Thin-section deep groove ball bearings are specifically designed for high radial loads in compact equipment, while also supporting moderate bidirectional axial loads. They are suitable for high-precision, high-speed, and space-constrained applications. Their optimized symmetrical arc-shaped raceway design reduces friction and noise, maximizing radial load-bearing efficiency, making them ideal for equipment requiring stable rotation and space-saving solutions, such as semiconductor handling robots, medical MRI devices, precision measuring instruments, high-speed motors, aerospace instruments, and automotive electric power steering systems.

Materials: Bearing rings and rolling elements: GCr15 high-carbon chromium steel (with high wear resistance) or 440C stainless steel (corrosion-resistant).

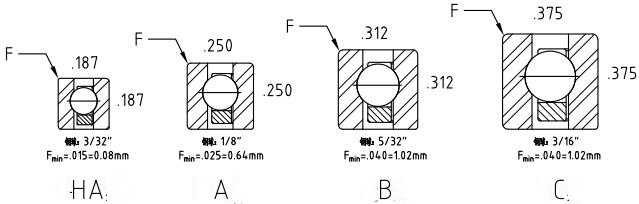

Size range: Inner diameter:20 mm - 1000 mm;Cross-section :4.7625×4.7625 mm - 25.4×25.4 mm.

Accuracy grades: P0, P6, P5, P4

Sealing options: Open type, rubber seal (RS), metal dust cover (ZZ)

| Deep Groove Ball Thin-Section Bearing Open Type (C) | ||||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KAA10CP0 | 1.000 | 1.375 | 1290 | 670 | 0.012 | KAA10CP0 |

| 25.400 | 34.925 | |||||

| NB.KAA15CP0 | 1.500 | 1.875 | 1780 | 800 | 0.018 | KAA15CP0 |

| 38.100 | 47.625 | |||||

| NB.KAA17CP0 | 1.750 | 2.125 | 2110 | 1770 | 0.020 | KAA17CP0 |

| 44.450 | 53.975 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KA020CP0 | 2.000 | 2.500 | 3020 | 1420 | 0.048 | KA020CP0 |

| 50.800 | 63.500 | |||||

| NB.KA025CP0 | 2.500 | 3.000 | 3690 | 1600 | 0.059 | KA025CP0 |

| 63.500 | 76.200 | |||||

| NB.KA030CP0 | 3.000 | 3.500 | 4400 | 1820 | 0.068 | KA030CP0 |

| 76.200 | 88.900 | |||||

| NB.KA035CP0 | 3.500 | 4.000 | 5070 | 2000 | 0.082 | KA035CP0 |

| 88.900 | 101.600 | |||||

| NB.KA040CP0 | 4.000 | 4.500 | 5730 | 2130 | 0.090 | KA040CP0 |

| 101.600 | 114.300 | |||||

| NB.KA042CP0 | 4.250 | 4.750 | 6090 | 2220 | 0.095 | KA042CP0 |

| 107.950 | 120.650 | |||||

| NB.KA045CP0 | 4.500 | 5.000 | 6400 | 2310 | 0.100 | KA045CP0 |

| 114.300 | 127.000 | |||||

| NB.KA047CP0 | 4.750 | 5.250 | 6760 | 2400 | 0.104 | KA047CP0 |

| 120.650 | 133.350 | |||||

| NB.KA050CP0 | 5.000 | 5.500 | 7070 | 2490 | 0.109 | KA050CP0 |

| 127.000 | 139.700 | |||||

| NB.KA055CP0 | 5.500 | 6.000 | 7780 | 2620 | 0.118 | KA055CP0 |

| 139.700 | 152.400 | |||||

| NB.KA060CP0 | 6.000 | 6.500 | 8450 | 2800 | 0.130 | KA060CP0 |

| 152.400 | 165.100 | |||||

| NB.KA065CP0 | 6.500 | 7.000 | 9110 | 2930 | 0.140 | KA065CP0 |

| 165.100 | 177.800 | |||||

| NB.KA070CP0 | 7.000 | 7.500 | 9780 | 3070 | 0.150 | KA070CP0 |

| 177.800 | 190.500 | |||||

| NB.KA075CP0 | 7.500 | 8.000 | 10450 | 3200 | 0.160 | KA075CP0 |

| 190.500 | 203.200 | |||||

| NB.KA080CP0 | 8.000 | 8.500 | 11110 | 3330 | 0.172 | KA080CP0 |

| 203.200 | 215.900 | |||||

| NB.KA090CP0 | 9.000 | 9.500 | 12490 | 3600 | 0.200 | KA090CP0 |

| 228.600 | 241.300 | |||||

| NB.KA100CP0 | 10.000 | 10.500 | 13820 | 3870 | 0.227 | KA100CP0 |

| 254.000 | 266.700 | |||||

| NB.KA110CP0 | 11.000 | 11.500 | 15160 | 4130 | 0.236 | KA110CP0 |

| 279.400 | 292.100 | |||||

| NB.KA120CP0 | 12.000 | 12.500 | 16540 | 4360 | 0.254 | KA120CP0 |

| 304.800 | 317.500 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KB020CP0 | 2.000 | 2.625 | 4130 | 2000 | 0.073 | KB020CP0 |

