Materials

Rings: 42CrMo, 50Mn, or C45 alloy steel (raceway hardness HRC 55-62 after quenching).

Balls: GCr15 high-carbon chromium steel (high wear resistance).

Cage: Steel 20 or ZL102 cast aluminum alloy (lightweight and corrosion-resistant).

Spacers: Nylon 6/66 (low friction and thermal stability).

Size Range

External Diameter: 300–10,000 mm (customizable upon request).

Gear Options: No gear, internal gear, or external gear.

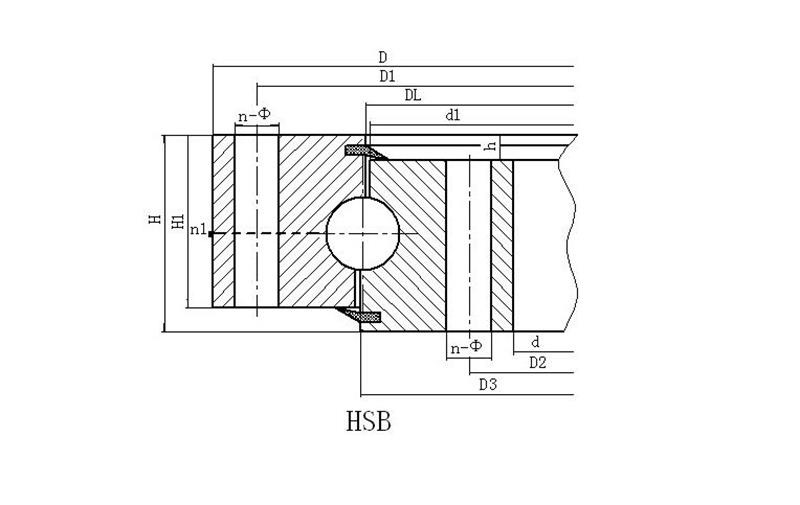

| Four point contact ball slewing bearing--- No gear(010 Series) | |||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | weight (kg) | |||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | mm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | ||

| 010.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 20 |

| 010.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 22 |

| 010.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 25 |

| 010.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 28 |

| 010.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 44 |

| 010.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 49 |

| 010.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 56 |

| 010.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 62 |

| 010.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 498 | 70 | 10 | 85 |

| 01025.500 | 1602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 | 70 | 10 | 85 |

| 010.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 558 | 70 | 10 | 95 |

| 010.25.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 | 70 | 10 | 95 |

| 010.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 628 | 70 | 10 | 110 |

| 010.25.630 | I732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 | 70 | 10 | 110 |

| 010.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 708 | 70 | 10 | 120 |

| 010.25.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 | 70 | 10 | 120 |

| 010.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 220 |

| 010.30.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 220 |

| 010.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 240 |

| 010.30.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 240 |

| 010.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 270 |

| 010.30.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 270 |

| 010.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 300 |

| 010.30.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 300 |

| 010.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 420 |

| 010.35.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1251 | 1248 | 100 | 10 | 420 |

| 010.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 480 |

| 010.35.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1401 | 1398 | 100 | 10 | 480 |

| 011.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 550 |

| 010.35.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1601 | 1598 | 100 | 10 | 550 |

| 010.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1802 | 1798 | 100 | 10 | 610 |

| 010.35.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1801 | 1798 | 100 | 10 | 610 |

| 010.60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2002 | 1998 | 132 | 12 | 1100 |

| 010.40.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2001 | 1998 | 132 | 12 | 1100 |

| 010.60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2242 | 2238 | 132 | 12 | 1250 |

| 010.40.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2241 | 2238 | 132 | 12 | 1250 |

| 010.60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2502 | 2498 | 132 | 12 | 1400 |

| 010.40.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2501 | 2498 | 132 | 12 | 1400 |

| 010.60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 1600 |

| 010.40.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 1600 |

| 010.75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 2800 |

| 010.50.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 2800 |

| 010.75.3550 | 3776 | 3322 | 174 | 3686 | 3014 | 56 | 45 | M42 | 84 | 8 | 3552 | 3547 | 162 | 12 | 3500 |

| 010.50.3550 | 3776 | 3322 | 174 | 3686 | 3014 | 56 | 45 | M42 | 84 | 10 | 3552 | 3548 | 162 | 12 | 3500 |

| 010.75.4000 | 4226 | 3772 | 174 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 4002 | 3997 | 162 | 12 | 4200 |

| 010.50.4000 | 4226 | 3772 | 174 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 4002 | 3998 | 162 | 12 | 4200 |

| 010.75.4500 | 4726 | 4272 | 174 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4502 | 4497 | 162 | 12 | 5100 |

