Newbee Transmission specializes in manufacturing high-performance stainless steel bearings for EFEM wafer handling robots. Our bearings are engineered to meet the extreme demands of semiconductor cleanroom environments.

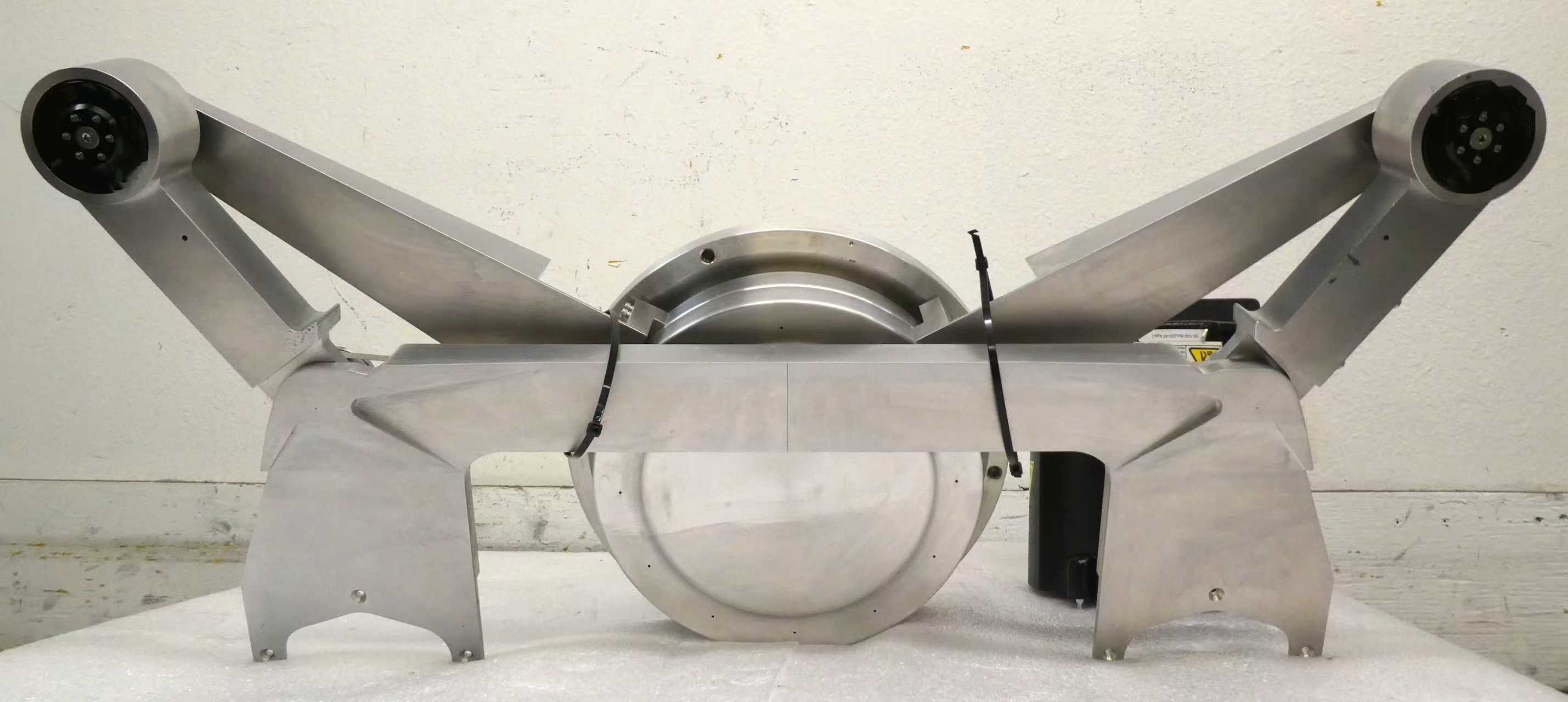

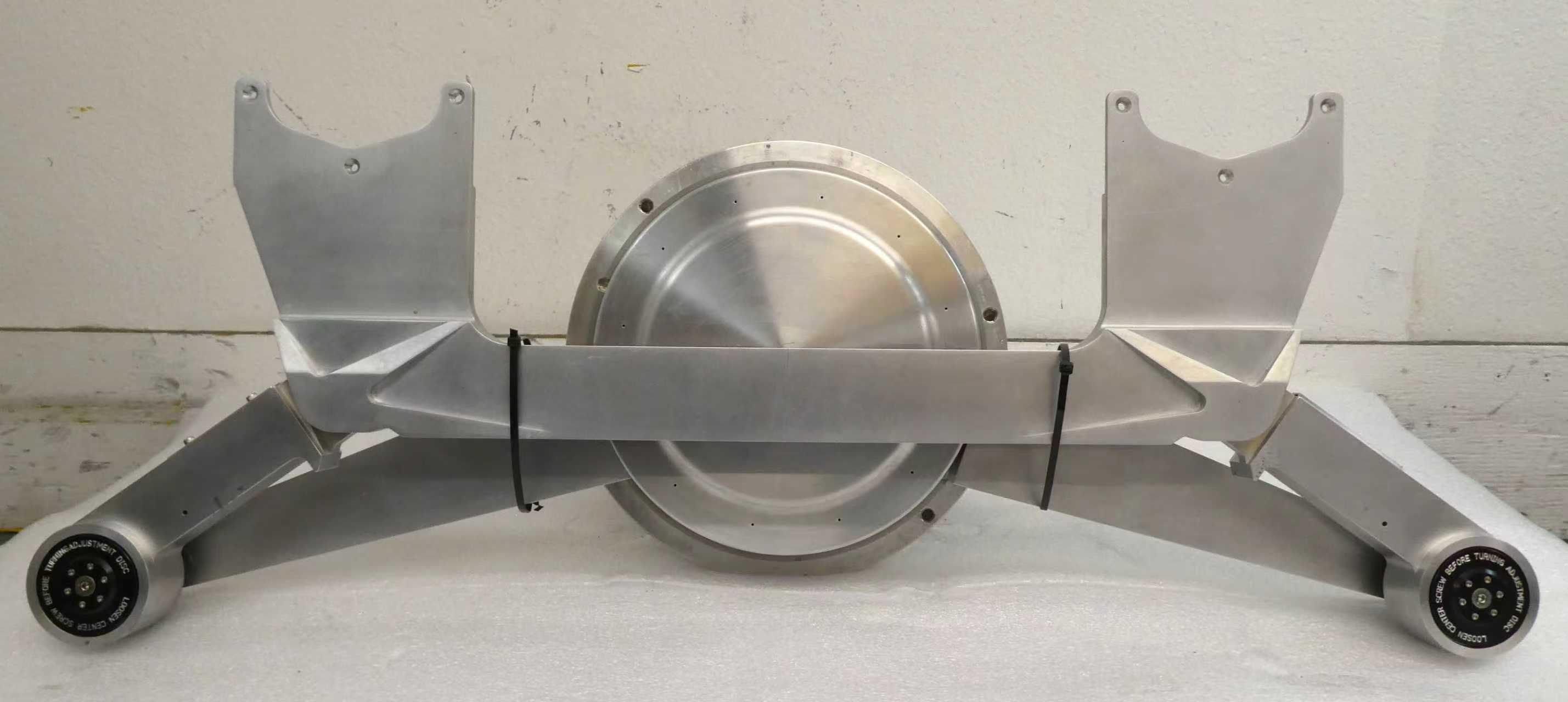

Our bearings are deployed in all critical robot arm components:

Central Hub Units

Arm Linkage Sections

Wrist Joint Mechanisms

Parameter | Specification Range |

Bore Diameter | 1"-12" (25-300mm) |

Accuracy Class | P4 (ABEC7) |

Starting Torque | <0.005Nm |

Torque Variation | ±5% |

1. Vacuum-Compatible Lubrication

Proprietary grease formulations

Outgassing rate <1×10⁻⁹ Torr·L/sec

Certified for ISO Class 1 cleanrooms

2. Precision Engineering

Mirror-polished raceways (Ra<0.05μm)