| 50.800 | 66.675 | |||||

| NB.KB025CP0 | 2.500 | 3.125 | 5070 | 2310 | 0.091 | KB025CP0 |

| 63.500 | 79.375 | |||||

| NB.KB030CP0 | 3.000 | 3.625 | 5960 | 2580 | 0.109 | KB030CP0 |

| 76.200 | 92.075 | |||||

| NB.KB035CP0 | 3.500 | 4.125 | 6850 | 2800 | 0.125 | KB035CP0 |

| 88.900 | 104.775 | |||||

| NB.KB040CP0 | 4.000 | 4.625 | 7780 | 3070 | 0.140 | KB040CP0 |

| 101.600 | 117.475 | |||||

| NB.KB042CP0 | 4.250 | 4.875 | 8130 | 3160 | 0.147 | KB042CP0 |

| 107.950 | 123.825 | |||||

| NB.KB045CP0 | 4.500 | 5.125 | 8670 | 3290 | 0.160 | KB045CP0 |

| 114.300 | 130.175 | |||||

| NB.KB047CP0 | 4.750 | 5.375 | 9020 | 3380 | 0.163 | KB047CP0 |

| 120.650 | 136.525 | |||||

| NB.KB050CP0 | 5.000 | 5.625 | 9560 | 3510 | 0.172 | KB050CP0 |

| 127.000 | 142.875 | |||||

| NB.KB055CP0 | 5.500 | 6.125 | 10490 | 3730 | 0.186 | KB055CP0 |

| 139.700 | 155.575 | |||||

| NB.KB060CP0 | 6.000 | 6.625 | 11380 | 3960 | 0.205 | KB060CP0 |

| 152.400 | 168.275 | |||||

| NB.KB065CP0 | 6.500 | 7.125 | 12270 | 4130 | 0.216 | KB065CP0 |

| 165.100 | 180.975 | |||||

| NB.KB070CP0 | 7.000 | 7.625 | 13200 | 4360 | 0.232 | KB070CP0 |

| 177.800 | 193.675 | |||||

| NB.KB075CP0 | 7.500 | 8.125 | 14090 | 4530 | 0.250 | KB075CP0 |

| 190.500 | 206.375 | |||||

| NB.KB080CP0 | 8.000 | 8.625 | 14980 | 4760 | 0.262 | KB080CP0 |

| 203.200 | 219.075 | |||||

| NB.KB090CP0 | 9.000 | 9.625 | 16800 | 5110 | 0.300 | KB090CP0 |

| 228.600 | 244.475 | |||||

| NB.KB100CP0 | 10.000 | 10.625 | 18620 | 5470 | 0.331 | KB100CP0 |

| 254.000 | 269.875 | |||||

| NB.KB110CP0 | 11.000 | 11.625 | 20400 | 5820 | 0.360 | KB110CP0 |

| 279.400 | 295.275 | |||||

| NB.KB120CP0 | 12.000 | 12.625 | 22230 | 6180 | 0.390 | KB120CP0 |

| 304.800 | 320.675 | |||||

| NB.KB140CP0 | 14.000 | 14.625 | 25830 | 6800 | 0.476 | KB140CP0 |

| 355.600 | 371.475 | |||||

| NB.KB160CP0 | 16.000 | 16.625 | 29430 | 7420 | 0.544 | KB160CP0 |

| 406.400 | 422.275 | |||||

| NB.KB180CP0 | 18.000 | 18.625 | 33070 | 8050 | 0.612 | KB180CP0 |

| 457.200 | 473.075 | |||||

| NB.KB200CP0 | 20.000 | 20.625 | 36670 | 8620 | 0.68 | KB200CP0 |

| 508.000 | 523.875 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KC040CP0 | 4.000 | 4.750 | 9330 | 3910 | 0.204 | KC040CP0 |

