CRBC crossed roller bearings are a type of high-precision bearing (often from brands like IKO) featuring cylindrical rollers arranged perpendicularly (crossed) for high rigidity, compact size, and the ability to handle loads in all directions (radial, axial, moment), making them ideal for industrial robots, machine tool tables, and automation where accuracy and space are critical, with the "CRBC" designation typically meaning a split outer ring for easy mounting and inner ring rotation.

Structural Features:

Inner Ring: Integral structure;

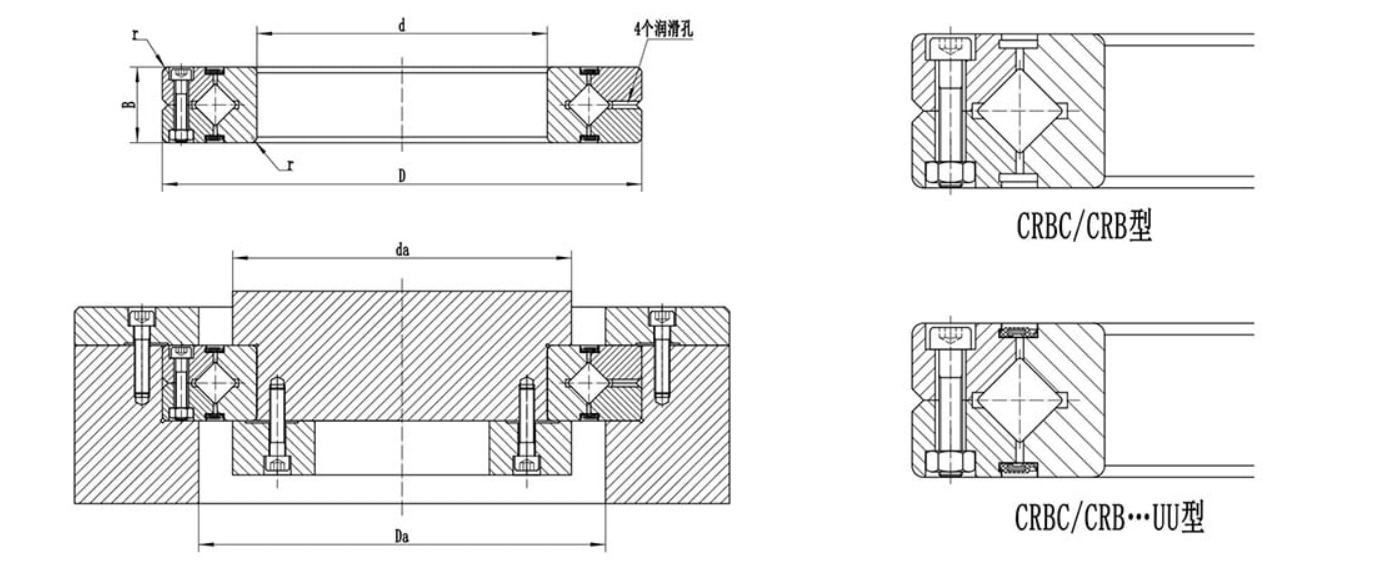

Outer Ring: Split structure (facilitates preload adjustment);

Roller Arrangement: 90° orthogonal "X"-shaped cylindrical rollers (simultaneously bears radial, axial and moment loads)

Accuracy Classes:

Rotational Accuracy: P5, P4, P2

Size:

Inner Diameter: 30–800 mm;

Outer Diameter: 55–1030 mm;

Cross-section Height: 10–100 mm

Materials:

Bearing Rings & Rollers: GCr15 high-carbon chromium steel (surface hardness HRC 60-62) or SUS440C stainless steel (corrosion-resistant);

Cages:

Nylon 66 (lightweight), brass (high-strength), or custom composite materials

Sealing Options:

Open Type: Requires regular external lubrication, suitable for clean and low-dust environments;

Contact Rubber Seals (UU/U): Dustproof and splash-proof, suitable for complex working conditions such as industrial dust and humidity

Delivery/Customization:

Standard models: 7–15 days;

