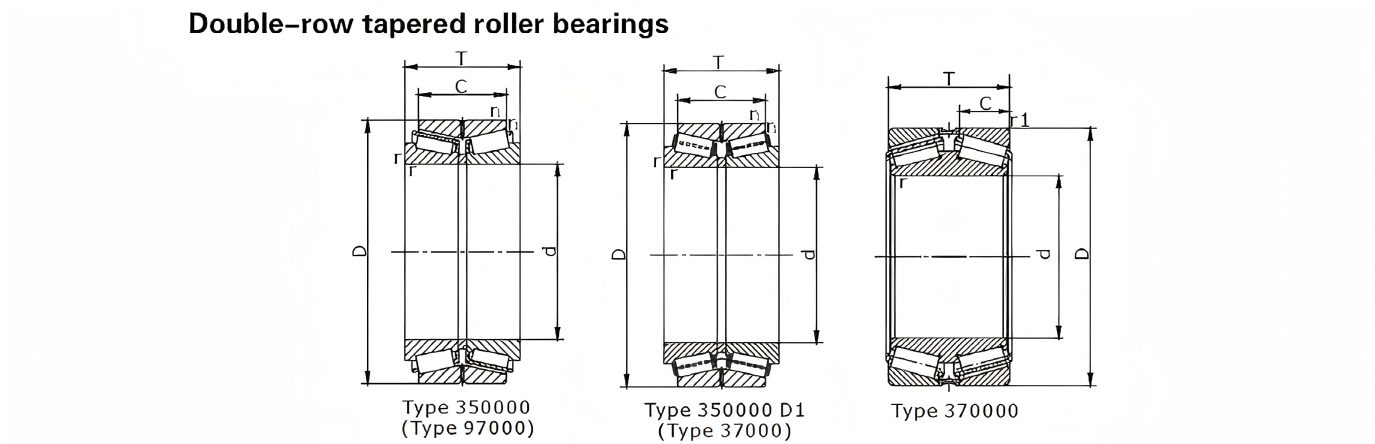

A Double Row Tapered Roller Bearing (DRTRB) is a robust bearing with two rows of tapered rollers, allowing it to handle heavy radial loads and significant axial loads in both directions, making it ideal for stiff, high-load industrial applications like gearboxes, rolling mills, and mining machinery where both overturning moments and bidirectional thrust are present, with common types being TDO (Double Outer) and TDI (Double Inner) configurations.

Features:

Inner Ring: Integral or separable structure (optional);Outer Ring: Integral or separable structure (optional);Roller Arrangement: Double row tapered rollers (symmetrical layout, synchronized bearing of radial and bidirectional axial loads);

Accuracy: P0, P6, P5, P4;

Size:Inner Diameter: 150–1778 mm;Outer Diameter: 210–2159 mm;Width: 86–393.7mm;

Materials:Bearing Rings & Rollers: GCr15 or SUS440C ;Cages: Brass, Nylon 66 , or stamped steel ;

Sealing Options:Open Type: Requires regular external lubrication, suitable for clean, heavy-load, low-to-medium speed working conditions;Contact Rubber Seals (2RS/ZZ): Dustproof and splash-proof, suitable for complex industrial environments with dust and humidity; Non-contact Seals (Z/RS): Low friction, suitable for medium-high speed operation scenarios;

Delivery:Standard models: 7–15 days;Customized models :Please contact the manufacturer.

