A Large Cylindrical Roller Bearing (CRB) is a heavy-duty mechanical component using cylindrical rollers instead of balls to support immense radial loads, offering high rigidity, speed capability, and a large contact area for industrial applications like rolling mills, gearboxes, and heavy machinery, with designs allowing for axial movement or handling one-directional axial loads.

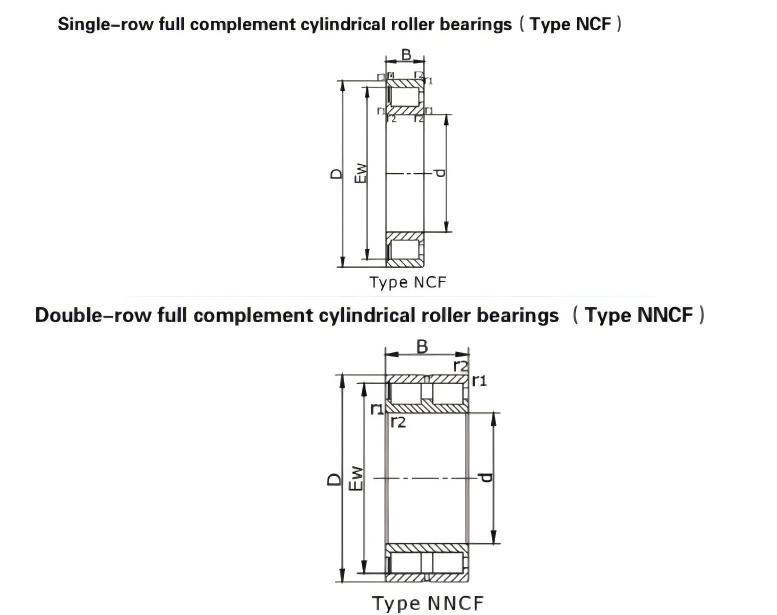

Features: Inner Ring: Separable or integral structure (optional); Outer Ring: Separable or integral structure (optional); Roller Arrangement: Large-size cylindrical rollers (parallel distribution, caged or full complement, line contact);

Accuracy: P0, P6, P5, P4;

Size:Inner Diameter: 90–1400 mm; Outer Diameter: 140–1900 mm; Width: 70–1360 mm;

Materials: Bearing Rings & Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel ; Cages: Brass , reinforced Nylon 66 , or stamped steel ;

Delivery: Standard models: 10–20 days ; Customized models:Please contact the manufacturer.

| Large Cylindrical Roller Bearing | |||||||||||||||

| Designations | Boundary dimensions | Basic load ratings | Installation dimersion | Mass | |||||||||||

| mm | kN | mm | |||||||||||||

| Current | Original | d | D | B | Fw | rmin | r1min | Cr | Cor | damin | Damin | Damax | ramax | rbmax | kg |

