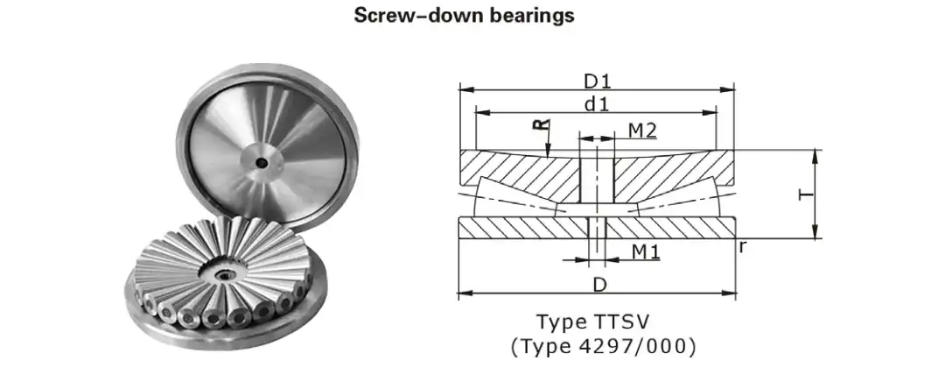

A Screw Down Bearing is a heavy-duty, full-complement tapered roller thrust bearing designed for rolling mills, handling extremely high axial loads and allowing angular movement of the screw spindle to precisely adjust metal thickness, featuring long, large-diameter rollers and often a sphered washer for alignment.

Features: Inner Ring & Outer Ring: Reinforced integral structure (deformation-resistant design); Roller Arrangement: Uniformly distributed cylindrical rollers (optimized contact area, bears radial and axial extreme loads);

Accuracy : P0, P6, P5;

Size:Inner Diameter (d1): 127–700 mm; Outer Diameter (D): 150–800 mm; Thickness (T): 48–270 mm;

Materials: Bearing Rings & Rollers: GCr15 high-carbon chromium steel , G20Cr2Ni4A alloy carburized steel or Chrome steel ; Cages: Brass or heavy-load dedicated composite materials ;

Delivery: Standard models (TTSV/TTSX series): 7–15 days;Customized models :Please contact the manufacturer.

| Screw Down Bearings | |||||||||||

| Designations | Boundary dimensions | Basic load ratings | Mass | ||||||||

| Current | Original | mm | KN | kg | |||||||

| D | D1 | d1 | T | R | M1 | M2 | rmin | Coa | |||

| NB.TTSV150 | 4297/150 | 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | 5 |

| NB.TTSV175 | 4297/175 | 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | 8 |

| NB.TTSV203 | 42971203 | 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | 11 |

| NB.TTSV205 | 42971205 | 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | 15 |

| NB.TTSV235 | 42971235 | 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | 18 |

| NB.TTSV265 | 4297/265 | 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | 24 |

| NB.TTSV320 | 4297/320 | 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | 42 |

| NB.TTSV377 | 4297/377 | 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | 86 |

| NB.TTSV380 | 4297/380 | 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | 67 |

| NB.TTSV410 | 42971410 | 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | 115 |

| NB.TTSV440 | 4297/440 | 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | 140 |

| NB.TTSV495 | 42971495 | 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | 198 |

| NB.TTSV525 | 4297/525 | 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | 210 |

| NB.TTSV555 | 4297/555 | 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | 275 |

| NB.TTSV580 | 4297/580 | 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | 250 |

| NB.TTSV610 | 4297/610 | 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | 350 |

| NB.TTSV640 | 4297/640 | 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | 410 |