| Double Row Tapered Roller Bearing | ||||||||||||

| Part number | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | ||||||||

| Current | Original | mm | kN | kg | r/min | |||||||

| d | D | T | C | rmin | r1min | Cr | Cor | Grease | Oil | |||

| NB.352930 | 2097930E | 150 | 210 | 86 | 70 | 2.5 | 1 | 419 | 887 | 8.5 | 900 | 1300 |

| NB.352130 | 2097730 | 250 | 138 | 112 | 2.5 | 1 | 858 | 1620 | 26 | 850 | 1100 | |

| NB.352230 | 97530E | 270 | 164 | 130 | 4 | 1 | 1250 | 2250 | 38 | 800 | 1000 | |

| 352230X2 | 97530 | 270 | 172 | 138 | 4 | 1 | 1250 | 2250 | 38 | 800 | 1000 | |

| 352032X2 | 2097132 | 160 | 240 | 115 | 90 | 3 | 1 | 641 | 1400 | 14.9 | 850 | 1100 |

| NB.352132 | 2097732 | 270 | 150 | 120 | 3 | 1 | 1050 | 2030 | 32.5 | 800 | 1000 | |

| NB.352232 | 97532E | 290 | 178 | 144 | 4 | 1 | 1400 | 2730 | 49 | 700 | 900 | |

| 352034X2 | 2097134 | 170 | 260 | 120 | 95 | 3 | 1 | 672 | 1460 | 21 | 800 | 1000 |

| 352036X2 | 2097136 | 180 | 280 | 134 | 108 | 3 | 1 | 952 | 1880 | 29 | 670 | 850 |

| NB.352036 | 2097136E | 280 | 142 | 110 | 3 | 1 | 952 | 1880 | 28.5 | 800 | 1000 | |

| NB.352136 | 2097736 | 300 | 164 | 134 | 3 | 1 | 1290 | 2540 | 44 | 670 | 850 | |

| NB.352236 | 97536E | 320 | 192 | 152 | 5 | 1.1 | 1750 | 3350 | 62.5 | 600 | 750 | |

| NB.372038 | - | 190 | 289.5 | 100 | 40 | 3 | 3 | 750 | 1500 | 27 | 700 | 900 |

| NB.352138 | 2097738 | 320 | 170 | 130 | 3 | 1 | 1440 | 2800 | 51 | 670 | 850 | |

| NB.352940X2/YA | 2097940EK | 200 | 280 | 116 | 92 | 3 | 1 | 758 | 1423 | 14.8 | 700 | 900 |

| NB.352940X2 | 2097940 | 280 | 105 | 80 | 3 | 1 | 650 | 2660 | 18.5 | 700 | 900 | |

| NB.352040X2 | 2097140 | 310 | 152 | 120 | 2.5 | 1.1 | 1180 | 2720 | 41 | 670 | 850 | |

| NB.352140 | 2097740 | 340 | 184 | 150 | 3 | 1 | 1680 | 3340 | 64 | 670 | 850 | |

| NB.352240 | 97540E | 360 | 218 | 174 | 5 | 1.1 | 2310 | 4250 | 90.5 | 600 | 750 | |

| NB.352944X2 | 2097944 | 220 | 300 | 110 | 88 | 3 | 1.2 | 660 | 1710 | 21.2 | 670 | 850 |

| NB.352044X2 | 2097144 | 340 | 165 | 130 | 4 | 1 | 1360 | 2790 | 47.7 | 600 | 750 | |

| NB.352144 | 2097744 | 370 | 195 | 150 | 4 | 1.1 | 1740 | 3450 | 76.3 | 600 | 750 | |

| 350646D1 | 37746 | 230 | 355 | 145 | 110 | 6 | 3 | 1060 | 2040 | 43.6 | 600 | 750 |

| NB.352948 | 2097948E | 240 | 320 | 116 | 92 | 3 | 1 | 820 | 1910 | 22.3 | 600 | 750 |

| NB.352948X2 | 2097948 | 320 | 110 | 90 | 3 | 1.5 | 820 | 1910 | 23 | 600 | 750 | |

| NB.352048X2 | 2097148 | 360 | 165 | 130 | 4 | 1 | 1370 | 3180 | 52.8 | 530 | 670 | |

| NB.352048 | 2097148E | 360 | 166 | 128 | 4 | 1 | 1370 | 3180 | 55.6 | 530 | 670 | |

| NB.372952K | - | 260 | 360 | 134 | 52 | 3.5 | 2.5 | 1150 | 2300 | 43.5 | 530 | 670 |

| NB.352952X2 | 2097952 | 360 | 134 | 108 | 3 | 1 | 1263 | 2430 | 36.8 | 530 | 670 | |

| - | 37852 | 400 | 150 | 110 | 6 | 1.5 | 1240 | 2330 | 60.3 | 530 | 670 | |