| 010.50.4500 | 4726 | 4272 | 174 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4502 | 4498 | 162 | 12 | 5100 |

| Four point contact ball slewing bearing--- External gear(011/012 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | omm | dmmm | Lmm | n1 | D3mm | d1mm | H1mm | hmm | bmm | x | Mmm | Demm | z | ||

| 011.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 90 | 0.5 | 12 | 1605.6 | 131 | 480 |

| 012.45.1400 | 14 | 1607.2 | 112 | |||||||||||||||||

| 011.35.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1401 | 1398 | 100 | 10 | 90 | 0.5 | 12 | 1605.6 | 131 | 480 |

| 012.35.1400 | 14 | 1607.2 | 112 | |||||||||||||||||

| 011.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 90 | 0.5 | 14 | 1817.2 | 127 | 550 |

| 012.45.1600 | 16 | 1820.8 | 111 | |||||||||||||||||

| 011.35.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1601 | 1598 | 100 | 10 | 90 | 0.5 | 14 | 1817.2 | 127 | 550 |

| 012.35.1600 | 16 | 1820.8 | 111 | |||||||||||||||||

| 011.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1802 | 1798 | 100 | 10 | 90 | 0.5 | 14 | 2013.2 | 141 | 610 |

| 012.45.1800 | 16 | 2012.8 | 123 | |||||||||||||||||

| 011.35.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1801 | 1798 | 100 | 10 | 90 | 0.5 | 14 | 2013.2 | 141 | 610 |

| 012.35.1800 | 16 | 2012.8 | 123 | |||||||||||||||||

| 011.60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2002 | 1998 | 132 | 12 | 120 | 0.5 | 16 | 2268.8 | 139 | 1100 |

| 012.60.2000 | 18 | 2264.4 | 123 | |||||||||||||||||

| 011.40.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2001 | 1998 | 132 | 12 | 120 | 0.5 | 16 | 2268.8 | 139 | 1100 |

| 012.40.2000 | 18 | 2264.4 | 123 | |||||||||||||||||

| 011.60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2242 | 2238 | 132 | 12 | 120 | 0.5 | 16 | 2492.8 | 153 | 1250 |

| 012.60.2240 | 18 | 2498.4 | 136 | |||||||||||||||||

| 011.40.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2241 | 2238 | 132 | 12 | 120 | 0.5 | 16 | 2492.8 | 153 | 1250 |

| 012.40.2240 | 18 | 2498.4 | 136 | |||||||||||||||||

| 011.60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2502 | 2498 | 132 | 12 | 120 | 0.5 | 18 | 2768.4 | 151 | 1400 |

| 012.60.2500 | 20 | 2776 | 136 | |||||||||||||||||

| 011.40.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2501 | 2498 | 132 | 12 | 120 | 0.5 | 18 | 2768.4 | 151 | 1400 |

| 012.40.2500 | 20 | 2776 | 136 | |||||||||||||||||

| 011.60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 120 | 0.5 | 18 | 3074.4 | 168 | 1600 |

| 012.60.2800 | 20 | 3076 | 151 | |||||||||||||||||

| 011.40.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 120 | 0.5 | 18 | 3074.4 | 168 | 1600 |

| 012.40.2800 | 20 | 3076 | 151 | |||||||||||||||||

| 011.75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 150 | 0.5 | 20 | 3476 | 171 | 2800 |

| 012.75.3150 | 22 | 3471.6 | 155 | |||||||||||||||||

| 011.50.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 150 | 0.5 | 20 | 3476 | 171 | 2800 |

| 012.50.3150 | 22 | 3471.6 | 155 | |||||||||||||||||

| 011.75.3550 | 3776 | 3322 | 174 | 3686 | 3014 | 56 | 45 | M42 | 84 | 8 | 3552 | 3547 | 162 | 12 | 150 | 0.5 | 20 | 3876 | 191 | 3500 |

| 012.75.3550 | 22 | 3889.6 | 174 | |||||||||||||||||

| 011.50.3550 | 3776 | 3322 | 174 | 3686 | 3014 | 56 | 45 | M42 | 84 | 10 | 3552 | 3548 | 162 | 12 | 150 | 0.5 | 20 | 3876 | 191 | 3500 |

| 012.50.3550 | 22 | 3889.6 | 174 | |||||||||||||||||

| 011.75.4000 | 4226 | 3772 | 174 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 4002 | 3997 | 162 | 12 | 150 | 0.5 | 22 | 4329.6 | 194 | 4200 |

| 012.75.4000 | 25 | 4345 | 171 | |||||||||||||||||

| 011.50.4000 | 4226 | 3772 | 174 | 4136 | 3864 | 60 | 45 | M42 | 84 | 10 | 4002 | 3998 | 162 | 12 | 150 | 0.5 | 22 | 4329.6 | 194 | 4200 |

