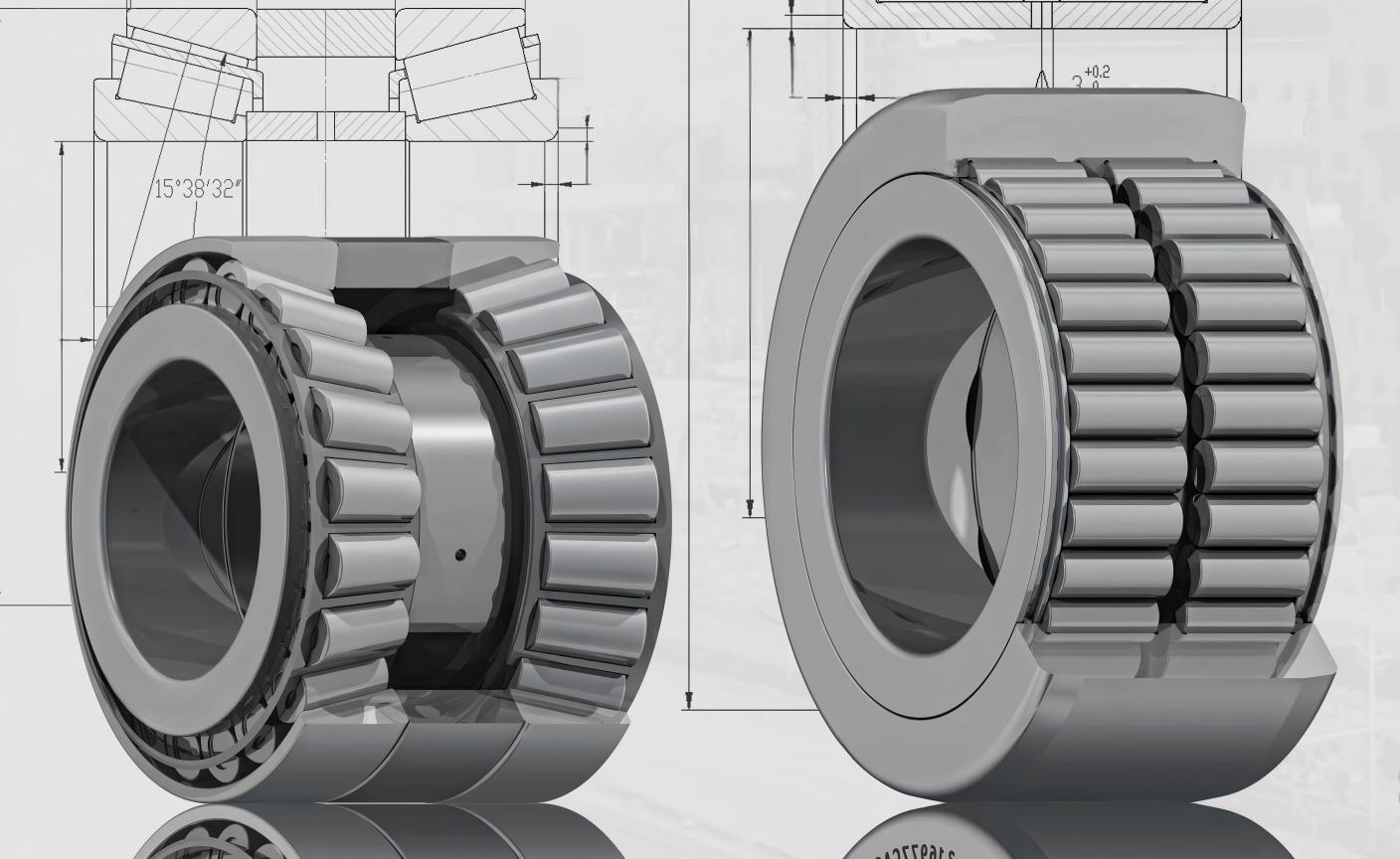

A Tapered Roller Bearing (TRB) is a type of rolling-element bearing with truncated conical rollers and raceways designed so their projected surfaces meet at a single point on the bearing's axis, allowing it to handle heavy combined radial (downward) and axial (sideways) loads efficiently with low friction, common in automotive, machine tools, andheavy machinery.

