RU Crossed Roller Bearings RU crossed roller bearings are specifically designed for high-precision rotary systems, featuring integral inner and outer rings with precision-ground integrated raceways and built-in mounting holes (PCD). They are suitable for high-accuracy, rigid, and easy-lubrication applications. Their 90° orthogonal cross-arranged cylindrical rollers ensure stable load-bearing, making them ideal for robotic joints, precision rotary tables, semiconductor equipment, and medical instruments requiring precise rotation.

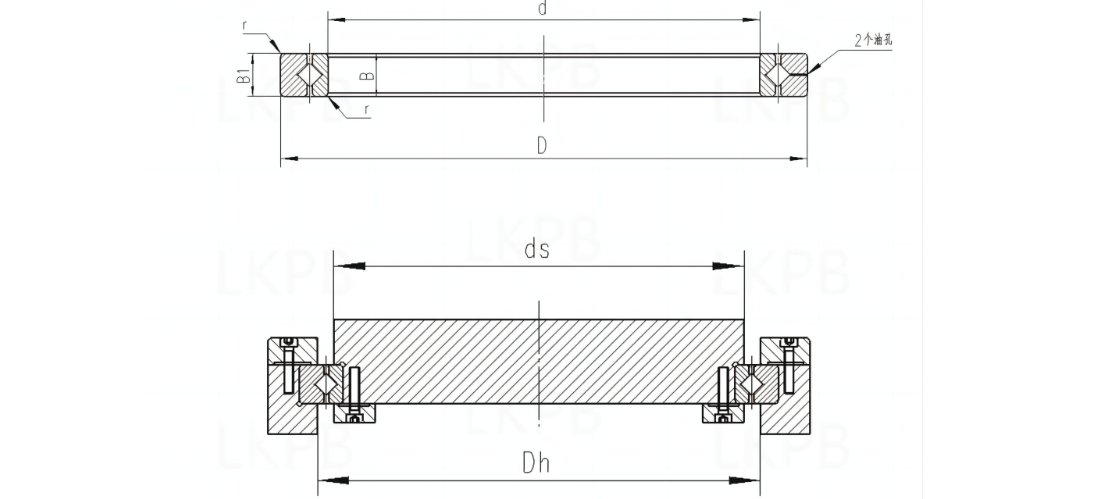

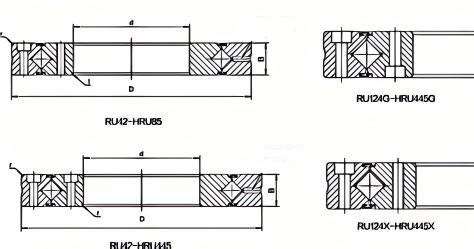

Structural Features:Inner & Outer Rings: Integral design with precision-ground raceways; built-in mounting holes (PCD);Roller Arrangement: 90° orthogonal cross layout (X series), separated by nylon cage;Lubrication Holes: 2 standard holes, supporting external grease or oil lubrication

Accuracy Class:Rotational Accuracy: P5, P4, P2;Runout Tolerance: P5;Mounting Hole Direction: G, X

Size:Inner diameter (d): 10–350 mm;Outer diameter (D): 52–540 mm;Section height (B): 8–45 mm;Mounting hole diameter: M3–M12 (varies by model)

Materials:Bearing rings & rollers: GCr15 high-carbon chromium steel (surface hardness HRC 60-62) or SUS440C stainless steel (corrosion-resistant);Cage: Nylon 66 (lightweight) or brass (high-strength)

Sealing Options:Open Series: Requires regular external lubrication, suitable for clean environments;Contact Rubber Seal (U/UU): Dust-proof and splash-proof, suitable for industrial dusty environments

Lubrication Methods:Grease Lubrication: Standard lubricating grease;Oil Lubrication: Circulating oil system, suitable for heavy-duty scenarios

Delivery/Customization:Standard models: 7–15 days;Customized models: Requires prior communication, delivery cycle arranged based on customization needs

| Size | Main dimensions | Shoulde height | Basic load rating (radial) | weight | Size | ||||||