| 012.50.4000 | 25 | 4345 | 171 | |||||||||||||||||

| 011.75.4500 | 4726 | 4272 | 174 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4502 | 4497 | 162 | 12 | 150 | 0.5 | 22 | 4835.6 | 217 | 5100 |

| 012.75.4500 | 25 | 4845 | 191 | |||||||||||||||||

| 011.50.4500 | 4726 | 4272 | 174 | 4636 | 4364 | 60 | 45 | M42 | 84 | 10 | 4502 | 4498 | 162 | 12 | 150 | 0.5 | 22 | 4835.6 | 217 | 5100 |

| 012.50.4500 | 25 | 4845 | 191 | |||||||||||||||||

| Four point contact ball slewing bearing--- Internal gear(013/014 Series) | ||||||||||||||||||||

| Bearing Model | Dimensions | Mounting Dimensions | Structural Dimension | Gear data | weight (kg) | |||||||||||||||

| Dmm | dmm | Hmm | D1mm | D2mm | n | mm | dmmm | Lmm | n1 | D3mm | d1mm | HImm | hmm | bmm | x | Mmm | Demm | z | ||

| 013.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 50 | 0 | 5 | 190 | 40 | 49 |

| 013.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 50 | 0 | 5 | 235 | 49 | 54 |

| 013.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 50 | 0 | 6 | 276 | 48 | 62 |

| 013.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 50 | 0 | 6 | 324 | 56 | 71 |

| 013.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 498 | 70 | 10 | 60 | 0.5 | 5 | 367 | 74 | 85 |

| 014.30.500 | 6 | 368.4 | 62 | |||||||||||||||||

| 013.25.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 | 70 | 10 | 60 | 0.5 | 5 | 367 | 74 | 85 |

| 014.25.500 | 6 | 368.4 | 62 | |||||||||||||||||

| 013.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 558 | 70 | 10 | 60 | 0.5 | 5 | 427 | 86 | 95 |

| 014.30.560 | 6 | 428.4 | 72 | |||||||||||||||||

| 013.25.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 | 70 | 10 | 60 | 0.5 | 5 | 427 | 86 | 95 |

| 014.25.560 | 6 | 428.4 | 72 | |||||||||||||||||

| 013.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 628 | 70 | 10 | 60 | 0.5 | 6 | 494.4 | 83 | 110 |

| 014.30.630 | 8 | 491.2 | 62 | |||||||||||||||||

| 013.25.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 | 70 | 10 | 60 | 0.5 | 6 | 494.4 | 83 | 110 |

| 014.25.630 | 8 | 491.2 | 62 | |||||||||||||||||

| 013.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 708 | 70 | 10 | 60 | 0.5 | 6 | 572.4 | 96 | 120 |

| 014.30.710 | 8 | 571.2 | 72 | |||||||||||||||||

| 013.25.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 | 70 | 10 | 60 | 0.5 | 6 | 572.4 | 96 | 120 |

| 014.25.710 | 8 | 571.2 | 72 | |||||||||||||||||

| 013.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 635.2 | 80 | 220 |

| 014.40.800 | 10 | 634 | 64 | |||||||||||||||||

| 013.30.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 635.2 | 80 | 220 |

| 014.30.800 | 10 | 634 | 64 | |||||||||||||||||

| 013.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 739.2 | 93 | 240 |

| 014.40.900 | 10 | 734 | 74 | |||||||||||||||||

| 013.30.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 739.2 | 93 | 240 |

| 014.30.900 | 10 | 734 | 74 | |||||||||||||||||

| 013.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 824 | 83 | 270 |

| 014.40.1000 | 12 | 820.8 | 69 | |||||||||||||||||

| 013.30.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 824 | 83 | 270 |

| 014.30.1000 | 12 | 820.8 | 69 | |||||||||||||||||

| 013.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 944 | 95 | 300 |

| 014.40.1120 | 12 | 940.8 | 79 | |||||||||||||||||

| 013.30.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 944 | 95 | 300 |

| 014.30.1120 | 12 | 940.8 | 79 | |||||||||||||||||

| 013.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 90 | 0.5 | 12 | 1049 | 88 | 420 |

| 014.45.1250 | 14 | 1042 | 75 | |||||||||||||||||

| 013.35.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1251 | 1248 | 100 | 10 | 90 | 0.5 | 12 | 1049 | 88 | 420 |

| 014.35.1250 | 14 | 11042 | 75 | |||||||||||||||||

Handles axial, radial, and moment loads in a single bearing.

Options for gears, seals, and non-standard dimensions.

Sealed-for-life designs reduce lubrication frequency.

Disc cage configurations support higher rotational speeds.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.