| NB.FC182870 | 672718 | 90 | 140 | 70 | 105 | 1.5 | 1.1 | 222 | 454 | 98 | 126 | 132 | 1 | 1 | 4.4 |

| NB.FC182874 | 140 | 74 | 105 | 1.5 | 1.1 | 222 | 454 | 98 | 126 | 132 | 1 | 1 | 4.5 | ||

| NB.FC202870 | 672820 | 100 | 140 | 70 | 111 | 1.5 | 1.1 | 194 | 416 | 108 | 129 | 135 | 1 | 1 | 3.5 |

| NB.FC202890 | 140 | 90 | 111 | 1.5 | 1.1 | 290 | 616 | 108 | 129 | 135 | 1 | 1 | 4.3 | ||

| NB.FC2028104 | 672720 | 140 | 104 | 111 | 1.5 | 1.1 | 335 | 730 | 108 | 129 | 135 | 1 | 1 | 5.1 | |

| NB.FC202970 | 6727 20K | 145 | 70 | 113 | 1.5 | 1.1 | 219 | 457 | 108 | 133 | 137 | 1 | 1 | 4.1 | |

| NB.FC2030106 | 150 | 106 | 113 | 1.5 | 1.1 | 347 | 736 | 6.8 | |||||||

| NB.FC223080 | 110 | 150 | 80 | 122 | 1.5 | 1.1 | 241 | 602 | 4.4 | ||||||

| NB.FC223490 | 170 | 90 | 127 | 2 | 2 | 358 | 754 | 121 | 155 | 159 | 2 | 2 | 7.9 | ||

| NB.FC2234120 | 672722 | 170 | 120 | 127 | 2 | 2 | 605 | 1060 | 121 | 155 | 159 | 2 | 2 | 10.6 | |

| NB.FC2242170 | 210 | 170 | 136.5 | 2 | 2 | 923 | 1610 | 27.3 | |||||||

| NB.FC243692 | 120 | 180 | 92 | 137 | 2 | 2 | 375 | 820 | 128 | 165 | 169 | 2 | 1 | 8.7 | |

| NB.FC2436105 | 672724 | 180 | 105 | 136 | 2 | 2 | 459 | 894 | 128 | 165 | 169 | 2 | 1 | 9.8 | |

| NB.FC2436120 | 180 | 120 | 136 | 2 | 2 | 477 | 1061 | 128 | 165 | 169 | 2 | 1 | 11.2 | ||

| NB.FC 2640104 | 130 | 200 | 104 | 149 | 2 | 2 | 478 | 1006 | 141 | 183 | 189 | 2 | 2 | 12.5 | |

| NB.FC 2640125 | 672726 | 200 | 125 | 149 | 2 | 2 | 738 | 1220 | 141 | 183 | 189 | 2 | 2 | 15 | |

| NB.FC 2842100 | 140 | 210 | 100 | 158 | 2 | 2 | 503 | 1096 | 151 | 192 | 199 | 1.5 | 1.5 | 12.8 | |

| NB.FC 2842106 | 210 | 106 | 158 | 2 | 2 | 503 | 1096 | 151 | 192 | 199 | 1.5 | 15 | 13.6 | ||

| NB.FC 2842125 | 672728 | 210 | 125 | 158 | 2 | 2 | 718 | 1365 | 151 | 192 | 199 | 1.5 | 15 | 15.8 | |

| NB.FC 2842155 | 210 | 155 | 158 | 2 | 2 | 756 | 1774 | 151 | 192 | 199 | 1.5 | 15 | 19.6 | ||

| NB.FC 2942155 | 145 | 210 | 155 | 166 | 2 | 2 | 720 | 1560 | 154 | 196 | 201 | 1 | 1 | 20 | |

| NB.FC 2945156 | 672729 | 225 | 156 | 169 | 2 | 2 | 815 | 1660 | 156 | 205 | 214 | 2 | 2 | 24.4 | |

| NB.FC 3045120 | 150 | 225 | 120 | 169 | 2 | 2 | 788 | 1586 | 161 | 207 | 216 | 1.5 | 1.5 | 17.5 | |

| NB.FC 3045150 | 225 | 150 | 169 | 2 | 2 | 865 | 1770 | 161 | 207 | 216 | 1.5 | 1.5 | 21 | ||

| NB.FC 3046156 | 672730 | 230 | 156 | 174 | 2 | 2 | 840 | 1760 | 161 | 210 | 219 | 2 | 2 | 24.6 | |

| NB.FC 3246130 | 160 | 230 | 130 | 180 | 2 | 2 | 781 | 1384 | 171 | 214 | 219 | 1.5 | 1.5 | 22.7 | |

| NB.FC 3246168 | 230 | 168 | 179 | 3 | 2 | 818 | 2218 | 171 | 214 | 219 | 2 | 2 | 24.2 | ||

| NB.FC 3248124 | 6727 32K | 240 | 124 | 183 | 2.1 | 2.1 | 690 | 1543 | 172 | 219 | 228 | 2 | 2 | 20.6 | |

| NB.FC 3248168 | 672732 | 240 | 168 | 183 | 2.1 | 2.1 | 947 | 2310 | 172 | 219 | 228 | 2 | 2 | 28 | |

| NB.FC 3252168 | 260 | 168 | 183 | 2.5 | 2.1 | 953 | 2326 | 38.2 | |||||||

| NB.FC 3446130 | 170 | 230 | 130 | 188.5 | 2 | 2 | 680 | 1720 | 181 | 215 | 219 | 2 | 2 | 16.3 | |

| NB.FC 3446152 | 230 | 152 | 186 | 2 | 2 | 765 | 1790 | 181 | 215 | 219 | 2 | 2 | 17.4 | ||

| NB.FC 3446180 | 230 | 180 | 186 | 2 | 2 | 707 | 2041 | 181 | 215 | 219 | 2 | 2 | 22.7 | ||

