A thrust ball bearing is a specialized rotary bearing designed to support axial loads (forces parallel to the shaft's axis) at high speeds, featuring balls within grooved washers to enable smooth rotation, commonly used in applications like car steering, turntables, and appliances where radial loads are minimal. Unlike radial bearings, they excel at managing thrust but cannot handle radial (perpendicular) forces, coming in single-direction (one way) or double-direction (both ways) types.

Features: Type: Single-row (unidirectional axial load) / Double-row (bidirectional axial load); Shaft Washer & Housing Washer: Split structure (easy installation); Ball Arrangement: High-precision steel balls (evenly distributed, point contact, guided by cage);

Accuracy : P0, P6, P5, P4;

Size: Single-row (Metric Series): Inner Diameter: 160–1400 mm; Outer Diameter: 200–1630 mm; Total Thickness: 31–195 mm;

Materials: Bearing Rings & Balls: GCr15 high-carbon chromium steel or SUS440C stainless steel; Cages: Brass, reinforced Nylon 66, or stamped steel;

Delivery: Standard models: 3–10 days (single-row), 5–12 days (double-row); Customized models: Please contact the manufacturer.

| Thrust Ball Bearing | |||||||||||||||

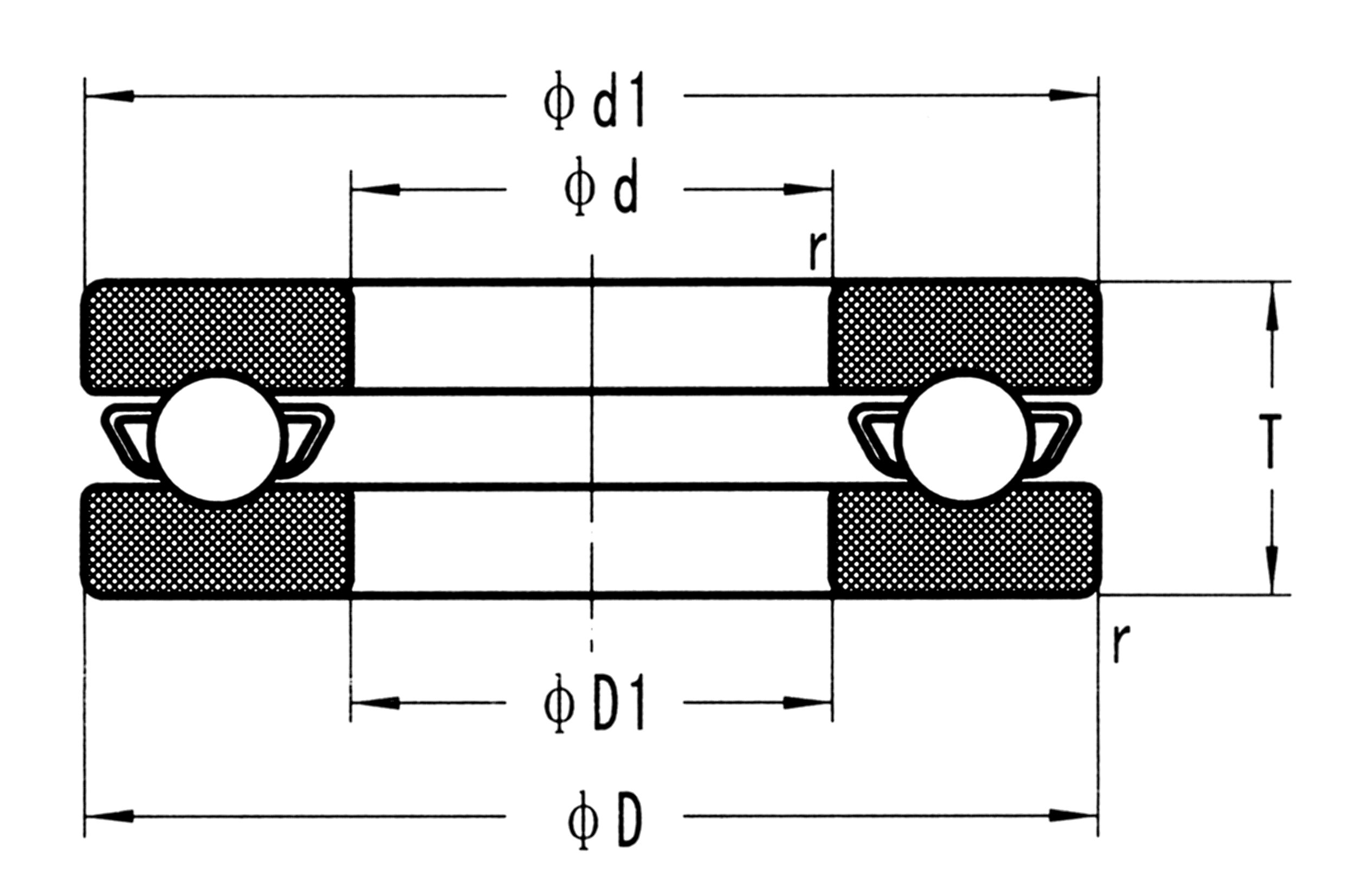

| Part number | Boundary dimensions | Basic load ralings | Mass | Installation dimersion | Limiting speeds | ||||||||||

| Current | Original | mm | kN | kg | mm | r/min | |||||||||

| d | d1min | D | D1max | T | rmin | Ca | Coa | da | Da | ramax | Gresae | oil | |||

