A Full Complement Cylindrical Roller Bearing (FCCRB) is a high-capacity radial bearing that fits the maximum number of cylindrical rollers by omitting the cage, allowing for heavier loads in a compact space but at lower speeds due to increased internal friction from rollers contacting each other. These bearings offer high stiffness and rigidity and are essential for heavy-duty applications like cranes, material handling, and mining.

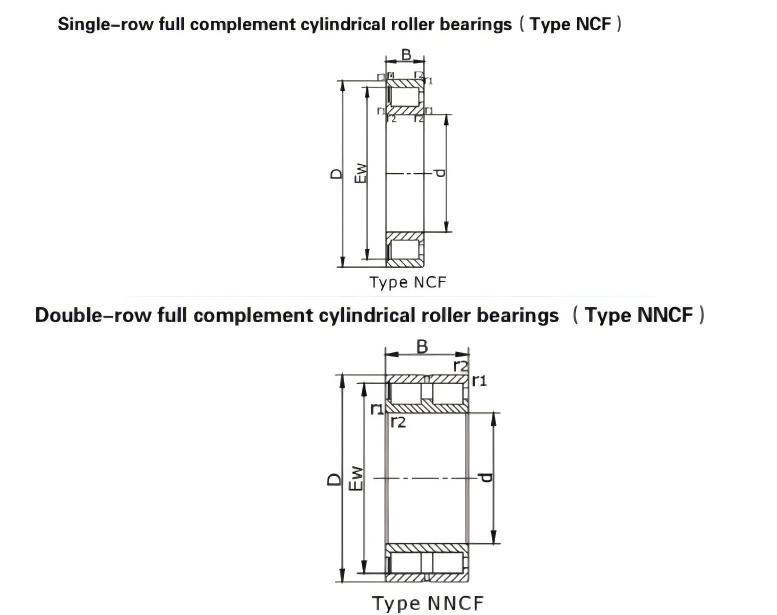

Features: Inner Ring: Integral or separable structure (optional); Outer Ring: Integral structure; Roller Arrangement: Full complement cylindrical rollers (parallel distribution, cage-free, line contact);

Accuracy : P0, P6, P5, P4;

Size: Inner Diameter: 150–1000 mm; Outer Diameter: 210–1320 mm; Width:36–272mm;

Materials: Bearing Rings & Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel ;

Special Note: Cage-free design, reducing friction interference through optimized roller arrangement, suitable for medium-low speed heavy-load scenarios;

Delivery: Standard models: 5–12 days; Customized models :Please contact the manufacturer.

| SPECIFICATIONS-SINGLE ROW | ||||||||||||||

| Designations | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | Installation dimersion | |||||||||

| mm | kN | kg | r/min | (mm) | ||||||||||

| d | D | B | r1、2min | r3、4min | Ew | Cr | Cor | Grease | Oil | da(min) | Da(max) | ra(max) | ||