| d | D | dp | width B B1 | Chamfer | ds | Dh | C | C0 | Kg | ||

| (mm) | (mm) | (mm) | (mm) | (min) | KN | KN | |||||

| NB.RU42 | 20 | 70 | 41.5 | 12 | 0.6 | 37 | 47 | 7.35 | 8.35 | 0.29 | NB.RU42 |

| NB.RU66 | 35 | 95 | 66 | 15 | 0.6 | 59 | 74 | 17.5 | 22.3 | 0.62 | NB.RU66 |

| NB.RU85 | 55 | 120 | 85 | 15 | 0.6 | 79 | 93 | 20.3 | 29.5 | 1 | NB.RU85 |

| NB.RU 124(G) | 80 | 165 | 124 | 22 | 1 | 114 | 134 | 33.1 | 50.9 | 2.6 | NB.RU 124(G) |

| NB.RU 124X | NB.RU 124X | ||||||||||

| NB.RU148(G) | 90 | 210 | 147.5 | 25 | 1.5 | 133 | 162 | 49.1 | 76.8 | 4.9 | NB.RU148(G) |

| NB.RU 148X | NB.RU 148X | ||||||||||

| NB.RU 178(G) | 115 | 240 | 178 | 28 | 1.5 | 161 | 195 | 80.3 | 135 | 6.8 | NB.RU 178(G) |

| NB.RU 178X | NB.RU 178X | ||||||||||

| NB.RU 228(G) | 160 | 295 | 227.5 | 35 | 2 | 208 | 246 | 104 | 172 | 11.4 | NB.RU 228(G) |

| NB.RU 228X | NB.RU 228X | ||||||||||

| NB.RU 297(G) | 210 | 380 | 297.3 | 40 | 2.5 | 272 | 320 | 156 | 281 | 21.3 | NB.RU 297(G) |

| NB.RU 297X | NB.RU 297X | ||||||||||

| NB.RU 445(G) | 350 | 540 | 445.4 | 45 | 2.5 | 417 | 473 | 222 | 473 | 35.4 | NB.RU 445(G) |

| NB.RU 445X | NB.RU 445X | ||||||||||

| Cross Roller Bearing NB.RAU Series | ||||||||||

| MODEL | MAIN DIMENSIONS | SHOULDER DIMENSION | BASIC LOAD RATING(RADIAL DIRECTION) | MASS | ||||||

| INNER RING | OUTER RING | ROLLER PITCH DIAMETER | HEIGHT | CHAMFER | CR | COR | ||||

| d | D | DP | B B1 | RMIN | DS | DH | KN | KN | KG | |

| NB.RAU1005 | 10 | 21 | 14.7 | 5 | 0.15 | 12.5 | 17 | 1.12 | 0.809 | 0.009 |

| NB.RAU1505 | 15 | 26 | 19.7 | 5 | 0.15 | 17.5 | 22 | 1.32 | 1.1 | 0.012 |

| NB.RAU2005 | 20 | 31 | 24.7 | 5 | 0.15 | 22.5 | 27 | 1.49 | 1.4 | 0.015 |

| NB.RAU2505 | 25 | 36 | 29.7 | 5 | 0.15 | 27.5 | 32 | 1.65 | 1.77 | 0.018 |

| NB.RAU3005 | 30 | 41 | 34.7 | 5 | 0.15 | 32.5 | 37 | 1.89 | 2.14 | 0.021 |

| NB.RAU3505 | 35 | 46 | 39.7 | 5 | 0.15 | 37.5 | 42 | 2.05 | 2.42 | 0.024 |

| NB.RAU4005 | 40 | 51 | 44.7 | 5 | 0.15 | 42.5 | 47 | 2.14 | 2.74 | 0.027 |

| NB.RAU4505 | 45 | 56 | 49.7 | 5 | 0.15 | 47.5 | 52 | 2.3 | 3.09 | 0.029 |

| NB.RAU5005 | 50 | 61 | 54.7 | 5 | 0.15 | 52.5 | 57 | 2.43 | 3.49 | 0.032 |

| NB.RAU5505 | 55 | 66 | 59.7 | 5 | 0.15 | 57.5 | 62 | 2.53 | 3.79 | 0.035 |

| NB.RAU6005 | 60 | 71 | 64.7 | 5 | 0.15 | 62.5 | 67 | 2.63 | 4.09 | 0.038 |

| NB.RAU6505 | 65 | 76 | 69.7 | 5 | 0.15 | 67.5 | 72 | 2.71 | 4.29 | 0.041 |

| NB.RAU7005 | 70 | 81 | 74.7 | 5 | 0.15 | 72.5 | 77 | 2.81 | 4.68 | 0.044 |

| NB.RAU7505 | 75 | 86 | 79.7 | 5 | 0.15 | 77.5 | 82 | 2.9 | 5.05 | 0.047 |

| NB.RAU8005 | 80 | 91 | 84.7 | 5 | 0.15 | 82.5 | 87 | 3.05 | 5.43 | 0.050 |

| NB.RAU8505 | 85 | 96 | 89.7 | 5 | 0.15 | 87.5 | 92 | 3.11 | 5.7 | 0.053 |

| NB.RAU9005 | 90 | 101 | 94.7 | 5 | 0.15 | 92.5 | 97 | 3.19 | 6.03 | 0.056 |

| NB.RAU9505 | 95 | 106 | 99.7 | 5 | 0.15 | 97.5 | 102 | 3.22 | 6.31 | 0.059 |

| NB.RAU10005 | 100 | 111 | 104.7 | 5 | 0.15 | 102.5 | 107 | 3.37 | 6.63 | 0.061 |

| NB.RAU5008 | 50 | 66 | 57 | 8 | 0.5 | 53.5 | 60 | 5.1 | 7.19 | 0.08 |

| NB.RAU6008 | 60 | 76 | 67 | 8 | 0.5 | 63.5 | 70.5 | 5.68 | 8.68 | 0.09 |

| NB.RAU7008 | 70 | 86 | 77 | 8 | 0.5 | 73.5 | 80.5 | 5.98 | 9.8 | 0.1 |

| NB.RAU8008 | 80 | 96 | 87 | 8 | 0.5 | 83.5 | 90.5 | 6.37 | 11.3 | 0.11 |

| NB.RAU9008 | 90 | 106 | 97 | 8 | 0.5 | 93.5 | 100.5 | 6.76 | 12.4 | 0.12 |

| NB.RAU10008 | 100 | 116 | 107 | 8 | 0.5 | 103.5 | 110.5 | 7.15 | 13.9 | 0.14 |

| NB.RAU11008 | 110 | 126 | 117 | 8 | 0.5 | 113.5 | 120.5 | 7.45 | 15 | 0.15 |

| NB.RAU12008 | 120 | 136 | 127 | 8 | 0.5 | 123.5 | 130.5 | 7.84 | 16.5 | 0.17 |

| NB.RAU13008 | 130 | 146 | 137 | 8 | 0.5 | 133.5 | 140.5 | 7.94 | 17.6 | 0.18 |

| NB.RAU4008 | 140 | 156 | 147 | 8 | 0.5 | 143.5 | 150.5 | 8.33 | 19.1 | 0.19 |

| NB.RAU15008 | 150 | 166 | 157 | 8 | 0.5 | 153.5 | 160.5 | 8.82 | 20.6 | 0.2 |

| NB.RAU16013 | 160 | 186 | 172 | 13 | 0.8 | 165 | 179 | 23.3 | 44.9 | 0.59 |

