Structural Types:

Cage: Integral precision-molded structure

Materials:

Cage Materials: Stainless steel (17-4PH), engineering plastics (PEEK, PI)

Size Range:

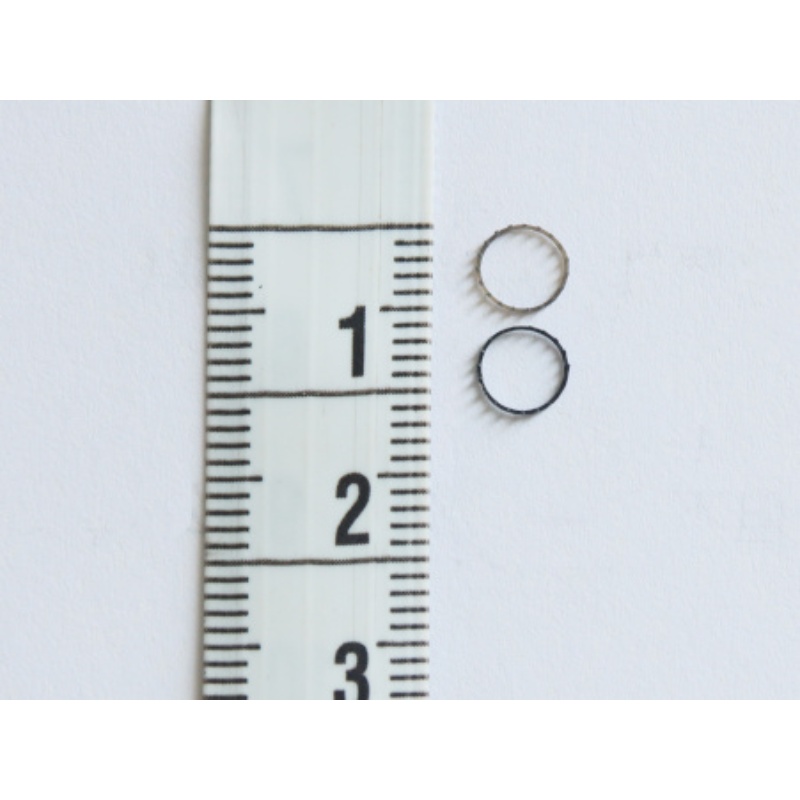

Inner Diameter Range: 1mm - 10mm (custom special sizes available)

Accuracy Classes:ABEC-7 and above

Delivery Cycle: 7 - 15 days. For customized models, prior communication is required, and the delivery cycle will be arranged according to customization requirements.

| Parameter | Specification | Remarks |

| Cage Material | Stainless steel (17-4PH) / Engineering plastics (PEEK, PI) | Steel for rigidity, plastics for ultra-lightweight |

| Bore Diameter Range | 1mm - 10mm | Custom sizes available |

| Weight | As low as 0.01g (plastic) | Reduces rotational inertia |

| Precision Grade | ABEC-7 or higher | Radial runout ≤0.003mm |

| Max. Speed | 50,000 rpm (plastic) / 30,000 rpm (steel) | Depends on lubrication |

| Operating Temperature | -60°C to +250°C (PEEK) / -40°C to +200°C (steel) | Wide thermal tolerance |

| Wear Resistance | Low friction coefficient (μ<0.05) | Special coatings available |

| Applications | Micro-motors, medical robotics, watch movements, drones | Space-constrained precision systems |

Maintains micron-level roller alignment for vibration-free operation.

Plastic cages reduce weight by up to 70% vs. metal.

Wear-resistant materials/coatings triple lifespan in high-cycle apps.

Tailored pocket designs for ceramic, steel, or hybrid micro rollers.

Medical: Surgical tool joints, insulin pump gears.

Electronics: HDD spindles, micro-drone actuators.

Industrial: Fiber-optic alignment stages, miniature robotics.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.