| NB.FC 3448130 | 240 | 130 | 190 | 2 | 2 | 830 | 1830 | 181 | 222 | 229 | 2 | 2 | 19 | ||

| NB.FC 3450170 | 6727 34H | 250 | 170 | 192 | 2.1 | 2.1 | 1000 | 2400 | 182 | 232 | 238 | 2 | 2 | 29.9 | |

| NB.FC 3452120 | 6727 34Y | 260 | 120 | 195 | 2.1 | 2.1 | 863 | 1730 | 182 | 237 | 248 | 2 | 2 | 24.2 | |

| NB.FC 3452150 | - | 260 | 150 | 195 | 2.1 | 2.1 | 860 | 1948 | 182 | 237 | 248 | 2 | 2 | 30.2 | |

| NB.FC 3452170 | 260 | 170 | 196 | 2.1 | 2.1 | 1080 | 2460 | 182 | 237 | 248 | 2 | 2 | 34.9 | ||

| NB.FC 3452225 | 260 | 225 | 196 | 2.1 | 2.1 | 1270 | 3350 | 182 | 237 | 248 | 2 | 2 | 43.5 | ||

| NB.FC 3650120 | 180 | 250 | 120 | 200 | 2.1 | 2.1 | 609 | 1583 | 191 | 234 | 239 | 2 | 2 | 19 | |

| NB.FC 3650156 | 672836 | 250 | 156 | 200 | 2 | 2 | 710 | 1527 | 191 | 234 | 239 | 2 | 2 | 24.7 | |

| NB.FC 3652120 | 260 | 120 | 202 | 2.5 | 2.1 | 693 | 860 | 192 | 242 | 248 | 2 | 2 | 20.2 | ||

| NB.FC 3652124 | 6727 36K | 180 | 260 | 124 | 202 | 2.1 | 2.1 | 718 | 1668 | 192 | 242 | 248 | 2 | 2 | 22.6 |

| NB.FC 3652154 | 260 | 154 | 202 | 2.5 | 2.1 | 983 | 2200 | 192 | 242 | 248 | 2 | 2 | 28.2 | ||

| NB.FC 3652160 | 260 | 160 | 202 | 2.1 | 2.1 | 893 | 2206 | 192 | 242 | 248 | 2 | 2 | 29.2 | ||

| NB.FC 3652168 | 672736 | 260 | 168 | 202 | 2.1 | 2.1 | 1060 | 2440 | 192 | 242 | 248 | 2 | 2 | 30.7 | |

| NB.FC 3652180 | 260 | 180 | 202 | 2.1 | 2.1 | 1150 | 2560 | 192 | 242 | 248 | 2 | 2 | 32.9 | ||

| NB.FC 3656180 | 280 | 180 | 207 | 2.1 | 2.1 | 1220 | 2580 | 43.4 | |||||||

| NB.FC 3852168 | 190 | 260 | 168 | 212 | 2.1 | 2.1 | 1020 | 2600 | 202 | 244 | 248 | 2 | 2 | 27.9 | |

| NB.FC 3853124 | 6728 38K | 265 | 124 | 213 | 2.1 | 2.1 | 816 | 1926 | 22.1 | ||||||

| NB.FC 3854124 | 270 | 124 | 212 | 2.1 | 2.1 | 816 | 1925 | 201 | 252 | 259 | 2 | 2 | 24.2 | ||

| NB.FC 3854168 | 6727 38K | 270 | 168 | 212 | 2.1 | 2.1 | 1062 | 2798 | 201 | 252 | 259 | 2 | 2 | 32 | |

| NB.FC 3854200 | 672738 | 270 | 200 | 212 | 2.1 | 2.1 | 1359 | 3350 | 201 | 252 | 259 | 2 | 2 | 38.2 | |

| NB.FC 3856200 | 280 | 200 | 214 | 2.1 | 2.1 | 1540 | 3350 | 41.5 | |||||||

| NB.FC 4054120 | 200 | 270 | 120 | 222 | 2.1 | 2.1 | 615 | 1626 | 212 | 254 | 258 | 2 | 2 | 20.8 | |

| NB.FC 4054170 | 270 | 170 | 222 | 2.1 | 2.1 | 985 | 2670 | 212 | 254 | 258 | 2 | 2 | 29.5 | ||

| NB.FC 4056170 | 280 | 170 | 222 | 2.1 | 2.1 | 1130 | 2730 | 212 | 262 | 268 | 2 | 2 | 33 | ||

| NB.FC 4056200 | - | 280 | 200 | 222 | 2.1 | 2.1 | 1360 | 3460 | 211 | 262 | 269 | 2 | 2 | 39.9 | |

| NB.FC 4058130 | 200 | 290 | 130 | 226 | 2.5 | 2.1 | 840 | 1975 | 212 | 268 | 278 | 2 | 2 | 29.9 | |

| NB.FC 4058192 | 672740 | 290 | 192 | 226 | 2.1 | 2.1 | 1386 | 3250 | 212 | 268 | 278 | 2 | 2 | 44.9 | |

| NB.FC 4258192 | 210 | 290 | 192 | 236 | 2.1 | 2.1 | 1300 | 3400 | 223 | 274 | 277 | 2 | 2 | 40.6 | |

| NB.FC 4260170 | 300 | 170 | 234 | 2.1 | 2.1 | 1031 | 2814 | 223 | 278 | 287 | 2 | 2 | 414 | ||

| NB.FC 4260210 | 672742 | 300 | 210 | 234 | 2.1 | 2.1 | 1300 | 3040 | 223 | 278 | 287 | 2 | 2 | 50.3 | |

| NB.FC 4460192 | 220 | 300 | 192 | 242 | 2.1 | 2.1 | 1085 | 3310 | 41.5 | ||||||

| NB.FC 4462157 | 310 | 157 | 246 | 2.1 | 2.1 | 1132 | 2627 | 233 | 286 | 298 | 2 | 2 | 39.7 | ||

