RB crossed roller bearings are specifically designed for heavy-load and high-rigidity rotary systems, featuring a 90° orthogonal "X"-shaped crossed roller layout that enables simultaneous bearing of radial loads, axial loads, and moment loads. They are suitable for high-precision, heavy-duty, and stable-operation applications. Their split outer-ring and rotating inner-ring structure simplifies installation, while the optimized roller arrangement ensures excellent rigidity, making them ideal for equipment requiring reliable load-bearing and precise rotation, such as heavy-duty machine tools, construction machinery, metallurgical equipment, and energy equipment.

Accuracy Grades: P5, P4, P2

Size:Inner diameter (d): 30mm – 1250mm;Outer diameter (D): 55mm – 1500mm;Cross-section (B/B1): 8mm – 110mm

Materials:Rings & rollers: GCr15 chrome steel (surface hardness HRC 60-62), SUS440C stainless steel (corrosion-resistant);Cages: Nylon 66 (lightweight)

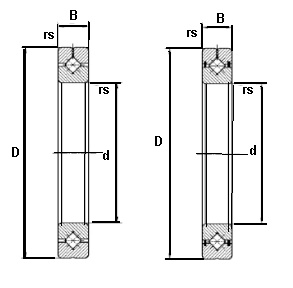

Structural Configuration & Lubrication:Outer Ring: Split type; Inner Ring: Rotating type

Sealing: Open Type (standard); Contact Rubber Seal (UU/U) for dust and splash protection;Heavy-duty industrial grade grease lubrication

Delivery/Customization:Standard models: In stock for immediate delivery;Custom orders: 7–20 days delivery; support for customized specifications based on actual application requirements

| Cross Roller Bearing RB Series | ||||||||||

| Bearing Model | Main dimensions | Shoulder height | Basic load rating(radial) | Weight | ||||||

| Inner ring d (mm) | Outer ring D(mm) | Roller pitch circle diameter dp(mm) | Width B B1 (mm) | Chamfer r(min) | ds | Dh | C kN | C0 kN | Kg | |