| 101.600 | 120.650 | |||||

| NB.KC042CP0 | 4.250 | 5.000 | 9780 | 4090 | 0.213 | KC042CP0 |

| 107.950 | 127.000 | |||||

| NB.KC045CP0 | 4.500 | 5.250 | 10400 | 4220 | 0.225 | KC045CP0 |

| 114.300 | 133.350 | |||||

| NB.KC047CP0 | 4.750 | 5.000 | 10930 | 4360 | 0.235 | KC047CP0 |

| 120.650 | 139.700 | |||||

| NB.KC050CP0 | 5.000 | 5.750 | 11510 | 4490 | 0.263 | KC050CP0 |

| 127.000 | 146.050 | |||||

| NB.KC055CP0 | 5.500 | 6.250 | 12580 | 4800 | 0.268 | KC055CP0 |

| 139.700 | 158.750 | |||||

| NB.KC060CP0 | 6.000 | 6.750 | 13650 | 5070 | 0.295 | KC060CP0 |

| 152.400 | 171.450 | |||||

| NB.KC065CP0 | 6.500 | 7.250 | 14710 | 5330 | 0.312 | KC065CP0 |

| 165.100 | 184.150 | |||||

| NB.KC070CP0 | 7.000 | 7.750 | 15780 | 5560 | 0.34 | KC070CP0 |

| 177.800 | 196.850 | |||||

| NB.KC075CP0 | 7.500 | 8.250 | 16850 | 5820 | 0.36 | KC075CP0 |

| 190.500 | 209.550 | |||||

| NB.KC080CP0 | 8.000 | 8.750 | 17910 | 6050 | 0.387 | KC080CP0 |

| 203.200 | 222.250 | |||||

| NB.KC090CP0 | 9.000 | 9.750 | 20050 | 6530 | 0.45 | KC090CP0 |

| 228.600 | 247.650 | |||||

| NB.KC100CP0 | 10.000 | 10.750 | 22180 | 6980 | 0.481 | KC100CP0 |

| 254.000 | 273.050 | |||||

| NB.KC110CP0 | 11.000 | 11.750 | 24310 | 7420 | 0.526 | KC110CP0 |

| 279.400 | 298.450 | |||||

| NB.KC120CP0 | 12.000 | 12.750 | 26450 | 7870 | 0.567 | KC120CP0 |

| 304.800 | 323.850 | |||||

| NB.KC140CP0 | 14.000 | 14.750 | 30720 | 8670 | 0.689 | KC140CP0 |

| 355,600 | 374.650 | |||||

| NB.KC160CP0 | 16.000 | 16.750 | 35030 | 9470 | 0.785 | KC160CP0 |

| 406.400 | 425.450 | |||||

| NB.KC180CP0 | 18.000 | 18.750 | 39290 | 10220 | 0.88 | KC180CP0 |

| 457.200 | 476.250 | |||||

| NB.KC200CP0 | 20.000 | 20.750 | 43560 | 10980 | 0.98 | KC200CP0 |

| 508.000 | 527.050 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KD040CP0 | 4.000 | 5.000 | 13690 | 6270 | 0.366 | KD040CP0 |

| 101.600 | 127.000 | |||||

| NB.KD042CP0 | 4.250 | 5.250 | 14180 | 6400 | 0.386 | KD042CP0 |

| 107.950 | 133.350 | |||||

| NB.KD045CP0 | 4.500 | 5.500 | 15200 | 6710 | 0.405 | KD045CP0 |

| 114.300 | 139.700 | |||||

| NB.KD047CP0 | 4.750 | 5.750 | 15690 | 6850 | 0.426 | KD047CP0 |

| 120.650 | 146.050 | |||||

| NB.KD050CP0 | 5.000 | 6.000 | 16710 | 7160 | 0.454 | KD050CP0 |

| 127.000 | 152.400 | |||||

| NB.KD055CP0 | 5.500 | 6.500 | 18230 | 7560 | 0.485 | KD055CP0 |

| 139.700 | 165.100 | |||||

| NB.KD060CP0 | 6.000 | 7.000 | 19780 | 8000 | 0.526 | KD060CP0 |

| 152.400 | 177.800 | |||||

| NB.KD065CP0 | 6.500 | 7.500 | 21290 | 8400 | 0.566 | KD065CP0 |

| 165.100 | 190.500 | |||||

| NB.KD070CP0 | 7.000 | 8.000 | 22800 | 8800 | 0.606 | KD070CP0 |

| 177.800 | 203.200 | |||||

| NB.KD075CP0 | 7.500 | 8.500 | 24310 | 9160 | 0.650 | KD075CP0 |

| 190.500 | 215.900 | |||||

| NB.KD080CP0 | 8.000 | 9.000 | 25830 | 9560 | 0.694 | KD080CP0 |

| 203.200 | 228.600 | |||||

| NB.KD090CP0 | 9.000 | 10.000 | 28890 | 10310 | 0.780 | KD090CP0 |

| 228.600 | 254.000 | |||||

| NB.KD100CP0 | 10.000 | 11.000 | 31920 | 10980 | 0.853 | KD100CP0 |

| 254.000 | 279.400 | |||||

| NB.KD110CP0 | 11.000 | 12.000 | 34980 | 11690 | 0.934 | KD110CP0 |

| 279.400 | 304.800 | |||||

| NB.KD120CP0 | 12.000 | 13.000 | 38010 | 12360 | 1.020 | KD120CP0 |

| 304.800 | 330.200 | |||||

| NB.KD140CP0 | 14.000 | 15.000 | 44090 | 13650 | 1.240 | KD140CP0 |

| 355.600 | 381.000 | |||||

| NB.KD160CP0 | 16.000 | 17.000 | 50180 | 14890 | 1.410 | KD160CP0 |

| 406.400 | 431.800 | |||||

| NB.KD180CP0 | 18.000 | 19.000 | 56230 | 16050 | 1.580 | KD180CP0 |

| 457.200 | 482.600 | |||||

| NB.KD200CP0 | 20.000 | 21.000 | 62320 | 17200 | 1.750 | KD200CP0 |

| 508.000 | 533.400 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KF040CP0 | 4.000 | 5.500 | 23830 | 12130 | 0.875 | KF040CP0 |