Customized models: Negotiated according to design complexity; OEM cooperation supported

| Cross Roller Bearing CRBC Series | ||||||||||||

| MODEL | SIZES(MM) | MOUNTING | NB.CRBC | NB.CRB | WEIGHT | |||||||

| With cage | Fully rollers | d | D | B | r (min) | DIMENSIONS | Dynamic Load Rating | Static Load Rating | Dynamic Load Rating | Static Load Rating | KG | |

| mm | mm | mm | (mm) | C(KN) | Co(KN) | C(KN) | Co(KN) | |||||

| NB.CRBC3010 | NB.CRB3010 | 30 | 55 | 10 | 0.3 | 34 | 44 | 3.8 | 4.1 | 5.29 | 6.35 | 0.12 |

| NB.CRBC4010 | NB.CRB4010 | 40 | 65 | 10 | 0.3 | 44 | 54 | 4.28 | 5.14 | 5.98 | 8.04 | 0.15 |

| NB.CRBC5013 | NB.CRB5013 | 50 | 80 | 13 | 0.6 | 55 | 71 | 10.7 | 12.6 | 14.2 | 18.4 | 0.29 |

| NB.CRBC6013 | NB.CRB6013 | 60 | 90 | 13 | 0.6 | 64 | 81 | 11.6 | 14.6 | 15.4 | 21.5 | 0.33 |

| NB.CRBC7013 | NB.CRB7013 | 70 | 100 | 13 | 0.6 | 75 | 91 | 12.3 | 16.7 | 17 | 25.5 | 0.38 |

| NB.CRBC8016 | NB.CRB8016 | 80 | 120 | 16 | 0.6 | 86 | 107 | 18.2 | 25.5 | 24.3 | 37.5 | 0.74 |

| NB.CRBC9016 | NB.CRB9016 | 90 | 130 | 16 | 1 | 98 | 118 | 19.4 | 28.6 | 25.9 | 42.1 | 0.81 |

| NB.CRBC10020 | NB.CRB10020 | 100 | 150 | 20 | 1 | 108 | 134 | 31.5 | 45.1 | 39.4 | 61.1 | 1.45 |

| NB.CRBC11020 | NB.CRB11020 | 110 | 160 | 20 | 1 | 118 | 144 | 33.5 | 50.7 | 41.2 | 66.7 | 1.56 |

| NB.CRBC12025 | NB.CRB12025 | 120 | 180 | 25 | 1.5 | 132 | 164 | 47.7 | 70.5 | 59.9 | 95.4 | 2.62 |

| NB.CRBC13025 | NB.CRB13025 | 130 | 190 | 25 | 1.5 | 140 | 172 | 49.2 | 74.8 | 61 | 99.8 | 2.82 |

| NB.CRBC14025 | NB.CRB14025 | 140 | 200 | 25 | 1.5 | 151 | 183 | 50.7 | 79.2 | 64.1 | 108 | 2.96 |

| NB.CRBC15025 | NB.CRB15025 | 150 | 210 | 25 | 1.5 | 160 | 192 | 53.8 | 87.7 | 65 | 113 | 3.16 |

| NB.CRBC15030 | NB.CRB15030 | 150 | 230 | 30 | 1.5 | 166 | 202 | 69.2 | 108 | 85.9 | 144 | 5.3 |

| NB.CRBC20025 | NB.CRB20025 | 200 | 260 | 25 | 2 | 208 | 239 | 60.2 | 110 | 75.3 | 148 | 4 |

| NB.CRBC20030 | NB.CRB20030 | 200 | 280 | 30 | 2 | 218 | 262 | 108 | 178 | 133 | 234 | 6.7 |

| NB.CRBC20035 | NB.CRB20035 | 200 | 295 | 35 | 2 | 221 | 274 | 137 | 215 | 168 | 282 | 9.58 |

| NB.CRBC25025 | NB.CRB25025 | 250 | 310 | 25 | 2.5 | 259 | 290 | 67.2 | 136 | 83.9 | 183 | 4.97 |

| NB.CRBC25030 | NB.CRB25030 | 250 | 330 | 30 | 2.5 | 265 | 310 | 116 | 208 | 146 | 283 | 8.1 |

| NB.CRBC25040 | NB.CRB25040 | 250 | 355 | 40 | 2.5 | 271 | 330 | 179 | 299 | 215 | 382 | 14.8 |

| NB.CRBC30025 | NB.CRB30025 | 300 | 360 | 25 | 2.5 | 310 | 341 | 73.8 | 162 | 91.9 | 217 | 5.88 |

| NB.CRBC30035 | NB.CRB30035 | 300 | 395 | 35 | 2.5 | 318 | 372 | 163 | 299 | 205 | 408 | 13.4 |

| NB.CRBC30040 | NB.CRB30040 | 300 | 405 | 40 | 2.5 | 321 | 381 | 194 | 351 | 235 | 451 | 17.2 |

| NB.CRBC40035 | NB.CRB40035 | 400 | 480 | 35 | 2.5 | 414 | 457 | 133 | 300 | 165 | 400 | 14.5 |

| NB.CRBC40040 | NB.CRB40040 | 400 | 510 | 40 | 2.5 | 423 | 483 | 222 | 455 | 270 | 590 | 23.5 |

| NB.CRBC40070 | NB.CRB40070 | 400 | 580 | 70 | 2.5 | 430 | 532 | 470 | 811 | 576 | 1060 | 72.4 |

| NB.CRBC50040 | NB.CRB50040 | 500 | 600 | 40 | 2.5 | 517 | 573 | 211 | 497 | 259 | 648 | 26 |

| NB.CRBC50050 | NB.CRB50050 | 500 | 625 | 50 | 2.5 | 531 | 592 | 247 | 561 | 306 | 747 | 41.7 |

| NB.CRBC50070 | NB.CRB50070 | 500 | 680 | 70 | 2.5 | 530 | 633 | 536 | 1020 | 653 | 1330 | 86.1 |

| NB.CRBC60040 | NB.CRB60040 | 600 | 700 | 40 | 3 | 621 | 676 | 231 | 581 | 287 | 774 | 30.6 |

