Materials

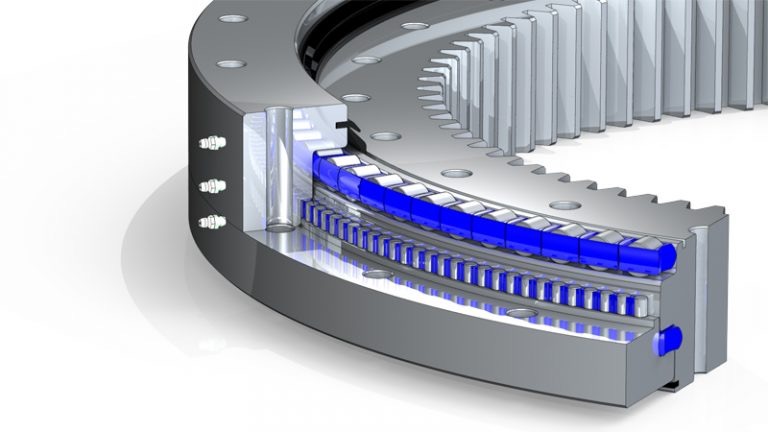

Bearing ring: 42CrMo / 50Mn / C45 (high-strength alloy steel)

Rollers: GCr15 (high-carbon chromium steel)

Cage: Steel 20 / ZL102 cast aluminum alloy

Spacer: Nylon 6 / Nylon 66

Size Range

Outer diameter: 300mm-6000mm (standard) / 100mm-15000mm (customized)

Accuracy Class: P0,P5

Sealing Options: Open type / Contact rubber seal (RS) / Metal dust cover (ZZ)

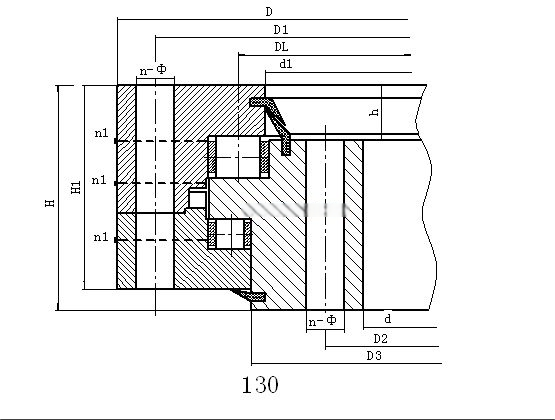

| Three row roller slewing bearing--- No gear(130 Series) | |||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Weight (kg) | |||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | mm | dmmm | Lmm | nl | D3mm | d1mm | H1mm | hmm | ||

| 130.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 474 | 463 | 4 | 10 | 32 | 224 |

| 130.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 534 | 523 | 4 | 10 | 32 | 240 |

| 130.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 604 | 593 | 4 | 10 | 32 | 270 |

| 130.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 684 | 673 | 4 | 10 | 32 | 300 |

| 130.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 770 | 759 | 4 | 10 | 40 | 500 |

| 130.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 870 | 859 | 4 | 10 | 40 | 600 |

| 130.32.1000 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 970 | 959 | 5 | 10 | 40 | 680 |

| 130.32.1120 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1090 | 1079 | 5 | 10 | 40 | 820 |

| 130.40.1250 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1213 | 1200 | 5 | 10 | 50 | 1200 |

| 130.40.1400 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1363 | 1350 | 5 | 10 | 50 | 1300 |

| 130.40.1600 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1563 | 1550 | 6 | 10 | 50 | 1520 |

| 130.40.1800 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1763 | 1750 | 6 | 10 | 50 | 1750 |

| 130.45.2000 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 1967 | 1945 | 6 | 12 | 54 | 2400 |

| 130.45.2240 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M3O | 60 | 2207 | 2185 | 6 | 12 | 54 | 2700 |

| 130.45.2500 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2467 | 2445 | 8 | 12 | 54 | 3000 |

| 130.45.2800 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2767 | 2745 | 8 | 12 | 54 | 3400 |

| 130.50.3150 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3104 | 3090 | 8 | 12 | 65 | 5000 |

| 130.50.3550 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3504 | 3490 | 8 | 258 | 65 | 5680 |

| 130.05.4000 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 3954 | 3940 | 8 | 258 | 65 | 6470 |

| 130.50.4500 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4454 | 4440 | 8 | 258 | 65 | 7320 |

| Three row roller slewing bearing--- External gear(131/132 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 131.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 537 | 526 | 4 | 138 | 32 | 80 | 0.5 | 5 | 664 | 130 | 224 |

| 132.25.500 | 6 | 664.8 | 108 | |||||||||||||||||

| 131.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 597 | 586 | 4 | 138 | 32 | 80 | 0.5 | 5 | 724 | 142 | 240 |

| 132.25.560 | 6 | 724.8 | 118 | |||||||||||||||||

| 131.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 667 | 656 | 4 | 138 | 32 | 80 | 0.5 | 6 | 808.8 | 132 | 270 |