| NB.51132 | 8132 | 160 | 162 | 200 | 198 | 31 | 1 | 112 | 428 | 2.3 | 184 | 176 | 1 | 1000 | 1600 |

| NB.51232 | 8232 | 163 | 225 | 222 | 51 | 1.5 | 240 | 768 | 6.7 | 199 | 186 | 1.5 | 750 | 1100 | |

| NB.51332 | 8332 | 164 | 270 | 265 | 87 | 3 | 470 | 1570 | 21.5 | 225 | 205 | 2.5 | 500 | 700 | |

| NB.51134 | 8134 | 170 | 172 | 215 | 213 | 34 | 1.1 | 133 | 528 | 3.3 | 197 | 188 | 1 | 950 | 1500 |

| NB.51234 | 8234 | 173 | 240 | 237 | 55 | 1.5 | 280 | 915 | 8.3 | 212 | 198 | 1.5 | 700 | 1000 | |

| NB.51334 | 8334 | 174 | 280 | 275 | 87 | 3 | 470 | 1580 | 22.5 | 235 | 215 | 2.5 | 480 | 670 | |

| NB.51136 | 8136 | 180 | 183 | 225 | 222 | 34 | 1.1 | 135 | 528 | 3.6 | 207 | 198 | 1 | 900 | 1400 |

| NB.51236 | 8236 | 183 | 250 | 247 | 56 | 1.5 | 285 | 958 | 8.08 | 222 | 208 | 1.5 | 670 | 950 | |

| NB.51336 | 8336 | 184 | 300 | 295 | 95 | 3 | 518 | 1820 | 28.7 | 251 | 229 | 2.5 | 430 | 600 | |

| NB.51138 | 8138 | 190 | 193 | 240 | 237 | 37 | 1.1 | 172 | 678 | 4.2 | 220 | 210 | 1 | 850 | 1300 |

| NB.51238 | 8238 | 194 | 270 | 267 | 62 | 2 | 328 | 1160 | 13 | 238 | 222 | 2 | 630 | 900 | |

| NB.51338 | 8338 | 195 | 320 | 315 | 105 | 4 | 608 | 2220 | 34.5 | 266 | 244 | 3 | 400 | 560 | |

| NB.51140 | 8140 | 200 | 203 | 250 | 247 | 37 | 1.1 | 172 | 698 | 3.8 | 230 | 220 | 1 | 800 | 1200 |

| NB.51240 | 8240 | 204 | 280 | 277 | 62 | 2 | 350 | 1210 | 11.9 | 248 | 232 | 2 | 600 | 850 | |

| NB.51340 | 8340 | 205 | 340 | 335 | 110 | 4 | 660 | 2220 | 31.8 | 282 | 258 | 3 | 360 | 500 | |

| NB.51144 | 8144 | 220 | 223 | 270 | 267 | 37 | 1.1 | 188 | 782 | 4.6 | 250 | 240 | 1 | 750 | 1100 |

| NB.51244 | 8244 | 224 | 300 | 297 | 63 | 2 | 365 | 1360 | 13.3 | 268 | 252 | 2 | 560 | 800 | |

| NB.51148 | 8148 | 240 | 243 | 300 | 297 | 45 | 1.5 | 258 | 1040 | 7.5 | 276 | 264 | 1.5 | 700 | 1000 |

| NB.51248 | 8248 | 244 | 340 | 335 | 78 | 2.1 | 468 | 1870 | 23.5 | 299 | 281 | 2 | 450 | 630 | |

| NB.51152 | 8152 | 260 | 263 | 320 | 317 | 45 | 1.5 | 270 | 1140 | 8.1 | 296 | 284 | 1.5 | 670 | 950 |

| NB.51252 | 8252 | 264 | 360 | 355 | 79 | 2.1 | 488 | 2050 | 25.5 | 319 | 301 | 2 | 430 | 600 | |

| NB.51156 | 8156 | 280 | 283 | 350 | 347 | 53 | 1.5 | 338 | 1430 | 11.8 | 322 | 308 | 1.5 | 560 | 800 |

| NB.51256 | 8256 | 284 | 380 | 375 | 80 | 2.1 | 490 | 2140 | 27.5 | 339 | 321 | 2 | 400 | 560 | |

| NB.51160 | 8160 | 300 | 304 | 380 | 376 | 62 | 2 | 415 | 1860 | 17.5 | 348 | 332 | 2 | 500 | 700 |

| NB.51260 | 8260 | 304 | 420 | 415 | 95 | 3 | 578 | 2670 | 42.5 | 371 | 349 | 2.5 | 360 | 560 | |

