ZKLDF thrust angular contact ball bearings are specifically designed for high-speed, high-precision rotary systems, featuring a unified outer ring, two inner rings, two rows of balls, and a cage assembly with a 60° contact angle. They are capable of simultaneously bearing radial loads, bidirectional axial loads, and tilting moments. Their integrated structure with mounting holes on inner and outer rings facilitates easy installation, while the double-sided sealing design ensures dust resistance and grease retention. These bearings are ideal for equipment requiring high rigidity, low friction torque, and precise rotation, such as high-speed rotary worktables, milling heads, grinding machines, honing heads, and precision measuring instruments.

Accuracy Classes: P4, P2

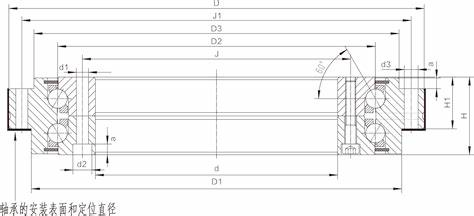

Size:Inner diameter: 100-650mmOuter diameter: 185-870mmHeight: 38-122mm

Materials:

Bearing rings and rolling elements: GCr15 high-carbon chromium steel (hardness HRC 60-62) or SUS440C stainless steel (corrosion-resistant)

Cage: Brass (high-strength), Nylon 66 (lightweight) or steel materials

Sealing Options:

Open Type: Requires regular external lubrication

Contact Rubber Seal (-2RS): Dust-proof and splash-proof, with built-in complex barium-base grease and grease holes for refilling

| Model | Inner Diameter (d) [mm] | Outer Diameter (D) [mm] | Height (H) [mm] | Dynamic Load (C) [kN] | Static Load (C₀) [kN] | Max. Speed (n) [rpm] | Weight (kg) |

|---|---|---|---|---|---|---|---|

| ZKLDF 200 | 200 | 310 | 102 | 220 | 440 | 850 | 15.5 |

| ZKLDF 250 | 250 | 370 | 122 | 315 | 630 | 750 | 24 |

| ZKLDF 320 | 320 | 460 | 142 | 425 | 850 | 630 | 38.5 |

| ZKLDF 400 | 400 | 560 | 172 | 600 | 1200 | 530 | 62 |

| ZKLDF 500 | 500 | 680 | 202 | 850 | 1700 | 450 | 95 |

A single bearing can simultaneously bear radial force (≤50 kN), axial force (≤30 kN) and moment (≤3000 N·m).

With P4-level precision, the radial runout is ≤0.002 mm.

Pre-installed alignment washers simplify the installation process.

The option of stainless steel material plus a fully sealed design makes it suitable for humid, corrosive or vacuum environments.

1. Heavy-Duty Gearboxes

Industrial Gearboxes: Used in the input and output shafts of large gearboxes for conveyors, mixers, extruders, and mining equipment.

Wind Turbine Gearboxes: Their high capacity and rigidity are essential for supporting the main shaft and intermediate stages in a wind turbine's gearbox, which experiences highly variable and significant loads.

2. Mining and Quarrying Equipment

Vibrating Screens: These applications involve extreme shock loads and continuous vibration. ZKLDF bearings are chosen for their ability to withstand these punishing conditions.

Crushers and Mills: In jaw crushers, cone crushers, and ball mills where immense forces are used to break down rock and minerals.

Conveyor Drums and Pulleys: Supporting the high-tension shafts of heavy-duty belt conveyors.

3. Material Handling

Crane Slewing Rings: In the slewing mechanism of mobile cranes and portal cranes, providing rotation while handling the combined load of the boom and the load.

Hoist Mechanisms: In the drum assemblies of industrial hoists and winches.

4. Steel and Metal Processing

Rolling Mills: Used in the backup roll assemblies of rolling mills, where they must withstand tremendous radial forces from deforming metal.

Continuous Casters: In guide rolls and support rolls that handle red-hot slabs of metal.

5. Construction and Off-Highway Vehicles

Wheel Hubs: On large off-road vehicles, construction equipment, and agricultural machinery.

Track Rollers and Idlers: In the undercarriage of excavators and bulldozers.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.