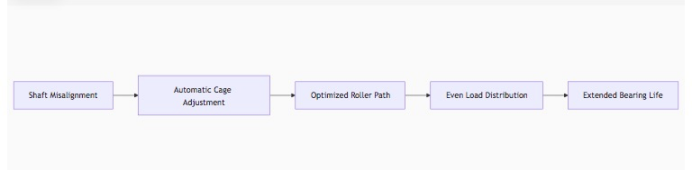

Our spherical roller bearing cages are precision-engineered to automatically compensate for shaft misalignment while maintaining optimal roller positioning. Designed for the most demanding industrial applications including mining equipment, paper machinery, and vibrating screens where shaft deflection and installation inaccuracies commonly occur.

| Material Options & Characteristics | |||||

| Material Type | Hardness | Density (g/cm³) | Max Speed (rpm) | Temp Range | Key Properties |

| Machined Brass | 80-100 HB | 8.4 | 3,000 | -50°C~200°C | Excellent embeddability |

| Case-Hardened Steel | 58-62 HRC | 7.85 | 2,500 | -40°C~300°C | Extreme load capacity |

| Polyamide 66+GF | 85 HRR | 1.15 | 4,000 | -40°C~150°C | Vibration damping |

| Bronze-Alloy | 90-110 HB | 8.8 | 2,800 | -30°C~250°C | High fatigue resistance |

Adjusts for 0.5-3° shaft misalignment

Dual-contact design maintains proper roller orientation

Spherical geometry optimizes stress distribution

Hardened guide surfaces extend service life 2-3×

45° angled oil grooves ensure complete lubrication coverage

Shock-absorbing pocket design withstands heavy loads

| Industry | Recommended Cage | Key Benefit |

| Mining Equipment | Case-Hardened Steel | 50% longer life in abrasive environments |

| Paper Machinery | Machined Brass | Withstands chemical exposure |

| Vibrating Screens | Polyamide 66+GF | 60% vibration reduction |

| Steel Mill Stands | Bronze-Alloy | 300°C continuous operation |

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.