors caused by clearance.

3. Multi-Lubrication Adaptability to Meet Different Speed Requirements

The limiting speed can reach 800rpm under grease lubrication and up to 2400rpm under oil lubrication, adapting to speed requirements under different working conditions while balancing stability and efficiency.

Strong lubrication compatibility allows flexible selection of lubrication methods according to actual application scenarios, extending the service life of the bearing.

4. Flexible Structure for Easy Installation

The basic model ZARN70130-TN has an inner diameter of 70mm, outer diameter of 130mm, total height of 82mm, and the matching bolt tightening torque is 330Nm, enabling precise and efficient installation and positioning.

The derivative model ZARN70130-L-TN is marked with an extended structure by the suffix "L", with a tolerance class of P5, supporting shaft shoulder diameter installation. The inner and outer ring structure design enhances positioning stability, adapting to more complex installation scenarios.

Application Value: Core Improvements for Precision Transmission Systems

1. Improve Transmission Precision: Class CN axial clearance and high-precision processing technology control transmission positioning errors within a minimal range, adapting to the high-precision requirements of machine tools and precision instruments.

2. Extend Service Life: High load-bearing capacity and wide temperature adaptability reduce wear and failure risks under complex working conditions, extending equipment maintenance cycles by more than 30%.

3.Adapt to Diverse Scenarios: Flexible selection between basic and extended models supports different installation methods and speed requirements, covering diverse applications such as machine tool spindles, automated production lines, and ball screw transmission modules.

4. Reduce Operation and Maintenance Costs: The plastic cage and multi-lubrication adaptability design reduce maintenance frequency and lubrication loss, lowering overall operation and maintenance costs.

1. Brand Quality Assurance As a professional bearing manufacturer, NewBee has mature precision bearing production technology. Products undergo strict quality inspections, with stable and reliable performance, complying with strict standards in the industrial transmission field.

2. Precise Adaptation to Transmission Needs Targeted optimized load design, temperature adaptation, and installation structure perfectly match the core needs of ball screw support, solving pain points related to precision and stability during transmission.

3. Flexible Expansion of Derivative Models The ZARN70130-L-TN’s extended structure and special installation method design allow flexible selection according to equipment structure requirements, reducing adaptation and modification difficulties.

4. Full-Scenario Adaptability Support for wide temperature range, high load, and multi-lubrication methods enables adaptation to different working conditions such as high and low temperatures, high speeds, and heavy loads, without the need for additional customization, ensuring strong versatility.

Contact Us: Obtain Precision Transmission Bearing Solutions For detailed technical specifications, sample testing, or adaptation plans of ZARN70130-TN/ZARN70130-L-TN bearings, please contact us via the following methods:

Email: paul@newbeetrans.com

Phone: +86 15122832049

Official Website: www.newbeetrans.com