| NB.FC 4462190 | 310 | 190 | 246 | 2.1 | 2.1 | 1283 | 3503 | 233 | 286 | 298 | 2 | 2 | 47.2 | ||

| NB.FC 4462192 | 672744 | 310 | 192 | 246 | 2.1 | 2.1 | 1250 | 3070 | 233 | 286 | 298 | 2 | 2 | 48.6 | |

| NB.FC 4464210 | 320 | 210 | 248 | 2.1 | 2.1 | 1321 | 3534 | 233 | 296 | 307 | 2 | 2 | 59.8 | ||

| NB.FC 4468192 | 340 | 192 | 246 | 2.5 | 2.1 | 1599 | 3444 | 65.6 | |||||||

| NB.FC 4666170 | 230 | 330 | 170 | 260 | 2.1 | 2.1 | 1142 | 2974 | 243 | 306 | 317 | 2 | 2 | 50.2 | |

| NB.FC 4666206 | 672746 | 330 | 206 | 260 | 2.1 | 2.1 | 1470 | 3760 | 243 | 306 | 317 | 2 | 2 | 60.8 | |

| NB.FC 4673250 | 365 | 250 | 266 | 3 | 3 | 2400 | 4900 | 244 | 334 | 351 | 2.5 | 2.5 | 100 | ||

| NB.FC 4866220 | 672748 | 240 | 330 | 220 | 264 | 2.1 | 2.1 | 1373 | 3789 | 253 | 308 | 317 | 2 | 2 | 58.4 |

| NB.FC 4868192 | 340 | 192 | 268 | 2.1 | 2.1 | 1219 | 3161 | 254 | 318 | 326 | 2.5 | 2.5 | 58 | ||

| NB.FC 4872220 | 360 | 220 | 272 | 2.1 | 2.1 | 1600 | 4065 | 254 | 330 | 346 | 2.5 | 2.5 | 83 | ||

| NB.FC 5068170 | - | 250 | 340 | 170 | 274 | 3 | 3 | 1141 | 3281 | 47.9 | |||||

| NB.FC 5070220 | 672750 | 350 | 220 | 278 | 3 | 3 | 1350 | 3804 | 264 | 326 | 336 | 2.5 | 2.5 | 70.2 | |

| NB.FC 5072160 | - | 360 | 160 | 282 | 3 | 3 | 1077 | 2781 | 57 | ||||||

| NB.FC 5072220 | 360 | 220 | 282 | 3 | 3 | 1486 | 4210 | 78.5 | |||||||

| NB.FC 5272192 | 260 | 360 | 192 | 287 | 3 | 3 | 1274 | 3468 | 273 | 335 | 347 | 2 | 2 | 62.3 | |

| NB.FC 5272200 | 360 | 200 | 288 | 3 | 3 | 1483 | 4217 | 273 | 335 | 347 | 2 | 2 | 64.9 | ||

| NB.FC 5272204 | 360 | 204 | 287 | 2.1 | 2.1 | 1620 | 3990 | 273 | 335 | 347 | 2 | 2 | 63.5 | ||

| NB.FC 5274200 | 370 | 200 | 292 | 3 | 3 | 1407 | 4057 | 274 | 342 | 356 | 2.5 | 2.5 | 74.2 | ||

| NB.FC 5274220 | 672752 | 370 | 220 | 292 | 3 | 3 | 1964 | 4650 | 274 | 342 | 356 | 2.5 | 2.5 | 77.3 | |

| NB.FC 5276220 | 380 | 220 | 292 | 3 | 3 | 1516 | 4353 | 274 | 354 | 366 | 2.5 | 2.5 | 91.2 | ||

| NB.FC 5276280 | 380 | 280 | 295 | 3 | 3 | 2250 | 5680 | 274 | 354 | 366 | 2.5 | 2.5 | 110 | ||

| NB.FC 5280200 | 400 | 200 | 296 | 4 | 4 | 1795 | 4051 | 274 | 370 | 391 | 2.5 | 2.5 | 95.6 | ||

| NB.FC 5280290 | 400 | 290 | 296 | 4 | 4 | 2710 | 7100 | 274 | 370 | 391 | 2.5 | 2.5 | 135 | ||

| NB.FC 5476230 | 672754 | 270 | 380 | 230 | 298 | 3 | 3 | 1725 | 4598 | 283 | 354 | 367 | 2 | 2 | 85.3 |

| NB.FC 5480220 | - | 400 | 220 | 305 | 3 | 3 | 1833 | 4570 | 100 | ||||||

| NB.FC 5675200 | 672956 | 280 | 375 | 200 | 307 | 3 | 3 | 1480 | 4311 | 293 | 356 | 367 | 2 | 2 | 65.1 |

| NB.FCD 5676220 | - | 380 | 220 | 312 | 3 | 3 | 1360 | 3960 | 68.5 | ||||||

| NB.FC 5676290 | - | 380 | 290 | 308 | 3 | 3 | 1888 | 5835 | 100 | ||||||

| NB.FC 5678220 | 6727 56Q | 390 | 220 | 312 | 3 | 3 | 1600 | 4730 | 294 | 362 | 376 | 2.5 | 2.5 | 86.2 | |

| NB.FC 5678240 | 390 | 240 | 312 | 3 | 3 | 1763 | 5235 | 294 | 362 | 376 | 2.5 | 2.5 | 93.4 | ||

| NB.FCD 5678275 | 390 | 275 | 308 | 3 | 3 | 2250 | 6500 | 293 | 363 | 377 | 2 | 2 | 105.1 | ||

| NB.FCD 5680285 | 400 | 285 | 316 | 3 | 3 | 3200 | 7500 | 121 | |||||||

| NB.FCD 5682300 | 410 | 300 | 313 | 4 | 4 | 3590 | 7650 | 294 | 378 | 396 | 2.5 | 2.5 | 132 | ||

| NB.FCD 5684280 | 420 | 280 | 318 | 4 | 4 | 2430 | 6350 | 143.4 | |||||||