| 101.600 | 139.700 | |||||

| NB.KF042CP0 | 4.250 | 5.750 | 25070 | 12580 | 0.930 | KF042CP0 |

| 107.950 | 146.050 | |||||

| NB.KF045CP0 | 4.500 | 6.000 | 26360 | 12980 | 0.975 | KF045CP0 |

| 114.300 | 152.400 | |||||

| NB.KF047CP0 | 4.750 | 6.250 | 27600 | 13380 | 1.040 | KF047CP0 |

| 120.650 | 158.750 | |||||

| NB.KF050CP0 | 5.000 | 6.500 | 28850 | 13780 | 1.090 | KF050CP0 |

| 127.000 | 165.100 | |||||

| NB.KF055CP0 | 5.500 | 7.000 | 31340 | 14580 | 1.180 | KF055CP0 |

| 139.700 | 177.800 | |||||

| NB.KF060CP0 | 6.000 | 7.500 | 33870 | 15340 | 1.240 | KF060CP0 |

| 152.400 | 190.500 | |||||

| NB.KF065CP0 | 6.500 | 8.000 | 36360 | 16090 | 1.350 | KF065CP0 |

| 165.100 | 203.200 | |||||

| NB.KF070CP0 | 7.000 | 8.500 | 38890 | 16850 | 1.450 | KF070CP0 |

| 177.800 | 215.900 | |||||

| NB.KF075CP0 | 7.500 | 9.000 | 41380 | 17560 | 1.560 | KF075CP0 |

| 190.500 | 228.600 | |||||

| NB.KF080CP0 | 8.000 | 9.500 | 43920 | 18230 | 1.660 | KF080CP0 |

| 203.200 | 241.300 | |||||

| NB.KF090CP0 | 9.000 | 10.500 | 48900 | 19600 | 1.810 | KF090CP0 |

| 228.600 | 266.700 | |||||

| NB.KF100CP0 | 10.000 | 11.500 | 53920 | 20940 | 2.020 | KF100CP0 |

| 254.000 | 292,100 | |||||

| NIKF110CP0 | 11.000 | 12.500 | 58940 | 22230 | 2.180 | KF110CP0 |

| 279.400 | 317.500 | |||||

| NB.KF120CP0 | 12.000 | 13.500 | 63960 | 23470 | 2.380 | KF120CP0 |

| 304.800 | 342.900 | |||||

| NB.KF140CP0 | 14.000 | 15.500 | 74010 | 25830 | 2.720 | KF140CP0 |

| 355.600 | 393.700 | |||||

| NB.KF160CP0 | 16.000 | 17.500 | 84010 | 28140 | 3.220 | KF160CP0 |

| 406.400 | 444.500 | |||||

| NB.KF180CP0 | 18.000 | 19.500 | 94060 | 30320 | 3.580 | KF180CP0 |

| 457.200 | 495.300 | |||||

| NB.KF200CP0 | 20.000 | 21.500 | 104100 | 32450 | 4.040 | KF200CP0 |

| 508.000 | 546.100 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.KG040CP0 | 4.000 | 6.000 | 36490 | 20000 | 1.650 | KG040CP0 |

