What is thin-section bearing?

The thin-section bearing is a type of bearing that has achieved an extremely thin bearing cross-section as well as miniaturized and lightweight designs.Our company provides deep groove ball bearings, angular contact bearings and four-point contact ball bearings.

The Type-X 4-point contact thin section bearings are ideal for moment loading for moment loading and reversing axial loading....

Type-A thin-walled angular contact ball bearings are specifically designed for combined loads (combined radial and axial loads), and are suitable for application scenarios featuring high precision, high rotational speeds, and limited space. Their con......

Type-C thin-section deep groove ball bearings are specifically designed for compact devices that require high radial load capacity. Their structure optimizes the contact mode between the rolling elements and the raceways, supporting moderate axial lo......

Professional Team: Comprising over 30 senior engineers, covering fields such as mechanical design, materials science, and industrial automation. They are well - versed in international standards like ISO, DIN, and JIS. By leveraging CAD/CAE assisted design, 3D models can be rapidly generated and simulated for analysis, ensuring the feasibility of the plan and performance optimization.Customization Process: Conduct in - depth communication regarding application scenarios such as high - temperature, high - speed, and heavy - load conditions. Design bearing structures, material selection, and lubrication solutions in a targeted manner. Complete the sample design within 15 days, support parameter adjustment and performance verification to shorten the development cycle. A strict confidentiality agreement is in place to safeguard the safety of clients' drawings and patents.