| NB.FCD 5684300 | 420 | 300 | 319 | 4 | 4 | 3540 | 7500 | 151 | |||||||

| NB.FC 5882240 | 672758 | 290 | 410 | 240 | 320 | 4 | 4 | 2070 | 5670 | 304 | 380 | 396 | 3 | 3 | 105 |

| NB.FC 6084218 | 300 | 420 | 218 | 332 | 4 | 4 | 2060 | 5695 | 314 | 390 | 406 | 2.5 | 2.5 | 97 | |

| NB.FCD 6084240 | 420 | 240 | 332 | 4 | 4 | 2225 | 5750 | 314 | 392 | 406 | 3 | 3 | 107 | ||

| NB.FCD 6084300 | 420 | 300 | 332 | 3 | 3 | 2305 | 6565 | 314 | 392 | 406 | 2.5 | 2.5 | 134.7 | ||

| NB.FC 6488240 | 320 | 440 | 240 | 351 | 3 | 3 | 2120 | 6101 | 335 | 411 | 425 | 2.5 | 2.5 | 113.9 | |

| NB.FCD 6488300 | 440 | 300 | 352 | 3 | 3 | 2530 | 7660 | 335 | 409 | 425 | 2.5 | 2.5 | 142.3 | ||

| NB.FCD 6490240 | 450 | 240 | 355 | 4 | 4 | 2145 | 5860 | 335 | 419 | 435 | 2.5 | 2.5 | 125.3 | ||

| NB.FCD 6492240 | 460 | 240 | 355 | 4 | 4 | 2980 | 7340 | 335 | 428 | 445 | 2.5 | 2.5 | 140 | ||

| NB.FC 6492280 | 460 | 280 | 357 | 3 | 3 | 2450 | 6534 | 335 | 428 | 445 | 2.5 | 2.5 | 159 | ||

| NB.FCD 6492300 | 460 | 300 | 360 | 4 | 4 | 3640 | 9700 | 335 | 428 | 445 | 2.5 | 2.5 | 166.5 | ||

| NB.FCD 6492340 | 460 | 340 | 360 | 3 | 3 | 2895 | 8105 | 335 | 428 | 445 | 2.5 | 2.5 | 193.1 | ||

| NB.FCDP 6496290 | 480 | 290 | 364 | 4 | 4 | 3580 | 7400 | 346 | 462 | 466 | 3 | 3 | 200 | ||

| NB.FCDP 6496350 | 480 | 350 | 364 | 4 | 4 | 3790 | 10500 | 346 | 462 | 466 | 3 | 3 | 227 | ||

| NB.FCD 6692340 | 330 | 460 | 340 | 365 | 4 | 4 | 3760 | 8265 | 344 | 428 | 446 | 2 | 2 | 175 | |

| NB.FC 6890250 | 340 | 450 | 250 | 368 | 3 | 3 | 2299 | 6312 | 354 | 424 | 436 | 2 | 2 | 111.2 | |

| NB.FCD 6890250 | 450 | 250 | 368 | 3 | 3 | 2045 | 6134 | 354 | 424 | 436 | 2 | 2 | 112.6 | ||

| NB.FC 6892260 | 460 | 260 | 370 | 4 | 4 | 2132 | 5977 | 128.2 | |||||||

| NB.FCD 6896350 | 480 | 350 | 378 | 4 | 4 | 3790 | 10500 | 355 | 446 | 465 | 2.5 | 2.5 | 207 | ||

| NB.FCDP 68100370 | 500 | 370 | 385 | 4 | 4 | 5350 | 12000 | 263 | |||||||

| NB.FCDP 68112380 | 560 | 380 | 396 | 40 | 4 | 6930 | 13100 | 352 | |||||||

| NB.FCD 70100380 | 672770 | 350 | 500 | 380 | 389 | 5 | 5 | 4290 | 11700 | 363 | 464 | 487 | 2 | 2 | 242 |

| NB.FCD 70100410 | 500 | 410 | 388 | 4 | 4 | 5950 | 13950 | 363 | 464 | 487 | 2 | 2 | 287 | ||

| NB.FCD 70104300 | 520 | 300 | 401 | 5 | 5 | 3860 | 9000 | 220 | |||||||

| NB.FCD 72100250 | 360 | 500 | 250 | 394 | 3 | 3 | 2940 | 6740 | 143 | ||||||

| NB.FCD 72102370 | 510 | 370 | 399 | 4 | 4 | 4010 | 10700 | 377 | 470 | 493 | 3 | 3 | 273 | ||

| NB.FCD 74104380 | 672974 | 370 | 520 | 380 | 409 | 4 | 4 | 4900 | 10750 | 389 | 481 | 500 | 3 | 3 | 263 |

| NB.FCDP 74104380 | 520 | 380 | 409 | 4 | 4 | 4160 | 12312 | 389 | 481 | 500 | 3 | 3 | 261 | ||

| NB.FCD 74104400 | 520 | 400 | 409 | 4 | 4 | 4140 | 11200 | 389 | 481 | 500 | 3 | 3 | 267 | ||

| NB.FCD 74108400 | 672774 | 540 | 400 | 415 | 4 | 4 | 3970 | 11240 | 387 | 499 | 523 | 3 | 3 | 322.4 | |

| NB.FCD 76104280 | 380 | 520 | 280 | 426 | 4 | 4 | 2910 | 7360 | 186 | ||||||

| NB.FCDP 76108260 | 540 | 260 | 428 | 4 | 4 | 3480 | 8820 | 205 | |||||||

| NB.FCDP 76108300 | 540 | 300 | 421 | 4 | 4 | 5120 | 11220 | 222 | |||||||

| NB.FCD 76108380 | 540 | 380 | 422 | 4 | 4 | 3766 | 10930 | 397 | 502 | 523 | 3 | 3 | 290.9 | ||

