A Tapered Roller Thrust Bearing is a robust bearing designed for heavy axial (thrust) loads and some radial loads, using tapered rollers for efficient load distribution, high rigidity, and shock resistance, commonly found in heavy machinery like cranes, gear drives, and steel mills for precise axial guidance. Its design allows it to handle significant forces in one direction while offering a compact, stiff solution with long life.

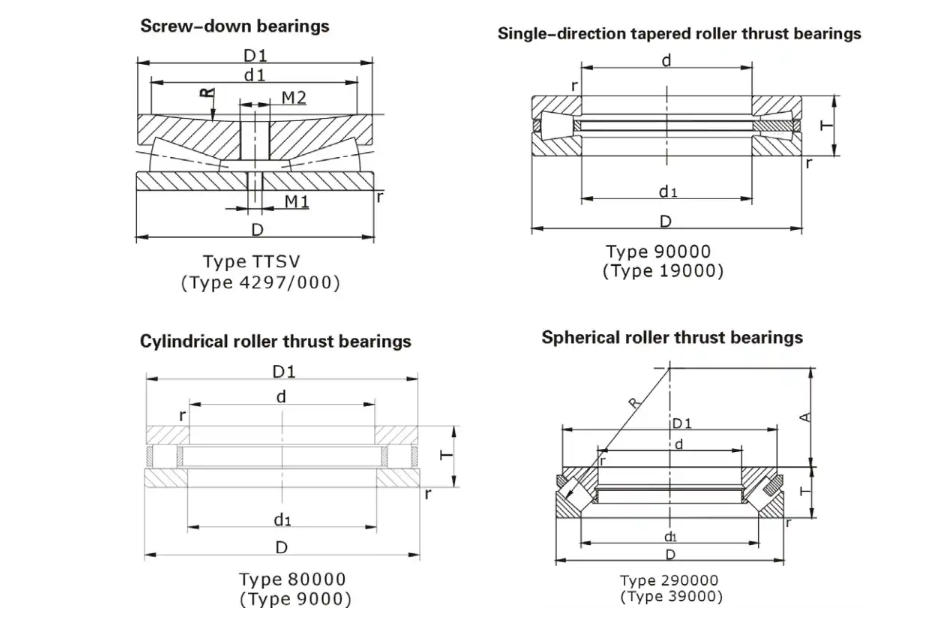

Features: Type: Single-row (unidirectional axial load) / Double-row (bidirectional axial load, self-aligning); Shaft Washer & Housing Washer: Split structure (easy installation); Roller Arrangement: Tapered rollers (evenly distributed, matched taper angles, line contact);

Accuracy: P0, P6, P5, P4;

Size:Inner Diameter: 127–550 mm; Outer Diameter: 150–640 mm; Total Thickness: 48–185 mm;

Materials: Bearing Rings & Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel; Cages: Brass, reinforced Nylon 66, or stamped steel;

Delivery: Standard models: 7–15 days (single-row), 10–20 days (double-row); Customized models: Please contact the manufacturer.

