CRBH cross roller bearings are specifically designed for high-precision rotary systems, featuring integral inner and outer rings with precision-ground integrated raceways and 90° orthogonal "X"-shaped cylindrical rollers. They can simultaneously bear radial loads, axial loads, and moment loads, suitable for high-accuracy, high-rigidity, and stable-operation applications. Their optimized structure reduces runout errors, making them ideal for industrial robots, precision rotary tables, semiconductor equipment, and automation machinery requiring reliable load-bearing and precise rotation.

Structural Features:Inner & Outer Rings: Integral structure with precision-ground integrated raceways (reduces runout errors);Roller Arrangement: 90° orthogonal "X"-shaped cylindrical rollers (simultaneously bears radial, axial, and moment loads)

Accuracy Classes:Rotational Accuracy: P5, P4, P2

Size: Metric Series:Inner Diameter: 20–1250 mm;Outer Diameter: 36–1500 mm;Cross-section Height: 8–110 mm

Materials:Bearing Rings & Rollers: GCr15 high-carbon chromium steel (surface hardness HRC 60-62) or SUS440C stainless steel (corrosion-resistant);Cages: Nylon 66 (lightweight), brass (high-strength), or custom composite materials

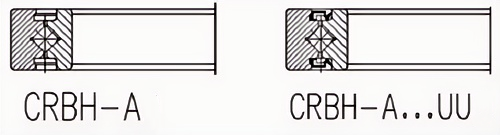

Sealing Options:Open Type: Requires regular external lubrication, suitable for clean environments;Contact Rubber Seals (UU/U): Dustproof and splash-proof, suitable for industrial dusty or humid environments

Lubrication Methods:Grease Lubrication: Long-acting grease (e.g., Krytox®), suitable for high-temperature (≤120°C) or vacuum environments;Oil Lubrication: Circulating oil system, suitable for ultra-high-speed (≤3,000 rpm) or heavy-load scenarios

Delivery/Customization:Standard models: 7–15 days;Customized models: Requires additional negotiation

| Cross Roller Bearing CRBH Series | |||||||||||

| Shaft diameter (mm) | Bearing Model | Main dimensions | Mounting dimensions (mm) | Basic dynamic load rating | Basic static load rating | Weight | |||||

| (mm) | |||||||||||

| Open type with separator | Two sides sealed type with separator | Inner ring d | Outer diameter D | Width B | Chamfer r(min) | da | Da | C | Co | (Kg) | |