| NB.FCD 76108400 | 672776 | 540 | 400 | 422 | 4 | 4 | 4800 | 12000 | 397 | 502 | 523 | 3 | 3 | 305 | |

| NB.FCDP 76108400 | 540 | 400 | 422 | 4 | 4 | 5140 | 14000 | 397 | 502 | 523 | 3 | 3 | 305 | ||

| NB.FCDP 76112300 | 560 | 300 | 424 | 4 | 4 | 5050 | 9850 | 261 | |||||||

| NB.FCDP 76112325 | 560 | 325 | 428 | 4 | 4 | 5330 | 10810 | 265 | |||||||

| NB.FCDP 78108320 | 390 | 540 | 320 | 431 | 10×20° | 2 | 4750 | 12200 | 230 | ||||||

| NB.FCDP 92130355 | 460 | 650 | 355 | 509.5 | 5 | 5 | 6400 | 14900 | |||||||

| NB.FCDP 92130424 | 650 | 424 | 510 | 12×20° | 3 | 7000 | 18300 | 450 | |||||||

| NB.FCDP 92130470 | 650 | 470 | 509 | 5 | 5 | 7900 | 22400 | 484 | 609 | 626 | 4 | 4 | 510 | ||

| NB.FCDP 92136400 | 680 | 400 | 518 | 6 | 6 | 8250 | 17620 | 642 | |||||||

| NB.FCDP 96124420 | 480 | 620 | 420 | 514 | 6 | 6 | 6540 | 21000 | 332 | ||||||

| NB.FCDP 96130450 | 650 | 450 | 525 | 6 | 6 | 7420 | 21200 | 500 | 610 | 630 | 4 | 4 | 440 | ||

| NB.FCDP 96136420 | 680 | 420 | 528 | 5 | 5 | 7500 | 19300 | 515 | |||||||

| NB.FCDP 96136500 | · | 680 | 500 | 532 | 5 | 5 | 7323 | 24000 | 500 | 632 | 660 | 4 | 4 | 605 | |

| NB.FCDP 100136260 | 500 | 650 | 260 | 542 | 6 | 6 | 4100 | 10400 | 225 | ||||||

| NB.FCDP 100134450 | 6728/ 500Y | 670 | 450 | 540 | 5 | 5 | 5343 | 17490 | 520 | 629 | 650 | 4 | 4 | 460 | |

| NB.FCD 100136405 | 680 | 405 | 550 | 6 | 6 | 5495 | 16570 | 520 | 634 | 660 | 4 | 4 | 453 | ||

| NB.FCDP 100136450 | 680 | 450 | 550 | 5 | 5 | 7420 | 22000 | 520 | 634 | 660 | 4 | 4 | 500 | ||

| NB.FCD 100142480 | 710 | 480 | 558 | 5 | 5 | 7920 | 21600 | 610 | |||||||

| NB.FCD 100144400 | 720 | 400 | 558 | 6 | 3 | 7120 | 17600 | 530 | |||||||

| NB.FCD 100144530 | 720 | 530 | 568 | 6 | 6 | 9720 | 19890 | 755 | |||||||

| NB.FCDP 102136500 | 510 | 680 | 500 | 560 | 7.5×20° | 5 | 8070 | 26000 | 522 | ||||||

| NB.FCD 102146520 | 730 | 520 | 569 | 6 | 6 | 8560 | 22000 | 750 | |||||||

| NB.FCDP 102152550 | 760 | 550 | 570 | 16×20° | 3 | 10800 | 26500 | 950 | |||||||

| NB.FCDP 104134450 | 520 | 670 | 450 | 560 | 6 | 6 | 7420 | 24000 | 402 | ||||||

| NB.FCDP 106152520 | 530 | 760 | 520 | 587 | 6 | 6 | 10530 | 28500 | 775 | ||||||

| NB.FCD 106156500 | 780 | 500 | 591 | 6 | 6 | 8410 | 20400 | 805 | |||||||

| NB.FCDP 106156570 | 780 | 570 | 595 | 6 | 6 | 11520 | 32500 | 555 | 719 | 755 | 5 | 5 | 960 | ||

| NB.FCDP 110148510 | 550 | 740 | 510 | 600 | 6 | 6 | 7769 | 27000 | 615 | ||||||

| NB.FCDP 110160520 | 800 | 520 | 612 | 6 | 6 | 10530 | 26500 | 895 | |||||||

| NB.FC 110160560 | 800 | 560 | 610 | 6 | 6 | 10890 | 28000 | 930 | |||||||

| NB.FCDP 112164600 | 560 | 820 | 600 | 625 | 6 | 6 | 14400 | 34800 | 577 | 757 | 803 | 4 | 4 | 1085 | |

| NB.FCDP 112164630 | 820 | 630 | 625 | 6 | 6 | 15600 | 33900 | 577 | 757 | 803 | 4 | 4 | 1160 | ||

| NB.FCD 114150530 | 67271570 | 570 | 750 | 530 | 622 | 5 | 5 | 6745 | 25200 | 662.5 | |||||

| NB.FCDP 114163594 | 815 | 594 | 628 | 6 | 6 | 13400 | 33550 | 595 | 757 | 790 | 4 | 4 | 1003 | ||

| NB.FCDP 120164450 | 820 | 450 | 654 | 6 | 6 | 11000 | 30000 | 721 | |||||||

| NB.FCDP 120164575 | 820 | 575 | 660 | 6 | 6 | 11700 | 35100 | 939 | |||||||