| NB.CRBC60070 | NB.CRB60070 | 600 | 780 | 70 | 3 | 630 | 734 | 591 | 1230 | 700 | 1540 | 102 |

| NB.CRBC600120 | NB.CRB600120 | 600 | 870 | 120 | 3 | 643 | 817 | 1250 | 2210 | 1490 | 2800 | 274 |

| NB.CRBC70045 | NB.CRB70045 | 700 | 815 | 45 | 3 | 730 | 785 | 250 | 681 | 301 | 917 | 46.5 |

| NB.CRBC70070 | NB.CRB70070 | 700 | 880 | 70 | 3 | 731 | 834 | 630 | 1390 | 766 | 1810 | 115 |

| NB.CRBC700150 | NB.CRB700150 | 700 | 1020 | 150 | 3 | 751 | 953 | 1660 | 3010 | 1980 | 3820 | 478 |

| NB.CRBC80070 | NB.CRB80070 | 800 | 950 | 70 | 4 | 831 | 907 | 417 | 1090 | 513 | 1440 | 109 |

| NB.CRBC800100 | NB.CRB800100 | 800 | 1030 | 100 | 4 | 840 | 972 | 936 | 2040 | 1140 | 2640 | 247 |

A single bearing simultaneously bears radial, axial, and moment loads, simplifying equipment structural design.

P2-class precision meets micron-level positioning requirements, and high rigidity ensures stability during cutting, machining, and other working conditions.

The split outer ring design facilitates preload adjustment and maintenance, making it suitable for complex assembly scenarios.

The thin-walled structure significantly saves installation space, adapting to the compact layout requirements of robots, micro-devices, and other equipment.

Independently researched, developed, and manufactured in China, it replaces imported products, reduces procurement costs, and ensures a stable supply.

1. Industrial Robots & Collaborative Robots (Cobots)

Robot arm joints

Wrist units

End-effectors requiring precise rotation

CRBC bearings provide high rigidity, minimal rotational error, and strong moment load capacity—ideal for robotic motion.

2. Precision Rotary Tables

CNC indexing tables

Rotary positioning platforms

Laser cutting and inspection rotaries

Crossed rollers give high axial and radial stiffness, essential for accurate angular positioning.

3. Medical Equipment

CT scanner rotary parts

MRI positioning systems

Surgical robots

The quiet, smooth, high-precision rotation is suitable for sensitive medical devices.

4. Semiconductor Manufacturing Equipment

Wafer handling arms

Lithography stages

Inspection/measurement stages

CRBC bearings deliver extremely stable, low-friction rotation, crucial for semiconductor precision.

5. Optical & Photonics Instruments

Telescope mounts

Camera gimbals

Beam-steering platforms

Their ultra-low rotational error ensures stability in optical alignment.

6. Aerospace & Defense Equipment

Satellite antenna gimbals

Radar rotation units

UAV cameras & stabilizers

Lightweight and high-rigidity performance is ideal for mission-critical systems.

7. Machine Tool Equipment

Tool changers

Measuring heads

Small precision spindles

Stable rotation improves machining repeatability.

8. Automation Systems

Pick-and-place machines

Precision indexing arms

Automated inspection devices

They handle both multi-direction loads and repetitive high-speed cycles.

9. Measuring & Metrology Systems

CMM (coordinate measuring machines) rotate axes

Laser measurement tools

High-accuracy encoder systems

The smooth, backlash-free rotation is essential for sub-micron precision measurements.

10. Small Slewing & Turntable Mechanisms

Compact industrial turntables

Light-load slewing rings

Pan-tilt mechanisms

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.