| 101.600 | 152.400 | |||||

| NB.KG042CP0 | 4.250 | 6.250 | 36490 | 20000 | 1.750 | KG042CP0 |

| 107.950 | 158.750 | |||||

| NB.KG045CP0 | 4.500 | 6.500 | 38940 | 20900 | 1.810 | KG045CP0 |

| 114.300 | 165.100 | |||||

| NB.KG047CP0 | 4.750 | 6.750 | 41340 | 21740 | 1.910 | KG047CP0 |

| 120.650 | 171.450 | |||||

| NB.KG050CP0 | 5.000 | 7.000 | 43780 | 22580 | 2.020 | KG050CP0 |

| 127.000 | 177.800 | |||||

| NB.KG055CP0 | 5.500 | 7.500 | 46230 | 23430 | 2.170 | KG055CP0 |

| 139.700 | 190.500 | |||||

| NB.KG060CP0 | 6.000 | 8.000 | 51070 | 25030 | 2.310 | KG060CP0 |

| 152.400 | 203.200 | |||||

| NB.KG065CP0 | 6.500 | 8.500 | 53520 | 25830 | 2.470 | KG065CP0 |

| 165.100 | 215.900 | |||||

| NB.KG070CP0 | 7.000 | 9.000 | 58360 | 27380 | 2.670 | KG070CP0 |

| 177.800 | 228.600 | |||||

| NB.KG075CP0 | 7.500 | 9.500 | 60810 | 28140 | 2.830 | KG075CP0 |

| 190.500 | 241.300 | |||||

| NB.KG080CP0 | 8.000 | 10.000 | 65650 | 29600 | 3.000 | KG080CP0 |

| 203.200 | 254.000 | |||||

| NB.KG090CP0 | 9.000 | 11.000 | 72990 | 31780 | 3.300 | KG090CP0 |

| 228.600 | 279.400 | |||||

| NB.KG100CP0 | 10.000 | 12.000 | 80280 | 33870 | 3.650 | KG100CP0 |

| 254.000 | 304.800 | |||||

| NB.KG110CP0 | 11.000 | 13.000 | 87570 | 35870 | 3.960 | KG110CP0 |

| 279.400 | 330.200 | |||||

| NB.KG120CP0 | 12.000 | 14.000 | 94860 | 37830 | 4.320 | KG120CP0 |

| 304.800 | 355.600 | |||||

| NB.KG140CP0 | 14.000 | 16.000 | 109440 | 41600 | 4.960 | KG140CP0 |

| 355.600 | 406.400 | |||||

| NB.KG160CP0 | 16.000 | 18.000 | 124060 | 45250 | 5.650 | KG160CP0 |

| 406.400 | 457.200 | |||||

| NB.KG180CP0 | 18.000 | 20.000 | 138640 | 48720 | 6.280 | KG180CP0 |

| 457.200 | 508.000 | |||||

| NB.KG200CP0 | 20.000 | 22.000 | 153220 | 52100 | 7.530 | KG200CP0 |

| 508.000 | 558.800 | |||||

| NB.KG250CP0 | 25.000 | 27.000 | 174000 | 71000 | 8.850 | KG250CP0 |

| 635.000 | 685.800 | |||||

| Deep Groove Ball Thin-Section Bearing Sealed Type (C) | ||||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.JHA10CP0 | 1.000 | 1.375 | 1290 | 670 | 0.016 | JHA10CP0 |

| 25.400 | 34.925 | |||||

| NB.JHA15CP0 | 1.500 | 1.875 | 1780 | 800 | 0.024 | JHA15CP0 |

| 38.100 | 47.625 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.JA020CP0 | 2.000 | 2.500 | 3020 | 1420 | 0.045 | JA020CP0 |

| 50.800 | 63.500 | |||||

| NB.JA025CP0 | 2.500 | 3.000 | 3690 | 1600 | 0.054 | JA025CP0 |

| 63.500 | 76.200 | |||||

| NB.JA030CP0 | 3.000 | 3.500 | 4400 | 1820 | 0.064 | JA030CP0 |

| 76.200 | 88.900 | |||||

| NB.JA035CP0 | 3.500 | 4.000 | 5070 | 2000 | 0.077 | JA035CP0 |

| 88.900 | 101.600 | |||||

| NB.JA040CP0 | 4.000 | 4.500 | 5730 | 2130 | 0.086 | JA040CP0 |

| 101.600 | 114.300 | |||||

| NB.JA042CP0 | 4.250 | 4.750 | 6090 | 2220 | 0.091 | JA042CP0 |

| 107.950 | 120.650 | |||||

| NB.JA045CP0 | 4.500 | 5.000 | 6400 | 2310 | 0.095 | JA045CP0 |

| 114.300 | 127.000 | |||||

| NB.JA047CP0 | 4.750 | 5.250 | 6760 | 2400 | 0.100 | JA047CP0 |

| 120.650 | 133.350 | |||||

| NB.JA050CP0 | 5.000 | 5.500 | 7070 | 2490 | 0.104 | JA050CP0 |

| 127.000 | 139.700 | |||||

| NB.JA055CP0 | 5.500 | 6.000 | 7780 | 2620 | 0.113 | JA055CP0 |

| 139.700 | 152.400 | |||||

| NB.JA060CP0 | 6.000 | 6.500 | 8450 | 2800 | 0.127 | JA060CP0 |

| 152.400 | 165.100 | |||||

| NB.JA065CP0 | 6.500 | 7.000 | 9110 | 2930 | 0.136 | JA065CP0 |

| 165.100 | 177.800 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.JB020CP0 | 2.000 | 2.625 | 4130 | 2000 | 0.068 | JB020CP0 |

