A

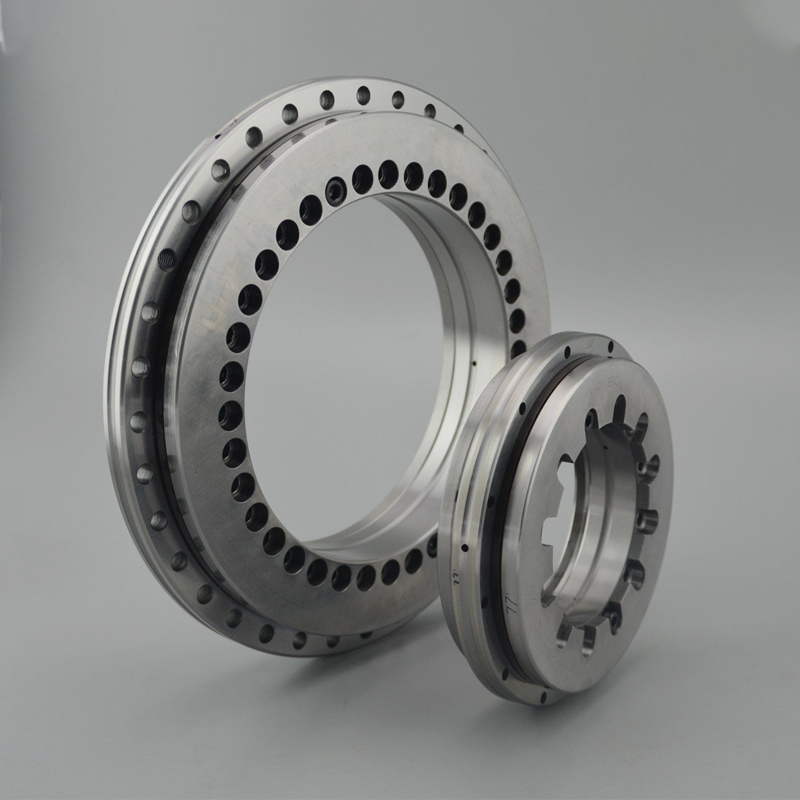

Turntable Bearing, also known as a rotary table bearing, is a high-precision combined bearing that integrates axial and radial load-carrying capabilities. It consists of two thrust needle roller bearings and a radial cylindrical roller bearing, with axial and radial pre-load applied to ensure stable operation. For the convenience of transportation and fixing, two or three symmetrical screws are fastened to its two rings to prevent collisions between rollers and rings that could affect bearing accuracy. As a professional bearing manufacturer and a representative enterprise of precision bearing china, NEWBEE Transmission Turntable Bearing, relying on advanced structural design and precision processing technology, achieves nanometer-level rotational accuracy (with precision grades up to P2, and common grades P4/P5). It is widely used in high-precision transmission systems of equipment such as CNC machinery and measuring instruments, fully demonstrating the R&D and manufacturing capabilities of professional bearing manufacturers.

- Excellent Combined Load-Bearing Capacity: Turntable Bearings can efficiently bear radial loads, axial loads, and overturning moments simultaneously. For example, the YRT series adopts a design of double-row crossed rollers arranged orthogonally, and the ZKLDF series uses double rows of orthogonally arranged cylindrical rollers—both structures enable the bearing to stably support combined loads. A single Turntable Bearing can replace the combination of multiple ordinary bearings, greatly simplifying the equipment’s transmission structure and adapting to the high-load requirements of precision equipment.

- Ultra-High Rotational Precision Performance: This bearing boasts outstanding rotation accuracy, with the highest precision reaching P2 grade and common application grades being P4/P5. It can achieve nanometer-level rotational accuracy through the precise matching between the finely ground inner and outer ring raceways and the rollers. Relying on advanced manufacturing equipment such as fully automatic CNC machine tools and high-precision grinding machines, NEWBEE Transmission controls the key dimensions of Turntable Bearings with high precision (monitored online by profilometers and roundness testers), ensuring smooth and accurate transmission during the bearing’s operation. This represents a technological advantage of precision bearing china enterprises in the high-precision bearing field.