| NB.352052X2 | 2097152 | 400 | 186 | 146 | 5 | 1.1 | 1780 | 3830 | 76.8 | 500 | 630 | |

| NB.352052 | 2097152E | 400 | 190 | 146 | 5 | 1.1 | 1780 | 3830 | 79.5 | 500 | 630 | |

| NB.350652D1 | 37752 | 430 | 180 | 130 | 10 | 3 | 2100 | 2800 | 87.9 | 500 | 630 | |

| NB.350652 | 97752 | 430 | 180 | 130 | 7.5 | 1.5 | 2237 | 3016 | 93.4 | 500 | 630 | |

| NB.352152 | 2097752 | 440 | 225 | 180 | 4 | 1.1 | 2480 | 5050 | 124 | 450 | 560 | |

| NB.352956X2 | 2097956 | 280 | 380 | 134 | 108 | 3 | 1.1 | 1080 | 2810 | 41.3 | 480 | 600 |

| NB.351056 | 97156 | 420 | 133 | 106 | 4 | 2 | 1270 | 1936 | 58.1 | 450 | 560 | |

| NB.352056X2 | 2097156 | 420 | 186 | 146 | 5 | 1.1 | 1860 | 4000 | 81.5 | 450 | 560 | |

| NB.352960X2 | 2097960 | 300 | 420 | 160 | 128 | 4 | 1.1 | 1470 | 3530 | 64 | 450 | 560 |

| NB.352060X2 | 2097160 | 460 | 210 | 165 | 4 | 1.5 | 2200 | 4940 | 118 | 430 | 530 | |

| NB.351160 | 1097760 | 500 | 205 | 152 | 5 | 1.5 | 2200 | 4500 | 144 | 400 | 500 | |

| NB.352964X2 | 2097964 | 320 | 440 | 160 | 128 | 4 | 1.5 | 1410 | 3830 | 67 | 430 | 530 |

| NB.372064X2 | - | 480 | 210 | 84 | 5 | 4 | 2340 | 6130 | 133 | 400 | 500 | |

| NB.352064X2 | 2097164 | 480 | 210 | 160 | 5 | 1.1 | 1830 | 4390 | 122 | 400 | 500 | |

| NB.352968X2 | 2097968 | 340 | 460 | 160 | 128 | 4 | 1 | 1575 | 4050 | 71 | 400 | 500 |

| NB.351068 | 97168 | 520 | 180 | 135 | 5 | 1.5 | 1904 | 4070 | 119 | 380 | 480 | |

| NB.351168 | 1097768 | 580 | 242 | 170 | 5 | 1.5 | 2870 | 5970 | 214 | 340 | 430 | |

| NB.350670 | 97770 | 350 | 590 | 200 | 140 | 9.5 | 1.5 | 2800 | 5500 | 212 | 320 | 400 |

| NB.352972X2 | 2097972 | 360 | 480 | 160 | 128 | 4 | 1 | 1490 | 4270 | 74.3 | 380 | 480 |

| NB.350672D1 | 37772 | 530 | 155 | 110 | 5 | 1.5 | 1690 | 3300 | 109 | 380 | 480 | |

| NB.350672 | 97772 | 530 | 155 | 110 | 5 | 1.5 | 1690 | 3300 | 107 | 380 | 480 | |

| NB.351072X2 | 97872 | 540 | 169 | 134 | 6 | 2 | 1980 | 3950 | 122 | 340 | 430 | |

| NB.351072 | 97172 | 540 | 185 | 140 | 5 | 1.5 | 2120 | 4910 | 127 | 360 | 450 | |

| NB.351172 | 1097772 | 600 | 242 | 170 | 5 | 1.5 | 2950 | 6270 | 235 | 320 | 400 | |

| NB.3706/379 | - | 379 | 681.5 | 307 | 118 | 2.5 | 6 | 5600 | 11700 | 512 | 300 | 380 |

| NB.351976 | 1097976 | 380 | 520 | 145 | 105 | 4 | 1.1 | 1210 | 3250 | 80.3 | 360 | 450 |

| NB.351076 | 97176 | 560 | 190 | 140 | 5 | 1.5 | 2150 | 5090 | 146 | 340 | 430 | |

| NB.351176 | 1097776 | 620 | 242 | 170 | 5 | 1.5 | 3310 | 7430 | 243 | 300 | 380 | |

| NB.351980 | 1097980 | 400 | 540 | 150 | 105 | 4 | 1.1 | 1210 | 3110 | 86.9 | 320 | 400 |

| NB.350180D | 37780 | 590 | 185 | 123 | 5 | 2 | 2710 | 5950 | 166 | 320 | 400 | |

| NB.351080 | 97180 | 600 | 206 | 150 | 5 | 1.5 | 2620 | 6380 | 180 | 300 | 380 | |

| NB.351984 | 1097984 | 420 | 560 | 145 | 105 | 4 | 1.1 | 1450 | 3740 | 88.7 | 300 | 380 |

