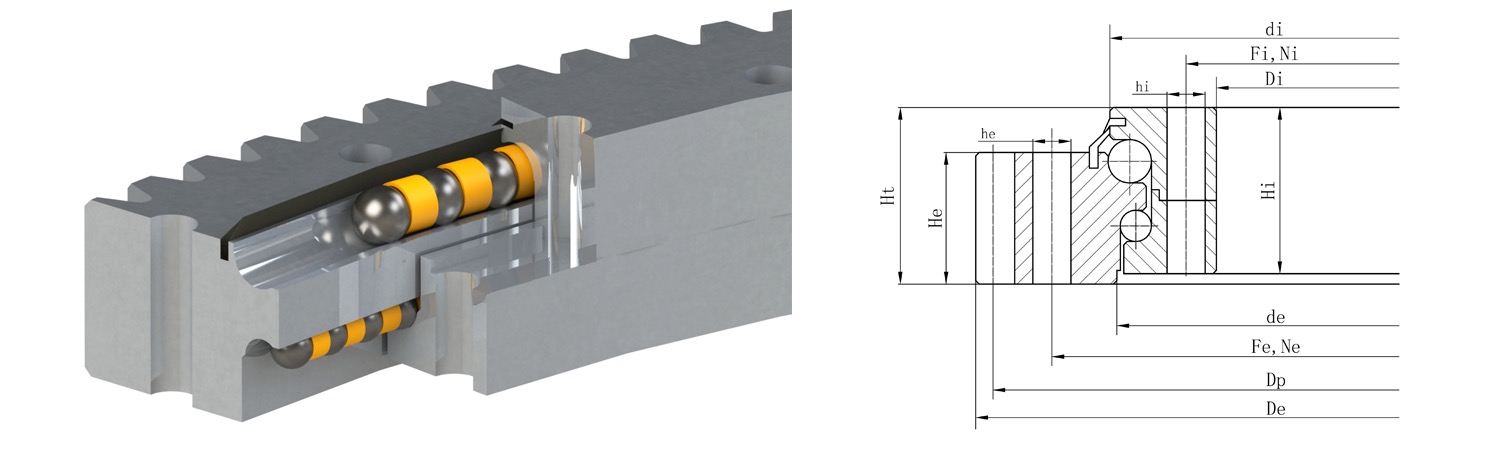

Materials:

Rings: 42CrMo&50Mn.

Balls: GCr15.

Seals: Nitrile rubber (standard) or polyurethane (enhanced dust and water resistance); in special environments,fluoropolymer seals can be selected.

Cages: Carbon steel (standard),bronze (for high-load and high-temperature environments) or high-performance engineering plastics (lightweight with good self-lubrication).

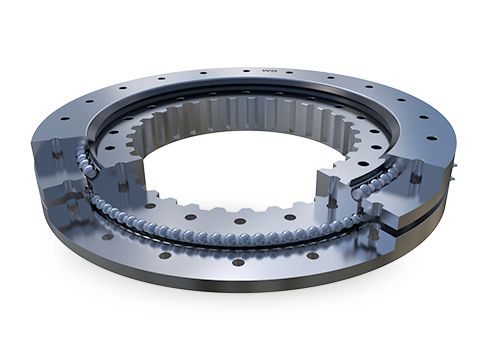

Size Range:

Inner diameter: 100-4000mm.

Outer diameter: 150-4500mm.

Height: 50-400mm.

Accuracy Classes: P0,P6,P5.

