Materials

Rings: 42CrMo, 50Mn, or C45 alloy steel (raceway hardness HRC 55-62 after quenching).

Rollers: GCr15 high-carbon chromium steel (high wear resistance).

Cage: Steel 20 or ZL102 cast aluminum alloy (lightweight and durable).

Spacers: Nylon 6/66 (low friction and thermal stability).

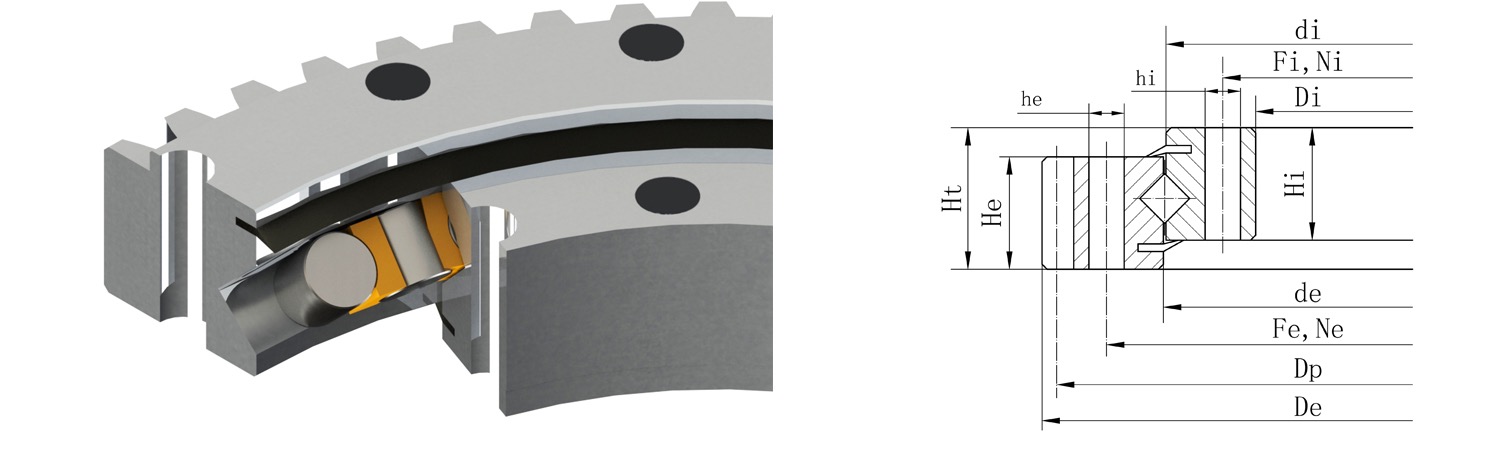

Size Range

External Diameter: 300–6,000 mm (customizable upon request).

Performance

Load Capacity: Axial ≤ 25,000 kN, radial ≤ 15,000 kN, moment ≤ 100,000 kN·m.

Speed Range: Suitable for low to moderate rotational speeds (≤20 rpm).

| Cross roller slewing bearing--- No gear(110 Series) | |||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | weight (kg) | |||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | mm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | ||

| 110.25.500 | 602 | 398 | 75 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 498 | 502 | 65 | 10 | 80 |

| 110.25.560 | 662 | 458 | 75 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 558 | 562 | 65 | 10 | 90 |

| 110.25.630 | 732 | 528 | 75 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 628 | 632 | 65 | 10 | 100 |

| 110.25.710 | 812 | 608 | 75 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 708 | 712 | 65 | 10 | 110 |

| 110.28.800 | 922 | 678 | 82 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 798 | 802 | 72 | 10 | 170 |

| 110.28.900 | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 898 | 902 | 72 | 10 | 190 |

| 110.28. 1000 | 1122 | 878 | 82 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 998 | 1002 | 72 | 10 | 210 |

| 110.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1118 | 1122 | 72 | 10 | 230 |

| 110.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1248 | 1252 | 81 | 10 | 350 |

| 110.32.1400 | 1540 | 1260 | 91 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1398 | 1402 | 81 | 10 | 400 |

| 110.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1598 | 1602 | 81 | 10 | 440 |

| 110.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1798 | 1802 | 81 | 10 | 500 |

| 110.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 1997 | 2003 | 100 | 12 | 900 |

| 110.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2237 | 2243 | 100 | 12 | 1000 |

| 110.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2497 | 2503 | 100 | 12 | 1100 |

| 110.40.2800 | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2797 | 2803 | 100 | 12 | 1250 |

| 110.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3147 | 3153 | 122 | 12 | 2150 |

| 110.50.3550 | 376 | 3322 | 134 | 3686 | 3414 | 56 | 45 | M42 | 84 | 8 | 3547 | 3553 | 122 | 12 | 2470 |

| 1 10.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 3997 | 4003 | 122 | 12 | 2800 |

| 110.50.4500 | 4726 | 4272 | 134 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4497 | 4503 | 122 | 12 | 3100 |

| Cross roller slewing bearing--- External gear(111/112 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 111.25.500 | 602 | 398 | 75 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 498 | 502 | 65 | 10 | 60 | 0.5 | 5 | 629 | 123 | 80 |

