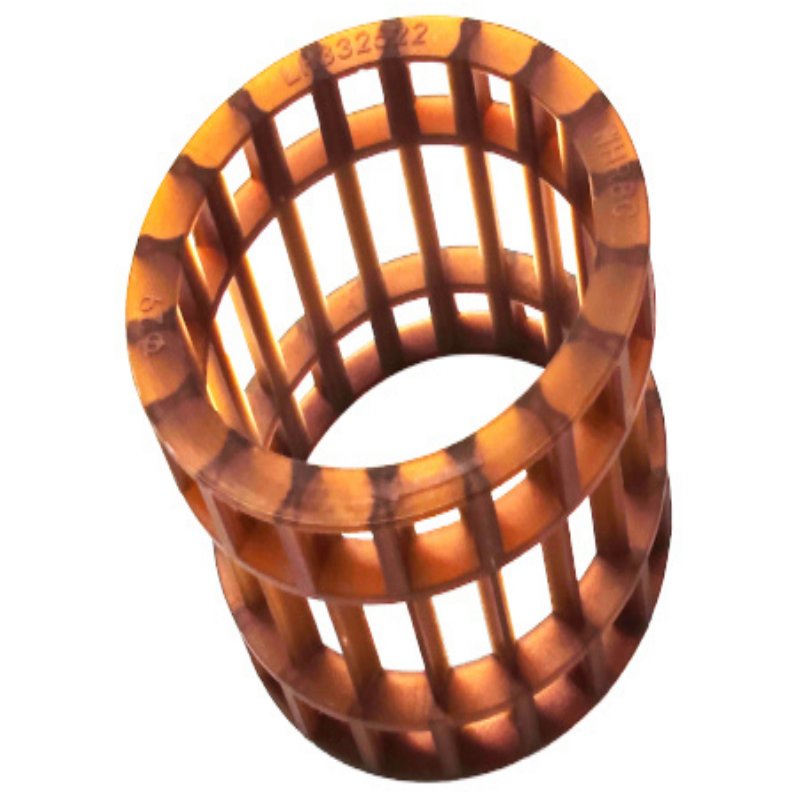

The needle roller bearing cage ensures proper alignment and spacing of needle rollers, preventing friction and wear while optimizing load distribution. Its lightweight and durable construction makes it suitable for high-load, high-speed applications in confined spaces.

| Technical Data Table | ||

| Parameter | Specification | Remarks |

| Cage Material | Stamped steel / Engineering plastics (e.g., PA66) | Steel for heavy loads, plastic for high speed |

| Load Density | High (supports maximum rollers in minimal space) | Ideal for compact designs |

| Max. Speed | Up to 20,000 rpm (plastic) / 15,000 rpm (steel) | Depends on lubrication & load |

| Temperature Range | -30°C to +120°C (plastic) / -40°C to +150°C (steel) | Wider range with special materials |

| Precision | Roller spacing tolerance ±0.01mm | Ensures smooth operation |

| Friction Reduction | Low friction design | Extends bearing life |

| Applications | Automotive transmissions, small high-speed motors, aerospace actuators | Compact & high-load environments |

Maximizes roller count for superior radial load support in tight spaces.

Prevents roller-to-roller contact, reducing friction and wear.

Customizable to needle roller dimensions for optimal motion control.

Engineered plastics enable higher RPMs; steel offers durability.

Automotive: Transmissions, engine components, steering systems.

Industrial:Small high-speed motors, robotics, conveyor systems.

Aerospace: Actuators, landing gear mechanisms.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.