Features: Type:Inner Ring & Outer Ring: Integral structure; Roller Arrangement: Tapered rollers (matched with raceway angles, single/double row distribution);

Accuracy : P0, P6, P5, P4;

Size:Inner Diameter: 150–950mm; Outer Diameter: 270–1250 mm; Width: 30–170 mm;

Materials: Bearing Rings & Rollers: GCr15 high-carbon chromium steel or SUS440C stainless steel ; Cages: Brass , reinforced Nylon 66 , or stamped steel ;

Delivery: Standard models: 5–12 days (single-row), 7–15 days (double-row); Customized models : Please contact the manufacturer.

| Tapered Rolling Bearing | |||||||||||||

| Designations | Boundary dimensions | Basic load ratings | Mass | Limiting speeds | |||||||||

| Current | Original | mm | kN | kg | r/min | ||||||||

| d | D | T | B | C | rmin | r1min | Cr | Cor | Grease | oil | |||

| NB.32230 | 7530E | 150 | 270 | 77 | 73 | 60 | 4 | 3 | 718 | 1200 | 18.2 | 1200 | 1700 |

| NB.32330 | 7630 | 320 | 114 | 108 | 90 | 5 | 4 | 1110 | 1580 | 37.1 | 950 | 1400 | |

| NB.32032 | 2007132E | 160 | 240 | 51 | 51 | 38 | 3 | 2.5 | 420 | 735 | 7.7 | 1200 | 1700 |

| NB.30332 | 7332E | 340 | 75 | 68 | 58 | 5 | 4 | 765 | 960 | 28.4 | 1000 | 1500 | |

| NB.32332 | 7632 | 340 | 121 | 114 | 95 | 5 | 4 | 1210 | 1770 | 48.3 | 950 | 1400 | |

| NB.70DB170 | 170 | 230 | 32 | 30 | 23 | 3 | 3 | 200 | 400 | 3 | 1200 | 1700 | |

| NB.32234 | 7534E | 310 | 91 | 86 | 71 | 5 | 4 | 835 | 1320 | 27.6 | 1000 | 1500 | |

| NB.30334 | 7334E | 360 | 80 | 72 | 62 | 5 | 4 | 950 | 1400 | 35 | 950 | 1400 | |

| NB.32334 | 7634 | 360 | 127 | 120 | 100 | 5 | 4 | 975 | 1764 | 58.3 | 1000 | 1300 | |

| NB.32036X2 | 2007136 | 180 | 280 | 64 | 60 | 52 | 3 | 2.5 | 540 | 890 | 13 | 1100 | 1600 |

| NB.32036 | 2007136E | 280 | 64 | 64 | 48 | 3 | 2.5 | 569 | 950 | 14 | 1100 | 1600 | |

| NB.30236 | 7236E | 320 | 57 | 52 | 43 | 5 | 4 | 610 | 912 | 17.8 | 1000 | 1500 | |

| NB.32236 | 7536E | 320 | 91 | 86 | 71 | 5 | 4 | 998 | 1727 | 29.8 | 950 | 1400 | |

| NB.32938X2 | 2007938 | 190 | 260 | 45 | 42 | 36 | 2.5 | 2 | 292 | 580 | 6.52 | 1000 | 1400 |

| - | 7138 | 290 | 51 | 46 | 40 | 3 | 2.5 | 435 | 365 | 10.5 | 1000 | 1500 | |

| NB.32038X2 | 2007138 | 290 | 64 | 60 | 52 | 3 | 2.5 | 502 | 932 | 14.2 | 950 | 1300 | |

| NB.32038 | 2007138E | 290 | 64 | 64 | 48 | 3 | 2.5 | 520 | 950 | 15.6 | 950 | 1300 | |

| NB.32238 | 7538E | 340 | 97 | 92 | 75 | 5 | 4 | 1117 | 1919 | 36.1 | 900 | 1300 | |

| NB.32940X2 | 2007940 | 200 | 280 | 51 | 48 | 41 | 3 | 2.5 | 345 | 710 | 8.86 | 950 | 1300 |

| NB.32940 | 2007940E | 280 | 51 | 51 | 39 | 3 | 2.5 | 460 | 950 | 9.5 | 950 | 1300 | |

| NB.32040X2 | 2007140 | 310 | 70 | 66 | 56 | 3 | 2.5 | 575 | 1120 | 17.9 | 900 | 1200 | |

| NB.32040 | 2007140E | 310 | 70 | 70 | 53 | 3 | 2.5 | 650 | 1300 | 18.9 | 900 | 1200 | |