| NB.RB3010 | 30 | 55 | 41.5 | 10 | 0.6 | 37 | 47 | 7.35 | 8.36 | 0.12 |

| NB.RB3510 | 35 | 60 | 46.5 | 10 | 0.6 | 41 | 51.5 | 7.64 | 9.12 | 0.13 |

| NB.RB4010 | 40 | 65 | 51.5 | 10 | 0.6 | 47.5 | 57.5 | 8.33 | 10.6 | 0.16 |

| NB.RB4510 | 45 | 70 | 56.5 | 10 | 0.6 | 51 | 61.5 | 8.62 | 11.3 | 0.17 |

| NB.RB5013 | 50 | 80 | 64 | 13 | 0.6 | 57.4 | 72 | 16.7 | 20.9 | 0.27 |

| NB.RB6013 | 60 | 90 | 74 | 13 | 0.6 | 68 | 82 | 18 | 24.3 | 0.3 |

| NB.RB7013 | 70 | 100 | 84 | 13 | 0.6 | 78 | 92 | 19.4 | 27.7 | 0.35 |

| NB.RB8016 | 80 | 120 | 98 | 16 | 0.6 | 91 | 111 | 30.1 | 42.1 | 0.7 |

| NB.RB9016 | 90 | 130 | 108 | 16 | 1 | 98 | 118 | 31.4 | 45.3 | 0.75 |

| NB.RB10016 | 100 | 140 | 119.3 | 16 | 1 | 109 | 129 | 31.7 | 48.6 | 0.83 |

| NB.RB10020 | 150 | 123 | 20 | 1 | 113 | 133 | 33.1 | 50.9 | 1.45 | |

| NB.RB11012 | 110 | 135 | 121.8 | 12 | 0.6 | 117 | 127 | 12.5 | 24.1 | 0.4 |

| NB.RB11015 | 145 | 126.5 | 15 | 0.6 | 122 | 136 | 23.7 | 41.5 | 0.75 | |

| NB.RB11020 | 110 | 160 | 133 | 20 | 1 | 120 | 143 | 34 | 54 | 1.56 |

| NB.RB12016 | 120 | 150 | 134.2 | 16 | 1.6 | 127 | 141 | 24.2 | 43.2 | 0.72 |

| NB.RB12025 | 180 | 148.7 | 25 | 1.5 | 133 | 164 | 66.9 | 100 | 2.62 | |

| NB.RB13015 | 130 | 160 | 144.5 | 15 | 0.6 | 137 | 152 | 25 | 46.7 | 0.72 |

| NB.RB13025 | 190 | 158 | 15 | 1.5 | 143 | 174 | 69.5 | 107 | 2.82 | |

| NB.RB14016 | 140 | 175 | 154.8 | 16 | 1 | 147 | 162 | 25.9 | 50.1 | 1 |

| NB.RB14025 | 200 | 168 | 25 | 1.5 | 154 | 185 | 74.8 | 121 | 2.96 | |

| NB.RB15013 | 150 | 180 | 164 | 13 | 0.6 | 157 | 172 | 27 | 53.5 | 0.68 |

| NB.RB15025 | 210 | 178 | 25 | 1.5 | 164 | 194 | 76.8 | 128 | 3.16 | |

| NB.RB15030 | 230 | 188 | 30 | 1.5 | 173 | 211 | 100 | 156 | 5.3 | |

| NB.RB16025 | 160 | 220 | 188.6 | 25 | 1.5 | 173 | 204 | 81.7 | 135 | 3.14 |

| NB.RB17020 | 170 | 220 | 191 | 20 | 1.5 | 184 | 198 | 29 | 62.1 | 2.21 |

| NB.RB18025 | 180 | 240 | 210 | 25 | 1.5 | 195 | 225 | 84 | 143 | 3.44 |

| NB.RB19025 | 190 | 2 | 211.9 | 25 | 1 | 202 | 222 | 41.7 | 82.9 | 2.99 |

| NB.RB20025 | 200 | 2 | 230 | 25 | 2 | 245 | 245 | 84.2 | 157 | 4 |

| NB.RB20030 | 2 | 240 | 30 | 2 | 258 | 258 | 114 | 200 | 6.7 | |

| NB.RB20035 | 2 | 247.7 | 35 | 2 | 270 | 270 | 151 | 252 | 9.6 | |

| NB.RB22025 | 220 | 280 | 250.1 | 25 | 2 | 235 | 265 | 92.3 | 171 | 4.1 |

| NB.RB24025 | 240 | 300 | 269 | 25 | 2.5 | 256 | 281 | 68.3 | 145 | 4.5 |

| NB.RB25025 | 250 | 310 | 277.5 | 25 | 2.5 | 265 | 290 | 69.3 | 150 | 5 |

| NB.RB25030 | 330 | 287.5 | 30 | 2.5 | 269 | 306 | 126 | 244 | 8.1 | |

| NB.RB25040 | 355 | 300.7 | 40 | 2.5 | 275 | 326 | 195 | 348 | 14.8 | |

| NB.RB30025 | 300 | 360 | 328 | 25 | 2.5 | 315 | 340 | 76.3 | 178 | 5.9 |

| NB.RB30035 | 395 | 345 | 35 | 2.5 | 322 | 368 | 183 | 367 | 13.4 | |

| NB.RB30040 | 300 | 405 | 351.6 | 40 | 2.5 | 326 | 377 | 212 | 409 | 17.2 |

| NB.RB35020 | 350 | 400 | 373.4 | 20 | 2.5 | 363 | 383 | 54.1 | 143 | 3.9 |

| NB.RB40035 | 400 | 480 | 440.3 | 35 | 2.5 | 422 | 459 | 156 | 370 | 14.5 |

| NB.RB40040 | 510 | 453.4 | 40 | 2.5 | 428 | 479 | 241 | 531 | 23.5 | |

| NB.RB45025 | 450 | 500 | 474 | 25 | 1 | 464 | 484 | 61.7 | 182 | 6.6 |

| NB.RB50025 | 500 | 550 | 524.2 | 25 | 1 | 514 | 534 | 65.5 | 201 | 7.3 |

| NB.RB50040 | 600 | 548.8 | 40 | 2.5 | 526 | 572 | 239 | 607 | 26 | |

| NB.RB50050 | 625 | 561.6 | 50 | 2.5 | 536 | 587 | 267 | 653 | 41.7 | |

| NB.RB60040 | 600 | 700 | 650 | 40 | 3 | 627 | 673 | 264 | 721 | 29 |