Sealing Options: Non-contact labyrinth seal (standard,suitable for general environments),triple-lip seal (for harsh environments,such as underwater or dusty environments).

| Double row ball slewing bearing--- No gear(020 Series) | |||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | weight (kg) | |||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | D3mm | d1mm | n1 | H1mm | hmm | ||

| 020.25.500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 482 | 477 | 4 | 96 | 26 | 100 |

| 020.25.560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 542 | 537 | 4 | 96 | 26 | 115 |

| 020.25.630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 612 | 607 | 4 | 96 | 26 | 130 |

| 020.25.710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 692 | 687 | 4 | 96 | 26 | 140 |

| 020.30.800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 777 | 771 | 6 | 114 | 29 | 200 |

| 020.30.900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 877 | 871 | 6 | 114 | 29 | 250 |

| 020.30.1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 977 | 971 | 6 | 114 | 29 | 300 |

| 020.30.1120 | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 1097 | 1091 | 6 | 114 | 29 | 340 |

| 020.40.1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1215 | 1214 | 5 | 150 | 39 | 580 |

| 020.40.1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1365 | 1364 | 5 | 150 | 39 | 650 |

| 020.40.1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 1565 | 1564 | 5 | 150 | 39 | 750 |

| 020.40 1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1765 | 1764 | 5 | 150 | 39 | 820 |

| 020.50.2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 1965 | 1962 | 8 | 178 | 47 | 1150 |

| 020.50.2240 | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 2206 | 2202 | 8 | 178 | 47 | 1500 |

| 020.50.2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2465 | 2462 | 8 | 178 | 47 | 1700 |

| 020.50.2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2765 | 2762 | 8 | 178 | 47 | 1900 |

| 020.60.3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3104 | 3102 | 8 | 214 | 56 | 3300 |

| 020.60.3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3504 | 3502 | 8 | 214 | 56 | 3700 |

| 020.60.4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 3954 | 3952 | 10 | 214 | 56 | 4200 |

| 020.60.4500 | 4778 | 4222 | 226 | 4288 | 4312 | 60 | 45 | 4454 | 4452 | 10 | 214 | 56 | 4700 |

| Double row ball slewing bearing--- External gear(021/022 Series) | ||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | D3mm | d1mm | n1 | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 021.25.500 022.25.500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 523 | 518 | 4 | 96 | 26 | 60 | 0.5 | 5 | 644 | 126 | 100 |

| 6 | 646.8 | 105 | ||||||||||||||||

| 021.25.560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 583 | 578 | 4 | 96 | 26 | 60 | 0.5 | 5 | 704 | 138 | 115 |

| 022.25.560 | 6 | 706.8 | 115 | |||||||||||||||

| 021.25.630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 653 | 648 | 4 | 96 | 26 | 60 | 0.5 | 6 | 790.8 | 129 | 130 |

| 022.25.630 | 8 | 790.4 | 96 | |||||||||||||||

| 021.25.710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 733 | 728 | 4 | 96 | 26 | 60 | 0.5 | 6 | 862.8 | 141 | 140 |

| 022.25.710 | 8 | 862.4 | 105 | |||||||||||||||

| 021.30.800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 829 | 823 | 6 | 114 | 29 | 80 | 0.5 | 8 | 982.4 | 120 | 200 |

| 022.30.800 | 10 | 988 | 96 | |||||||||||||||

| 021.30.900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 929 | 923 | 6 | 114 | 29 | 80 | 0.5 | 8 | 1086.4 | 133 | 250 |

| 022.30.900 | 10 | 1088 | 106 | |||||||||||||||

| 021.30.1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 1029 | 1023 | 6 | 114 | 29 | 80 | 0.5 | 10 | 1198 | 117 | 300 |

| 022.30.1000 | 12 | 1197.6 | 97 | |||||||||||||||

| 021.30.1120 | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 1148 | 1143 | 6 | 114 | 29 | 80 | 0.5 | 10 | 1318 | 129 | 340 |

| 022.30.1120 | 12 | 1317.6 | 107 | |||||||||||||||

| 021.40. 1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1286 | 1282 | 5 | 150 | 39 | 90 | 0.5 | 12 | 1497.6 | 122 | 580 |

| 022.40. 1250 | 14 | 1495.2 | 104 | |||||||||||||||

| 021.40.1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1436 | 1432 | 5 | 150 | 39 | 90 | 0.5 | 12 | 1641.6 | 134 | 650 |