| (N) | (N) | ||||||||||

| 20 | NB.CRBH 208A | NB.CRBH 208A UU | 20 | 36 | 8 | 0.3 | 24 | 31 | 2910 | 2430 | 0.04 |

| 25 | NB.CRBH 258A | NB.CRBH 258A UU | 25 | 41 | 8 | 0.3 | 29 | 36 | 3120 | 2810 | 0.05 |

| 30 | NB.CRBH 3010A | NB.CRBH 3010A UU | 30 | 55 | 10 | 0.3 | 36.5 | 48.5 | 7600 | 8370 | 0.12 |

| 35 | NB.CRBH 3510A | NB.CRBH 3510A UU | 35 | 60 | 10 | 0.3 | 41.5 | 53.5 | 7900 | 9310 | 0.13 |

| 40 | NB.CRBH 4010A | NB.CRBH 4010A UU | 40 | 65 | 10 | 0.3 | 46.5 | 58.5 | 8610 | 10600 | 0.15 |

| 45 | NB.CRBH 4510A | NB.CRBH 4510A UU | 45 | 70 | 10 | 0.3 | 51.5 | 63.5 | 8860 | 11300 | 0.16 |

| 50 | NB.CRBH 5013 A | NB.CRBH 5013 A UU | 50 | 80 | 13 | 0.6 | 56 | 74 | 17.3 | 20.9 | 0.29 |

| 60 | NB.CRBH 6013 A | NB.CRBH 6013 A UU | 60 | 90 | 13 | 0.6 | 66 | 84 | 18.8 | 24.3 | 0.33 |

| 70 | NB.CRBH 7013 A | NB.CRBH 7013 A UU | 70 | 100 | 13 | 0.6 | 76 | 94 | 20.1 | 27.7 | 0.38 |

| 80 | NB.CRBH 8016 A | NB.CRBH 8016 A UU | 80 | 120 | 16 | 0.6 | 88 | 112 | 32.1 | 43.4 | 0.74 |

| 90 | NB.CRBH 9016 A | NB.CRBH 9016 A UU | 90 | 130 | 16 | 0.6 | 98 | 122 | 33.1 | 46.8 | 0.81 |

| 100 | NB.CRBH 10020 A | NB.CRBH 10020 A UU | 100 | 150 | 20 | 0.6 | 110 | 140 | 50.9 | 72.2 | 1.45 |

| 110 | NB.CRBH 11020 A | NB.CRBH 11020 A UU | 110 | 160 | 20 | 0.6 | 120 | 150 | 52.4 | 77.4 | 1.56 |

| 120 | HGCRBH 12025 A | NB.CRBH 12025 A UU | 120 | 180 | 25 | 1 | 132 | 168 | 73.4 | 108 | 2.62 |

| 130 | NB.CRBH 13025 A | NB.CRBH 13025 A UU | 130 | 190 | 25 | 1 | 142 | 178 | 75.9 | 115 | 2.82 |

| 140 | NB.CRBH 14025 A | NB.CRBH 14025 A UU | 140 | 200 | 25 | 1 | 152 | 188 | 81.9 | 130 | 2.96 |

| 150 | NB.CRBH 15025 A | HGCRBH 15025 A UU | 150 | 210 | 25 | 1 | 162 | 198 | 84.3 | 138 | 3.16 |

| 200 | NB.CRBH 20025 A | NB.CRBH 20025 A UU | 200 | 260 | 25 | 1 | 212 | 248 | 92.3 | 169 | 4 |

| 250 | NB.CRBH 25025 A | NB.CRBH 25025 A UU | 250 | 310 | 25 | 1.5 | 262 | 298 | 102 | 207 | 4.97 |

A single bearing can simultaneously bear radial, axial, and moment loads, reducing system complexity.

The orthogonal roller layout enhances the anti-deformation capacity by 3 to 4 times, making it suitable for high-torque scenarios.

With P4-class accuracy, it meets micron-level positioning requirements (e.g., alignment mechanisms of lithography machines)

The nylon cage and thin-walled structure reduce overall weight, making it suitable for mobile devices.

1. Robotics (A Dominant Application)

Robot Joints: They are the ideal choice for the core rotational joints of articulated robots, SCARA robots, and collaborative robots (cobots). Their compactness allows for slim arm designs, while their high rigidity ensures precise positioning of the end-effector without flexing.

End-of-Arm Tooling (EOAT): Used in the wrist and rotation units of grippers, welders, and dispensers.

Robot Rotary Actuators: Many integrated servo-driven rotary actuators use a CRBH bearing as their foundational frame and rotation element.

2. Precision Rotary Tables and Indexing Heads

4th and 5th Axis on CNC Machining Centers: Used in smaller to medium-sized rotary tables. They provide the stiffness needed to resist cutting forces, ensuring accuracy when machining complex parts.

Automated Assembly and Inspection Stations: In indexing tables that require precise, repeatable angular positioning.

3. Semiconductor and Electronic Manufacturing Equipment

Wafer Handling Robots: Their clean, compact, and precise nature makes them perfect for the rotary joints of robots that transport silicon wafers in cleanrooms.

PCB (Printed Circuit Board) Automation: Used in stages that require precise rotation for component placement or inspection.

4. Medical and Optical Equipment

Medical Robot Joints: In surgical robots where compact size, precision, and reliability are critical.

Optical Scanner Rotors: For rotating mirrors and lenses in laser marking, engraving, and measurement systems.

Pan-Tilt Units (PTU): For positioning cameras and sensors smoothly and accurately.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.