- Ready-to-Install and Convenient Structural Design: Turntable Bearings feature a ready-to-fit design, with mounting holes uniformly distributed around the bearing rings for direct and convenient fixing. This design reduces the difficulty of on-site installation and shortens the assembly time of equipment. Meanwhile, the integrated structure of some series (such as the ZKLDF series) is particularly suitable for CNC equipment that requires ultra-high integration, further improving the operational stability of the equipment’s transmission system.

- Strong Customization Adaptability: NEWBEE Transmission has a professional R&D team composed of over 30 senior engineers, covering fields such as mechanical design, materials science, and industrial automation. The team is well-versed in international standards like ISO, DIN, and JIS. For different application scenarios (such as high-temperature, high-speed, and heavy-load conditions), they can design bearing structures, select appropriate materials, and formulate lubrication solutions in a targeted manner. The sample design can be completed within 15 days, and parameter adjustment and performance verification are supported to shorten the development cycle. Additionally, a strict confidentiality agreement is in place to safeguard the safety of clients' drawings and patents.

- Reliable Quality and Long Service Life: The raw materials of Turntable Bearings undergo double verification by a spectral analyzer and a metallographic microscope to ensure material quality. Key manufacturing processes include precision cold ring rolling and super-fine grinding, which enhance the bearing’s wear resistance and fatigue resistance. Moreover, the bearings are equipped with reasonable lubrication solutions—lubrication can be carried out through the oil hole in the outer ring and the L-shaped inner ring, and the quantity of grease or oil is determined based on the lubrication cycle, load, speed, and working time. These measures extend the service life of Turntable Bearings, making them highly reliable in long-term operation.

With the advantages of high precision, strong load-bearing capacity, and good customization, Turntable Bearings, as core products of professional bearing manufacturers, are widely used in the following fields:

- High-Precision CNC Machinery Field: High-speed rotary tables and index heads rely on the YRT series Turntable Bearings, which can support bidirectional axial loads, radial loads, and tilting moments, ensuring stable operation during high-speed rotation. High-precision CNC rotary tables and measuring instruments adopt YRTM series Turntable Bearings (a bidirectional thrust cylindrical roller YRT combination bearing with an angle measuring system), which can monitor and adjust the rotation accuracy of the bearing in real time, meeting the ultra-high precision requirements of CNC processing and measurement.

- Direct Drive Equipment Field: Direct drive shafts use YRTS series Turntable Bearings, which have the same structure as YRT rotary table bearings but with a special internal design. This design gives them higher speed and low, uniform friction, making them suitable for the high-speed and low-noise operation requirements of direct drive equipment.

- High-Precision Grinding Machinery Field: High-precision grinding machines and gear grinding machines require bearings that can adapt to extremely high speeds and extremely low friction torque. The ZKLDF series high-speed double-direction rotary table axial angular contact ball bearings can support combined loads and ensure high rotation accuracy, fully meeting the operational requirements of high-precision grinding equipment.

The price of Turntable Bearings is affected by the following factors. As a professional bearing manufacturer, NEWBEE Transmission can provide a transparent quotation plan:

- Precision Grade: The higher the precision grade of the Turntable Bearing, the higher the manufacturing cost and price. The price of P2-grade Turntable Bearings is significantly higher than that of P4/P5-grade ones—due to the stricter processing and inspection requirements for P2-grade bearings (such as more precise grinding of raceways and stricter dimensional control). P2-grade bearings are suitable for ultra-high-precision scenarios such as high-end measuring instruments, while P4/P5-grade bearings are more cost-effective for general precision CNC machinery scenarios.