| NB.NCF2930V | 150 | 210 | 36 | 2 | 1.1 | 195.5 | 289 | 505 | 670 | 1400 | 159 | 201 | 2 | 3.7 |

| NB.NCF3030V | 225 | 56 | 2.1 | 1.1 | 211.7 | 460 | 710 | 630 | 1300 | 161 | 214 | 2 | 7.1 | |

| NB.NCF2932V | 160 | 220 | 36 | 2 | 1.1 | 205.7 | 310 | 535 | 630 | 1300 | 169 | 211 | 2 | 3.8 |

| NB.NCF3032V | 240 | 60 | 2.1 | 1.1 | 225.1 | 520 | 810 | 600 | 1200 | 171 | 229 | 2 | 8.6 | |

| NB.NCF1834V | 170 | 215 | 22 | 1.5 | 1.1 | 203.5 | 149 | 272 | 600 | 1200 | 182 | 204 | 1.5 | 1.8 |

| NB.NCF2934V | 230 | 36 | 2 | 1.1 | 216 | 320 | 570 | 600 | 1200 | 179 | 221 | 2 | 4.1 | |

| NB.NCF3034V | 260 | 67 | 2.1 | 1.1 | 243.2 | 675 | 1070 | 560 | 1100 | 181 | 249 | 2 | 11.9 | |

| NB.NCF1836V | 180 | 225 | 22 | 1.1 | 1 | 215.2 | 154 | 290 | 600 | 1200 | 187.5 | 217.5 | 1 | 1.8 |

| NB.NCF2936V | 250 | 42 | 2 | 1.1 | 232 | 390 | 695 | 560 | 1100 | 189 | 241 | 2 | 6 | |

| NB.NCF3036V | 280 | 74 | 2.1 | 2.1 | 260.5 | 785 | 1260 | 560 | 1100 | 191 | 269 | 2 | 15.8 | |

| NB.NCF1838V | 190 | 240 | 24 | 1.5 | 1.1 | 229 | 178 | 335 | 560 | 1100 | 198 | 232 | 1.5 | 2.4 |

| NB.NCF2938V | 260 | 42 | 2 | 1.1 | 244 | 435 | 785 | 560 | 1100 | 199 | 251 | 2 | 6.5 | |

| NB.NCF3038V | 290 | 75 | 2.1 | 2.1 | 270 | 805 | 1320 | 530 | 1000 | 201 | 279 | 2 | 16.7 | |

| NB.NCF1840V | 200 | 250 | 24 | 1.5 | 1.1 | 237.5 | 193 | 356 | 560 | 1100 | 208 | 242 | 1.5 | 2.5 |

| NB.NCF2940V | 280 | 48 | 2.1 | 1.5 | 262 | 530 | 955 | 530 | 1000 | 211 | 269 | 2 | 8.9 | |

| NB.NCF3040V | 310 | 82 | 2.1 | 2.1 | 288.2 | 910 | 1510 | 500 | 950 | 211 | 299 | 2 | 21.4 | |

| NB.NCF3056V | 280 | 420 | 106 | 4 | 4 | 390.5 | 1740 | 3110 | 49 | 360 | 670 | 302 | 395 | 3 |

| NB.NCF1860V | 300 | 380 | 38 | 2.1 | 1.5 | 363 | 445 | 870 | 9.7 | 360 | 670 | 311 | 369 | 2 |

| NB.NCF2960V | 420 | 72 | 3 | 3 | 385 | 805 | 1730 | 30.7 | 340 | 630 | 320 | 398 | 2.5 | |

| NB.NCF3060V | 460 | 118 | 4 | 4 | 432 | 1980 | 3500 | 67.6 | 320 | 600 | 316 | 444 | 3 | |

| NB.NCF1864V | 320 | 400 | 38 | 2.1 | 1.5 | 383 | 460 | 925 | 10.3 | 340 | 630 | 331 | 389 | 2 |

| NB.NCF2964V | 440 | 72 | 3 | 3 | 411 | 1150 | 2340 | 33 | 320 | 600 | 333 | 427 | 2.5 | |

| NB.NCF3064V | 480 | 121 | 4 | 4 | 447.3 | 2170 | 3900 | 73 | 300 | 560 | 336 | 464 | 3 | |

| NB.NCF1868V | 340 | 420 | 38 | 2.1 | 1.5 | 401 | 475 | 985 | 10.7 | 320 | 600 | 359 | 402 | 2 |