| NB.51164 | 8164 | 320 | 324 | 400 | 396 | 63 | 2 | 418 | 1920 | 18.8 | 368 | 352 | 2 | 480 | 670 |

| NB.51264 | 8264 | 325 | 440 | 435 | 95 | 3 | 612 | 2920 | 45.5 | 391 | 369 | 2.5 | 340 | 480 | |

| NB.51168 | 8168 | 340 | 344 | 420 | 416 | 64 | 2 | 428 | 2050 | 19.8 | 388 | 372 | 2 | 450 | 630 |

| NB.51268 | 8268 | 345 | 460 | 455 | 96 | 3 | 620 | 3040 | 45 | 411 | 389 | 2.5 | 320 | 450 | |

| NB.51368 | 8368 | 345 | 540 | 535 | 160 | 5 | 1120 | 5720 | 142 | 457 | 425 | 4 | 150 | 220 | |

| NB.51172 | 8172 | 360 | 364 | 440 | 436 | 65 | 2 | 432 | 2110 | 21.1 | 408 | 392 | 2 | 430 | 600 |

| NB.51272 | 8272 | 365 | 500 | 495 | 110 | 4 | 775 | 3940 | 69.2 | 443 | 417 | 3 | 260 | 380 | |

| NB.51176 | 8176 | 380 | 384 | 460 | 456 | 65 | 2 | 440 | 2210 | 23 | 428 | 412 | 2 | 430 | 600 |

| NB.51276 | 8276 | 385 | 520 | 515 | 112 | 4 | 788 | 4120 | 73 | 463 | 437 | 3 | 240 | 360 | |

| NB.51180 | 8180 | 400 | 404 | 480 | 476 | 65 | 2 | 452 | 2320 | 23 | 448 | 432 | 2 | 400 | 560 |

| NB.51280 | 8280 | 405 | 540 | 535 | 112 | 4 | 802 | 4310 | 74.5 | 483 | 457 | 3 | 220 | 340 | |

| NB.51184 | 8184 | 420 | 424 | 500 | 495 | 65 | 2 | 462 | 2480 | 25.5 | 468 | 452 | 2 | 380 | 530 |

| NB.51784 | 8784 | 422 | 550 | 550 | 80 | 5 | 463 | 2574 | 53.6 | 468 | 452 | 2 | 310 | 430 | |

| NB.51188 | 8188 | 440 | 444 | 540 | 535 | 80 | 2.1 | 527 | 3000 | 42 | 499 | 481 | 2 | 360 | 500 |

| NB.59188/YB2 | 9008188 | 444 | 540 | 535 | 60 | 2.1 | 360 | 2112 | 28.2 | 499 | 481 | 2 | 320 | 470 | |

| NB.51288 | 8288 | 445 | 600 | 595 | 130 | 5 | 808 | 4430 | 109 | 537 | 505 | 4 | 180 | 280 | |

| NB.51192 | 8192 | 460 | 464 | 560 | 555 | 80 | 2.1 | 578 | 3310 | 41.7 | 518 | 502 | 2 | 320 | 450 |

| NB.51292 | 8292 | 465 | 620 | 615 | 130 | 5 | 892 | 5230 | 114 | 557 | 525 | 4 | 170 | 260 | |

| NB.51196 | 8196 | 480 | 484 | 580 | 575 | 80 | 2.1 | 592 | 3490 | 42.5 | 538 | 522 | 2 | 300 | 430 |

| NB.51396 | 8396 | 485 | 730 | 725 | 195 | 6 | 1065 | 6886 | 308 | 620 | 590 | 5 | 230 | 330 | |

| NB.511/500 | 81/500 | 500 | 504 | 600 | 595 | 80 | 2.1 | 595 | 3570 | 45.7 | 559 | 541 | 2 | 280 | 400 |

| NB.512/500 | 82/500 | 505 | 670 | 665 | 135 | 5 | 1020 | 6200 | 137 | 601 | 569 | 4 | 150 | 220 | |

| NB.593/500 | 90083/500 | 505 | 750 | 745 | 150 | 6 | 950 | 6320 | 228 | 641 | 609 | 5 | 180 | 220 | |

| NB.511/530 | 81/530 | 530 | 534 | 640 | 635 | 85 | 3 | 708 | 4000 | 55.8 | 595 | 575 | 2.5 | 260 | 380 |

| NB.590/560 | 90089/560 | 560 | 560.6 | 610 | 610 | 30 | 1.1 | 128 | 960 | 9.55 | 592 | 578 | 1 | 560 | 800 |