| 50.800 | 66.700 | |||||

| NB.JB025CP0 | 2.500 | 3.125 | 5070 | 2310 | 0.086 | JB025CP0 |

| 63.500 | 79.375 | |||||

| NB.JB030CP0 | 3.000 | 3.625 | 5960 | 2580 | 0.100 | JB030CP0 |

| 76.200 | 92.075 | |||||

| NB.JB035CP0 | 3.500 | 4.125 | 6850 | 2800 | 0.122 | JB035CP0 |

| 88.900 | 104.775 | |||||

| NB.JB040CP0 | 4.000 | 4.625 | 7780 | 3070 | 0.136 | JB040CP0 |

| 101.600 | 117.475 | |||||

| NB.JB042CP0 | 4.250 | 4.875 | 8130 | 3160 | 0.141 | JB042CP0 |

| 107.950 | 123.825 | |||||

| NB.JB045CP0 | 4.500 | 5.125 | 8670 | 3290 | 0.154 | JB045CP0 |

| 114.300 | 130.175 | |||||

| NB.JB047CP0 | 4.750 | 5.375 | 9020 | 3380 | 0.159 | JB047CP0 |

| 120.650 | 136.525 | |||||

| NB.JB050CP0 | 5.000 | 5.625 | 9560 | 3510 | 0.168 | JB050CP0 |

| 127.000 | 142.875 | |||||

| NB.JB055CP0 | 5.500 | 6.125 | 10490 | 3730 | 0.181 | JB055CP0 |

| 139.700 | 155.575 | |||||

| NB.JB060CP0 | 6.000 | 6.625 | 11380 | 3960 | 0.200 | JB060CP0 |

| 152.400 | 168.275 | |||||

| NB.JB065CP0 | 6.500 | 7.125 | 12270 | 4130 | 0.213 | JB065CP0 |

| 165.100 | 180.975 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.JG120CP0 | 12.000 | 14.000 | 94860 | 37830 | 4.218 | JG120CP0 |

