Structural Types

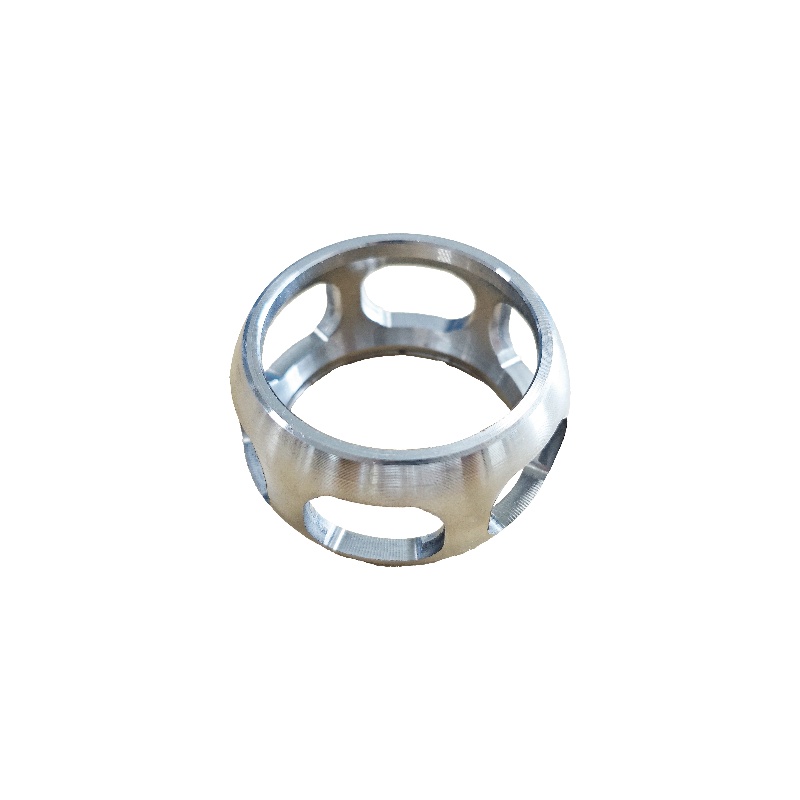

Overall Shape: Annular symmetric structure

Internal Channels: Arc-shaped guide grooves

Cage Material: Reinforced Nylon (vibration-damping type), Phosphor Bronze (fatigue-resistant type) or PEEK Composite (self-lubricating type)

Adapted Lubrication

Grease Lubrication: Compatible with special long-acting grease for constant velocity joints, achieving uniform distribution through guide grooves

Pre-installed Lubrication: Supports factory pre-filling of high-temperature grease (180°C rated temperature)

Delivery Cycle

Standard Models: 8-10 weeks,Custom Models (including material replacement): 12-14 weeks

| Material Type | Hardness | Density (g/cm³) | Max Speed (rpm) | Temp Range | Key Properties |

| Reinforced Nylon | 85 HRR | 1.15 | 3,500 | -40℃~140℃ | Vibration damping |

| Phosphor Bronze | 80-100 HB | 8.8 | 4,000 | -50℃~200℃ | High fatigue resistance |

| PEEK Composite | 95 HRR | 1.32 | 5,000 | -60℃~250℃ | Self-lubricating |

Arc-shaped guide grooves reduce ball sliding friction, lower power loss by 10%, and are suitable for high-frequency shifting scenarios of automobiles.

It can withstand combined radial/axial loads up to 15kN, meeting the heavy-load requirements of heavy-duty vehicles.

From reinforced nylon (-40℃~140℃) to PEEK composite (-60℃~250℃), it covers different working conditions.

4. It supports reverse mapping customization and can match the dimensions of existing constant velocity joints (with an accuracy of ±0.02mm).

Automotive Field: Passenger Car Drive Shafts, Heavy Truck Axles, High-performance Vehicle Universal Joints

Industrial Equipment: Industrial Robot Joints, Automated Production Line Articulated Joints

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.