An XR/JXR Cross Tapered Roller Bearing is a high-precision, compact bearing using tapered rollers arranged perpendicularly (crossed at 90°) within inner and outer rings, allowing it to handle heavy radial, axial, and overturning moment loads simultaneously, offering superior rigidity, high accuracy, and space savings for demanding applications like rotary tables, robots, and machine tools. It's similar in concept to crossed cylindrical roller bearings (CRB) but uses tapered rollers for even higher load capacity and stability.

Features:

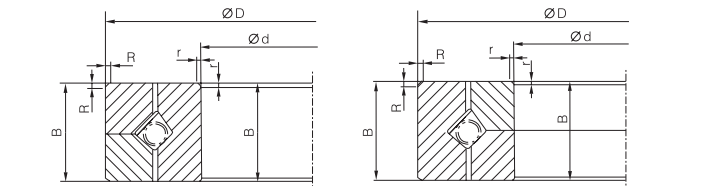

Inner Ring: Integral structure;

Outer Ring: Integral structure;

Shoulder: Integrated positioning design with standard mounting holes and greasing holes; Roller Arrangement: 90° orthogonal crossed tapered rollers (optimized cone angle, line contact load-bearing);

Accuracy:P5, P4, P2;

Size:

Inner Diameter: 150–2463.8 mm;

Outer Diameter:230–2819.4 mm;

Cross-section Height: 30–114.3 mm; S

Materials:

Bearing Rings & Rollers: GCr15SiMn high-carbon chromium silicon manganese steel or SUS440C stainless steel ;

Cages: High-strength brass , phenolic resin or custom dedicated composite materials for cross tapered rollers;

Sealing Options:

Open Type: Requires regular external lubrication, suitable for clean, high-load medium-low speed working conditions such as heavy-duty machine tools;

Contact Rubber Seals (UU/U): Dustproof and splash-proof, suitable for complex heavy-load industrial environments with dust and humidity;

Labyrinth Seals (ZZ): Enhanced protection performance, suitable for dusty, high-impact heavy-duty machinery scenarios;

Delivery

Standard models: 10–20 days;

Customized:Please contact the manufacturer.

| Models | Dimensions | Radial Rated load kN | Axial Rated load (kN) | Maximum rotational speed | Inter Change | Weight | |||||||