| 132.25.630 | 8 | 806.4 | 98 | |||||||||||||||||

| 131.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 747 | 736 | 4 | 138 | 32 | 80 | 0.5 | 6 | 886.8 | 145 | 300 |

| 132.25.710 | 8 | 886.4 | 108 | |||||||||||||||||

| 131.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 841 | 830 | 4 | 172 | 40 | 120 | 0.5 | 8 | 1006.4 | 123 | 500 |

| 132.32.800 | 10 | 1008 | 98 | |||||||||||||||||

| 131.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 941 | 930 | 4 | 172 | 40 | 120 | 0.5 | 8 | 1102.4 | 135 | 600 |

| 132.32.900 | 10 | 1108 | 108 | |||||||||||||||||

| 131.32.1000 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 1041 | 1030 | 5 | 172 | 40 | 120 | 0.5 | 10 | 1218 | 119 | 680 |

| 132.32.1000 | 12 | 1221.6 | 99 | |||||||||||||||||

| 131.32.1120 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1161 | 1150 | 5 | 172 | 40 | 120 | 0.5 | 10 | 1338 | 131 | 820 |

| 132.32.1120 | 12 | 1341.6 | 109 | |||||||||||||||||

| 131.40.1250 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1300 | 1287 | 5 | 210 | 50 | 150 | 0.5 | 12 | 150.6 | 123 | 1200 |

| 132.40.1250 | 14 | 1509.2 | 105 | |||||||||||||||||

| 131.40.1400 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1450 | 1437 | 5 | 210 | 50 | 150 | 0.5 | 12 | 1665.6 | 136 | 1300 |

| 132.40.1400 | 14 | 1663.2 | 116 | |||||||||||||||||

| 131.40.1600 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1650 | 1637 | 6 | 210 | 50 | 150 | 0.5 | 14 | 1873.2 | 131 | 1520 |

| 132.40.1600 | 16 | 1868.8 | 114 | |||||||||||||||||

| 131.40 1800 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1850 | 1837 | 6 | 210 | 50 | 150 | 0.5 | 14 | 2069.2 | 145 | 1750 |

| 132.40.1800 | 16 | 2076.8 | 127 | |||||||||||||||||

| 131.45.2000 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 2055 | 2033 | 6 | 219 | 54 | 160 | 0.5 | 16 | 2300.8 | 141 | 2400 |

| 132.45.2000 | 18 | 2300.4 | 125 | |||||||||||||||||

| 131.45.2240 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M30 | 60 | 2295 | 2273 | 6 | 219 | 54 | 160 | 0.5 | 16 | 2556.8 | 157 | 2700 |

| 132.45.2240 | 18 | 2552.4 | 139 | |||||||||||||||||

| 131.45.2500 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2555 | 2533 | 8 | 219 | 54 | 160 | 0.5 | 18 | 2822.4 | 154 | 3000 |

| 132.45.2500 | 20 | 2816 | 138 | |||||||||||||||||

| 131.45.2800 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2855 | 2833 | 8 | 219 | 54 | 160 | 0.5 | 18 | 3110.4 | 170 | 3400 |

| 132.45.2800 | 20 | 3116 | 153 | |||||||||||||||||

| 131.50.3150 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3213 | 3196 | 8 | 258 | 65 | 180 | 0.5 | 20 | 3536 | 174 | 50000 |

| 132.50.3150 | 22 | 3537.6 | 158 | |||||||||||||||||

| 131.50.3550 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3613 | 3596 | 8 | 258 | 65 | 180 | 0.5 | 22 | 3936 | 194 | 5680 |

| 132.50.3550 | 22 | 393.6 | 176 | |||||||||||||||||

| 131.50.4000 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 4063 | 4046 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4395.6 | 197 | 6470 |

| 132.50.4000 | 25 | 4395 | 173 | |||||||||||||||||

| 131.50.4500 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4563 | 4546 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4901.6 | 220 | 7320 |

| 132.50.4500 | 25 | 4895 | 193 | |||||||||||||||||

| Three row roller slewing bearing--- Internal gear(133/134 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 133.25.500 | 634 | 366 | 148 | 598 | 402 | 24 | 18 | M16 | 32 | 474 | 463 | 4 | 0 | 32 | 80 | 0.5 | 5 | 337 | 68 | 224 |

| 134.25.500 | 6 | 338.4 | 57 | |||||||||||||||||

| 133.25.560 | 694 | 426 | 148 | 658 | 462 | 24 | 18 | M16 | 32 | 534 | 523 | 1 | 10 | 32 | 80 | 0.5 | 5 | 397 | 80 | 240 |

| 134.25.560 | 6 | 398.4 | 67 | |||||||||||||||||

| 133.25.630 | 764 | 496 | 148 | 728 | 532 | 28 | 18 | M16 | 32 | 604 | 593 | 4 | 10 | 32 | 80 | 0.5 | 6 | 458.4 | 77 | 270 |