| NB.350184D | 37784 | 620 | 190 | 125 | 5 | 1 | 2450 | 5700 | 171 | 280 | 360 | |

| NB.351084 | 97184 | 620 | 206 | 150 | 5 | 1.5 | 2650 | 6600 | 187 | 280 | 360 | |

| NB.351184 | 1097784 | 700 | 275 | 200 | 6 | 2.5 | 4270 | 8810 | 392 | 240 | 340 | |

| NB.351988 | 1097988 | 440 | 600 | 170 | 125 | 4 | 1.1 | 1890 | 4860 | 114 | 280 | 360 |

| NB.351088 | 97188 | 650 | 212 | 152 | 6 | 2.5 | 2750 | 7020 | 213 | 260 | 340 | |

| NB.351992 | 1097992 | 460 | 620 | 174 | 130 | 4 | 1.1 | 1910 | 4990 | 130 | 260 | 340 |

| NB.351092 | 97192 | 680 | 230 | 175 | 6 | 2.5 | 2680 | 5900 | 253 | 220 | 300 | |

| NB.351996 | 1097996 | 480 | 650 | 180 | 130 | 5 | 1.5 | 1950 | 5270 | 151 | 240 | 320 |

| NB.351096 | 97196 | 700 | 240 | 180 | 6 | 2.5 | 3330 | 8190 | 281 | 200 | 280 | |

| NB.350698 | 97798 | 490 | 640 | 180 | 144 | 7.5 | 3 | 2290 | 6600 | 140 | 220 | 300 |

| NB.3519/500 | 10979/500 | 500 | 670 | 180 | 130 | 5 | 1.5 | 2150 | 6120 | 159 | 220 | 300 |

| NB.3510/500 | 971/500 | 720 | 236 | 180 | 6 | 2.5 | 3390 | 8450 | 289 | 190 | 260 | |

| NB.3506/520 | 977/520 | 520 | 740 | 190 | 120 | 2.5 | 2.5 | 2780 | 6800 | 231 | 190 | 260 |

| NB.3519/530 | 10979/530 | 530 | 710 | 190 | 136 | 5 | 1.5 | 2390 | 6800 | 190 | 190 | 260 |

| NB.3706/530 | - | 730 | 250 | 106 | 6 | 6 | 5350 | 14800 | 354 | 160 | 200 | |

| NB.3519/560 | 10979/560 | 560 | 750 | 213 | 156 | 5 | 1.5 | 2550 | 7060 | 235 | 170 | 220 |

| NB.3510/560 | 971/560 | 820 | 260 | 185 | 6 | 2.5 | 4340 | 10800 | 409 | 160 | 200 | |

| NB.3519/600 | 10979/600 | 600 | 800 | 205 | 156 | 5 | 1.5 | 3210 | 9460 | 266 | 150 | 190 |

| NB.3510/600 | 971/600 | 870 | 270 | 198 | 6 | 2.5 | 4880 | 12730 | 500 | 130 | 170 | |

| NB.3519/630 | 10979/630 | 630 | 850 | 242 | 182 | 6 | 2.5 | 3730 | 10390 | 368 | 130 | 170 |

| NB.3519/670 | 10979/670 | 670 | 900 | 240 | 180 | 6 | 2.5 | 5300 | 12300 | 416 | 120 | 160 |

| NB.3519/710×2 | 10979/710 | 710 | 950 | 240 | 175 | 6 | 2.5 | 4070 | 12400 | 444 | 100 | 140 |

| NB.3506/710 | 977/710 | 1030 | 236 | 208 | 7.5 | 4 | 5750 | 14300 | 651 | 90 | 120 | |

| NB.3510/710 | 971/710 | 1030 | 315 | 220 | 7.5 | 3 | 7830 | 18400 | 774 | 90 | 120 | |

| NB.3506/720 | 9771720 | 720 | 915 | 190 | 140 | 3 | 6 | 3200 | 9650 | 277 | 100 | 140 |

| NB.3519/750 | 10979/750 | 750 | 1000 | 264 | 194 | 6 | 2.5 | 5020 | 14480 | 499 | 90 | 120 |

| NB.3519/800 | 10979/800 | 800 | 1060 | 270 | 204 | 6 | 2.5 | 5020 | 15000 | 604 | 80 | 100 |

| NB.3519/850 | 10979/850 | 850 | 1120 | 268 | 188 | 6 | 2.5 | 5460 | 16860 | 636 | 75 | 95 |

| NB.3519/950 | 10979/950 | 950 | 1250 | 300 | 220 | 7.5 | 3 | 6790 | 21100 | 909 | - | - |

| NB.BT2B 332756 | - | 1120 | 1480 | 400 | 296 | 12 | A | 12060 | 34200 | 1760 | - | - |

| NB.BT2B 332780 | - | 1160 | 1540 | 400 | 290 | 12 | 4 | 12780 | 34200 | 1900 | - | - |