| (mm) | |||||||||||||

| d | D | B | r | Cr | Cor | Cr | Cor | r/min | Timken | SKF | NACHI | KG | |

| NB.XR060-NT | 150 | 230 | 30 | 1 | 95.2 | 156 | 111 | 279 | 1000 | BFKB353243/HA4 | 4.9 | ||

| NB.XR063-NT | 160 | 240 | 30 | 1.1 | 96.8 | 162 | 118 | 300 | 900 | BFKB353240/HA4 | 5.15 | ||

| NB.XR079-NT | 200 | 280 | 30 | 1.5 | 102 | 175 | 120 | 320 | 850 | 200XRN28 | 6.7 | ||

| NB.XR080-NT | 203.2 | 279 | 31.75 | 1.5 | 110 | 188 | 134 | 348 | 850 | XR496051 | 616093A | 5.59 | |

| NB.XR080-W | 203.2 | 279 | 31.75 | 1.5 | 110 | 188 | 134 | 348 | 750 | XR496052 | 5.59 | ||

| NB.XR094-NT | 240 | 300 | 30 | 1 | 88 | 184 | 114 | 361 | 700 | BFKB353203/HA4 | 5.4 | ||

| NB.XR098-NT | 250 | 310 | 25 | 1 | 88 | 188 | 114 | 361 | 670 | BFKB353212/HA4 | 4.5 | ||

| NB.XR099-NT | 250 | 350 | 40 | 1.3 | 187 | 355 | 228 | 657 | 560 | BFKB353215/HA4 | 250XRN35 | 13 | |

| NB.XR110-NTL | 300 | 400 | 36.492 | 1.5 | 183 | 355 | 223 | 657 | 560 | JXR637050 | 12.5 | ||

| NB.XR110-NT | 300 | 400 | 37 | 1.5 | 183 | 355 | 223 | 657 | 600 | XR637050 | 616094A | 300XRN50 | 12.5 |

| NB.XR110-NF | 300 | 480 | 60 | 1.5 | 258 | 495 | 305 | 920 | 640 | JXR678054 | 38 | ||

| NB.XR120-NT | 310 | 425 | 45 | 2.5 | 216 | 427 | 281 | 837 | 620 | JXR652050 | BFKB634097 | 19.5 | |

| NB.XR130-NT | 330 | 457 | 63.5 | 3.3 | 264 | 515 | 312 | 954 | 560 | XR678052 | 615661A | 32 | |

| NB.XR138-NT | 350 | 470 | 50 | 3.3 | 308 | 635 | 376 | 1180 | 600 | BFKB353216/HA4 | 350XRN47 | 27 | |

| NB.XR140-NT | 370 | 495 | 50 | 3.3 | 93.6 | 119 | 430 | JXR699050 | 30 | ||||

| NB.XR157-NT | 400 | 480 | 40 | 1.1 | 216 | 497 | 281 | 957 | 400 | BFKB353224/HA4 | 15 | ||

| NB.XR158-NT | 400 | 550 | 60 | 2.5 | 429 | 920 | 523 | 1700 | 400 | BFKB353219/HA4 | 400XRN55 | 46.5 | |

| NB.XR170-W | 432.03 | 571.5 | 38.1 | 3.3 | 435 | 910 | 530 | 1600 | 420 | XR736052 | 27.5 | ||

| NB.XR180-NT | 457.2 | 609.6 | 63.5 | 3.3 | 396 | 856 | 514 | 1680 | 380 | XR766051 | 615894A | 0457XRN060 | 51 |

| NB.XR160-NT | 424.95 | 614.924 | 65 | 470 | 960 | 600 | 1720 | 300 | XR766052 | 62 | |||

| NB.XR220-NT | 580 | 760 | 80 | 3.3 | 627 | 1380 | 765 | 2560 | 300 | XR820060 | 615662A | 580XRN76 | 100 |

| NB.XR220-W | 580 | 760 | 80 | 6.4 | 627 | 1380 | 765 | 2560 | 300 | XR820061 | 100 | ||

| NB.XR230-NF | 600 | 830 | 80 | 6.4 | 680 | 1460 | 820 | 2870 | 260 | XR836050 | 600XRN83 | 148 | |

| NB.XR270-N | 685.8 | 914.4 | 79.375 | 6.4 | 693 | 1660 | 900 | 3250 | 260 | XRA844050 | 150 | ||

| NB.XR270-NT | 685.8 | 914.4 | 79.375 | 3.3 | 693 | 1660 | 900 | 3250 | 260 | XR855053 | 615659A | 0685XRN091 | 150 |

| NB.XR270-W | 685.8 | 914.4 | 79.375 | 693 | 1660 | 900 | 3250 | 300 | XR855056 | 150 | |||

| NB.XR350-W | 901.7 | 1117.6 | 82.555 | 3.3 | 781 | 2060 | 1060 | 4290 | 200 | XR882054 | 185 | ||

| NB.XR350-NT | 901.7 | 1117.6 | 82.555 | 3.3 | 781 | 2060 | 1060 | 4290 | 200 | XR882055 | 615895A | 0901XRN112 | 185 |

| NB.XR370-N | 939.8 | 1117.6 | 82.55 | 3.3 | 920 | 2580 | 1200 | 5000 | 200 | XR882058 | 158 | ||

| NB.XR374-NF | 950 | 1170 | 85 | 3 | 968 | 2690 | 1310 | 5600 | 215 | BFKB353251/HA4 | 215 | ||

| NB.XR400-NT | 1028.7 | 1327.15 | 114.3 | 3.3 | 1230 | 3310 | 600 | 6490 | 430 | XR889058 | BFKB353282/HA4 | 1028XRN132 | 430 |

| NB.XR400-WL | 1028.7 | 1327.15 | 95.25 | 3.3 | 1060 | 3100 | 1420 | 6020 | 450 | XR889059 | 358 | ||

| NB.XR400-NF | 1028.7 | 1327.15 | 114.3 | 3.3 | 1230 | 3310 | 600 | 6490 | 430 | XR889060 | 430 | ||

| NB.XR500-NT | 1270 | 1524 | 95.25 | 1.8 | 1300 | 3830 | 1760 | 2980 | 95 | 615897A | 350 | ||

| NB.XR610-NT | 1549.4 | 1828.8 | 101.6 | 3.3 | 1400 | 4510 | 1890 | 9400 | 80 | XR897051 | 615898A | 500 | |

| NB.XR740-NT | 1879.6 | 2197.1 | 101.6 | 5.4 | 1510 | 5240 | 2040 | 10900 | 43 | XR903054 | 615899A | 675 | |

| NB.XR1040-NT | 2463.8 | 2819.4 | 114.3 | 5.4 | 2330 | 8740 | 3150 | 18200 | 19 | 634078A | 1130 | ||

Line-contact load-bearing + integral structure, rigidity increased by 50% compared with similar products, meeting the high rigidity requirements of heavy-duty precision equipment and ensuring no deformation under heavy loads.

Maximum axial bearing capacity of 800 KN and radial bearing capacity of 650 KN, line-contact design distributes loads, adapting to ultra-heavy composite load scenarios, with industry-leading bearing capacity.

Integral structure + integrated shoulder positioning, reducing assembly steps and cumulative errors, coaxiality error ≤0.003 mm, simplifying the installation process.

Technical indicators fully aligned with SKF/INA/THK imported series, stable supply, procurement cost reduced by 35%-50%, supporting urgent production to meet emergency project needs.

Compatible with heavy-load needs in multiple fields such as heavy-duty machine tools, port machinery, wind power, and robots, multiple sealing and lubrication solutions adapt to complex and harsh environments.

1. Heavy-Duty Machine Tools

CNC rotary tables

Vertical & horizontal machining centers

Large indexing tables

XR/JXR bearings provide extreme stiffness and high moment load capacity, ensuring machining accuracy under heavy cutting forces.

2. Industrial Turntables & Indexing Equipment

Large precision rotary tables

Automated indexing platforms

Heavy positioning systems

They offer stable rotation and precise positioning even under eccentric and impact loads.

3. Construction & Heavy Industrial Equipment

Excavators (upper structure rotation)

Cranes and lifting platforms

Drilling and boring machinery

The crossed tapered rollers can withstand shock loads and high overturning moments.

4. Steel & Metallurgical Machinery

Rolling mills

Continuous casting equipment

Coil handling systems

XR/JXR bearings perform reliably in extreme load and harsh environments.

5. Wind Power Equipment

Yaw and pitch systems

Wind turbine gear and rotation assemblies

They provide long service life under large, fluctuating loads and vibration.

6.Aerospace & Defense Equipment

Radar antenna rotation systems

Missile launch platforms

Heavy-duty gimbal assemblies

High rigidity ensures stable tracking and accurate positioning.

7. Mining Equipment

Crushers

Bucket wheel excavators

Stackers and reclaimers

Designed to handle very high loads, shock, and vibration.

8.Precision Measuring & Testing Equipment (Large Scale)

Heavy load test rigs

Structural testing machines

Large rotating measurement systems

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.