| 618 Series | ||||||||||||||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 100 | 125 | 13 | 1 | 19.6 | 21.2 | 61820 | 0.31 | 105 | 120 | 1 | 4800 | 5700 | ||

| 110 | 140 | 16 | 1 | 28.1 | 30.7 | 61822 | 0.61 | 115 | 135 | 1 | 4300 | 5100 | ||

| 120 | 150 | 16 | 1 | 29 | 33 | 61824 | 0.66 | 125 | 145 | 1 | 4000 | 4700 | ||

| 130 | 165 | 18 | 1.1 | 36.9 | 41.2 | 61826 | 0.94 | 136.5 | 158.5 | 1 | 3600 | 4300 | ||

| 140 | 175 | 18 | 1.1 | 38.2 | 44.4 | 61828 | 1 | 146.5 | 168.5 | 1 | 3400 | 4000 | ||

| 150 | 190 | 20 | 1.1 | 49.1 | 58.5 | 61830 | 1.15 | 156.6 | 183.5 | 1 | 3000 | 3600 | ||

| 160 | 200 | 20 | 1.1 | 48.5 | 61 | 61832 | 1.23 | 166.5 | 193.5 | 1 | 2800 | 3400 | ||

| 170 | 215 | 22 | 1.1 | 61.5 | 78 | 61834 | 1.9 | 176.5 | 208.5 | 1 | 2600 | 3200 | ||

| 180 | 225 | 22 | 1.1 | 62.3 | 78.5 | 61836 | 1.72 | 186.5 | 218.5 | 1 | 2400 | 3000 | ||

| 190 | 240 | 24 | 1.5 | 75.1 | 93.5 | 61838 | 2.53 | 198 | 232 | 1.5 | 2200 | 2800 | ||

| 200 | 250 | 24 | 1.5 | 74 | 98 | 61840 | 2.67 | 208 | 242 | 1.5 | 2200 | 2800 | ||

| 220 | 270 | 24 | 1.5 | 76.5 | 97.8 | 61844 | 2.9 | 228 | 262 | 1.5 | 1900 | 2400 | ||

| 240 | 300 | 28 | 2 | 83.5 | 108 | 61848 | 4.48 | 249 | 291 | 2 | 1800 | 2200 | ||

| 260 | 320 | 28 | 2 | 101 | 148 | 61852 | 4.84 | 269 | 311 | 2 | 1700 | 2000 | ||

| 280 | 350 | 33 | 2 | 133 | 191 | 61856 | 7.2 | 289 | 341 | 2 | 1600 | 1900 | ||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 300 | 380 | 38 | 2.1 | 166 | 233 | 61860 | 10.3 | 311 | 369 | 2 | 1400 | 1700 | ||

| 320 | 400 | 38 | 2.1 | 168 | 244 | 61864 | 10.8 | 331 | 389 | 2 | 1300 | 1600 | ||

| 340 | 420 | 38 | 2.1 | 175 | 265 | 61868 | 11.5 | 351 | 409 | 2 | 1200 | 1500 | ||

| 360 | 440 | 38 | 2.1 | 192 | 290 | 61872 | 11.8 | 371 | 429 | 2 | 1100 | 1400 | ||

| 380 | 480 | 46 | 2.1 | 238 | 375 | 61876 | 19.5 | 391 | 469 | 2 | 1000 | 1300 | ||

| 400 | 500 | 46 | 2.1 | 241 | 390 | 61880 | 20.5 | 411 | 489 | 2 | 1000 | 1300 | ||

| 420 | 520 | 46 | 2.1 | 245 | 410 | 61884 | 21.4 | 431 | 509 | 2 | 950 | 1200 | ||

| 440 | 540 | 46 | 2.1 | 249 | 425 | 61888 | 22.3 | 451 | 529 | 2 | 900 | 1100 | ||

| 460 | 580 | 56 | 3 | 310 | 550 | 61892 | 34.3 | 473 | 567 | 2.5 | 900 | 1100 | ||

| 480 | 600 | 56 | 3 | 315 | 575 | 61896 | 35.4 | 493 | 587 | 2.5 | 850 | 1000 | ||