| 134.25.630 | 8 | 459.2 | 58 | |||||||||||||||||

| 133.25.710 | 844 | 576 | 148 | 808 | 612 | 28 | 18 | M16 | 32 | 684 | 673 | 4 | 10 | 32 | 80 | 0.5 | 6 | 536.4 | 90 | 300 |

| 134.25.710 | 8 | 539.2 | 68 | |||||||||||||||||

| 133.32.800 | 964 | 636 | 182 | 920 | 680 | 36 | 22 | M20 | 40 | 770 | 759 | 4 | 10 | 40 | 120 | 0.5 | 8 | 595.2 | 75 | 500 |

| 134.32.800 | 10 | 594 | 60 | |||||||||||||||||

| 133.32.900 | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | M20 | 40 | 870 | 859 | 4 | 10 | 40 | 120 | 0.5 | 8 | 691.2 | 87 | 600 |

| 134.32.900 | 10 | 60 | 70 | |||||||||||||||||

| 133.32.100 | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | M20 | 40 | 970 | 959 | 5 | 10 | 40 | 120 | 0.5 | 10 | 784 | 79 | 680 |

| 134.32.100 | 12 | 784.8 | 66 | |||||||||||||||||

| 133.32.112 | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | M20 | 40 | 1090 | 1079 | 5 | 10 | 40 | 120 | 0.5 | 10 | 904 | 91 | 820 |

| 134.32.112 | 12 | 904 | 76 | |||||||||||||||||

| 133.40.125 | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | M24 | 48 | 1213 | 100 | 5 | 10 | 50 | 150 | 0.5 | 12 | 988.8 | 83 | 1200 |

| 134.40.125 | 14 | 985.6 | 71 | |||||||||||||||||

| 133.40.140 | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | M24 | 48 | 1363 | 1350 | 5 | 10 | 50 | 150 | 0.5 | 12 | 1145 | 96 | 1300 |

| 134.40.140 | 14 | 1410 | 82 | |||||||||||||||||

| 133.40.160 | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | M24 | 48 | 1563 | 1550 | 6 | 10 | 50 | 150 | 0.5 | 14 | 1336 | 96 | 1520 |

| 134.40.160 | 16 | 1334 | 84 | |||||||||||||||||

| 133.40.180 | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | M24 | 48 | 1763 | 1750 | 6 | 10 | 50 | 150 | 0.5 | 14 | 1532 | 110 | 1750 |

| 134.40.180 | 16 | 1526 | 96 | |||||||||||||||||

| 133.45.200 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | M30 | 60 | 1967 | 1945 | 6 | 12 | 54 | 160 | 0.5 | 16 | 1702 | 107 | 2400 |

| 134.45.200 | 18 | 1699 | 95 | |||||||||||||||||

| 133.45.224 | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | M30 | 60 | 2207 | 2185 | 6 | 12 | 54 | 160 | 0.5 | 16 | 1926 | 121 | 2700 |

| 134.45.224 | 18 | 1933 | 108 | |||||||||||||||||

| 133.45.250 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | M30 | 60 | 2467 | 2445 | 8 | 12 | 54 | 160 | 0.5 | 18 | 2185 | 12 | 3000 |

| 134.45.250 | 20 | 2188 | 110 | |||||||||||||||||

| 133.45.280 | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | M30 | 60 | 2767 | 2745 | 8 | 12 | 54 | 160 | 0.5 | 18 | 2491 | 139 | 3400 |

| 134.45.280 | 20 | 2488 | 125 | |||||||||||||||||

| 133.50.315 | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | M42 | 84 | 3104 | 3090 | 8 | 12 | 65 | 180 | 0.5 | 20 | 2768 | 139 | 5000 |

| 134.50.315 | 22 | 2759 | 126 | |||||||||||||||||

| 131.50.355 | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | M42 | 84 | 3504 | 3490 | 8 | 258 | 65 | 180 | 0.5 | 20 | 3168 | 159 | 5680 |

| 132.50.355 | 22 | 3155 | 144 | |||||||||||||||||

| 131.50.400 | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | M42 | 84 | 3954 | 3940 | 8 | 258 | 65 | 180 | 0.5 | 22 | 311 | 165 | 6470 |

| 132.50.400 | 25 | 3610 | 145 | |||||||||||||||||

| 131.50.450 | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | M42 | 84 | 4454 | 4440 | 8 | 258 | 65 | 180 | 0.5 | 22 | 4123 | 188 | 7320 |

| 132.50.450 | 25 | 4110 | 165 | |||||||||||||||||

No additional bearing combinations are required,simplifying the mechanical structure.

Adaptable to harsh working conditions (dust,vibration,impact).

Standardized interfaces are suitable for a variety of equipment.

Long-acting lubrication design reduces downtime.

Cranes: Rotary support for wheeled cranes and port cranes.

Excavation Equipment: Bucket-wheel excavators and heavy-duty mobile cranes.

Wind Power Generation: Rotational connection of wind turbine towers.

Metallurgical Machinery: Ladle turrets.

Ship Engineering: Marine cranes and offshore platform equipment.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.