Corrosion-resistant 440C

3. Cross-Reference Capability

Comprehensive OEM numbering database

Direct replacements for major robot brands

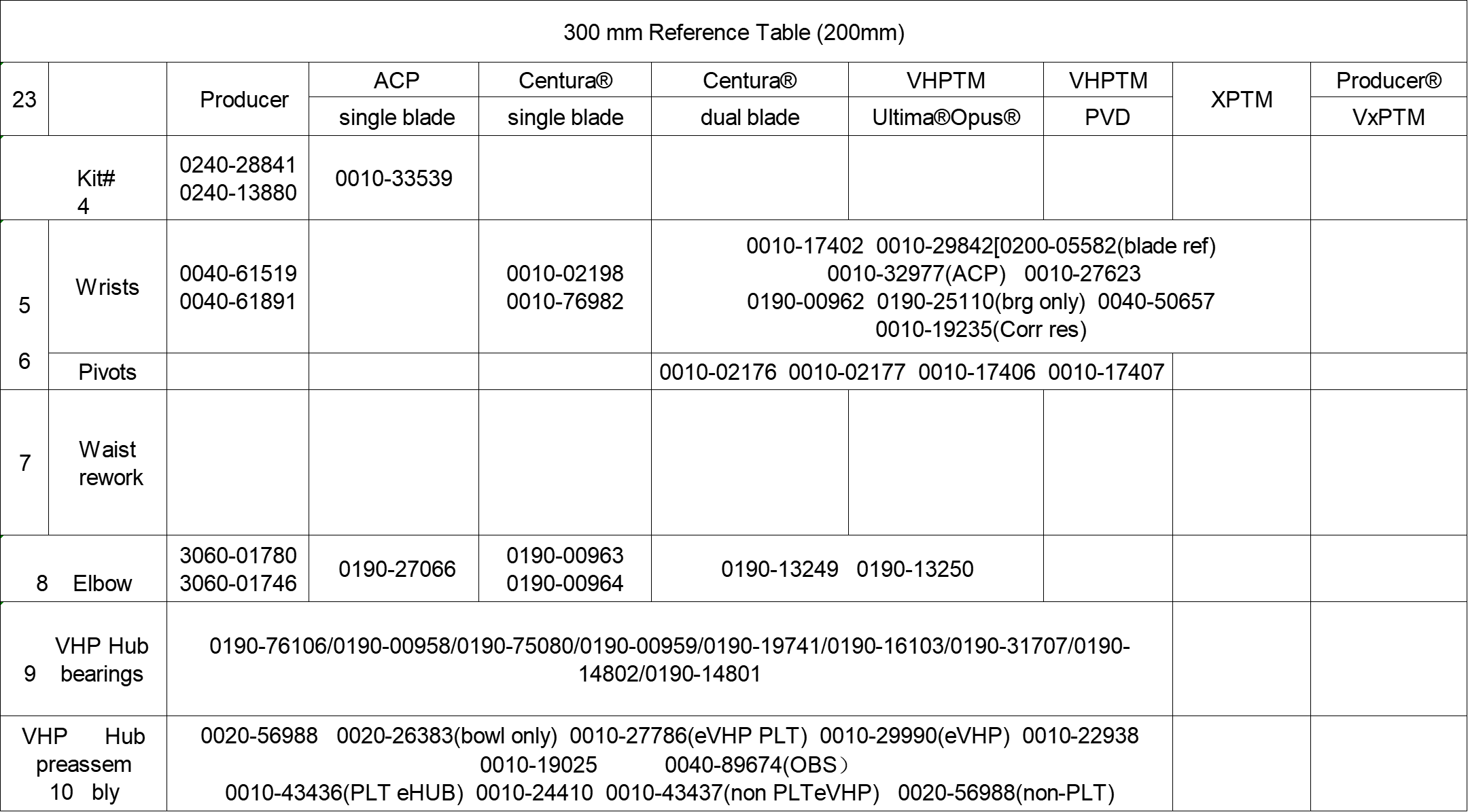

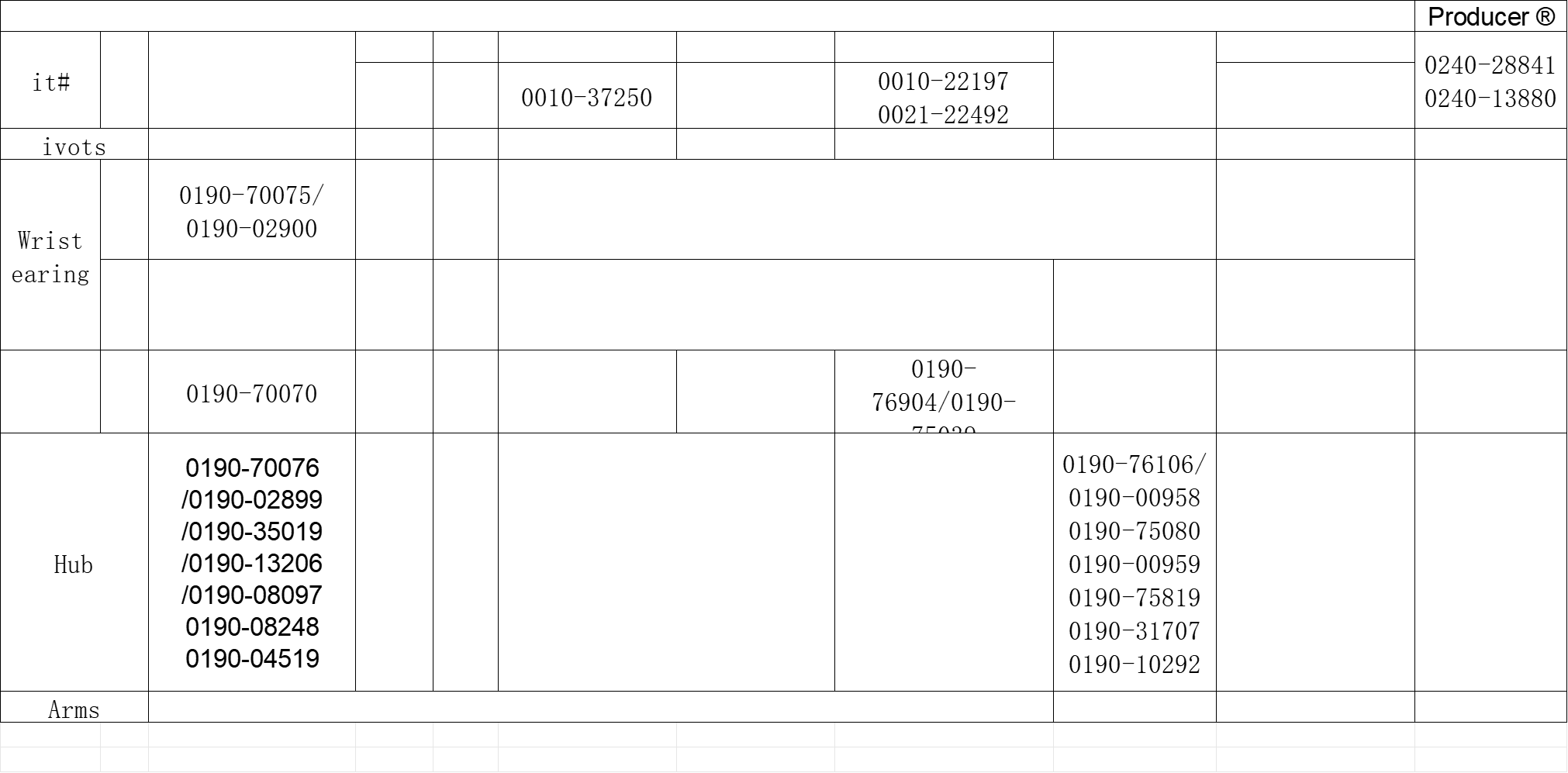

Bearing Cross-Reference Service

We maintain complete matching data for:

Brooks Automation

RORZE Corporation

JEL Corporation

Kensington Laboratories

(Sample reference table shown below-full database available upon request)

10+ years semiconductor bearing experience

100% traceability with material certifications

48-hour response for emergency replacements

Contact Our Cleanroom Bearing Experts

frank@newbeetrans.com

+86 15090185276 (24/7 support)

Value-Added Services

Bearing failure analysis with SEM/EDS reports

Custom preloading for specific robot models

On-site installation training

(All products comply with SEMI F72-0708 particle standards)