| 112.25.500 | 6 | 628.8 | 102 | |||||||||||||||||

| 111.25.560 | 662 | 458 | 75 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 558 | 562 | 65 | 10 | 60 | 0.5 | 5 | 689 | 135 | 90 |

| 112.25.560 | 6 | 688.8 | 112 | |||||||||||||||||

| 111.25.630 | 732 | 528 | 75 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 628 | 632 | 65 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 100 |

| 112.25.630 | 8 | 774.4 | 94 | |||||||||||||||||

| 111.25.710 | 812 | 608 | 75 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 708 | 712 | 65 | 10 | 60 | 0.5 | 8 | 850.8 | 139 | 110 |

| 112.25.710 | 8 | 854.4 | 104 | |||||||||||||||||

| 111.28.800 | 922 | 678 | 82 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 798 | 802 | 72 | 10 | 65 | 0.5 | 8 | 966.4 | 118 | 170 |

| 112.28.800 | 10 | 968 | 94 | |||||||||||||||||

| 111.28.900 | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 898 | 902 | 72 | 10 | 65 | 0.5 | 8 | 1062.4 | 130 | 190 |

| 112.28.900 | 10 | 1068 | 104 | |||||||||||||||||

| 111.28.1000 | 122 | 878 | 82 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 998 | 1002 | 72 | 10 | 65 | 0.5 | 10 | 1188 | 116 | 210 |

| 112.28.1000 | 12 | 1185.6 | 96 | |||||||||||||||||

| 111.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1118 | 1122 | 72 | 10 | 65 | 0.5 | 10 | 1298 | 127 | 230 |

| 112.28.1120 | 12 | 1305.6 | 106 | |||||||||||||||||

| 111.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1248 | 1252 | 81 | 10 | 75 | 0.5 | 12 | 1449.6 | 118 | 350 |

| 112.32.1250 | 14 | 1453 | 101 | |||||||||||||||||

| 111.32.1400 | 1540 | 1260 | 91 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1398 | 1402 | 81 | 10 | 75 | 0.5 | 12 | 1605.6 | 131 | 400 |

| 112.32.1400 | 14 | 1607.2 | 112 | |||||||||||||||||

| 112.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1598 | 1602 | 81 | 10 | 75 | 0.5 | 14 | 1817.2 | 127 | 440 |

| 112.32.1600 | 16 | 1820.8 | 111 | |||||||||||||||||

| 111.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1798 | 1802 | 81 | 10 | 75 | 0.5 | 14 | 2013.2 | 141 | 500 |

| 112.32.1800 | 16 | 2012.8 | 123 | |||||||||||||||||

| 111.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 1997 | 2003 | 100 | 12 | 90 | 0.5 | 16 | 2268.8 | 139 | 9000 |

| 112.40.2000 | 18 | 2264.4 | 123 | |||||||||||||||||

| 111.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2237 | 2243 | 100 | 12 | 90 | 0.5 | 16 | 2492.8 | 153 | 1000 |

| 112.40.2240 | 18 | 2498.4 | 136 | |||||||||||||||||

| 112.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2497 | 2503 | 100 | 12 | 90 | 0.5 | 18 | 2768.4 | 151 | 1100 |

| 112.40.2500 | 20 | 2776 | 136 | |||||||||||||||||

| 111.40.2800 | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2797 | 2803 | 100 | 12 | 90 | 0.5 | 18 | 3074.4 | 168 | 1250 |

| 112.40.2800 | 20 | 3076 | 151 | |||||||||||||||||

| 111.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3147 | 3153 | 122 | 12 | 110 | 0.5 | 20 | 3476 | 171 | 2150 |

| 112.50.3150 | 22 | 3471.6 | 155 | |||||||||||||||||

| 111.50.3550 | 3776 | 3322 | 134 | 3686 | 3414 | 56 | 45 | M42 | 84 | 8 | 3547 | 3553 | 122 | 12 | 110 | 0.5 | 20 | 3876 | 191 | 2470 |

| 112.50.3550 | 22 | 3889.6 | 174 | |||||||||||||||||

| 111.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 3997 | 4003 | 122 | 12 | 110 | 0.5 | 22 | 4329.6 | 194 | 2800 |

| 112.50.4000 | 25 | 4345 | 171 | |||||||||||||||||

| 111.50.4500 | 4726 | 422 | 134 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4497 | 4503 | 122 | 12 | 110 | 0.5 | 22 | 4835.6 | 217 | 3100 |

| 112.50.4500 | 25 | 4845 | 191 | |||||||||||||||||

| Cross roller slewing bearing--- Internal gear(113/114 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 113.25.500 | 602 | 398 | 75 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 498 | 502 | 65 | 10 | 60 | 0.5 | 5 | 367 | 74 | 80 |

| 114.25.500 | 6 | 368.4 | 62 | |||||||||||||||||

| 113.25.560 | 662 | 458 | 75 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 558 | 562 | 65 | 10 | 60 | 0.5 | 5 | 427 | 86 | 90 |