| NB.FCDP 120174540 | - | 600 | 870 | 540 | 672 | 22×20° | 4 | 11800 | 31500 | 1100 | |||||

| NB.FCDP 120174640 | 870 | 640 | 682 | 6 | 6 | 13600 | 41700 | 1370 | |||||||

| NB.FCDP 122164430 | - | 610 | 820 | 430 | 665 | 19×20° | 3 | 8400 | 23600 | 650 | |||||

| NB.FCDP 126180670 | - | 630 | 900 | 670 | 698 | 6 | 6 | 15900 | 41400 | 1430 | |||||

| NB.FCDP 130180650 | 650 | 900 | 650 | 704 | 7.5 | 7.5 | 15480 | 41500 | 1260 | ||||||

| NB.FCDP 130184670 | 920 | 670 | 723 | 7.5 | 7.5 | 15480 | 46500 | 680 | 856 | 890 | 6 | 6 | 1450 | ||

| NB.FCD 132164440 | 660 | 820 | 440 | 702 | 7.5 | 4 | 6730 | 22800 | 530 | ||||||

| NB.FCD 132176450 | 880 | 450 | 727 | 6 | 6 | 5546 | 23600 | 785 | |||||||

| NB.FCDP 134190700 | 670 | 950 | 700 | 750 | 7.5 | 7.5 | 16400 | 50300 | 1630 | ||||||

| NB.FCDP 136188600 | 680 | 940 | 600 | 743 | 4 | 4 | 16900 | 53400 | 1380 | ||||||

| NB.FCDP 136196640 | 980 | 640 | 760 | 20×20° | 4 | 13230 | 41800 | 1590 | |||||||

| NB.FCDP 138196715 | 690 | 980 | 715 | 767.5 | 7.5 | 7.5 | 17820 | 51300 | 720 | 911.5 | 950 | 4 | 4 | 1780 | |

| NB.FCDP 138196750 | 980 | 750 | 766 | 7.5 | 7.5 | 17000 | 53000 | 720 | 910 | 954 | 6 | 6 | 1880 | ||

| NB.FCDP 140186620 | 700 | 930 | 620 | 763 | 18×20° | 7.5 | 11600 | 40850 | 1180 | ||||||

| NB.FCDP 140196700 | 980 | 700 | 774 | 6 | 6 | 17800 | 48200 | 726 | 914 | 954 | 5 | 5 | 1720 | ||

| NB.FCDP 142200715 | 710 | 1000 | 715 | 787.5 | 7.5 | 7.5 | 15400 | 53200 | 1860 | ||||||

| NB.FCDP 144196700 | 720 | 980 | 700 | 772 | 7.5 | 7.5 | 14540 | 51300 | 1545 | ||||||

| NB.FCDP 146188500 | 730 | 940 | 500 | 780 | 3 | 3 | 10150 | 42500 | 1000 | ||||||

| NB.FCDP 146192620 | 960 | 620 | 790 | 7.5 | 7.5 | 11800 | 48750 | 1220 | |||||||

| NB.FCDP 146206750 | 1030 | 750 | 809 | 7.5 | 7.5 | 16000 | 55500 | 2040 | |||||||

| NB.FCD 150200500 | 750 | 1000 | 500 | 816 | 6 | 6 | 9460 | 32000 | 1150 | ||||||

| NB.FCDP 150200670 | 1000 | 670 | 813 | 7.5 | 7.5 | 13500 | 47500 | 1480 | |||||||

| NB.FCDP 152216790 | 760 | 1080 | 790 | 846 | 7.5 | 7.5 | 18690 | 62430 | 787 | 1005 | 1053 | 5 | 5 | 2445 | |

| NB.FCDP 156214780 | 780 | 1070 | 780 | 853 | 7.5 | 7.5 | 17200 | 57900 | 2300 | ||||||

| NB.FCDP 160216700 | 800 | 1080 | 700 | 878 | 7.5 | 7.5 | 15200 | 55500 | 827 | 1010 | 1050 | 5 | 5 | 1950 | |

| NB.FCDP 160230850 | 1150 | 850 | 905 | 7.5 | 7.5 | 21000 | 76600 | 3150 | |||||||

| NB.FCDP 164226800 | 820 | 1130 | 800 | 903 | 7.5 | 7.5 | 18600 | 64600 | 2540 | ||||||

| NB.FCDP 170230840 | 850 | 1150 | 840 | 928 | 7.5 | 7.5 | 19600 | 72009 | 875 | 1088 | 1130 | 5 | 5 | 2570 | |

| NB.FCDP 170236850 | 1180 | 850 | 940 | 7.5 | 7.5 | 20100 | 72700 | 881 | 1104 | 1149 | 6 | 6 | 2850 | ||

| NB.FCDP 170244900 | 1220 | 900 | 940 | 5 | 5 | 23000 | 84000 | 3720 | |||||||

| NB.FCDP 180244840 | 900 | 1220 | 840 | 989 | 7.5 | 7.5 | 20300 | 76000 | 931 | 1145 | 1190 | 5 | 5 | 3060 | |

| NB.FCDP 180256930 | 1280 | 930 | 1000 | 7.5 | 7.5 | 25300 | 88350 | 4080 | |||||||

| NB.FCDP 190260850 | 67271 950Y | 950 | 1300 | 850 | 1044 | 5 | 5 | 22168 | 81318 | 980 | 1210 | 1270 | 5 | 5 | 3505 |

| NB.FCDP 190272975 | 950 | 1360 | 975 | 1075 | 26×20° | 7.5 | 26200 | 90000 | 4900 | ||||||

| NB.FCDP 1902721000 | 1360 | 1000 | 1075 | 22×20° | 7.5 | 29200 | 99000 | 5020 | |||||||