| NB.NCF2968V | 460 | 72 | 3 | 3 | 431 | 1190 | 2470 | 34.1 | 300 | 560 | 353 | 447 | 2.5 | |

| NB.NCF3068V | 520 | 133 | 5 | 5 | 486 | 2480 | 4350 | 97 | 280 | 530 | 360 | 500 | 4 | |

| NB.NCF1872V | 360 | 440 | 38 | 2.1 | 1.5 | 423.2 | 562 | 1180 | 11.5 | 300 | 560 | 371 | 429 | 2 |

| NB.NCF2972V | 480 | 72 | 3 | 3 | 451.5 | 1220 | 2610 | 36 | 280 | 530 | 373 | 467 | 2.5 | |

| NB.NCF3072V | 540 | 134 | 5 | 5 | 503.2 | 2550 | 4600 | 102 | 260 | 500 | 380 | 520 | 4 | |

| NB.NCF1876V | 380 | 480 | 46 | 2.1 | 1.5 | 458 | 575 | 1230 | 18.6 | 280 | 530 | 391 | 469 | 2 |

| NB.NCF2976V | 520 | 82 | 4 | 4 | 486.7 | 1480 | 3210 | 52 | 260 | 500 | 404 | 493 | 3 | |

| NB.NCF3076V | 560 | 135 | 5 | 5 | 520.5 | 2610 | 4800 | 108 | 240 | 480 | 400 | 540 | 4 | |

| NB.NCF1880V | 400 | 500 | 46 | 2.1 | 1.5 | 475 | 590 | 1300 | 19.5 | 260 | 500 | 411 | 489 | 2 |

| NB.NCF2980V | 540 | 82 | 4 | 4 | 511 | 1650 | 3550 | 53.4 | 240 | 480 | 416 | 524 | 3 | |

| NB.NCF3080V | 600 | 148 | 5 | 5 | 559.1 | 2940 | 5450 | 139 | 220 | 450 | 420 | 580 | 4 | |

| NB.NCF1884V | 420 | 520 | 46 | 2.1 | 1.5 | 499 | 600 | 1340 | 20.5 | 240 | 480 | 431 | 509 | 2 |

| NB.NCF2984V | 560 | 82 | 4 | 4 | 524 | 1740 | 3590 | 55.7 | 220 | 450 | 436 | 544 | 3 | |

| NB.NCF3084V | 620 | 150 | 5 | 5 | 578.2 | 3000 | 5650 | 147 | 200 | 430 | 440 | 600 | 4 | |

| NB.NCF1888V | 440 | 540 | 46 | 2.1 | 1.5 | 516 | 615 | 1410 | 21.3 | 220 | 450 | 451 | 529 | 2 |

| NB.NCF2988V | 600 | 95 | 4 | 4 | 565.5 | 2100 | 4160 | 78.2 | 200 | 430 | 456 | 584 | 3 | |

| NB.NCF1892V | 460 | 580 | 56 | 3 | 3 | 553 | 920 | 1950 | 32.5 | 200 | 430 | 473 | 567 | 2.5 |

| NB.NCF2992V | 620 | 95 | 4 | 4 | 579 | 2130 | 4480 | 81.2 | 190 | 400 | 476 | 604 | 3 | |

| NB.NCF1896V | 480 | 600 | 56 | 3 | 3 | 573.5 | 940 | 2040 | 33.8 | 190 | 400 | 493 | 587 | 2.5 |

| NB.NCF2996V | 650 | 100 | 5 | 5 | 606 | 2380 | 5100 | 95.1 | 180 | 380 | 500 | 630 | 4 | |

| NB.NCF18/500V | 500 | 620 | 56 | 3 | 3 | 594 | 1030 | 2200 | 35 | 180 | 380 | 513 | 607 | 2.5 |

| NB.NCF29/500V | 670 | 100 | 5 | 5 | 634.5 | 2420 | 5250 | 98.4 | 170 | 360 | 520 | 650 | 4 | |

| NB.NCF18/530V | 530 | 650 | 56 | 3 | 3 | 624.5 | 990 | 2240 | 36.9 | 170 | 360 | 543 | 637 | 2.5 |

| NB.NCF29/530V | 710 | 106 | 5 | 5 | 673 | 2700 | 6000 | 120 | 160 | 340 | 550 | 690 | 4 | |