| 500 | 620 | 56 | 3 | 320 | 600 | 618/500 | 37.2 | 513 | 607 | 2.5 | 800 | 950 | ||

| 530 | 650 | 56 | 3 | 325 | 625 | 618/530 | 39.8 | 543 | 637 | 2.5 | 750 | 900 | ||

| 560 | 680 | 56 | 3 | 330 | 650 | 618/560 | 41.5 | 573 | 667 | 2.5 | 700 | 850 | ||

| 600 | 730 | 60 | 3 | 355 | 735 | 618/600 | 50.9 | 613 | 717 | 2.5 | 670 | 800 | ||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 630 | 780 | 69 | 4 | 420 | 890 | 618/630 | 71.3 | 646 | 767 | 3 | 630 | 750 | ||

| 670 | 820 | 69 | 4 | 435 | 965 | 618/670 | 75.4 | 686 | 807 | 3 | 560 | 670 | ||

| 710 | 870 | 74 | 4 | 480 | 1100 | 618/710 | 92.6 | 726 | 854 | 3 | 530 | 630 | ||

| 750 | 920 | 78 | 5 | 525 | 1260 | 618/750 | 110 | 770 | 900 | 4 | 500 | 600 | ||

| 800 | 980 | 82 | 5 | 530 | 1310 | 618/800 | 132 | 820 | 960 | 4 | 450 | 530 | ||

| 850 | 1030 | 82 | 5 | 559 | 1430 | 618/850 | 140 | 868 | 1012 | 4 | 410 | 470 | ||

| 900 | 1090 | 85 | 5 | 618 | 1532 | 618/900 | 160 | 920 | 1070 | 4 | 350 | 410 | ||

| 950 | 1150 | 90 | 5 | 637 | 1730 | 618/950 | 190 | 968 | 1132 | 4 | 290 | 350 | ||

| 619 Series | ||||||||||||||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 100 | 140 | 20 | 1.1 | 45 | 41.9 | 61920 | 0.96 | 106.5 | 133.5 | 1 | 4500 | 5300 | ||

| 110 | 150 | 20 | 1.1 | 47.9 | 47.8 | 61922 | 1.04 | 116.5 | 43.5 | 1 | 4100 | 4900 | ||

| 120 | 165 | 22 | 1.1 | 57.2 | 56.9 | 61924 | 1.41 | 126.5 | 158.5 | 1 | 3800 | 4400 | ||

| 130 | 180 | 24 | 1.5 | 69.6 | 70 | 61926 | 1.86 | 138 | 172 | 1.5 | 3400 | 4100 | ||

| 140 | 190 | 24 | 1.5 | 71.3 | 74.8 | 61928 | 1.98 | 148 | 182 | 1.5 | 3200 | 3800 | ||

| 150 | 210 | 28 | 2 | 85 | 90.5 | 61930 | 2.59 | 159 | 201 | 2 | 2800 | 3400 | ||

| 160 | 220 | 28 | 2 | 87 | 96 | 61932 | 2.71 | 169 | 211 | 2 | 2600 | 3200 | ||

| 170 | 230 | 28 | 2 | 88.8 | 100 | 61934 | 2.85 | 179 | 221 | 2 | 2400 | 3000 | ||

| 180 | 250 | 33 | 2 | 119 | 133 | 61936 | 4.16 | 189 | 241 | 2 | 2200 | 2800 | ||

| 190 | 260 | 33 | 2 | 117 | 133 | 61938 | 5.18 | 199 | 251 | 2 | 2200 | 2800 | ||

| 200 | 280 | 38 | 2.1 | 149 | 168 | 61940 | 7.28 | 211 | 269 | 2 | 2000 | 2600 | ||

| 220 | 300 | 38 | 2.1 | 152 | 178 | 61944 | 7.88 | 231 | 289 | 2 | 1900 | 2400 | ||

| 240 | 320 | 38 | 2.1 | 154 | 190 | 61948 | 8.49 | 251 | 309 | 2 | 1800 | 2200 | ||