| 304.800 | 355.600 | |||||

| NB.JG140CP0 | 14.000 | 16.000 | 109440 | 41600 | 4.899 | JG140CP0 |

| 355.600 | 406.400 | |||||

| NB.JG160CP0 | 16.000 | 18.000 | 124060 | 45250 | 5.579 | JG160CP0 |

| 406.400 | 457.200 | |||||

| NB.JG180CP0 | 18.000 | 20.000 | 138640 | 48720 | 6.214 | JG180CP0 |

| 457.200 | 508.000 | |||||

| NB.JG200CP0 | 20.000 | 22.000 | 153220 | 52100 | 7.167 | JG200CP0 |

| 508.000 | 558.800 | |||||

| Bearing Model | Dimension | Basic Cap | Unit | Interchange | ||

| (inch/mm) | (N) | Weight | ||||

| d | D | Cor | Cr | Kg | KAYDON | |

| NB.JU040CP0 | 4.000 | 4.750 | 9340 | 3910 | 0.249 | JU040CP0 |

| 101.600 | 120.650 | |||||

| NB.JU042CP0 | 4.250 | 5.000 | 9870 | 4090 | 0.263 | JU042CP0 |

| 107.950 | 127.000 | |||||

| NB.JU045CP0 | 4.500 | 5.250 | 10400 | 4220 | 0.277 | JU045CP0 |

| 114.300 | 133.350 | |||||

| NB.JU047CP0 | 4.750 | 5.500 | 10940 | 4360 | 0.295 | JU047CP0 |

| 120.650 | 139.700 | |||||

| NB.JU050CP0 | 5.000 | 5.750 | 11510 | 4490 | 0.308 | JU050CP0 |

| 127.000 | 146.050 | |||||

| NB.JU055CP0 | 5.500 | 6.250 | 12580 | 4800 | 0.336 | JU055CP0 |

| 139.700 | 158.750 | |||||

| NB.JU060CP0 | 6.000 | 6.750 | 13650 | 5070 | 0.367 | JU060CP0 |

| 152.400 | 171.450 | |||||

| NB.JU065CP0 | 6.500 | 7.250 | 14740 | 5330 | 0.395 | JU065CP0 |

| 165.100 | 184.150 | |||||

| NB.JU070CP0 | 7.000 | 7.750 | 15780 | 5560 | 0.422 | JU070CP0 |

| 177.800 | 196.850 | |||||

| NB.JU075CP0 | 7.500 | 8.250 | 16850 | 5820 | 0.449 | JU075CP0 |

| 190.500 | 209.550 | |||||

| NB.JU080CP0 | 8.000 | 8.750 | 17910 | 6050 | 0.481 | JU080CP0 |

| 203.200 | 222.250 | |||||

| NB.JU090CP0 | 9.000 | 9.750 | 20050 | 6530 | 0.535 | JU090CP0 |

| 228.600 | 247.650 | |||||

| NB.JU100CP0 | 10.000 254.000 | 10.750 273.050 | 22180 | 6980 | 0.594 | JU100CP0 |

| NB.JU110CP0 | 11.000 | 11.750 | 24310 | 7420 | 0.649 | JU110CP0 |

| 279.400 | 298.450 | |||||

| NB.JU120CP0 | 12.000 | 12.750 | 26450 | 7870 | 0.708 | JU120CP0 |

| 304.800 | 323.850 | |||||

| 8mm Series - Deep Groove Ball Bearing | ||||||

| Bearing Model | Inner Dia | Outer Dia | Width | Dynamic | Weight | |

| d | D | B | Radial | Radial | ||

| (mm) | (mm) | (mm) | (N) | (N) | (kg) | |

| NB.K02508CP0 | 25 | 41 | 8 | 2501 | 2971 | 0.06 |

| NB.K05008CP0 | 50 | 66 | 8 | 3432 | 5452 | 0.08 |

| NB.K06008CP0 | 60 | 76 | 8 | 3766 | 6433 | 0.09 |

| NB.K07008CP0 | 70 | 86 | 8 | 4089 | 7433 | 0.1 |

| NB.K08008CP0 | 80 | 96 | 8 | 4393 | 8424 | 0.11 |

| NB.K09008CP0 | 90 | 106 | 8 | 4688 | 9405 | 0.13 |

| NB.K10008CP0 | 100 | 116 | 8 | 4972 | 10405 | 0.14 |

| NB.K11008CP0 | 110 | 126 | 8 | 5237 | 11395 | 0.15 |

| NB.K12008CP0 | 120 | 136 | 8 | 5502 | 12376 | 0.16 |

| NB.K13008CP0 | 130 | 146 | 8 | 5766 | 13376 | 0.17 |

| NB.K14008CP0 | 140 | 156 | 8 | 6011 | 14367 | 0.18 |

| NB.K15008CP0 | 150 | 166 | 8 | 6257 | 15347 | 0.2 |

| NB.K16008CP0 | 160 | 176 | 8 | 6492 | 16338 | 0.2 |

| NB.K17008CP0 | 170 | 186 | 8 | 6727 | 17328 | 0.2 |

| NB.K18008CP0 | 180 | 196 | 8 | 6953 | 18319 | 0.21 |

| NB.K19008CP0 | 190 | 206 | 8 | 7110 | 19064 | 0.21 |

| NB.K20008CP0 | 200 | 216 | 8 | 7335 | 20055 | 0.22 |

| NB.K25008CP0 | 250 | 266 | 8 | 8365 | 25007 | 0.28 |

| NB.K30008CP0 | 300 | 316 | 8 | 9307 | 29959 | 0.35 |

| NB.K32008CP0 | 320 | 336 | 8 | 9660 | 31940 | 0.39 |

| NB.K34008CP0 | 340 | 356 | 8 | 9660 | 31940 | 0.39 |

| NB.K36008CP0 | 360 | 376 | 8 | 10297 | 35657 | 0.46 |

| 13mm Series - Deep Groove Ball Bearing | ||||||

| Bearing Model | Inner Dia | Outer Dia | Width | Dynamic | Weight | |

| d | D | B | Radial | Radial | ||

| (mm) | (mm) | (mm) | (N) | (N) | (kg) | |

| NB.K02513CP0 | 25 | 51 | 13 | 5247 | 5070 | 0.11 |

| NB.K05013CP0 | 50 | 76 | 13 | 6835 | 8875 | 0.18 |

| NB.K06013CP0 | 60 | 86 | 13 | 7600 | 10778 | 0.21 |

| NB.K07013CP0 | 70 | 96 | 13 | 8032 | 12043 | 0.24 |

| NB.K08013CP0 | 80 | 106 | 13 | 8453 | 13317 | 0.26 |

| NB.K09013CP0 | 90 | 116 | 13 | 9130 | 15210 | 0.29 |

| NB.K10013CP0 | 100 | 126 | 13 | 9522 | 16485 | 0.32 |

| NB.K11013CP0 | 110 | 136 | 13 | 10150 | 18387 | 0.35 |

| NB.K12013CP0 | 120 | 146 | 13 | 10523 | 19653 | 0.38 |

| NB.K13013CP0 | 130 | 156 | 13 | 10885 | 20918 | 0.41 |

| NB.K14013CP0 | 140 | 166 | 13 | 11464 | 22820 | 0.44 |

| NB.K15013CP0 | 150 | 176 | 13 | 11807 | 24085 | 0.46 |

| NB.K16013CP0 | 160 | 186 | 13 | 12150 | 25360 | 0.49 |

| NB.K17013CP0 | 170 | 196 | 13 | 12690 | 27262 | 0.52 |

| NB.K18013CP0 | 180 | 206 | 13 | 13013 | 28528 | 0.55 |

| NB.K19013CP0 | 190 | 216 | 13 | 13337 | 29793 | 0.58 |

| NB.K20013CP0 | 200 | 226 | 13 | 13837 | 31695 | 0.61 |

| NB.K25013CP0 | 250 | 276 | 13 | 15671 | 39305 | 0.75 |

| NB.K30013CP0 | 300 | 326 | 13 | 17201 | 46278 | 0.89 |

| NB.K32013CP0 | 320 | 346 | 13 | 17878 | 49445 | 0.95 |

| NB.K34013CP0 | 340 | 366 | 13 | 18525 | 52613 | 1.01 |

| NB.K36013CP0 | 360 | 386 | 13 | 19162 | 55780 | 1.06 |

| 20mm Series - Deep Groove Ball Bearing | ||||||

