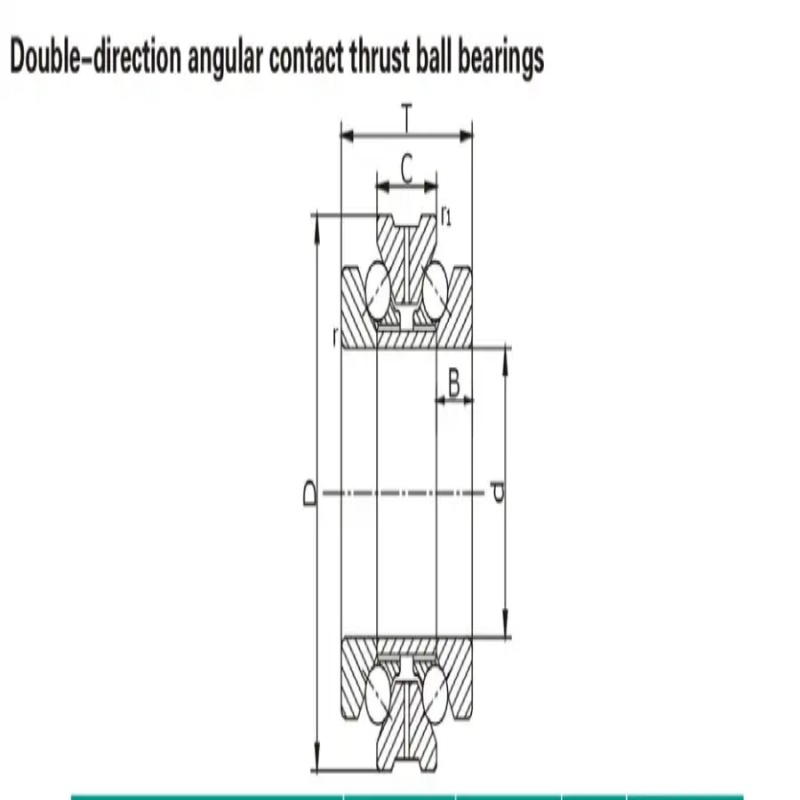

A Double-Direction Angular Contact Thrust Ball Bearing (DDAC TBB) is a super-precision bearing designed to handle heavy axial (thrust) loads in both directions, providing high stiffness and precise shaft location, commonly used with cylindrical roller bearings in machine tool spindles for applications like grinding, milling, and lathes. They typically have a large contact angle (often 60°) for rigidity and consist of two single thrust bearings back-to-back, allowing them to support axial forces while not supporting radial loads, enabling simpler housing designs.

Metric Series:Inner Diameter: 140–400 mm; Outer Diameter: 190–540 mm;Width: 60–164 mm; Weight: 135–693 kg.

Materials:Bearing Rings & Rolling Elements: High-grade Chrome Steel, Customized Materials;

Cages: Special materials suitable for high-speed operation and load requirements.

Delivery:Standard models: Determined based on order quantity negotiation;

Customized models: Please contact the manufacturer.

| Boundary dimensions | Basic load ratings | Designations | Mass | Limiting speeds | ||||||||