| NB.NCF18/560V | 560 | 680 | 56 | 3 | 3 | 655 | 1020 | 2360 | 39.3 | 160 | 340 | 573 | 667 | 2.5 |

| NB.NCF29/560V | 750 | 112 | 5 | 5 | 709 | 3030 | 6700 | 140 | 150 | 320 | 580 | 730 | 4 | |

| NB.NCF18/600V | 600 | 730 | 60 | 3 | 3 | 696 | 1140 | 2680 | 48.9 | 150 | 320 | 613 | 717 | 2.5 |

| NB.NCF29/600V | 800 | 118 | 5 | 5 | 754 | 3360 | 7500 | 170 | 140 | 300 | 620 | 780 | 4 | |

| NB.NCF18/630V | 630 | 780 | 69 | 4 | 4 | 739 | 1470 | 3400 | 68.8 | 140 | 300 | 646 | 764 | 3 |

| NB.NCF29/630V | 850 | 128 | 6 | 6 | 807 | 3740 | 8650 | 205 | 130 | 280 | 656 | 824 | 5 | |

| NB.NCF18/670V | 670 | 820 | 69 | 4 | 4 | 783 | 1520 | 3550 | 72.7 | 130 | 280 | 686 | 804 | 3 |

| NB.NCF28/670V | 820 | 88 | 4 | 4 | 783 | 2040 | 5340 | 90.8 | 130 | 280 | 686 | 804 | 3 | |

| NB.NCF18/710V | 710 | 870 | 74 | 4 | 4 | 831 | 1670 | 3900 | 79.7 | 120 | 260 | 726 | 854 | 3 |

| NB.NCF29/710V | 950 | 140 | 6 | 6 | 896 | 3910 | 9150 | 275 | 110 | 240 | 736 | 924 | 5 | |

| NB.NCF18/750V | 750 | 920 | 78 | 5 | 5 | 880 | 1890 | 4430 | 94.6 | 110 | 240 | 770 | 900 | 4 |

| NB.NCF287750V | 920 | 100 | 5 | 5 | 880 | 2630 | 6790 | 130 | 110 | 240 | 770 | 900 | 4 | |

| NB.NCF18/800V | 800 | 980 | 82 | 5 | 5 | 936 | 2070 | 4930 | 113 | 100 | 220 | 820 | 960 | 4 |

| NB.NCF29/800V | 1060 | 150 | 6 | 6 | 1002 | 4950 | 12200 | 360 | 95 | 200 | 836 | 1034 | 5 | |

| NB.NCF18/850V | 850 | 1030 | 82 | 5 | 5 | 986 | 2050 | 5200 | 135 | 95 | 200 | 870 | 1010 | 4 |

| NB.NCF29/850V | 1120 | 155 | 6 | 6 | 1061 | 5280 | 12900 | 405 | 90 | 190 | 886 | 1084 | 5 | |

| NB.NCF18/900V | 900 | 1090 | 85 | 5 | 5 | 1044 | 2390 | 5900 | 139 | 90 | 190 | 920 | 1070 | 4 |

| NB.NCF29/900V | 1180 | 165 | 6 | 6 | 1120 | 5940 | 14600 | 472 | 80 | 170 | 936 | 1154 | 5 | |

| NB.NCF18/950V | 950 | 1150 | 90 | 5 | 5 | 1103 | 2420 | 6300 | 185 | 80 | 170 | 970 | 1130 | 4 |

| NB.NCF29/950V | 1250 | 175 | 7.5 | 7.5 | 1179 | 6660 | 16300 | 565 | 75 | 160 | 983 | 1217 | 6 | |

| NB.NCF18/1000V | 1000 | 1220 | 100 | 6 | 6 | 1165 | 3110 | 7640 | 209 | 75 | 160 | 1026 | 1194 | 5 |

| NB.NCF29/1000V | 1320 | 185 | 7.5 | 7.5 | 1252 | 7480 | 18600 | 680 | 70 | 150 | 1033 | 1287 | 6 | |

| SPECIFICATIONS-DOUBLE ROW | |||||||||||||

| Designations | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | Installation dimersion | ||||||||