| Bearing Model | Inner Dia | Outer Dia | Width | Dynamic | Weight | |

| d | D | B | Radial | Radial | ||

| (mm) | (mm) | (mm) | (N) | (N) | (kg) | |

| NB.K02520CP0 | 25 | 65 | 20 | 11552 | 9983 | 0.34 |

| NB.K05020CP0 | 50 | 90 | 20 | 13827 | 15691 | 0.51 |

| NB.K06020CP0 | 60 | 100 | 20 | 14239 | 17113 | 0.58 |

| NB.K07020CP0 | 70 | 110 | 20 | 15426 | 19966 | 0.65 |

| NB.K08020CP0 | 80 | 120 | 20 | 15857 | 21388 | 0.72 |

| NB.K09020CP0 | 90 | 130 | 20 | 16966 | 24252 | 0.8 |

| NB.K10020CP0 | 100 | 140 | 20 | 17387 | 25674 | 0.86 |

| NB.K11020CP0 | 110 | 150 | 20 | 18437 | 28528 | 0.94 |

| NB.K12020CP0 | 120 | 160 | 20 | 19437 | 31381 | 1.01 |

| NB.K13020CP0 | 130 | 170 | 20 | 19839 | 32803 | 1.08 |

| NB.K14020CP0 | 140 | 180 | 20 | 20800 | 35657 | 1.15 |

| NB.K15020CP0 | 150 | 190 | 20 | 21192 | 37079 | 1.2 |

| NB.K16020CP0 | 160 | 200 | 20 | 22104 | 39933 | 1.3 |

| NB.K17020CP0 | 170 | 210 | 20 | 22487 | 42786 | 1.4 |

| NB.K18020CP0 | 180 | 220 | 20 | 23369 | 44208 | 1.5 |

| NB.K19020CP0 | 190 | 230 | 20 | 24222 | 47072 | 1.5 |

| NB.K20020CP0 | 200 | 240 | 20 | 24585 | 48494 | 1.6 |

| NB.K25020CP0 | 250 | 290 | 20 | 27665 | 59899 | 2.1 |

| NB.K30020CP0 | 300 | 340 | 20 | 30508 | 71314 | 2.3 |

| NB.K32020CP0 | 320 | 360 | 20 | 31509 | 75590 | 2.42 |

| NB.K34020CP0 | 340 | 380 | 20 | 32480 | 79865 | 2.54 |

| NB.K36020CP0 | 360 | 400 | 20 | 33421 | 84151 | 2.7 |

The single-row deep groove design maximizes the radial load-bearing efficiency.

Precision manufacturing ensures smooth operation, making it suitable for precision instruments.

The low-friction design is suitable for high-speed scenarios such as motors and spindles.

It can bear moderate bidirectional axial loads without the need for additional thrust bearings.

Maximum Radial Load Capacity in a Minimal Space: This is their primary advantage. For a given cross-section, a deep groove design can support higher radial loads than other thin-section types.

Moderate Bidirectional Axial Load Capacity: They can handle some axial loads from either direction, unlike a pure radial bearing. This makes them versatile for applications where the axial load is not the primary concern but is present.

High-Speed Capability: They are well-suited for high-speed operation, especially when paired with a cage (retainer) designed for such speeds.

Low Friction and Low Torque: The deep groove geometry and ball complement typically result in very smooth, low-torque rotation.

Simplified Design: They are non-separable and often simpler to integrate than paired angular contact bearings, as they do not require complex preload settings.

Primary Applications

Thin-section deep groove ball bearings are the ideal choice in situations where the main challenge is high radial load in a space-constrained assembly. They are ubiquitous in precision industries.

1. Robotics and Automation

Robot Joints and Arms: Used in the less critical joints of articulated robots or cobots where the primary load is radial (from the arm's weight and payload) and space for the joint housing is minimal.

Gripper Mechanisms: In the rotating bases of grippers.

Rotary Actuators: As the main support bearing in compact rotary actuators.

Precision Gearing Systems: Supporting idler and planetary gears where the shaft load is radial and the housing space is tight.

2. Aerospace & Defense

Instrumentation and Avionics: In control panels, navigation equipment, and other instrument rotors where weight and space are critical but loads are primarily radial.

Auxiliary Drives and Systems: In pumps, blowers, and generators within the aircraft, where a compact design is needed to support a shaft under radial load.

Guidance System Gimbals: In some secondary gimbal rings where axial loads are lower.

3. Medical Equipment

Scanner Rotors (CT/MRI): While the main gantry uses larger bearings, thin-section deep grooves are often used in smaller, internal rotating assemblies like cooling fans or sensor rotors.

Surgical Handpieces and Tools: In drills, saws, and other rotating surgical instruments where a compact, lightweight, and precise bearing is required.

Lab Automation: In centrifuges, sample handlers, and DNA sequencers where high speeds and radial load support are key.

4. Semiconductor Manufacturing

Wafer Handling Robots: These robots operate in cleanrooms and move silicon wafers between process stations. The thin section allows for slender robot arms, and the deep groove design supports the radial load of the arm and wafer.

Stages and Positioners: In the linear and rotary stages that position wafers under lithography tools.

5. Optical and Precision Instruments

Pan-Tilt Units: For professional cameras and sensors, providing smooth rotation.

Laser Scanning Mirrors: Supporting the high-speed rotation of polygonal mirrors.

Surveying Equipment: In theodolites and total stations, ensuring smooth and accurate rotation.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.