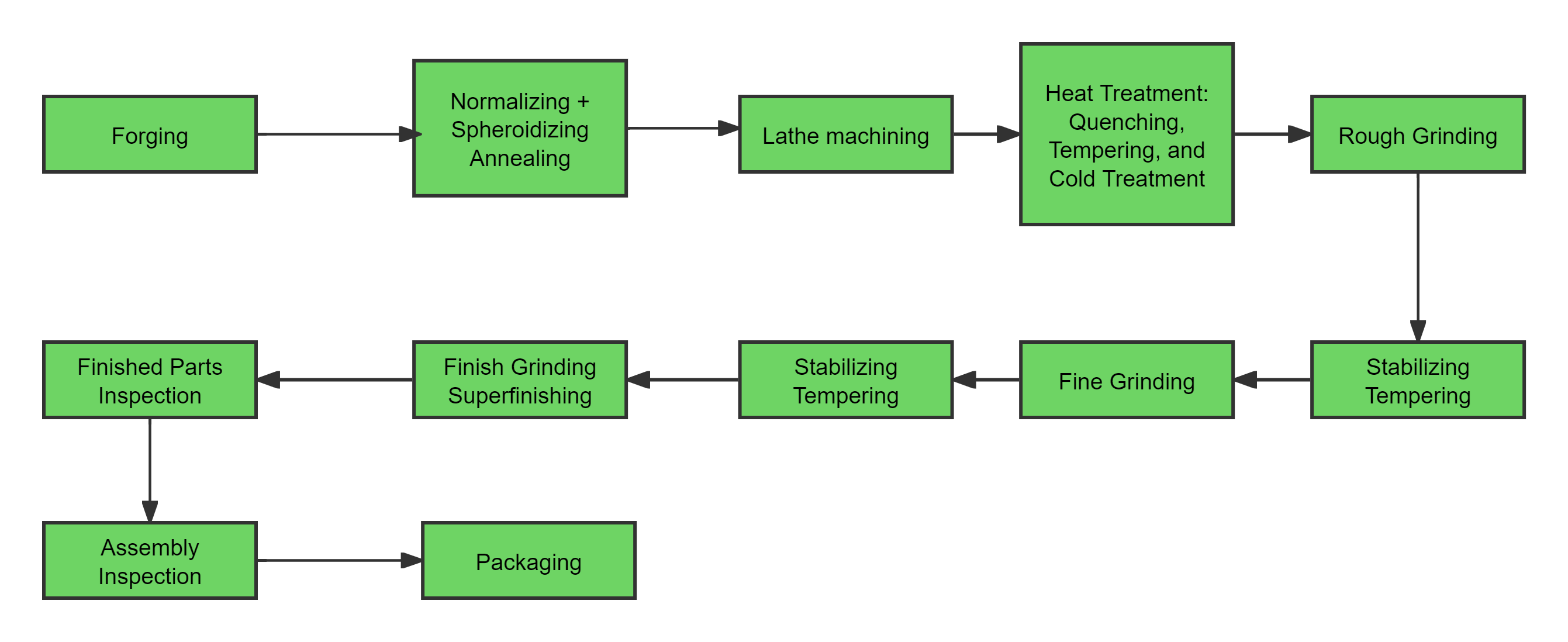

Advanced Manufacturing: Equipped with fully automatic CNC machine tools, high - precision grinding equipment, and heat - treatment production lines, capable of manufacturing all types of bearings. By adopting precision cold ring rolling and super - fine grinding processes, the tolerance can reach P5/P4 level, meeting high - precision requirements. The monthly production capacity exceeds 2 million sets, enabling flexible response to both small - batch trial production and large - volume orders. The regular delivery cycle is 30 days.Intelligent Management: The MES system monitors the production progress in real - time, and the entire order process is traceable. The modular production line can quickly change models to adapt to the production of multiple specifications and batches.

Full - process Quality Control: The raw materials are double - verified by a spectral analyzer and a metallographic microscope. Key dimensions are monitored online by a profilometer, a roundness tester, etc., with an automatic rejection rate of non - conforming products reaching 100%. The noise level, vibration value, and service life are fully inspected at a rate of 100%. Durability tests are carried out under simulated working conditions.

Authoritative Certifications: Passed ISO 9001 and GBT307.1 certifications. SGS third - party inspection reports can be provided along with the goods to meet the market access requirements worldwide.

Warehousing and Packaging The intelligent warehousing center dynamically manages inventory and supports the VMI (Vendor Managed Inventory) model. Customized anti - rust packaging with vacuum and shock - proof measures ensures zero damage during transportation. Global Network We cooperate with DHL, FedEx, etc., and offer trade terms such as FOB (Free on Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). With overseas warehouses established in Europe and North America, orders can be delivered within 7 - 10 days.

How to customize a thin-section bearig?

In industrial robotics, thin section bearings are crucial for joint parts, offering high precision and flexibility.Their compact design allows for reliable support in limited spaces, bearing radial an...

In aviation engines, thin section bearings support high - speed rotation, ensuring stable power output and flight safety. Landing gear benefits from thin section bearings' load - bearing capacity, red...

In medical centrifuges, thin section bearings provide precise and stable support during high - speed rotation, ensuring accurate sample separation. In imaging diagnostic equipment like X - ray machin...

Thin section bearings enable the precise rotation and positioning of radar antennas, ensuring accurate target detection. Their compact design allows them to be installed in space-constrained areas wit...

Thin section bearings provide precision positioning and stable support in optical devices, enhancing resolution and imaging quality.Their compact design enables them to fit into limited spaces, facili...

Thin-section bearings play a crucial role in the precision positioning of semiconductor manufacturing equipment, ensuring high-precision patterning. They enable high-speed and stable operation during ...

Features of Thin-Section Bearings

1. Load - bearing capacity

Thin section ball bearings mainly bear radial loads.. When the bearing radial clearance is increased, they have a certain degree of angular contact bearing performance, allowing them to withstand combined radial and axial loads.

2. Axial load - bearing situation

When the speed is high and thrust bearings are not suitable, thin section ball bearings can be used to withstand pure axial loads.

3. Coefficient of friction and speed

Compared with other types of bearings of the same size, thin section ball bearings have a small coefficient of friction and a high limit speed.

4. Weakness in impact resistance

Thin section ball bearings are not resistant to impact.

5. Load - bearing limitations

They are not suitable for bearing heavy loads.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.