| NB.30240 | 7240E | 360 | 64 | 58 | 48 | 5 | 4 | 765 | 1140 | 25.4 | 900 | 1300 | |

| NB.32240 | 7540E | 360 | 104 | 98 | 82 | 5 | 4 | 1090 | 1750 | 43.2 | 900 | 1300 | |

| NB.30641 | 7841E | 205 | 485 | 117.5 | 100 | 75 | 4 | 4 | 1400 | 2020 | 95 | 850 | 1200 |

| - | 7342X2 | 210 | 420 | 90 | 81 | 67 | 6 | 5 | 1280 | 1910 | 56 | 850 | 1200 |

| NB.32944×2 | 2007944 | 220 | 300 | 51 | 48 | 41 | 3 | 2.5 | 425 | 855 | 10.2 | 900 | 1200 |

| NB.32044X2 | 2007144 | 340 | 76 | 72 | 62 | 4 | 3 | 702 | 1330 | 22.2 | 800 | 1000 | |

| NB.32044 | 2007144E | 340 | 76 | 76 | 57 | 4 | 3 | 750 | 1350 | 24.4 | 800 | 1000 | |

| NB.30244 | 7244E | 400 | 72 | 65 | 54 | 4 | 3 | 810 | 1150 | 35.4 | 850 | 1200 | |

| NB.32244 | 7544E | 400 | 114 | 108 | 90 | 4 | 3 | 1320 | 2210 | 48.1 | 800 | 1100 | |

| NB.32948X2 | 2007948 | 240 | 320 | 51 | 48 | 41 | 3 | 2.5 | 390 | 860 | 10.8 | 800 | 1000 |

| NB.32048X2 | 2007148 | 360 | 76 | 72 | 62 | 4 | 3 | 710 | 1420 | 23.8 | 700 | 900 | |

| NB.32048 | 2007148E | 360 | 76 | 76 | 57 | 4 | 3 | 850 | 1560 | 20.4 | 700 | 900 | |

| NB.32248 | 7548 | 440 | 127 | 120 | 100 | 4 | 4 | 1630 | 2730 | 81.3 | 750 | 1000 | |

| NB.32952X2 | 2007952 | 260 | 360 | 63.5 | 60 | 52 | 3 | 2.5 | 525 | 1150 | 19.2 | 700 | 900 |

| NB.32952 | 2007952E | 360 | 63.5 | 63.5 | 48 | 3 | 2.5 | 550 | 1300 | 20 | 700 | 900 | |

| NB.32052X2 | 2007152 | 400 | 87 | 82 | 71 | 5 | 4 | 902 | 1810 | 36.9 | 670 | 850 | |

| NB.32052 | 2007152E | 400 | 87 | 87 | 65 | 5 | 4 | 1010 | 1850 | 37 | 670 | 850 | |

| NB.30352X2 | 7352 | 540 | 114 | 102 | 85 | 6 | 6 | 2014 | 2898 | 111 | 670 | 900 | |

| NB.32054 | 2007154 | 270 | 420 | 87 | 87 | 65 | 5 | 4 | 1150 | 2060 | 45 | 600 | 750 |

| NB.30656 | 1007856 | 280 | 350 | 36 | 33 | 26 | 2 | 2 | 279 | 469 | 6.33 | 870 | 1100 |

| NB.32956 | 2007956E | 380 | 63.5 | 63.5 | 48 | 3 | 2.5 | 635 | 1300 | 19.8 | 800 | 1100 | |

| NB.32056X2 | 2007156 | 420 | 87 | 82 | 71 | 5 | 4 | 622 | 1940 | 39.6 | 600 | 750 | |

| NB.32056 | 2007156E | 420 | 87 | 87 | 65 | 5 | 4 | 1170 | 2230 | 40.4 | 600 | 750 | |

| NB.32960 | 2007960E | 300 | 420 | 76 | 76 | 57 | 4 | 3 | 998 | 2128 | 28.7 | 700 | 950 |

| NB.30660 | 7860 | 440 | 73 | 70 | 55 | 4 | 3 | 959 | 2062 | 30.7 | 570 | 600 | |

| NB.32060X2 | 2007160 | 460 | 100 | 95 | 82 | 5 | 4 | 1050 | 2190 | 55.9 | 560 | 700 | |

| NB.31160X2 | 1007760 | 500 | 95 | 90 | 70 | 4 | 4 | 1225 | 2207 | 67.7 | 530 | 670 | |

| NB.32964X2 | 2007964 | 320 | 440 | 76 | 72 | 62 | 4 | 3 | 1040 | 2320 | 44.7 | 560 | 700 |

| NB.32964 | 2007964E | 440 | 76 | 76 | 57 | 4 | 3 | 962 | 2040 | 33 | 560 | 700 | |

| NB.32064X2 | 2007164 | 480 | 100 | 95 | 82 | 5 | 4 | 1050 | 2190 | 59 | 530 | 670 | |

| NB.32064 | 2007164E | 480 | 100 | 100 | 74 | 5 | 4 | 1649 | 3192 | 60 | 530 | 670 | |