| Tapered Roller Thrust Bearing | |||||||||||

| Designations | Boundary dimensions | Basic load ratings | Mass | ||||||||

| Current | Original | mm | KN | kg | |||||||

| D | D1 | d1 | T | R | M1 | M2 | rmin | Coa | |||

| NB.TTSV150 | 4297/150 | 150 | 148 | 127 | 48 | 228.6 | M12 | - | 1.5 | 1630 | 5 |

| NB.TTSV175 | 4297/175 | 175 | 173 | 152 | 53 | 228.6 | M12 | - | 1.5 | 2180 | 8 |

| NB.TTSV203 | 4297/203 | 203 | 201 | 178 | 65 | 254 | M12 | - | 1.5 | 2540 | 11 |

| NB.TTSV205 | 4297/205 | 205 | 203 | 178 | 65 | 254 | M20 | - | 1.5 | 3370 | 15 |

| NB.TTSV235 | 4297/235 | 235 | 233 | 208 | 73 | 280 | M20 | - | 1.5 | 3370 | 18 |

| NB.TTSV265 | 4297/265 | 265 | 263 | 229 | 81 | 304.8 | M20 | - | 1.5 | 4130 | 24 |

| NB.TTSV320 | 4297/320 | 320 | 318 | 280 | 95 | 380 | M24 | - | 1.5 | 7370 | 42 |

| NB.TTSV377 | 4297/377 | 377 | 375 | 330 | 112 | 457.2 | M24 | - | 2.5 | 8230 | 86 |

| NB.TTSV380 | 4297/380 | 380 | 378 | 330 | 112 | 457.2 | M24 | M30 | 1.5 | 8220 | 67 |

| NB.TTSV410 | 4297/410 | 410 | 408 | 355 | 122 | 508 | M24 | M30 | 3 | 11300 | 115 |

| NB.TTSV440 | 4297/440 | 440 | 438 | 380 | 130 | 508 | M24 | M36 | 3 | 18500 | 140 |

| NB.TTSV495 | 4297/495 | 495 | 492 | 432 | 146 | 558.8 | M24 | M36 | 3 | 19100 | 198 |

| NB.TTSV525 | 4297/525 | 525 | 522 | 460 | 155 | 635 | M24 | M36 | 3 | 20380 | 210 |

| NB.TTSV555 | 4297/555 | 555 | 552 | 482 | 165 | 635 | M24 | M36 | 3 | 21380 | 275 |

| NB.TTSV580 | 4297/580 | 580 | 577 | 510 | 165 | 710 | M24 | M42 | 3 | 23540 | 250 |

| NB.TTSV610 | 4297/610 | 610 | 607 | 533 | 178 | 762 | M30 | M42 | 3 | 24170 | 350 |

| NB.TTSV640 | 4297/640 | 640 | 637 | 550 | 185 | 762 | M30 | M42 | 3 | 28670 | 410 |

Maximum axial load up to 8000 KN, leading in the industry, adapting to the axial heavy-load requirements of ultra-heavy equipment, replacing multiple sets of ordinary thrust bearing combinations.

Single-row (compact) and double-row (self-aligning) options, selectable according to equipment load direction and working condition requirements, no need for additional bearings.

Split structure design, enabling installation and replacement without disassembling related components, reducing maintenance costs and downtime of large-size equipment.

Technical specifications fully match imported series, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with complex heavy-duty environments such as high-temperature, dusty, and humid conditions, supports multi-dimensional customization, covering metallurgy, mining, machine tools, wind power and other fields.

Applications of Tapered Roller Thrust Bearings

1. Heavy-Duty Industrial Gearboxes

Vertical and horizontal gear drives

Bevel and planetary gearboxes

They support high axial forces generated by gear meshing.

2. Machine Tools

Vertical machine tool spindles

Rotary tables

Indexing heads

Provide high axial rigidity and precise positioning.

3. Construction & Earthmoving Machinery

Cranes

Excavators

Loaders

Designed to withstand heavy thrust loads and shock.

4. Metallurgical Equipment

Rolling mills

Continuous casting machines

Handle extreme axial loads in harsh environments.

5.Marine & Offshore Equipment

Propeller thrust blocks

Winches

Offshore handling systems

Support propeller and operational thrust loads.

6. Mining Machinery

Crushers

Grinding mills

Hoisting equipment

Operate reliably under heavy loads and contamination.

7. Wind Energy Equipment

Wind turbine main shafts

Pitch and yaw systems

Used where high axial forces and stiffness are required.

8. Industrial Pumps & Compressors

Vertical pumps

Large compressors

Maintain axial shaft positioning under load.

9. Oil & Gas Equipment

Drilling rigs

Top drives

Designed for extreme loads and demanding conditions.

10. Special Purpose Heavy Machinery

Test rigs

Large rotating platforms

Provide stable axial load support.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.