- Material Selection: The choice of materials has a great impact on the price. Turntable Bearings made of high-quality bearing steel (with excellent mechanical properties and wear resistance) are more expensive than those made of ordinary steel. If corrosion resistance is required, stainless steel materials are used, which will increase the price by a certain percentage (usually 20%-30%) compared to ordinary bearing steel materials, making them suitable for humid or corrosive working environments.

- Customization Requirements: For Turntable Bearings with special customization requirements (such as non-standard structural design, special material selection for high-temperature/high-speed scenarios, or additional functional modules like angle measuring systems), the price will increase. The increase range is usually 15%-30%—this is because customization requires re-designing tooling, adjusting the production process, and increasing the R&D and manufacturing costs. For example, bearings customized for high-temperature environments need high-temperature resistant materials and special heat treatment processes, which significantly raise the production cost.

- Order Quantity: The order quantity affects the unit price of Turntable Bearings. Large-volume orders (usually more than 1000 sets) can enjoy a certain price discount—NEWBEE Machinery has a monthly production capacity of more than 2 million sets, and large-scale production can reduce the unit production cost. Small-batch trial production orders (less than 100 sets) have a relatively higher unit price due to the fixed costs of production preparation and debugging.

- Precision Matching: It is necessary to select the appropriate precision grade of Turntable Bearings according to the precision requirements of the equipment. For ultra-high-precision equipment such as high-end measuring instruments and precision grinding machines, P2-grade bearings should be selected; for general CNC rotary tables and direct drive shafts, P4/P5-grade bearings can meet the requirements while achieving a better cost-performance ratio. NEWBEE Machinery can provide precision inspection reports to ensure the consistency of product precision.

- Load and Working Condition Adaptation: First, clarify the load type (radial load, axial load, or combined load) and load magnitude borne by the bearing during equipment operation, and select the corresponding series of Turntable Bearings (such as YRT series for combined loads, ZKLDF series for high-speed combined loads). Second, consider the working environment—for high-temperature environments, select bearings with high-temperature resistant materials and heat treatment; for humid or corrosive environments, choose stainless steel bearings or bearings with anti-corrosion coatings.

- Supplier Qualifications: It is advisable to choose bearing manufacturers like NEWBEE Machinery that have a complete production chain (from material smelting to finished product inspection). Such manufacturers can provide material inspection reports, load test data, and after-sales technical support, avoiding the purchase of inferior products. NEWBEE Machinery has passed ISO 9001 and GBT307.1 certifications and can provide SGS third-party inspection reports along with the goods to meet the market access requirements worldwide.

- Delivery and Logistics Assurance: Consider the supplier’s production capacity and logistics support capabilities. NEWBEE Machinery has a monthly production capacity of more than 2 million sets, and the regular delivery cycle is 30 days, which can meet the delivery requirements of most orders. In terms of logistics, it cooperates with well-known international logistics companies such as DHL and FedEx, and offers trade terms such as FOB (Free on Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). It also has overseas warehouses established in Europe and North America, enabling orders to be delivered within 7-10 days, which is conducive to reducing the inventory pressure of customers.

- Price Rationality: When comparing quotations from different bearing manufacturers, attention should be paid to the "performance-price ratio" rather than simply pursuing low prices. Low-priced products may have defects in material quality or processing precision, which will increase the later maintenance cost and equipment failure rate. NEWBEE Machinery relies on large-scale production and advanced processing equipment to reduce unit costs while ensuring product quality, and provides long-term technical support to avoid excessive later maintenance costs.

NEWBEE Transmission is a professional manufacturer of Turntable Bearings. As a representative enterprise of precision bearing china, it has 20 years of experience in customizing machinery parts and has been deeply engaged in the precision bearing field for a long time. Its Turntable Bearings cover multiple series such as YRT, ZKLDF, YRTM, and YRTS, meeting the application needs of different precision equipment.