| mm | kN | kg | r/min | (mm) | |||||||||

| d | D | B | r1、2min | Ew | Cr | Cor | Grease | Oil | da(min) | Da(max) | ra(max) | ||

| NB.NNCF4930V | 150 | 210 | 60 | 2 | 192 | 390 | 865 | 6.6 | 670 | 1400 | 159 | 201 | 2 |

| NB.NNCF5030V | 225 | 100 | 2.1 | 209 | 785 | 1420 | 13 | 630 | 1300 | 161 | 214 | 2 | |

| NB.NNCF4932V | 160 | 220 | 60 | 2 | 203.9 | 410 | 930 | 7 | 630 | 1300 | 169 | 211 | 2 |

| NB.NNCF5032V | 240 | 109 | 2.1 | 225 | 895 | 1620 | 15.8 | 600 | 1200 | 171 | 229 | 2 | |

| NB.NNCF4934V | 170 | 230 | 60 | 2 | 212.2 | 415 | 975 | 7.3 | 600 | 1200 | 179 | 221 | 2 |

| NB.NNCF5034V | 260 | 122 | 2.1 | 243 | 1160 | 2140 | 22.1 | 560 | 1100 | 181 | 249 | 2 | |

| NB.NNCF4936V | 180 | 250 | 69 | 2 | 231.1 | 550 | 1230 | 10.7 | 560 | 1100 | 189 | 241 | 2 |

| NB.NNCF5036V | 280 | 136 | 2.1 | 260.5 | 1340 | 2510 | 29.4 | 560 | 1100 | 191 | 269 | 2 | |

| NB.NNCF4938V | 190 | 260 | 69 | 2 | 241.3 | 565 | 1290 | 11.1 | 560 | 1100 | 199 | 251 | 2 |

| NB.NNCF5038V | 290 | 136 | 2.1 | 270 | 1380 | 2630 | 30.8 | 530 | 1100 | 201 | 279 | 2 | |

| NB.NNCF4840V | 200 | 250 | 50 | 1.5 | 235.9 | 320 | 825 | 5.9 | 560 | 1100 | 208 | 242 | 1.5 |

| NB.NNCF4940V | 280 | 80 | 2.1 | 260 | 665 | 1500 | 15.7 | 530 | 1000 | 211 | 269 | 2 | |

| NB.NNCF5040V | 310 | 150 | 2.1 | 288 | 1560 | 3000 | 39.7 | 500 | 950 | 211 | 299 | 2 | |

| NB.NNCF4844V | 220 | 270 | 50 | 1.5 | 256.9 | 340 | 905 | 6.4 | 530 | 1000 | 228 | 262 | 1.5 |

| NB.NNCF4944V | 300 | 80 | 2.1 | 277.2 | 695 | 1620 | 17 | 500 | 950 | 231 | 289 | 2 | |

| NB.NNCF5044V | 340 | 160 | 3 | 308.5 | 1570 | 3080 | 50.7 | 450 | 850 | 233 | 327 | 2.5 | |

| NB.NNCF4848V | 240 | 300 | 60 | 2 | 282.4 | 495 | 1340 | 10.3 | 480 | 900 | 249 | 291 | 2 |

| NB.NNCF4948V | 320 | 80 | 2.1 | 300.1 | 725 | 1770 | 18.4 | 450 | 850 | 251 | 309 | 2 | |

| NB.NNCF5048V | 360 | 160 | 3 | 335.6 | 1990 | 4000 | 54.3 | 430 | 800 | 253 | 347 | 2.5 | |

| NB.NNCF4852V | 260 | 320 | 60 | 2 | 304.7 | 515 | 1450 | 11 | 430 | 800 | 269 | 311 | 2 |

| NB.NNCF4952V | 360 | 100 | 2.1 | 331.5 | 1050 | 2530 | 32 | 400 | 750 | 271 | 349 | 2 | |

| NB.NNCF5052V | 400 | 190 | 4 | 373.5 | 2690 | 5200 | 82.7 | 380 | 700 | 276 | 384 | 3 | |

| NB.NNCF4856V | 280 | 350 | 69 | 2 | 332.9 | 685 | 1860 | 16 | 400 | 750 | 289 | 341 | 2 |

| NB.NNCF4956V | 380 | 100 | 2.1 | 353.5 | 1090 | 2720 | 34 | 380 | 700 | 291 | 369 | 2 | |

| NB.NNCF5056V | 420 | 190 | 4 | 389 | 2770 | 5450 | 87.7 | 360 | 670 | 296 | 404 | 3 | |

