A thin section deep groove ball bearing is a specialized type of rolling-element bearing designed with a slim cross-section while maintaining high load capacity and smooth rotational performance. Unlike standard deep groove ball bearings, thin section bearings have a reduced radial thickness, making them ideal for applications where space and weight constraints are critical. These bearings are commonly used in robotics, medical equipment, aerospace, and precision machinery.

Features of Thin Section Deep Groove Ball Bearings

1. Compact Design – Reduced cross-section saves space without sacrificing performance.

2.High Precision – Manufactured to tight tolerances (ABEC 5/7/9) for smooth operation.

3.Low Friction – Optimized ball and raceway geometry minimizes energy loss.

4.Versatile Load Handling – Supports both radial and axial loads efficiently.

5. Corrosion-Resistant Options – Available in stainless steel or coated versions for harsh environments.

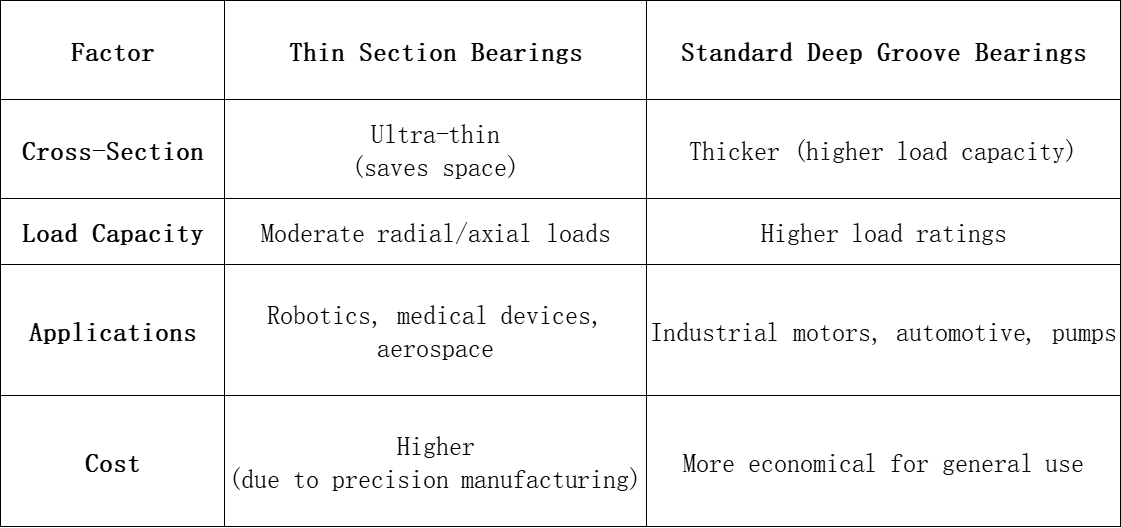

How to Choose Between Thin Section and Standard Deep Groove Ball Bearings?

1.Robotics – Used in robotic arms and joints for smooth motion.

2.Medical Equipment – Found in MRI machines, surgical robots, and imaging devices.

3.Aerospace – Lightweight design suits drones and satellite mechanisms.

4. Optical & Semiconductor – Precision movement in lens positioning stages.

Price Factors of Thin Section Deep Groove Ball Bearings

Pricing depends on:

Material (stainless steel vs. chrome steel)

Precision Grade (ABEC 1/3/5/7/9)

Customization (special seals, coatings, or sizes)

Order Volume (bulk discounts available)

For the latest pricing, contact us for a quote.

2.Speed Rating – Verify maximum RPM for high-speed applications.

3.Environmental Conditions – Choose corrosion-resistant materials if needed.

4.Supplier Reliability – Look for ISO-certified manufacturers with testing reports.

Luoyang Newbee Transmission Technology Co., Ltd. is a leading manufacturer specializing in high-precision bearings, including thin section deep groove ball bearings, slewing bearings, and custom-engineered solutions. With decades of expertise, we control the entire production chain—from raw material forging to precision machining and rigorous quality testing.

Full Industrial Chain Control – Ensures consistent quality from material to finished product.

Advanced Manufacturing – Equipped with CNC lathes, gear hobbing machines, and CMM inspection.

Global Supply – Successfully delivered large-diameter bearings (up to 3.5 meters) worldwide.

Custom Solutions – Tailored bearings for robotics, medical, and aerospace applications.

"Our partnership with international clients, including recent deliveries to India, reflects our commitment to high-performance bearing solutions. We continuously invest in R&D to enhance product reliability and lifespan." – General Manager, Luoyang Newbee Transmission

As a trusted thin section bearing supplier, we serve industries like:

Construction & Mining Machinery

Wind Power & Renewable Energy

Port & Material Handling Equipment

Medical & Precision Engineering

Explore our full range of bearings or request a custom solution:

Email: sales@newbeetrans.com

Website: https://www.newbeetrans.com

phone:008615090885276