| 260 | 360 | 46 | 2.1 | 210 | 268 | 61952 | 14 | 271 | 349 | 2 | 1600 | 1900 | ||

| 280 | 380 | 46 | 2.1 | 209 | 272 | 61956 | 15.1 | 291 | 369 | 2 | 1500 | 1800 | ||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 300 | 420 | 56 | 3 | 270 | 375 | 61960 | 24.5 | 313 | 407 | 2.5 | 1300 | 1600 | ||

| 320 | 440 | 56 | 3 | 275 | 392 | 61964 | 25.3 | 333 | 427 | 2.5 | 1200 | 1500 | ||

| 340 | 460 | 56 | 3 | 292 | 418 | 61968 | 26.6 | 353 | 447 | 2.5 | 1100 | 1400 | ||

| 360 | 480 | 56 | 3 | 280 | 425 | 61972 | 27.9 | 373 | 467 | 2.5 | 1100 | 1400 | ||

| 380 | 520 | 65 | 4 | 338 | 540 | 61976 | 40 | 425 | 475 | 3 | 1000 | 1300 | ||

| 400 | 540 | 65 | 4 | 335 | 540 | 61980 | 42 | 416 | 524 | 3 | 950 | 1200 | ||

| 420 | 560 | 65 | 4 | 340 | 570 | 61984 | 43.6 | 436 | 544 | 3 | 900 | 1100 | ||

| 440 | 600 | 74 | 4 | 395 | 680 | 61988 | 60.2 | 456 | 584 | 3 | 900 | 1100 | ||

| 460 | 620 | 74 | 4 | 405 | 720 | 61992 | 62.6 | 476 | 604 | 3 | 850 | 1000 | ||

| 480 | 650 | 78 | 5 | 450 | 815 | 61996 | 73.5 | 500 | 630 | 4 | 800 | 950 | ||

| 500 | 670 | 78 | 5 | 460 | 865 | 619/500 | 82 | 520 | 650 | 4 | 750 | 900 | ||

| 530 | 710 | 82 | 5 | 455 | 870 | 619/530 | 89.8 | 550 | 690 | 4 | 750 | 900 | ||

| 560 | 750 | 85 | 5 | 525 | 1040 | 619/560 | 105 | 580 | 730 | 4 | 670 | 800 | ||

| 600 | 800 | 90 | 5 | 550 | 1160 | 619/600 | 120 | 620 | 780 | 4 | 630 | 750 | ||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | ||||

| 630 | 850 | 100 | 6 | 625 | 1350 | 619/630 | 163 | 654 | 826 | 5 | 600 | 700 | ||

| 670 | 900 | 103 | 6 | 675 | 1460 | 619/670 | 181 | 694 | 876 | 5 | 530 | 630 | ||

| 710 | 950 | 106 | 6 | 715 | 1640 | 619/710 | 220 | 734 | 926 | 5 | 500 | 600 | ||

| 750 | 1000 | 112 | 6 | 785 | 1840 | 619/750 | 245 | 774 | 976 | 5 | 480 | 560 | ||

| 800 | 1060 | 115 | 6 | 825 | 2050 | 619/800 | 275 | 824 | 1036 | 5 | 430 | 500 | ||

| 850 | 1120 | 118 | 6 | 832 | 2160 | 619/850 | 310 | 873 | 1090 | 5 | 380 | 440 | ||

| 900 | 1180 | 122 | 6 | 852 | 2280 | 619/900 | 350 | 923 | 1157 | 5 | 320 | 380 | ||

| 950 | 1250 | 132 | 6 | 1010 | 2800 | 619/950 | 390 | 978 | 1222 | 5 | 260 | 320 | ||

| 718 Series | ||||||||||||||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | ra1 | Grease | Oil | ||

| 100 | 128 | 13 | 1 | 0.3 | 21.2 | 27.5 | 71820 | 0.2 | 104.6 | 120.4 | 1 | 1 | 8500 | 13000 |

| 110 | 140 | 16 | 1 | 0.3 | 31.9 | 40.5 | 71822 | 0.51 | 114.6 | 135.4 | 1 | 1 | 8000 | 13000 |