| mm | kN | kg | r/min | |||||||||

| d | D | T | C | B | rmin | r1min | Ca | Coa | Grease | oil | ||

| 140 | 190 | 60 | 30 | 15 | 1.5 | 1 | 91.5 | 365 | 234928 | 4.2 | 2000 | 2800 |

| 210 | 84 | 42 | 21 | 2.1 | 0.6 | 145 | 525 | 234428 | 8.75 | 1800 | 2600 | |

| 150 | 210 | 72 | 36 | 18 | 2 | 1 | 116 | 465 | 234930 | 6.6 | 1800 | 2400 |

| 225 | 90 | 45 | 22.5 | 2.1 | 0.6 | 172 | 620 | 234430 | 10.7 | 1700 | 2400 | |

| 160 | 220 | 72 | 36 | 18 | 2 | 1 | 118 | 490 | 234932 | 7 | 1700 | 2400 |

| 240 | 96 | 48 | 24 | 2.1 | 0.6 | 185 | 680 | 234432 | 13 | 1600 | 2200 | |

| 170 | 230 | 72 | 36 | 18 | 2 | 1 | 120 | 520 | 234934 | 7.35 | 1600 | 2200 |

| 260 | 108 | 54 | 27 | 2.1 | 0.6 | 218 | 810 | 234434 | 17.7 | 1500 | 2000 | |

| 180 | 250 | 84 | 42 | 21 | 2 | 1 | 158 | 655 | 234936 | 10.7 | 1500 | 2000 |

| 280 | 120 | 60 | 30 | 2.1 | 0.6 | 281 | 1020 | 234436 | 23.4 | 1400 | 1900 | |

| 190 | 260 | 84 | 42 | 21 | 2 | 1 | 161 | 695 | 234938 | 11 | 1400 | 2000 |

| 290 | 120 | 60 | 30 | 2.1 | 0.6 | 285 | 1060 | 234438 | 24.4 | 1300 | 1800 | |

| 200 | 280 | 96 | 48 | 24 | 2 | 1 | 204 | 855 | 234940 | 15.7 | 1300 | 1800 |

| 310 | 132 | 66 | 33 | 2.1 | 0.6 | 315 | 1180 | 234440 | 31.5 | 1200 | 1700 | |

| 220 | 300 | 96 | 48 | 24 | 2 | 1 | 210 | 930 | 234944 | 17 | 1200 | 1700 |

| 340 | 144 | 72 | 36 | 3 | 1 | 360 | 1390 | 234444 | 41 | 1100 | 1500 | |

| 240 | 320 | 96 | 48 | 24 | 2 | 1 | 213 | 980 | 234948 | 18.3 | 1100 | 1500 |

| 360 | 144 | 72 | 36 | 3 | 1 | 360 | 1450 | 234448 | 44 | 1000 | 1400 | |

| 260 | 360 | 120 | 60 | 30 | 2 | 1 | 315 | 1390 | 234952 | 30 | 1000 | 1400 |

| 400 | 164 | 82 | 41 | 3 | 1.5 | 440 | 1890 | 234452 | 64.5 | 900 | 1300 | |

| 280 | 380 | 120 | 60 | 30 | 2 | 1 | 320 | 1470 | 234956 | 33.5 | 900 | 1300 |

| 420 | 164 | 82 | 41 | 3 | 1.5 | 440 | 1960 | 234456 | 68 | 850 | 1200 | |

| 300 | 420 | 144 | 72 | 36 | 3 | 1 | 395 | 1810 | 234960 | 53 | 850 | 1200 |

| 320 | 440 | 144 | 72 | 36 | 3 | 1 | 405 | 1920 | 234964 | 55.5 | 800 | 1100 |

| 340 | 460 | 144 | 72 | 36 | 3 | 1.1 | 415 | 2020 | 234968 | 58.5 | 750 | 1000 |

| 360 | 480 | 144 | 72 | 36 | 3 | 1.1 | 420 | 2130 | 234972 | 61.5 | 710 | 950 |

| 380 | 520 | 164 | 82 | 41 | 4 | 1.5 | 485 | 2560 | 234976 | 87.5 | 630 | 900 |

| 400 | 540 | 164 | 82 | 41 | 4 | 1.5 | 495 | 2700 | 234980 | 91.5 | 600 | 850 |

1、Machine Tool Spindles: Used in CNC machines where the spindle may experience axial loads in both directions.

2、Automotive Transmissions: In automotive applications, such bearings are used in gearboxes and transmissions to handle high axial loads.

3、Turbines and Pumps: For applications where axial forces are common, such as in turbines, pumps, or motors.

4、Heavy Equipment: Used in equipment where the load is applied along the shaft, like cranes, excavators, and other industrial machinery.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.