| 114.25.560 | 6 | 428.4 | 72 | |||||||||||||||||

| 113.25.630 | 732 | 528 | 75 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 628 | 632 | 65 | 10 | 60 | 0.5 | 6 | 494.4 | 83 | 100 |

| 114.25.630 | 8 | 491.2 | 62 | |||||||||||||||||

| 113.25.710 | 812 | 608 | 75 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 708 | 712 | 65 | 10 | 60 | 0.5 | 6 | 572.4 | 96 | 110 |

| 114.25.710 | 8 | 571.2 | 72 | |||||||||||||||||

| 113.28.800 | 922 | 678 | 82 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 798 | 802 | 72 | 10 | 65 | 0.5 | 8 | 635.2 | 80 | 170 |

| 114.28.800 | 10 | 634 | 64 | |||||||||||||||||

| 113.28.900 | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 898 | 902 | 72 | 10 | 65 | 0.5 | 8 | 739.2 | 93 | 190 |

| 114.28.900 | 10 | 734 | 74 | |||||||||||||||||

| 113.28.1000 | 1122 | 878 | 82 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 998 | 1002 | 72 | 10 | 65 | 0.5 | 10 | 824 | 83 | 210 |

| 114.28.1000 | 12 | 820.8 | 69 | |||||||||||||||||

| 113.28.1120 | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1118 | 1122 | 72 | 10 | 65 | 0.5 | 10 | 944 | 95 | 230 |

| 114.28.1120 | 12 | 940.8 | 79 | |||||||||||||||||

| 113.32.1250 | 1390 | 1110 | 91 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1248 | 1252 | 81 | 10 | 75 | 0.5 | 12 | 1048.8 | 88 | 350 |

| 114.32.1250 | 14 | 1041.6 | 75 | |||||||||||||||||

| 113.32.1400 | 1540 | 1260 | 91 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1398 | 1402 | 81 | 10 | 75 | 0.5 | 12 | 1192.8 | 100 | 400 |

| 114.32.1400 | 14 | 1195.6 | 86 | |||||||||||||||||

| 113.32.1600 | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1598 | 1602 | 81 | 10 | 75 | 0.5 | 14 | 1391.6 | 100 | 440 |

| 114.32.1600 | 16 | 1382.4 | 87 | |||||||||||||||||

| 113.32.1800 | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1798 | 1802 | 81 | 10 | 75 | 0.5 | 14 | 1573.6 | 113 | 500 |

| 114.32.1800 | 16 | 1574.4 | 99 | |||||||||||||||||

| 113.40.2000 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 1997 | 2003 | 100 | 12 | 90 | 0.5 | 16 | 1734.4 | 109 | 900 |

| 114.40.2000 | 18 | 1735.2 | 97 | |||||||||||||||||

| 113.40.2240 | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2237 | 2243 | 100 | 12 | 90 | 0.5 | 16 | 1990.4 | 125 | 1000 |

| 114.40.2240 | 18 | 1987.2 | 111 | |||||||||||||||||

| 113.40.2500 | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2497 | 2503 | 100 | 12 | 90 | 0.5 | 18 | 2239.2 | 125 | 1100 |

| 114.40.2500 | 20 | 2228 | 112 | |||||||||||||||||

| 113.40.2800 | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2797 | 2803 | 100 | 12 | 90 | 0.5 | 18 | 2527.2 | 141 | 1250 |

| 114.40.2800 | 20 | 2528 | 127 | |||||||||||||||||

| 113.50.3150 | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3147 | 3153 | 122 | 12 | 110 | 0.5 | 20 | 2628 | 14 | 2150 |

| 114.50.3150 | 22 | 2824.8 | 129 | |||||||||||||||||

| 113.50.3550 | 3776 | 3322 | 134 | 3686 | 3414 | 56 | 45 | M42 | 84 | 8 | 3547 | 3553 | 122 | 12 | 110 | 0.5 | 20 | 3228 | 162 | 2470 |

| 114.50.3550 | 22 | 3220.8 | 147 | |||||||||||||||||

| 113.50.4000 | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 3997 | 4003 | 122 | 12 | 110 | 0.5 | 22 | 3660.8 | 16 | 2800 |

| 114.50.4000 | 25 | 3660 | 47 | |||||||||||||||||

| 113.50.4500 | 4726 | 4272 | 134 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4497 | 4503 | 122 | 12 | 110 | 0.5 | 22 | 4166.8 | 190 | 3100 |

| 114.50.4500 | 25 | 4160 | 167 | |||||||||||||||||

Handles axial, radial, and moment loads without additional bearings.

Compact structure ideal for equipment with limited installation space.

Options for gear types, seals, and non-standard dimensions.

Sealed-for-life designs reduce lubrication frequency.

Cranes: Port cranes, tower cranes, and mobile crane slewing systems.

Construction Machinery: Shield tunneling machines, excavators, and pile drivers.

Radar & Telescopes: Precision rotation for radar antennas and radio telescopes.

Industrial Equipment: Steel mill rollers, robotic arms, and automated production lines.

Military Systems: Turret rotation mechanisms and missile launch platforms.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.