| NB.TTSX150 | 4379/150 | 150 | 148 | 127 | 55 | 457.2 | M12 | - | 1.5 | 1630 | 7 |

| NB.TTSX175 | 4379/175 | 175 | 173 | 152 | 62 | 457 | M12 | - | 1.5 | 2180 | 11 |

| NB.TTSX205 | 4379/205 | 205 | 203 | 178 | 76 | 508 | M20 | - | 1.5 | 2540 | 18 |

| NB.TTSX235 | 4379/235 | 235 | 233 | 208 | 85 | 560 | M20 | - | 1.5 | 3370 | 26 |

| NB.TTSX265 | 4379/265 | 265 | 263 | 229 | 95 | 609.6 | M20 | - | 1.5 | 4130 | 37 |

| NB.TTSX320 | 4379/320 | 320 | 318 | 280 | 112 | 762 | M20 | - | 2.5 | 7370 | 62 |

| NB.TTSX380 | 4379/380 | 380 | 378 | 330 | 129 | 914.4 | M24 | M30 | 1.5 | 8550 | 101 |

| NB.TTSX410 | 4379/410 | 410 | 408 | 355 | 142 | 1016 | M24 | M30 | 3 | 11300 | 130 |

| NB.TTSX440 | 4379/440 | 440 | 438 | 380 | 152 | 1016 | M24 | M36 | 3 | 18500 | 160 |

| NB.TTSX495 | 4379/495 | 495 | 492 | 432 | 172 | 1066.8 | M24 | M36 | 3 | 19100 | 210 |

| NB.TTSX525 | 4379/525 | 525 | 522 | 460 | 180 | 1270 | M24 | M36 | 3 | 20380 | 250 |

| NB.TTSX555 | 4379/555 | 555 | 552 | 482 | 192 | 1270 | M24 | M36 | 3 | 21380 | 280 |

| NB.TTSX580 | 4379/580 | 580 | 577 | 510 | 195 | 1422.4 | M24 | M36 | 3 | 21540 | 310 |

| NB.TTSX610 | 4379/610 | 610 | 607 | 533 | 205 | 1520 | M30 | M42 | 3 | 24170 | 410 |

| NB.TTSX640 | 4379/640 | 640 | 637 | 550 | 214.8 | 1740 | M30 | M42 | 3 | 28670 | 450 |

| NB.TTSX710 | 4379/710 | 710 | 705 | 610 | 250 | 1600 | M30 | M42 | 4 | 31540 | 850 |

| NB.TTSX750 | 4379/750 | 750 | 745 | 650 | 260 | 1600 | M30 | M48 | 4 | 38430 | 750 |

| NB.TTSX800 | 4379/800 | 800 | 795 | 700 | 270 | 1700 | M30 | M48 | 5 | 40150 | 930 |

Maximum axial load up to 40150 kN, adapting to the combined load requirements of ultra-heavy equipment, leading in the industry.

Operating temperature of -40°C to +200°C, dustproof and impact-resistant, perfectly fitting harsh working conditions such as metallurgy and mining.

Reinforced integral structure, outstanding deformation resistance, ensuring operational stability under extreme loads.

Technical indicators aligned with international brands, stable supply, procurement cost reduced by 20%-30%, adapting to the import substitution needs of heavy-load equipment.

Supports customization of size, material, lubrication and seal, covering the adaptation needs of special equipment in multiple industries.

Applications of Screw Down Bearings

1. Rolling Mills (Primary Application)

Hot rolling mills

Cold rolling mills

Plate mills

Strip mills

Used in screwdown systems to precisely control the roll gap and rolling pressure.

2. Steel & Metallurgical Equipment

Blooming mills

Slabbing mills

Steckel mills

They withstand enormous axial forces generated during metal deformation.

3. Heavy Industrial Presses

Forging presses

Hydraulic presses

Provide accurate axial positioning under heavy load.

4. Non-Ferrous Metal Processing

Aluminum rolling mills

Copper rolling mills

Ensure stable thickness control and repeatable positioning.

5. Mining & Heavy Industrial Machinery

Crushers

Compactors

Used where heavy axial force transmission and rigidity are required.

6. Large Screw Mechanisms

Jack screws

Lifting systems

Positioning screws

Handle heavy thrust loads with high precision.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.