| 022.40.1400 | 14 | 1649.2 | 115 | |||||||||||||||

| 021.40.1600 | 1776 | 124 | 160 | 1724 | 176 | 45 | 26 | 1636 | 1635 | 5 | 150 | 39 | 90 | 0.5 | 14 | 1845.2 | 129 | 750 |

| 022.40.1600 | 16 | 1852.8 | 113 | |||||||||||||||

| 021.40.1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1836 | 1835 | 5 | 150 | 39 | 90 | 0.5 | 14 | 2055.2 | 144 | 820 |

| 022.40.1800 | 16 | 2060.8 | 126 | |||||||||||||||

| 021.50.2000 | 2215 | 1785 | 190 | 249 | 1851 | 48 | 33 | 2038 | 2035 | 8 | 178 | 47 | 120 | 0.5 | 16 | 2300.8 | 141 | 1150 |

| 022.50.2000 | 18 | 2300.4 | 125 | |||||||||||||||

| 021.50.2240 | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 278 | 2275 | 8 | 178 | 47 | 120 | 0.5 | 6 | 2540.8 | 156 | 1500 |

| 022.50.2240 | 18 | 2552.4 | 139 | |||||||||||||||

| 021.50.2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2538 | 2532 | 8 | 178 | 47 | 120 | 0.5 | 18 | 2804.4 | 153 | 1700 |

| 022.50.2500 | 20 | 2816 | 138 | |||||||||||||||

| 021.50.2800 022.50.2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2838 | 2832 | 8 | 178 | 47 | 120 | 0.5 | 18 | 3110.4 | 170 | 1900 |

| 20 | 3116 | 153 | ||||||||||||||||

| 021.60.3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3198 | 3196 | 8 | 214 | 56 | 150 | 0.5 | 20 | 3536 | 174 | 3300 |

| 022.60.3150 | 22 | 3537.6 | 158 | |||||||||||||||

| 021.60.3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3598 | 3596 | 8 | 214 | 56 | 150 | 0.5 | 20 | 3936 | 94 | 3700 |

| 022.60.3550 | 22 | 3933.6 | 176 | |||||||||||||||

| 021.60.4000 022.60.4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 4048 | 4046 | 10 | 214 | 56 | 150 | 0.5 | 22 | 4395.6 | 197 | 4200 |

| 25 | 4395 | 13 | ||||||||||||||||

| 021.60.4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 4548 | 4546 | 10 | 214 | 56 | 150 | 0.5 | 22 | 4879.6 | 219 | 4700 |

| 022.60.4500 | 25 | 4895 | 193 | |||||||||||||||

| Double row ball slewing bearing--- External gear(023/024 Series) | ||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | φmm | D3mm | d1mm | n1 | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 023.25.500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 482 | 477 | 4 | 96 | 26 | 60 | 0.5 | 5 | 257 | 72 | 100 |

| 024.25.500 | 6 | 350.4 | 59 | |||||||||||||||

| 023.25.560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 542 | 537 | 4 | 96 | 26 | 60 | 0.5 | 5 | 417 | 84 | 115 |

| 024.25.560 | 6 | 410.4 | 69 | |||||||||||||||

| 023.25.630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 612 | 607 | 4 | 96 | 26 | 60 | 0.5 | 6 | 482.4 | 81 | 130 |

| 024.25.630 | 8 | 475.2 | 60 | |||||||||||||||

| 023.25.710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 692 | 687 | 4 | 96 | 26 | 60 | 0.5 | 6 | 560.4 | 94 | 140 |

| 024.25.710 | 8 | 555.2 | 70 | |||||||||||||||

| 023.30.800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 777 | 771 | 6 | 114 | 29 | 80 | 0.5 | 8 | 619.2 | 78 | 200 |

| 024.30.800 | 10 | 614 | 62 | |||||||||||||||

| 023.30.900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 877 | 871 | 6 | 114 | 29 | 80 | 0.5 | 8 | 715.2 | 90 | 250 |