| 7264 | 580 | 110 | 105 | 80 | 6 | 6 | 2100 | 3100 | 114 | 480 | 600 | ||

| NB.32968X2 | 2007968 | 340 | 460 | 76 | 72 | 62 | 4 | 3 | 611 | 1428 | 34.3 | 530 | 670 |

| NB.32068X2 | 7168 | 520 | 86 | 82 | 64 | 4 | 4 | 807 | 1540 | 57 | 500 | 630 | |

| NB.32068 | - | 520 | 112 | 106 | 92 | 6 | 6 | 1660 | 3370 | 86.5 | 500 | 630 | |

| - | 7768 | 580 | 106 | 102 | 87 | 6 | 5 | 1840 | 2970 | 109 | 480 | 600 | |

| NB.32972X2 | 2007972 | 360 | 480 | 76 | 72 | 62 | 4 | 3 | 634 | 1526 | 35.9 | 500 | 630 |

| NB.31072X2 | 7172 | 540 | 86 | 82 | 64 | 4 | 4 | 919 | 1848 | 60.5 | 480 | 600 | |

| NB.32272X2 | 650 | 170 | 155 | 140 | 5 | 6 | 3580 | 6000 | 175 | 380 | 480 | ||

| NB.31976X2 | 1007976 | 380 | 520 | 66.5 | 65 | 46.5 | 3 | 3 | 529 | 1138 | 37.5 | 480 | 600 |

| NB.32976X2 | 2007976 | 520 | 87 | 82 | 71 | 5 | 4 | 800 | 1600 | 42.7 | 480 | 600 | |

| NB.31176X2 | 1007776 | 620 | 112 | 106 | 76 | 4 | 4 | 909 | 1708 | 114 | 400 | 500 | |

| 7880 | 400 | 500 | 60 | 57 | 47 | 4 | 3 | 665 | 775 | 45.7 | 450 | 530 | |

| NB.31980X2 | 1007980 | 540 | 70 | 65 | 51 | 3 | 3 | 1000 | 2070 | 43.2 | 450 | 530 | |

| NB.32980X2 | 2007980 | 540 | 87 | 82 | 71 | 5 | 4 | 1130 | 2760 | 57 | 450 | 530 | |

| NB.31080X2 | 7180 | 600 | 95 | 90 | 67 | 4 | 4 | 1040 | 2128 | 84 | 400 | 500 | |

| NB.31984X2 | 1007984 | 420 | 560 | 70 | 65 | 51 | 3 | 3 | 630 | 1383 | 42.4 | 400 | 500 |

| NB.32984X2 | 2007984 | 560 | 87 | 82 | 72 | 5 | 4 | 1250 | 2870 | 46 | 400 | 500 | |

| NB.R420-5 | 560 | 87 | 87 | 67 | 5 | 4 | 1250 | 2870 | 47 | 400 | 500 | ||

| NB.31084×2 | 7184 | 620 | 95 | 90 | 70 | 4 | 4 | 1132 | 2422 | 88 | 380 | 480 | |

| NB.31184X2 | 1007784 | 700 | 130 | 122 | 92 | 6 | 6 | 1620 | 2800 | 183 | 310 | 420 | |

| NB.31088X2 | 7188 | 440 | 650 | 96.4 | 94 | 67 | 6 | Δ | 1193 | 2422 | 99 | 360 | 450 |

| NB.31992X2 | 1007992 | 460 | 620 | 80 | 74 | 58 | 3 | 3 | 836 | 1834 | 59.8 | 380 | 480 |

| NB.31092X2 | 7192 | 680 | 105 | 100 | 78 | 6 | 6 | 1680 | 3550 | 118 | 330 | 450 | |

| NB.31996X2 | 1007996 | 480 | 650 | 84.2 | 78 | 60 | 4 | 4 | 854 | 1918 | 71 | 340 | 430 |

| NB.310/500X2 | 71/500 | 500 | 720 | 110 | 100 | 82 | 6 | 6 | 1459 | 3192 | 135 | 280 | 360 |

| NB.319/530X2 | 10079/530 | 530 | 710 | 88 | 82 | 62 | 4 | 4 | 1001 | 2380 | 94.8 | 280 | 360 |

| NB.319/560X2 | 10079/560 | 560 | 750 | 92.5 | 85 | 64 | 4 | 4 | 1001 | 2576 | 104 | 240 | 320 |

| NB.310/560X2 | 71/560 | 820 | 121 | 115 | 84 | 6 | 6 | 1887 | 4046 | 191 | 220 | 300 | |

| NB.310/600X2 | 71/600 | 600 | 870 | 124 | 118 | 89 | 6 | 6 | 2020 | 4438 | 235 | 180 | 240 |

| NB.310/630X2 | 71/630 | 630 | 920 | 135 | 128 | 94 | 7.5 | 7.5 | 2315 | 5222 | 278 | 170 | 220 |

| NB.319/710X2 | 10079/710 | 710 | 950 | 114 | 106 | 80 | 6 | 6 | 1765 | 4494 | 210 | 150 | 190 |

