RA crossed roller bearings are specifically designed for precision rotary systems, featuring a 90° orthogonal crossed roller layout that enables simultaneous bearing of radial loads, axial loads, and overturning moment loads. They are suitable for high-precision, high-rigidity, and space-constrained applications. Their integrated inner ring structure enhances system rigidity and simplifies installation, while the optional preload configuration eliminates internal clearances, making them ideal for equipment requiring stable and precise rotation, such as industrial robots, precision machine tools, optical instruments, and semiconductor manufacturing equipment.

Accuracy Grades: P4, P2

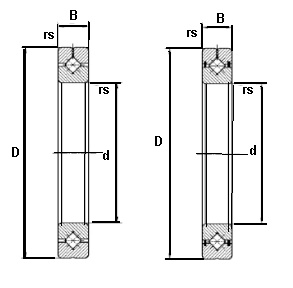

Size: Inner diameter: 50mm–200mm Section height: 8mm–13mm

Materials:Substrate materials: GCr15 high-carbon chromium steel (standard) /SUS440C stainless steel (corrosion-resistant)

Extreme condition adaptation: Vacuum-grade cleaning treatment (for medical/semiconductor fields), ceramic roller hybrid solutions (anti-magnetic/insulating)

Preload & Sealing:

Preload: Optional configuration to eliminate internal clearances

Sealing: Double-seal structure (UU/U) for dust and liquid prevention; open type available for clean environments requiring regular maintenance

Delivery/Customization:

Standard series:

Shipped within 72 hours

Customization: 10–15 days for customized specifications; support for special lubricating greases (for high-temperature/vacuum environments) and non-standard dimensions

| Cross Roller Bearing RA Series | ||||||||||

| Bearing Model | Main dimensions | Shoulder height | Basic load rating (radial) | Weight | ||||||

| Inner ring | Outer ring | Roller pitch circle diameter Dpw (mm) | Width B /B1 | Chamfer | ds | Dh | C | C0 | Kg | |

| d(mm) | D(mm) | (mm) | r(min) | kN | kN | |||||

| NB.RA5008 | 50 | 66 | 57 | 8 | 0.5 | 53.5 | 60.5 | 5.1 | 7.19 | 0.08 |

| NB.RA6008 | 60 | 76 | 67 | 8 | 0.5 | 63.5 | 70.5 | 5.68 | 8.68 | 0.09 |

| NB.RA7008 | 70 | 86 | 77 | 8 | 0.5 | 73.5 | 80.5 | 5.98 | 9.8 | 0.1 |

| NB.RA8008 | 80 | 96 | 87 | 8 | 0.5 | 83.5 | 90.5 | 6.37 | 11.3 | 0.11 |

| NB.RA9008 | 90 | 106 | 97 | 8 | 0.5 | 93.5 | 100.5 | 6.76 | 12.4 | 0.12 |

| NB.RA10008 | 100 | 116 | 107 | 8 | 0.5 | 103.5 | 110.5 | 7.15 | 13.9 | 0.14 |

| NB.RA11008 | 110 | 126 | 117 | 8 | 0.5 | 113.5 | 120.5 | 7.45 | 15 | 0.15 |

| NB.RA12008 | 120 | 136 | 127 | 8 | 0.5 | 123.5 | 130.5 | 7.84 | 16.5 | 0.17 |

| NB.RA13008 | 130 | 146 | 137 | 8 | 0.5 | 133.5 | 140.5 | 7.94 | 17.6 | 0.18 |

| NB.RA14008 | 140 | 156 | 147 | 8 | 0.5 | 143.5 | 150.5 | 8.33 | 19.1 | 0.19 |

| NB.RA15008 | 150 | 166 | 157 | 8 | 0.5 | 153.5 | 160.5 | 8.82 | 20.6 | 0.2 |

| NB.RA16013 | 160 | 186 | 172 | 13 | 0.5 | 165 | 179 | 23.3 | 44.9 | 0.59 |

| NB.RA17013 | 170 | 196 | 182 | 13 | 0.8 | 175 | 189 | 23.5 | 46.5 | 0.64 |

| NB.RA18013 | 180 | 206 | 192 | 13 | 0.8 | 185 | 199 | 24.5 | 49.8 | 0.68 |

| NB.RA19013 | 190 | 216 | 202 | 13 | 0.8 | 195 | 209 | 24.9 | 51.5 | 0.69 |

| NB.RA20013 | 200 | 226 | 212 | 13 | 0.8 | 205 | 219 | 25.8 | 54.7 | 0.71 |

It can bear radial, axial and moment loads simultaneously, eliminating the need for additional bearing combinations.

The crossed - roller layout provides rigid support, making it suitable for high - torque scenarios.

With P4 level accuracy, it can meet the positioning requirements at the nanometer level.

Homogeneous materials and surface hardening treatment (HRC 60 - 62) enhance the fatigue resistance.

1. Robotics (A Dominant Application)

Robotic Arm Joints: Especially in the critical 4th, 5th, and 6th axes (the "wrist") of articulated robots. This joint must support the combined moment, radial, and axial loads from the end-effector and payload with minimal flex, ensuring precise tool positioning.

Cobot (Collaborative Robot) Joints: Their compact size and high load capacity are perfect for the slim joints of collaborative robots.

Robot Rotary Actuators: Many integrated rotary actuators use a crossed roller bearing as their core structural element.

2. Machine Tool Rotary Tables

4th and 5th Axis Indexers: On CNC machining centers, these bearings provide the stiffness needed to resist cutting forces without deflecting, ensuring machining accuracy.

Grinding Machine Rotary Tables: For producing perfectly flat and parallel surfaces.

Precision Indexing Heads: In automated assembly and inspection lines.

3. Semiconductor Manufacturing Equipment

Wafer Handling Robots: The "shoulder" and "elbow" joints of these robots use crossed roller bearings for their compactness, cleanliness, and precise, vibration-free movement in vacuum environments.

Lithography and Inspection Stages: The linear and rotary stages that position silicon wafers require the ultimate in precision and stability, which these bearings provide.

4. Medical and Aerospace Equipment

Surgical Robot Arms: For joints that require absolute precision and zero backlash.

CT/MRI Scanner Gantries: In rotating components where smooth, precise rotation is critical for image quality.

Radar and Satellite Antenna Positioners: To provide stable and accurate rotation under wind and operational loads.

5. Precision Measuring Instruments

Coordinate Measuring Machine (CMM) Rotary Tables: The bearing's own accuracy directly influences the measurement accuracy of the CMM.

Optical and Laser Scanning Devices: In mirrors and sensor mounts that require jitter-free rotation.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.