1. Introduction

3D 5-axis laser cutting machines enable multi-angle, multi-directional flexible cutting of both metallic and non-metallic workpieces, offering superior processing flexibility and efficiency. These advanced systems are widely used in automotive manufacturing, molds, construction machinery, shipbuilding, hardware, home appliances, and medical devices.

Previously, this cutting-edge technology was monopolized by a few international corporations. However, the introduction of domestically developed 3D 5-axis intelligent laser cutting equipment has broken foreign dominance in the automotive sector. By replacing traditional machining methods, it reduces mold investment, shortens development cycles, enhances precision, and lowers production costs.

2. Challenges in High-Strength Automotive Component Processing

The AUTOBOT 3D Laser Cutting Machine for Automotive Hot-Formed Parts was developed to address challenges in processing high-strength steel (HSS) hot-formed components, including:

Precision cutting & edge-trimming of ultra-hard materials

High-speed, high-dynamic performance requirements

Strict automotive industry cycle-time demands

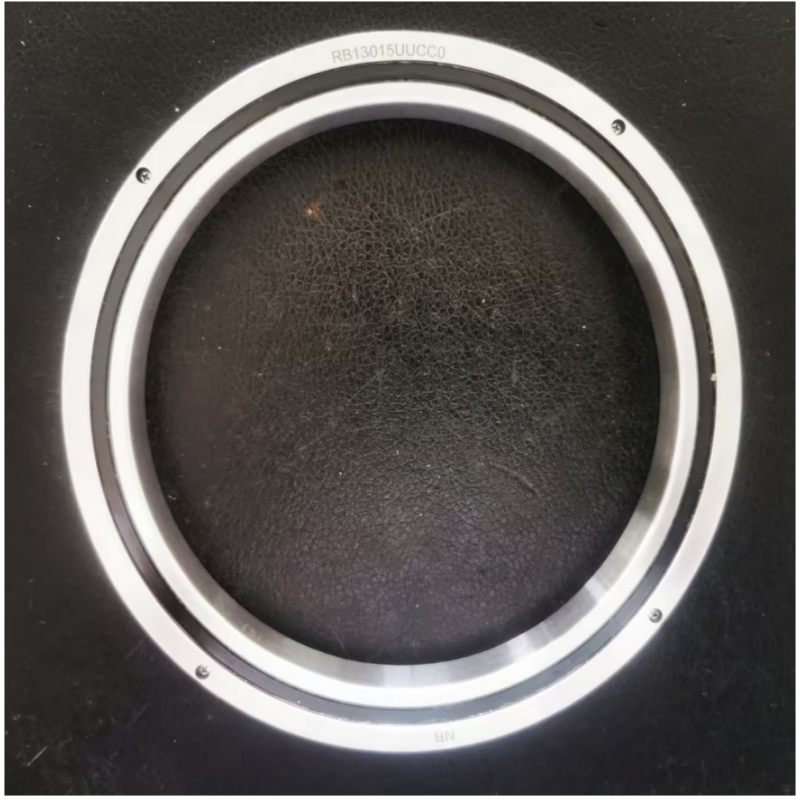

A critical component in these machines is the laser head’s cross roller bearing, which ensures high rigidity, rotational accuracy, and load capacity under extreme dynamic conditions.

3. Overcoming Import Dependence: Newbee’s Innovative Bearing Solution

Originally, laser cutting machine manufacturers relied on THK’s imported split-outer-ring cross roller bearings. However, this design had drawbacks:

High cost & long lead times due to import reliance

Complex installation & alignment requirements

Limited customization flexibility

Luoyang Newbee’s Breakthrough

To address these issues, Newbee Transmission developed a domestically produced, single-piece outer ring cross roller bearing, offering:

Integrated structure – Eliminates alignment issues, simplifying installation.

Superior rigidity & precision– Ensures stable laser head movement under high-speed operation.

Cost reduction – Cuts expenses by 30-40% compared to imported alternatives.

Faster delivery– Shortens procurement lead times by 50%.

4. Performance Advantages of Newbee’s Cross Roller Bearings

Parameter | THK Imported Bearing | Newbee’s Domestic Bearing |

Structure | Split outer ring | One-piece outer ring |

Installation | Complex alignment | Plug-and-play |

Cost | High (import premium) | 30-40% lower |

Lead Time | 3-6 months | 1-2 months |

Precision | P4/P5 grade | P4 grade (comparable) |

Load Capacity | High | Optimized for laser heads |

5. Industry Impact & Future Applications

Newbee’s bearing solution has enabled:

Localization of critical laser cutting machine components

Faster production ramp-up for automotive manufacturers

Improved machine reliability & maintenance efficiency

Looking ahead, Newbee is expanding its high-precision bearing solutions to:

Robotic laser welding systems

Aerospace composite cutting machines

Medical device micromachining equipment

6. Conclusion

By replacing import-dependent split-outer-ring bearings with an optimized integrated design, Luoyang Newbee Transmission has helped domestic laser cutting machine manufacturers achieve:

Lower costs & faster assembly

Reduced reliance on foreign suppliers

Enhanced competitiveness in high-end manufacturing

As China’s advanced manufacturing sector grows, Newbee continues to drive innovation in high-performance motion components, supporting the transition from "Made in China" to "Created in China.

Key Takeaways:

3D 5-axis laser cutting requires ultra-precise bearings for dynamic performance.

Newbee’s one-piece cross roller bearings simplify installation & cut costs.

Domestic alternatives reduce supply chain risks for smart manufacturing.

Would you like additional technical specifications or case studies?