Core Component of Deep Groove Ball Bearings:

The retainer (also known as bearing cage or separator) is an indispensable critical component in deep groove ball bearings. It precisely separates and guides rolling elements (steel balls), ensuring their orderly arrangement and uniform distribution within the raceways.

Foundation for Stable Operation:

Our retainers are engineered to optimize bearing performance by effectively reducing friction and collisions between rolling elements. This significantly decreases operational noise and vibration while enhancing overall running smoothness, rotational accuracy, and service life of the bearing.

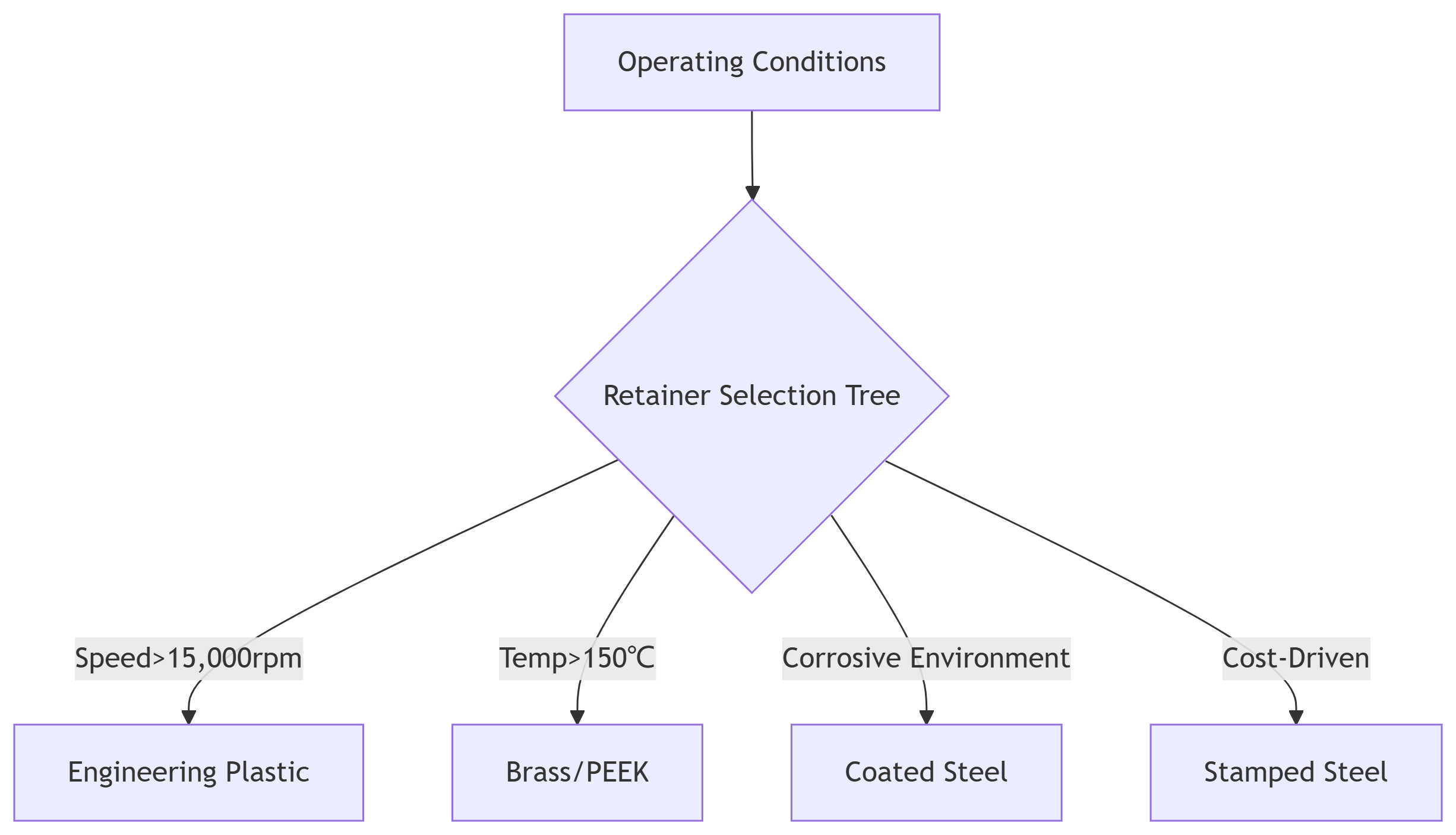

Diverse Material Selection:

We offer retainers manufactured from multiple high-performance materials – including high-strength stamped steel, engineering plastics (e.g., Nylon PA66, PEEK), and brass – to satisfy varying operational requirements across speed, temperature, load, and lubrication conditions.

| Material Type | Tensile Strength | Max Speed | Temp Range | Key Advantages |

| Stamped Steel | 400-600 MPa | 15,000 rpm | -30°C~120°C | Cost-effective, lightweight |

| Machined Brass | 350-500 MPa | 20,000 rpm | -50°C~200°C | Lubricant-resistant, high-speed |

| Glass-Filled Nylon | 80-150 MPa | 12,000 rpm | -40°C~150°C | Vibration damping, self-lubricating |

| PEEK | 90-100 MPa | 18,000 rpm | -60°C~250°C | Chemical resistance, high temp |

Streamlined geometry and precisely shaped pockets effectively reduce contact friction with rolling elements and raceways, minimizing power loss and enhancing efficiency.

Accurately manufactured pockets ensure consistent ball spacing, guiding smooth rotation to achieve even load distribution across rolling elements and reduce stress concentration.

Effectively isolates direct collisions between rolling elements, substantially reducing bearing operational noise and vibration – ideal for noise-sensitive applications (e.g., motors, household appliances).

Lightweight construction and low-friction characteristics make our retainers ideal for high-speed applications, mitigating centrifugal effects and maintaining bearing stability.

| Industry | Recommended Cage | Why Selected |

| Automotive | Stamped Steel | Cost-effective for mass production |

| Machine Tools | Brass | High-speed capability |

| Food Processing | PEEK | Corrosion resistance |

| Home Appliances | Nylon | Noise reduction |

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.