| NB.591/600 | 90081/600 | 600 | 604 | 710 | 705 | 67 | 3 | 690 | 4215 | 50.1 | 665 | 645 | 2.5 | 380 | 500 |

| NB.512/630 | 82/630 | 630 | 635 | 850 | 845 | 175 | 6 | 1320 | 9300 | 252 | 759 | 721 | 5 | 100 | 160 |

| NB.510/670 | 10089/670 | 670 | 672 | 730 | 730 | 45 | 1.5 | 284 | 2160 | 20.5 | 707 | 693 | 1.5 | 530 | 700 |

| NB.511/670 | 81/670 | 675 | 800 | 795 | 105 | 4 | 860 | 5020 | 92.2 | 748 | 722 | 3 | 160 | 240 | |

| NB.591/710 | 90081710 | 710 | 715 | 850 | 845 | 85 | 4 | 478 | 846 | 86 | 793 | 797 | 3 | 130 | 180 |

| NB.572710 | 70082/710 | 715 | 950 | 945 | 109 | 6 | 787 | 980 | 199 | 846 | 814 | 5 | 130 | 180 | |

| NB.592/710 | 90082/710 | 715 | 950 | 945 | 145 | 6 | 1025 | 1296 | 284 | 846 | 814 | 5 | 120 | 160 | |

| NB.591/750 | 90081/750 | 750 | 755 | 900 | 895 | 90 | 4 | 810 | 6210 | 105 | 838 | 812 | 3 | 160 | 240 |

| NB.517/780 | 87/780 | 780 | 782 | 930 | 930 | 100 | 3.5 | 800 | 6069 | 129 | 868 | 842 | 3 | 150 | 200 |

| NB.510/800 | 10089/800 | 800 | 802.5 | 870 | 867.5 | 53 | 1.5 | 334 | 2880 | 32.5 | 841 | 872 | 1.5 | 430 | 560 |

| NB.591/800 | 90081/800 | 805 | 950 | 945 | 90 | 4 | 685 | 5895 | 110 | 886 | 864 | 3 | 300 | 400 | |

| NB.511/800 | 81/800 | 805 | 950 | 945 | 120 | 4 | 909 | 8100 | 155 | 886 | 864 | 3 | 240 | 340 | |

| NB.510/850 | 10089/850 | 850 | 852.5 | 920 | 917.5 | 53 | 1.5 | 339 | 3105 | 34.5 | 891 | 879 | 1.5 | - | - |

| NB.591/850 | 90081/850 | 855 | 1000 | 995 | 90 | 4 | 685 | 6120 | 115 | 938 | 912 | 3 | - | - | |

| NB.511/850 | 81/850 | 855 | 1000 | 995 | 120 | 4 | 954 | 8550 | 165 | 938 | 912 | 3 | - | - | |

| NB.510/900 | 10089/900 | 900 | 903 | 980 | 977 | 63 | 2 | 474 | 4410 | 49 | 948 | 932 | 2 | - | - |

| NB.591/900 | 90081/900 | 906 | 1060 | 1054 | 95 | 5 | 567 | 6885 | 140 | 995 | 965 | 4 | - | - | |

| NB.511/900 | 81/900 | 906 | 1060 | 1054 | 130 | 5 | 1026 | 9720 | 205 | 995 | 965 | 4 | - | - | |

| NB.510/950 | 10089/950 | 950 | 953 | 1080 | 1074 | 63 | 2 | 486 | 4590 | 52 | 998 | 982 | 2 | - | - |

| NB.591/950 | 90081/950 | 956 | 1120 | 1114 | 103 | 5 | 767 | 7335 | 170 | 1047 | 1023 | 4 | - | - | |

| NB.511/950 | 81/950 | 956 | 1120 | 1114 | 135 | 5 | 1197 | 10800 | 235 | 1051 | 1019 | 4 | - | - | |

| NB.510/1000 | 10089/1000 | 1000 | 1003.5 | 1090 | 1086.5 | 70 | 2.1 | 514 | 4950 | 68.5 | 1053 | 1037 | 2 | - | - |

| NB.591/1000 | 90081/1000 | 1006 | 1180 | 1174 | 109 | 5 | 831 | 8235 | 210 | 1102 | 1078 | 4 | - | - | |

| NB.511/1000 | 81/1000 | 1006 | 1180 | 1174 | 140 | 5 | 1197 | 11880 | 275 | 1106 | 1074 | 4 | - | - | |

| NB.510/1060 | 10089/1060 | 1060 | 1063.5 | 1150 | 1146.5 | 70 | 2.1 | 677 | 5265 | 72.5 | 1113 | 1097 | 2 | - | - |