| NB.NNCF4860V | 300 | 380 | 80 | 2.1 | 357.4 | 805 | 2160 | 23 | 380 | 700 | 311 | 369 | 2 |

| NB.NNCF4960V | 420 | 118 | 3 | 390.2 | 1580 | 3800 | 52 | 340 | 630 | 313 | 407 | 2.5 | |

| NB.NNCF5060V | 460 | 218 | 4 | 432 | 3400 | 7000 | 125 | 320 | 600 | 316 | 444 | 3 | |

| NB.NNCF4864V | 320 | 400 | 80 | 2.1 | 380.3 | 835 | 2310 | 24.3 | 340 | 630 | 331 | 389 | 2 |

| NB.NNCF4964V | 440 | 118 | 3 | 409 | 1620 | 4000 | 55 | 320 | 600 | 333 | 427 | 2.5 | |

| NB.NNCF5064V | 480 | 218 | 4 | 447.5 | 3500 | 7350 | 131 | 300 | 560 | 336 | 464 | 3 | |

| NB.NNCF4868V | 340 | 420 | 80 | 2.1 | 397.4 | 855 | 2430 | 25.6 | 320 | 600 | 351 | 409 | 2 |

| NB.NNCF4968V | 460 | 118 | 3 | 427.1 | 1690 | 4300 | 58 | 300 | 560 | 353 | 447 | 2.5 | |

| NB.NNCF5068V | 520 | 243 | 5 | 486 | 4250 | 8750 | 177 | 280 | 530 | 360 | 500 | 4 | |

| NB.NNCF4872V | 360 | 440 | 80 | 2.1 | 420.2 | 885 | 2580 | 27 | 300 | 560 | 371 | 429 | 2 |

| NB.NNCF4972V | 480 | 118 | 3 | 446 | 1730 | 4500 | 61 | 300 | 560 | 373 | 467 | 2.5 | |

| NB.NNCF5072V | 540 | 243 | 5 | 503.6 | 4190 | 8850 | 186 | 260 | 500 | 380 | 520 | 4 | |

| NB.NNCF4876V | 380 | 480 | 100 | 2.1 | 456 | 1260 | 3600 | 45.5 | 280 | 530 | 391 | 469 | 2 |

| NB.NNCF4976V | 520 | 140 | 4 | 481.5 | 2180 | 5650 | 90.5 | 260 | 500 | 396 | 504 | 3 | |

| NB.NNCF5076V | 560 | 243 | 5 | 521.4 | 4280 | 9210 | 194 | 240 | 480 | 400 | 538 | 4 | |

| NB.NNCF4880V | 400 | 500 | 100 | 2.1 | 470.3 | 1290 | 3750 | 47.5 | 260 | 500 | 411 | 489 | 2 |

| NB.NNCF4980V | 540 | 140 | 4 | 502 | 2240 | 5900 | 94.5 | 240 | 480 | 416 | 524 | 3 | |

| NB.NNCF5080V | 600 | 272 | 5 | 560 | 5050 | 10900 | 256 | 220 | 450 | 420 | 580 | 4 | |

| NB.NNCF4884V | 420 | 520 | 100 | 2.1 | 492.6 | 1320 | 3950 | 49.5 | 240 | 480 | 431 | 509 | 2 |

| NB.NNCF4984V | 560 | 140 | 4 | 522.5 | 2290 | 6200 | 98.5 | 220 | 450 | 436 | 544 | 3 | |

| NB.NNCF5084V | 620 | 272 | 5 | 577.7 | 5150 | 11300 | 267 | 200 | 430 | 441 | 598 | 4 | |

| NB.NNCF4888V | 440 | 540 | 100 | 2.1 | 514.6 | 1350 | 4150 | 51.5 | 220 | 450 | 451 | 529 | 5 |

| NB.NNCF4988V | 600 | 160 | 4 | 563.5 | 3000 | 7850 | 136 | 200 | 430 | 456 | 584 | 3 | |

| NB.NNCF4892V | 460 | 580 | 118 | 3 | 543.3 | 1730 | 5150 | 77.5 | 200 | 430 | 473 | 567 | 2.5 |

| NB.NNCF4992V | 620 | 160 | 4 | 577 | 3050 | 8050 | 142 | 190 | 400 | 476 | 604 | 3 | |

| NB.NNCF4896V | 480 | 600 | 118 | 3 | 567.3 | 1760 | 5300 | 80.5 | 190 | 400 | 493 | 587 | 2.5 |