| - | 78/760 | 760 | 890 | 78 | 75 | 56 | 6 | 6 | 1510 | 1960 | 78.3 | 280 | 380 |

| NB.319/800X2 | 10079/800 | 800 | 1060 | 122 | 115 | 89 | 6 | 6 | 2132 | 5530 | 275 | 130 | 170 |

| NB.319/900X2 | 10079/900 | 900 | 1180 | 124 | 122 | 87 | 6 | 6 | 2173 | 5782 | 330 | 95 | 130 |

| NB.320/900X2 | 71/900 | 1280 | 190 | 170 | 135 | 7.5 | 7.5 | 5615 | 13913 | 703 | 95 | 130 | |

| NB.319/950X2 | 10079/950 | 950 | 1250 | 140 | 132 | 100 | 7.5 | 7.5 | 3930 | 10427 | 428 | 80 | 100 |

Simultaneously bears radial and bidirectional axial loads; double-row self-aligning models adapt to complex working conditions, replacing multiple sets of single-load bearing combinations.

Single-row (compact) and double-row (self-aligning) options, selectable according to equipment space and working condition requirements; single-row models achieve bidirectional positioning through paired installation.

Reinforced materials and conical contact design, outstanding deformation resistance and shock resistance, adapting to heavy-load high-frequency impact scenarios.

Technical specifications fully match imported series, ensuring stable supply and reducing procurement costs by 20%-30%.

Compatible with complex environments such as dusty, humid, and high-temperature conditions, supports non-standard customization, covering automotive, machinery, wind power and other fields.

Applications of Tapered Roller Bearings

1. Automotive & Transportation

Wheel hubs (cars, trucks, trailers)

Axles and differentials

Manual and automatic transmissions

They withstand combined loads during braking, cornering, and acceleration.

2. Industrial Gearboxes & Speed Reducers

Helical and bevel gearboxes

Heavy-duty speed reducers

Used to carry high radial and axial forces generated by gears.

3. Construction Machinery

Excavators

Loaders

Cranes

Provide high stiffness and shock load resistance.

4. Mining & Quarry Equipment

Crushers

Conveyors

Grinding mills

Designed for extreme loads and harsh operating conditions.

5. Steel & Metallurgical Machinery

Rolling mills

Continuous casting machines

Support heavy loads with high precision and reliability.

6. Wind Energy Equipment

Wind turbine gearboxes

Main shafts

Used where large combined loads are present.

7. Agricultural Machinery

Tractors

Harvesters

Gear drives

Operate reliably under shock loads and contamination.

8. Marine & Offshore Equipment

Propulsion systems

Winches

Designed for heavy loads and demanding environments.

9. Machine Tools

Spindles

Rotary tables

High stiffness ensures machining accuracy.

10. Railway Equipment

Axle boxes

Traction systems

Tapered roller bearings handle heavy loads and vibration.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.