| NB.FCDP 196262880 | 980 | 1310 | 880 | 1061.7 | 20×20° | 7.5 | 22000 | 82000 | 3310 | ||||||

| NB.FCDP 200272800 | 1000 | 1360 | 800 | 1101 | 23×20° | 7.5 | 22000 | 80000 | 3560 | ||||||

| NB.FCDP 2082881000 | · | 1040 | 1440 | 1000 | 1133 | 27×20° | 7.5 | 34200 | 51300 | 5100 | |||||

| NB.FCDP 2403181050 | 1200 | 1590 | 1050 | 1305 | 30×20° | 6 | 37620 | 120600 | 5970 | ||||||

| NB.FCDP 260331880 | 1300 | 1655 | 880 | 1391 | 7.5 | 7.5 | 33660 | 109800 | 4800 | ||||||

| NB.FCDP 2703531360 | 1350 | 1765 | 1360 | 1457 | 42×20° | 7.5 | 36180 | 109800 | 9100 | ||||||

| NB.FCDP 2803561200 | 1400 | 1780 | 1200 | 1493 | 40×20° | 9.5 | 47070 | 146700 | 7400 | ||||||

| NB.FCDP 2803801360 | 1900 | 1360 | 1521 | 40×20° | 12 | 55440 | 164700 | 11300 | |||||||

Maximum radial load up to 8000 KN, leading in the industry, adapting to the large-load requirements of ultra-heavy equipment.

Inner diameter 90-1400 mm, supporting non-standard customization, perfectly replacing imported large-size series, filling the gap of domestic large specifications.

Separable structure design, enabling installation and replacement without disassembling related components, reducing maintenance costs and downtime of large-size equipment.

Technical specifications fully match those of imported large-size series, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with complex heavy-duty environments such as high-temperature, dusty, and humid conditions, supporting multi-dimensional customization, covering machine tools, wind power, metallurgy and other fields.

Applications of Large Cylindrical Roller Bearings

1. Steel & Metallurgical Industry

Rolling mill work rolls and backup rolls

Continuous casting machines

Straightening and leveling equipment

They withstand heavy radial loads, shock, and high temperatures.

2. Mining & Quarry Equipment

Crushers

Grinding mills

Large conveyors

Designed for extreme loads, vibration, and harsh environments.

3. Wind Energy Equipment

Wind turbine gearboxes

Generator main shafts

Large cylindrical roller bearings support heavy radial forces with high reliability.

4. Power Generation Equipment

Hydropower turbines

Steam turbine auxiliary systems

Used to support large shafts and ensure long service life.

5. Marine & Offshore Machinery

Propulsion systems

Winches

Thrusters

Reliable performance under heavy loads and marine conditions.

6. Heavy Industrial Gearboxes

Large speed reducers

Planetary gear systems

They handle high radial loads generated by gear meshing forces.

7. Cement Industry

Kilns

Crushers

Ball mills

Operate continuously under heavy load and dusty environments.

8. Paper & Pulp Machinery

Large paper machine rolls

Press and dryer sections

Self-alignment of shaft components is supported through rigid bearing design.

9. Construction & Earthmoving Equipment

Excavators

Large cranes

Track rollers

Suitable for low-to-moderate speed, high-load conditions.

10. General Heavy Rotating Machinery

Large motors and generators

Industrial fans and blowers

Provide stable shaft support and long operating life.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.