As the "heart" of aircraft, aero-engines directly determine flight safety and operational efficiency. Bearings, as the key support for core components such as engine spindles and gas turbines, must achieve high precision, low vibration, and long service life under extreme operating conditions of ultra-high speed, high temperature, and high load. To meet the rigorous requirements of the aviation industry for bearings, NewBee Transmission has specially developed the LCQJS Series and XCQJS Series three-point contact ball bearings. With special material modification technology, optimized structural design, and excellent performance, they have become the ideal matching solution for high-end equipment such as aero-engines, high-speed fans, and ultra-high-speed motors. When used in conjunction with the FD10 Series floating bearings, their reliability and service life far exceed industry standards.

1. Ultra-High Speed Performance: Breaking the Speed Limit

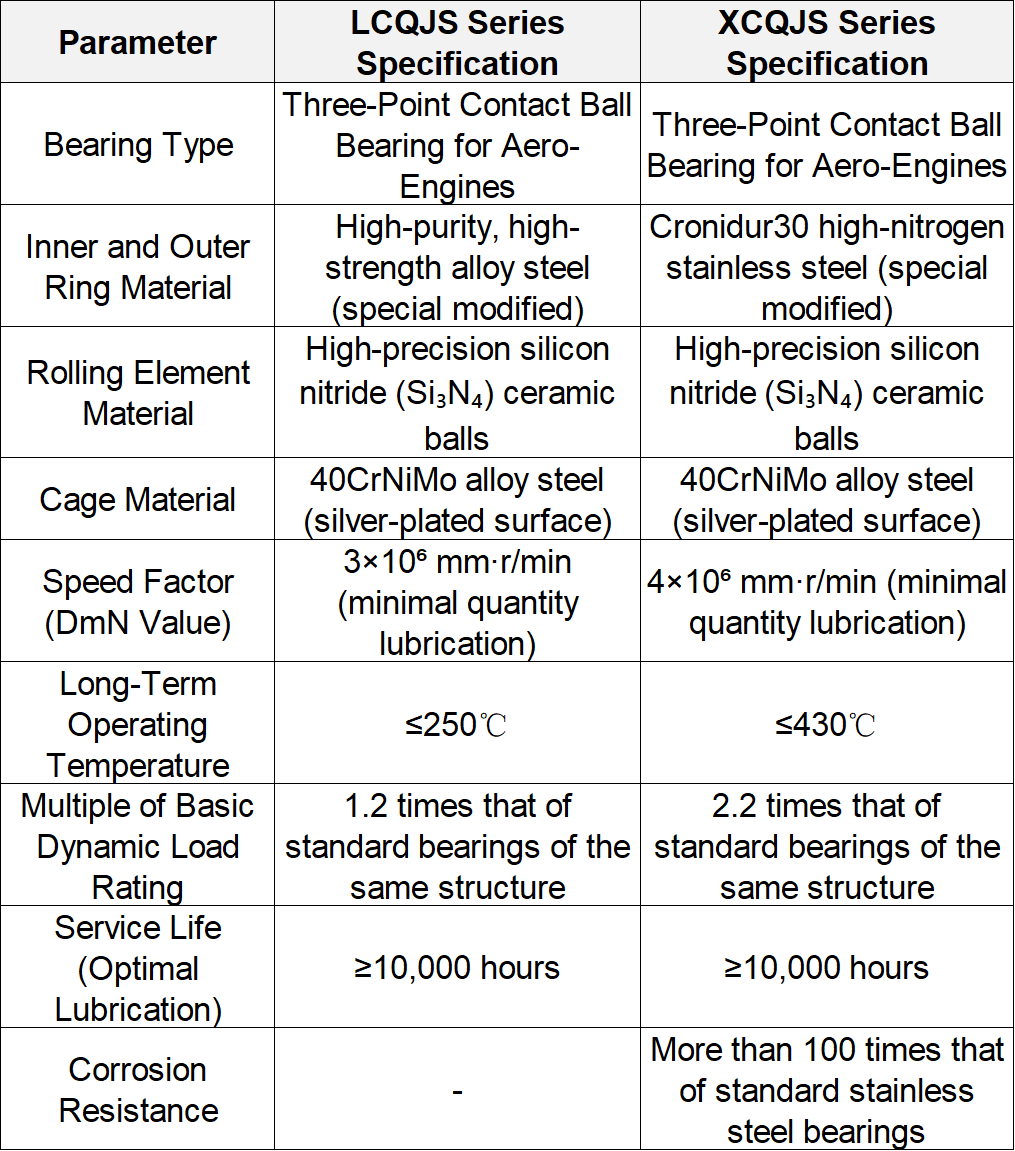

Adopts speed-specific design and special material modification technology, combined with minimal quantity lubrication (MQL) solution, delivering excellent speed factor (DmN value): the LCQJS Series reaches 3×10⁶ mm·r/min, while the XCQJS Series achieves an even higher 4×10⁶ mm·r/min, perfectly adapting to ultra-high-speed operation scenarios such as aero-engine spindles and ultra-high-speed air compressors.