| NB.RB70045 | 700 | 815 | 753.5 | 45 | 3 | 731 | 777 | 281 | 836 | 46 |

| NB.RB80070 | 800 | 950 | 868.1 | 70 | 4 | 836 | 900 | 468 | 1330 | 105 |

| NB.RB90070 | 900 | 1050 | 969 | 70 | 4 | 937 | 1001 | 494 | 1490 | 120 |

| NB.RB1000110 | 1000 | 1250 | 1114 | 110 | 5 | 1057 | 1171 | 1220 | 3220 | 360 |

| NB.RB1250110 | 1250 | 1500 | 1365.8 | 110 | 5 | 1308 | 1423 | 1350 | 1970 | 440 |

The rollers are arranged orthogonally and crosswise at a 90° angle, enabling synchronous bearing of radial, axial, and moment loads without the need for additional configuration of other bearings. The crosswise layout increases the contact area, and compared with traditional single-row bearings, the anti-deformation capacity is increased by 3 to 4 times, making it particularly suitable for high-torque scenarios.

The raceways and rollers are precisely ground, achieving P5 precision in rotational runout, which meets the positioning requirements at the nanometer level. The geometric shape of the roller end faces is optimized to reduce sliding friction, thereby extending the service life of the bearings.

With a thin-walled section design, the height of the metric section ranges from 10 to 30 mm, making it suitable for equipment with limited space. Compared with traditional bearings, the weight is reduced by 20% to 30%, reducing the overall inertia of the equipment and improving the dynamic response speed.

The bearing rings and rollers are made of GCr15 high-carbon chromium steel or SUS440C stainless steel, which improves fatigue resistance and wear resistance. The cages are made of nylon 66 or brass to reduce friction and wear. The split outer ring design facilitates preload adjustment, reduces assembly errors, and enhances the stability of the system.

1. Robotics

Complex Robotic Joints: When the bearing needs to be installed on a shaft that already has gears, pulleys, or other components press-fitted on either side, the separable design of the RB bearing is invaluable. It can be assembled without removing those other components.

Heavy or Long Robotic Arms: Simplifies the installation process on the central shafts of large robots.

2. Machine Tool Rotary Tables

Large Diameter Tables: For very large rotary tables, mounting a one-piece bearing can be logistically challenging. The separable design of an RB bearing allows for easier handling and installation onto the massive table structure.

Tables with Integrated Drives: If the table's drive mechanism (e.g., a motor rotor) is integrated with the shaft, the RB bearing can be installed around it.

3. Semiconductor Manufacturing Equipment

Wafer Handling Robots: Used in joints where the design prioritizes serviceability and easier assembly in a cleanroom environment.

Stages with Pre-Assembled Components: When the shaft is part of a larger pre-assembled module.

4. Medical Equipment

CT and MRI Gantries: The separable design can simplify the complex assembly process of these large, precision rotating assemblies.

Radiation Therapy Systems (e.g., Linac Gantries): Similar to medical imaging, these large rotating structures benefit from bearings that are easier to mount and service.

5. General Precision Machinery

Any application where the ease of installation and maintenance is a critical factor, and the load/rigidity requirements are met by a crossed roller design.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.