| NB.BT2B 328339 | - | 1250 | 1500 | 250 | 190 | 6 | 1.5 | 6633 | 20160 | 795 | - | - |

| NB.BT2B 332496 | - | 1778 | 2159 | 393.7 | 266.7 | 12.7 | 3 | 13860 | 47700 | 2750 | - | - |

Double row line contact design + tapered roller structure, leading radial and bidirectional axial load-bearing capacity in the industry, adapting to heavy-load and ultra-heavy-load scenarios.

No need for additional thrust bearings, directly bearing bidirectional axial loads, simplifying equipment design and reducing assembly costs

Integral structure and optimized roller distribution, strong deformation resistance and shock resistance, adapting to frequent start-stop and harsh working conditions.

Some models support separable inner and outer ring design, allowing separate installation/replacement, shortening maintenance cycles and reducing labor costs.

Technical specifications fully match imported series, ensuring stable supply and reducing procurement costs by 20%-30%, making it ideal for domestic substitution needs.

Applications of Double Row Tapered Roller Bearings

1. Automotive & Transportation

Truck and bus wheel hubs

Railway axle boxes

Heavy-duty vehicle transmissions

They handle combined loads and shocks encountered during braking, cornering, and acceleration.

2. Gearboxes & Speed Reducers

Industrial gearboxes

Heavy-duty reducers

Marine gear systems

Double row tapered roller bearings support large gear-induced axial and radial forces.

3. Construction Machinery

Excavators

Loaders

Cranes

These machines generate heavy, fluctuating loads and require robust bearings with high rigidity.

4.Mining & Quarry Equipment

Crushers

Conveyors

Grinding mills

Designed to withstand extreme loads, vibration, and harsh operating environments.

5. Steel & Metallurgical Equipment

Rolling mills

Continuous casting machines

Steel processing lines

High load capacity and stiffness are essential for dimensional accuracy and durability.

6. Wind Energy Equipment

Wind turbine main shafts

Gearbox input/output shafts

They support heavy radial and axial loads with long service life.

7. Marine & Offshore Equipment

Propulsion systems

Winches

Deck machinery

Excellent load handling and reliability in demanding marine conditions.

8. Machine Tools (Heavy Duty)

Large spindles

Rotary tables

Indexing heads

Double row tapered roller bearings maintain rigidity and precision under heavy cutting forces.

9. Agricultural Machinery

Tractors

Harvesters

Large tillage equipment

They withstand high loads, shock, and contamination in field operations.

10. Industrial Fans & Heavy Rotating Equipment

Large blowers

Cooling fans

Industrial mixers

They provide stable shaft support under combined loads.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.