| NB.591/1060 | 90081/1060 | 1066 | 1250 | 1244 | 115 | 5 | 909 | 9360 | 240 | 1172 | 1138 | 4 | - | - | |

| NB.511/1060 | 81/1060 | 1066 | 1250 | 1244 | 150 | 5 | 1287 | 13500 | 330 | 1172 | 1138 | 4 | - | - | |

| NB.511/1120 | 81/1120 | 1120 | 1126 | 1320 | 1314 | 160 | 5 | 1377 | 14670 | 395 | 1238 | 1202 | 4 | - | - |

| NB.511/1180 | 81/1180 | 1180 | 1188 | 1400 | 1392 | 175 | 6 | 1602 | 18000 | 495 | 1392 | 1358 | 5 | - | - |

| NB.511/1400 | 81/1400 | 1400 | 1408 | 1630 | 1622 | 180 | 8 | 1710 | 21240 | 665 | 1475 | 1445 | 4 | - | - |

P4-class ultra-precision, micron-level runout control, meeting the axial positioning requirements of precision equipment.

Small size and light weight, adapting to equipment with limited space, enabling unidirectional/bidirectional load bearing without additional bearings.

Split structure design, enabling installation and replacement without disassembling related components, reducing maintenance costs and downtime.

Technical specifications fully match imported series, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with various environments such as clean, high-temperature, and low-noise conditions, supports multi-dimensional customization, covering general machinery, machine tools, automotive, household appliances and other fields.

Applications of Thrust Ball Bearings

1. Machine Tools

Vertical lathes

Lead screws

Feed mechanisms

Provide accurate axial positioning with low friction.

2. Automotive Components

Clutches

Steering systems

Support axial forces during operation.

3. Industrial Gearboxes

Light-duty gearboxes

Auxiliary shafts

Used where axial load is present but radial load is minimal.

4. Pumps & Compressors

Vertical pumps

Small compressors

Maintain shaft axial position.

5. Valves & Actuators

Control valves

Linear actuators

Allow smooth axial movement under load.

6. Turntables & Rotating Platforms

Light-duty rotary tables

Positioning devices

Enable smooth rotation under axial loads.

7. Agricultural Machinery

Seeders

Light-duty transmission components

Operate reliably at low speeds.

8. Conveyors & Material Handling Equipment

Screw conveyors

Roller conveyors

Support thrust loads generated by operation.

9. Electrical & Mechanical Equipment

Electric motors (axial positioning)

Fans and blowers

Maintain axial alignment.

10. General Industrial Machinery

Presses

Lifting mechanisms

Used where simple axial load support is required.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.