The rolling elements are high-precision silicon nitride (Si₃N₄) ceramic balls, featuring both lightweight and high rigidity, reducing centrifugal force and friction loss during high-speed rotation, and ensuring stable bearing operation.

2.High Temperature Resistance: Withstanding Extreme Thermal Environments

Different series precisely match diverse temperature requirements: the LCQJS Series can operate stably for a long time below 250℃, while the XCQJS Series adopts Cronidur30 high-nitrogen stainless steel, upgrading high-temperature resistance to withstand operating conditions below 430℃, suitable for high-temperature areas such as around aero-engine combustion chambers.

The inner and outer ring materials undergo special modification treatment, maintaining structural strength and dimensional stability even in high-temperature environments, and avoiding precision degradation caused by thermal deformation.

3. Super High Load-Bearing Capacity and Long Service Life: Reducing Operation and Maintenance Costs

The load-bearing capacity far exceeds that of standard bearings: the basic dynamic load rating of the LCQJS Series is 1.2 times that of standard bearings of the same structure, and the XCQJS Series reaches 2.2 times, easily coping with instantaneous impact loads and long-term composite loads during aero-engine startup and acceleration.

Under optimal lubrication conditions, both series of bearings have a service life of over 10,000 hours, significantly extending the maintenance cycle of aviation equipment, reducing the number of shutdowns for inspection and repair, and lowering operational costs.

4.Extreme Corrosion Resistance: Adapting to Complex Medium Environments (Exclusive to XCQJS Series)

The XCQJS Series uses Cronidur30 high-nitrogen stainless steel, with corrosion resistance more than 100 times that of standard stainless steel bearings (such as 9Cr18). It can effectively resist erosion from aviation fuel, water vapor, and other media, suitable for harsh environments such as flight in marine climates and complex airspaces.

5. Structural Optimization: Ensuring Operational Stability

The cage is made of 40CrNiMo alloy steel with a silver-plated surface, integrating wear resistance, friction reduction, and thermal conductivity, avoiding wear and deformation under high speed and high temperature.

The three-point contact structure design balances radial and axial load-bearing capacity, reducing vibration and noise during bearing operation, and improving the operational smoothness of aero-engines.

1.Enhanced Power System Reliability: The ultra-high speed, high temperature resistance, and high load-bearing capacity ensure stable power output of aero-engines under extreme conditions, reducing failure risks and safeguarding flight safety.

2.Adaptability to Diverse High-End Equipment: In addition to aero-engines, they can be widely used in gas turbine spindles, high-speed fans, ultra-high-speed motors, high-speed air compressors, and other equipment, achieving "one bearing for multiple scenarios" adaptation.

3.Reduced Total Lifecycle Cost: The long service life and high reliability design reduce the frequency of bearing replacement and maintenance downtime, lowering the labor and material costs of aviation operations.

4.Strengthened Environmental Adaptability: The extreme corrosion resistance of the XCQJS Series expands the application boundaries of equipment in marine climates, complex medium environments, and other harsh conditions, improving equipment environmental adaptability.

1.In-Depth Technical Accumulation in the Aviation Field

Focuses on aero-engine bearing R&D, accurately grasping the industry’s core requirements for ultra-high speed, high temperature resistance, and high reliability. The technical solutions have undergone verification under harsh operating conditions, complying with high aviation industry standards.

Core technologies such as material modification and structural design are independently developed, breaking the performance bottlenecks of traditional bearings and providing customized bearing solutions for high-end equipment.

2.Rigorous Material and Process Control

Selects high-quality raw materials such as high-purity, high-strength alloy steel and Cronidur30 high-nitrogen stainless steel, combined with silicon nitride ceramic balls and silver-plated cages, ensuring bearing performance from the source.

The entire production process adheres to aviation-grade quality standards. Every set of bearings undergoes strict speed testing, high-temperature testing, and reliability verification to ensure consistent performance of delivered products.

3. Flexible Scenario Adaptability

The two series are designed for different temperature and corrosion resistance requirements, allowing flexible selection based on actual equipment operating conditions. They also support matching with the FD10 Series floating bearings, reducing adaptation and modification difficulties.

4. Full-Cycle Technical Support

Provides bearing installation guidance, lubrication scheme optimization, service life prediction, and fault diagnosis services, assisting customers in solving various problems during bearing application and ensuring long-term efficient operation of equipment. Contact Us: Obtain Customized Aero-Engine Bearing Solutions For detailed technical specifications, sample testing, or customized adaptation plans of the LCQJS/XCQJS Series bearings, please contact us via the following methods:

Email: paul@newbeetrans.com

Phone: +86 15122832049

Official Website: www.newbeetrans.com