| 024.30.900 | 10 | 714 | 72 | |||||||||||||||

| 023.30. 1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 977 | 971 | 6 | 114 | 29 | 80 | 0.5 | 10 | 814 | 82 | 300 |

| 024.30.1000 | 12 | 796.8 | 67 | |||||||||||||||

| 023.30.1120 | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 1097 | 1091 | 6 | 114 | 29 | 80 | 0.5 | 10 | 924 | 93 | 340 |

| 024.30.1120 | 12 | 916.8 | 77 | |||||||||||||||

| 023.40.1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1215 | 1214 | 5 | 150 | 39 | 90 | 0.5 | 12 | 1012.8 | 85 | 580 |

| 024.40.1250 | 14 | 1013.6 | 73 | |||||||||||||||

| 023.40.1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1365 | 1364 | 5 | 150 | 39 | 90 | 0.5 | 12 | 1156.8 | 97 | 650 |

| 024.40.1400 | 14 | 1153.6 | 83 | |||||||||||||||

| 023.40.1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 1565 | 1564 | 5 | 150 | 39 | 90 | 0.5 | 14 | 1349.6 | 97 | 750 |

| 024.40. 1600 | 16 | 1350.4 | 85 | |||||||||||||||

| 023.40. 1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1765 | 1764 | 5 | 150 | 39 | 90 | 0.5 | 14 | 1545.6 | 111 | 820 |

| 024.40.1800 | 16 | 1542.4 | 97 | |||||||||||||||

| 023.50.2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 1965 | 1962 | 8 | 178 | 47 | 120 | 0.5 | 16 | 1702.4 | 107 | 1150 |

| 024.50.2000 | 18 | 1699.2 | 95 | |||||||||||||||

| 023.50.2240 | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 2206 | 2202 | 8 | 178 | 47 | 120 | 0.5 | 16 | 1942.4 | 122 | 1500 |

| 024.50.2240 | 18 | 133.2 | 108 | |||||||||||||||

| 023.50.2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2465 | 2462 | 8 | 178 | 47 | 120 | 0.5 | 18 | 2203.2 | 123 | 1700 |

| 024.50.2500 | 20 | 2188 | 110 | |||||||||||||||

| 023.50.2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2765 | 2762 | 8 | 178 | 47 | 120 | 0.5 | 18 | 2491.2 | 139 | 1900 |

| 024.50.2800 | 20 | 2488 | 125 | |||||||||||||||

| 023.60.3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3104 | 3102 | 8 | 214 | 56 | 150 | 0.5 | 20 | 2768 | 139 | 3300 |

| 024.60.3150 | 22 | 2758.8 | 126 | |||||||||||||||

| 023.60.3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3504 | 3502 | 8 | 214 | 56 | 150 | 0.5 | 20 | 3168 | 159 | 3700 |

| 024.60.3550 | 22 | 3176.8 | 145 | |||||||||||||||

| 023.60.4000 024.60.4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 3954 | 3952 | 10 | 214 | 56 | 150 | 0.5 | 22 | 3616.8 | 165 | 4200 |

| 2 | 3600 | 145 | ||||||||||||||||

| 023.60.4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 4454 | 4452 | 10 | 214 | 56 | 150 | 0.5 | 22 | 4122.8 | 188 | 4700 |

| 024.60.4500 | 25 | 4110 | 165 | |||||||||||||||

It can handle multiple loads simultaneously without additional bearing combinations,simplifying the equipment structure.

It can still maintain good rotational accuracy and stability under heavy loads and complex working conditions.

It is suitable for heavy-duty equipment in various harsh environments and different industries.

4.Reasonable structural design and high-quality materials reduce the frequency of failures and lower the maintenance cost.

Construction Machinery: Key rotating parts of tower cranes,excavators,concrete pump trucks,etc.

Renewable Energy: Yaw and pitch systems of wind turbines.

Industrial Equipment: Rotary kilns,large-scale port cranes,rotating worktables of automated production lines.

Military Equipment: Rotating bases of radar antennas,slewing mechanisms of missile launchers.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.