| NB.RAU17013 | 170 | 196 | 182 | 13 | 0.8 | 175 | 189 | 23.5 | 46.5 | 0.64 |

| NB.RAU18013 | 180 | 206 | 192 | 13 | 0.8 | 185 | 199 | 24.5 | 49.8 | 0.68 |

| NB.RAU19013 | 190 | 216 | 202 | 13 | 0.8 | 195 | 209 | 24.9 | 51.5 | 0.69 |

| NB.RAU20013 | 200 | 226 | 212 | 13 | 0.8 | 205 | 219 | 25.8 | 54.7 | 0.71 |

The RU series crossed roller bearings, with their design of simultaneous multi-load handling and even load distribution, can bear radial, axial, and moment loads at once. This not only endows them with high-efficiency composite load-bearing capacity but also extends their service life by reducing local overload.

Thanks to the crossed roller layout that increases the contact area, these bearings have 3 to 4 times higher rigidity than traditional ones. Paired with the pre-tightening design of the split outer ring, they form a stable structure resistant to deformation, perfect for high-torque scenarios.

Through precise manufacturing processes and optimized roller end faces, the RU bearings achieve high-precision rotation with minimal friction. With a runout tolerance of ≤0.002mm (P4 level) and a maximum speed of 3000 rpm, they meet strict positioning and speed requirements.

Offering various sealing options like open series, RS rubber seals, and ZZ metal shields, along with wide lubrication compatibility (long-lasting greases like Krytox® or circulating oil), they provide flexible solutions for different working conditions, from clean to dusty environments.

Made of high-quality materials such as GCr15 high-carbon chromium steel (HRC 60-62) or SUS440C stainless steel for the rings and rollers, and nylon 66 or brass for the cage, and with advanced surface hardening treatment, these bearings significantly enhance durability and reliability, increasing the fatigue life by over 30%.

he ultra-thin section design (minimum 12mm, e.g., RU42) makes them suitable for space-limited equipment. The inner and outer rings with mounting holes (e.g., RU124) simplify installation and support modular applications, reducing maintenance costs.

1.Robot Joints

Shoulder and hip joints of humanoid robots: These joints need to withstand enormous tilting moments while operating within extremely limited structural space. RU bearings can be directly bolted to the "pelvis" and "thigh" structural components of the robot, forming a highly compact and rigid hip joint.

Base joints of collaborative robots: The rotating base of the robot can directly adopt RU bearings to connect the robot's fixed base and rotating body.

Moving platform of Delta parallel robots: At the center of the moving platform, RU bearings can provide a compact rotational degree of freedom.

2. Precision Rotary Tables and Indexing Plates

Automated rotary worktables: In automated assembly and inspection production lines, RU bearings can directly serve as the rotating core of the worktable. The worktable surface is bolted to the inner or outer ring of the bearing, and the drive system directly drives the table to rotate.

Rotating mechanisms of optical and testing equipment: Used for rotating lenses, sensors, or samples.

3. Semiconductor and Flat Panel Display Manufacturing Equipment

Manipulators inside vacuum chambers: The compactness and easy-to-clean characteristics of the RU series (compared to structures with complex bearing housings) make them suitable for vacuum environments. Bearings can be directly fixed to the chamber wall panels, simplifying the structural design of vacuum feedthroughs.

Wafer transfer modules: In various transfer units requiring precise rotation.

4. Medical Equipment

Rotating parts of CT scan gantries: In some designs, large-sized RU series bearings can be used to support and guide the rotating parts.

Rotating joints of surgical robots: Locations requiring high precision and compact design.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.