| NB.NNCF4996V | 650 | 170 | 5 | 605.5 | 3350 | 8900 | 167 | 180 | 380 | 500 | 630 | 4 | |

| NB.NNCF48/500V | 500 | 620 | 118 | 3 | 583.5 | 1810 | 5600 | 83.5 | 190 | 400 | 513 | 607 | 2.5 |

| NB.NNCF49/500V | 670 | 170 | 5 | 631.5 | 3400 | 9350 | 173 | 170 | 360 | 520 | 650 | 4 | |

Full complement roller design, load-bearing capacity 30%-50% higher than bearings with cages, leading in the industry, adapting to extreme radial heavy loads.

Cage-free design saves space, with stronger load-bearing capacity under the same size, adapting to heavy-load equipment with limited space.

Full complement distribution of rollers buffers impact loads, with operational failure rate much lower than conventional bearings.

Technical specifications fully match those of imported products, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with complex heavy-load environments such as dusty, humid, and high-temperature conditions, supports non-standard customization, covering heavy-load needs in multiple industries.

Applications of Full Complement Cylindrical Roller Bearings

1. Heavy Industrial Gearboxes

Large industrial gear reducers

Wind turbine gearboxes (planetary stages)

Marine gear systems

They support very high radial loads from gear meshing forces.

2. Steel & Metallurgical Equipment

Rolling mills

Continuous casting machines

Straightening machines

Designed to withstand heavy loads, shock, and vibration.

3. Mining & Quarry Equipment

Crushers

Grinding mills

Vibrating feeders

Operate reliably under extreme radial loads and harsh environments.

4. Construction Machinery

Excavators

Loaders

Track rollers

Suitable for low-speed, high-load applications.

5. Paper & Pulp Machinery

Paper machine rolls

Press sections

High load capacity and stability are essential for continuous operation.

6. Wind Energy Equipment

Main shafts

Gearbox planetary systems

Handle large radial loads with compact bearing design.

7. Machine Tools (Heavy Duty)

Rotary tables

Indexing heads

Provide high rigidity for heavy cutting forces.

8. Power Generation Equipment

Hydropower turbines

Auxiliary rotating machinery

Support heavy shafts under continuous load.

9. Industrial Presses & Extruders

Screw presses

Extrusion machines

Designed to carry large radial loads at low speeds.

10. General Heavy Machinery

Conveyors

Large fans and blowers

Material handling equipment

Used where high load capacity is more important than high speed.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.