1. Definition & Purpose

Electrically insulated bearings are specially designed to block stray currents that cause electrical erosion (pitting) in bearings, which can lead to:

Premature failure of rolling elements & raceways

Degradation of lubricants due to arcing

Increased noise & vibration from surface damage

These bearings are critical in electric motors, generators, wind turbines, and rail traction systems where electrically induced bearing currents are a major concern.

2. Key Manufacturing Technology

The insulation is achieved through advanced thermal spraying, forming a high-adhesion ceramic or oxide coating (typically Al₂O₃ or ZrO₂) on the bearing's outer/inner ring.

Process Characteristics:

Advantages vs. Traditional Methods:

Superior bonding-No delamination under thermal cycling

Uniform thickness-Eliminates weak spots in insulation

Chemical stability-Resists oils, acids, and moisture

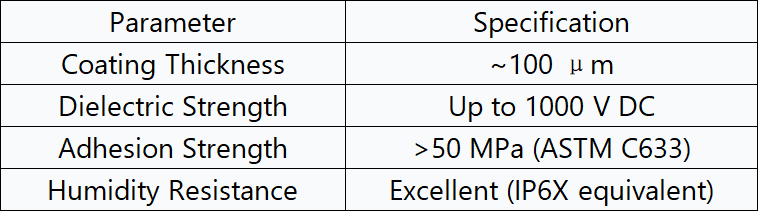

3. Product Specifications

Dimensional Range :

Bore Diameter : 40-140 mm

Outer Diameter: 80-300 mm

Width: 18-62 mm

Performance Features:

Voltage Resistance: Blocks AC/DC currents up to 1000 V

Temperature Range: -40℃ to +150℃ (short-term +200℃)

Coating Hardness: ≥800 HV (similar to bearing steel)

4. Applications

Industries:

Wind Power: Prevents generator shaft currents

Electric Vehicles: Mitigates PWM-induced bearing currents

Rail Transit: Insulates traction motor bearings

Industrial Motors: Protects VFD-driven machinery

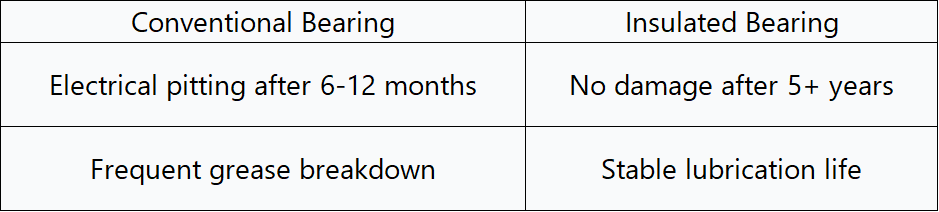

Failure Mode Comparison:

5. Luoyang Newbee's Innovations

Our third-generation plasma-sprayed insulation improves:

Coating Density: Porosity <2% (vs. 5% in conventional coatings)

Fatigue Life: 30% longer than competitors' insulated bearings

Cost Efficiency: 20% lower production cost via optimized spray parameters

Testing Standards:

IEC 60034-17 (Motor bearing current limits)

DIN 54150 (Insulation resistance testing)

6. Why Choose Insulated Bearings?

5-8x longer service life in electrified environments

Zero electrical downtime in critical applications

Retrofit-ready-Same dimensions as standard bearings

Maintenance Tip:

Periodically measure insulation resistance (>50 MΩ at 500 V DC) to ensure coating integrity.

Technical Support:

For customized solutions (e.g., hybrid ceramic bearings with insulation), contact Newbee's engineering team.