In terms of production capacity, NEWBEE Transmission is equipped with fully automatic CNC machine tools, high-precision grinding equipment, and heat-treatment production lines, capable of manufacturing all types of Turntable Bearings. The monthly production capacity exceeds 2 million sets, enabling flexible response to both small-batch trial production and large-volume orders. The MES system is used to monitor the production progress in real time, and the entire order process is traceable. The modular production line can quickly change models to adapt to the production of multiple specifications and batches.

In terms of quality control, NEWBEE Transmission implements full-process quality control. The raw materials are double-verified by a spectral analyzer and a metallographic microscope. Key dimensions are monitored online by a profilometer, a roundness tester, etc., with an automatic rejection rate of non-conforming products reaching 100%. The noise level, vibration value, and service life are fully inspected at a rate of 100%, and durability tests are carried out under simulated working conditions. The company has passed ISO 9001 and GBT307.1 certifications and can provide SGS third-party inspection reports along with the goods.

In terms of logistics and after-sales service, the intelligent warehousing center of NEWBEE Transmission dynamically manages inventory and supports the VMI (Vendor Managed Inventory) model. Customized anti-rust packaging with vacuum and shock-proof measures ensures zero damage during transportation. The company cooperates with DHL, FedEx, etc., and has overseas warehouses in Europe and North America to achieve fast global delivery. In addition, it provides long-term after-sales technical support to help customers solve problems encountered in the use of Turntable Bearings.

Currently, NEWBEE Transmission's Turntable Bearings have been widely used in high-precision CNC machinery, measuring instruments, direct drive equipment, and high-precision grinding machinery, becoming a trusted choice of bearing manufacturers for customers worldwide. For detailed parameters of Turntable Bearings, customized bearing design plans, or technical materials related to bearing installation and lubrication, you can contact the technical team of NEWBEE Transmission directly.

- Installation Specifications: When installing a Turntable Bearing, ensure that the mounting surface is clean and flat to avoid uneven stress on the bearing caused by impurities or unevenness. Use the mounting holes uniformly distributed around the bearing rings for fixing, and fasten the bolts with a torque wrench according to the specified torque value (the specific torque should comply with the product manual) to ensure stable and firm installation. Avoid over-tightening or under-tightening the bolts—over-tightening may damage the bearing ring, while under-tightening may cause the bearing to loosen during operation.

- Lubrication Management: Before the Turntable Bearing operates, inject the appropriate type and quantity of lubricant through the oil hole in the outer ring and the L-shaped inner ring. The quantity of grease or oil should be determined based on the lubrication cycle, load, speed, and working time—generally, the filling amount of grease should account for 1/2-2/3 of the internal space of the bearing. For high-temperature working conditions, select high-temperature resistant lubricants; for heavy-load working conditions, choose lubricants with good extreme pressure performance. Strictly follow the lubrication cycle for supplementary lubrication—under normal working conditions, supplementary lubrication is recommended every 500-800 hours; under harsh working conditions (such as high temperature, high dust), the lubrication interval should be shortened to 300-400 hours to avoid bearing wear and failure due to insufficient lubrication.

- Regular Inspection and Maintenance: During the daily operation of the Turntable Bearing, regularly monitor the bearing temperature (normal operating temperature should be ≤ 80℃) and noise level. If there is a sudden temperature rise, abnormal noise, or vibration, shut down the machine immediately for inspection to find out the cause (such as insufficient lubrication, impurity intrusion, or bearing damage) and take corresponding measures. Regularly check the integrity of the bearing’s sealing structure (if equipped)—if the seal is damaged, replace it in a timely manner to prevent impurities such as dust and moisture from entering the bearing and affecting its operation. In addition, conduct a comprehensive inspection of the bearing every 1000-1500 hours of operation, including checking the wear of the raceway and rollers, the tightness of the bolts, and the condition of the lubricant, to ensure the long-term stable operation of the Turntable Bearing.

For the latest price of Turntable Bearings, customized bearing design plans, or technical materials related to bearing use and maintenance, please contact NEWBEE Transmission:

- Email: Tom@newbeetrans.com