| 120 | 150 | 16 | 1 | 0.3 | 33.2 | 45 | 71824 | 0.55 | 124.8 | 145.4 | 1 | 1 | 7500 | 12000 |

| 130 | 165 | 18 | 1.1 | 0.6 | 39 | 53 | 71826 | 0.7 | 136 | 159 | 1 | 7000 | 11000 | |

| 140 | 175 | 18 | 1.1 | 0.6 | 44.9 | 62 | 71828 | 0.8 | 146 | 169 | 1 | 1 | 6300 | 10000 |

| 150 | 190 | 20 | 1.1 | 0.6 | 53.5 | 74.5 | 71830 | 1.32 | 156 | 184 | 1 | 1 | 6300 | 9500 |

| 160 | 200 | 20 | 1.1 | 0.6 | 54 | 78 | 71832 | 1.25 | 166 | 194 | 1 | 1 | 5600 | 8500 |

| 170 | 215 | 22 | 1.1 | 0.6 | 80 | 110 | 71834 | 2 | 175 | 210 | 1 | 1 | 5600 | 8500 |

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmln | Cr | Cor | da | Da | Ta | ral | Grease | Oil | ||

| 200 | 250 | 24 | 1.5 | 1 | 90 | 130 | 71840 | 2.5 | 208.5 | 241.5 | 1.5 | 1 | 4300 | 6000 |

| 220 | 270 | 24 | 1.5 | 1 | 151 | 263 | 71844 | 2.5 | 228.5 | 261.5 | 1.5 | 1 | 3800 | 5600 |

| 240 | 300 | 28 | 2 | 1 | 128 | 175 | 71848 | 4.1 | 250 | 290 | 2 | 1 | 3200 | 4800 |

| 260 | 320 | 28 | 2 | 1 | 127 | 190 | 71852 | 4.85 | 270 | 310 | 2 | 1 | 1400 | 1900 |

| 280 | 350 | 33 | 2 | 1 | 140 | 216 | 71856 | 7.2 | 290 | 340 | 2 | 1 | 1200 | 1700 |

| 320 | 400 | 38 | 2.1 | 1.1 | 190 | 290 | 71864 | 10 | 332 | 388 | 2 | 1 | 800 | 1000 |

| 340 | 440 | 38 | 2.1 | 1.1 | 219 | 345 | 71872 | 11.1 | 372 | 428 | 2 | 1 | ||

| 360 | 480 | 46 | 2.1 | 1.1 | 261.9 | 450 | 71876 | 18 | 392 | 468 | 2 | 1 | 1700 | 2400 |

| 380 | 500 | 46 | 2.1 | 1.1 | 292 | 501 | 71880 | 19.5 | 412 | 488 | 2 | 1 | ||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | Ta1 | Grease | Oil | ||

| 420 | 520 | 46 | 2.1 | 1.1 | 294 | 513 | 71884 | 20.4 | 432 | 508 | 2 | 1 | 750 | 1000 |

| 440 | 540 | 46 | 2.1 | 1.1 | 301 | 540 | 71888 | 21.1 | 452 | 528 | 2 | 1 | 750 | 1000 |

| 460 | 580 | 56 | 3 | 3 | 334 | 689 | 71892 | 34.5 | 474 | 566 | 2.5 | 1 | 850 | 1000 |

| 480 | 600 | 56 | 3 | 1.1 | 415 | 820 | 71896 | 35.5 | 494 | 686 | 2.5 | 1 | 850 | 1200 |

| 500 | 620 | 56 | 3 | 1.1 | 351 | 765 | 718/500 | 38 | 514 | 606 | 2.5 | 1 | 670 | 900 |

| 530 | 650 | 56 | 3 | 1.1 | 369 | 837 | 718/530 | 39.5 | 544 | 636 | 2.5 | 1 | 1100 | 1600 |

| 560 | 680 | 56 | 3 | 1.1 | 341 | 837 | 718/560 | 41.5 | 574 | 666 | 2.5 | 1 | 600 | 800 |

| 600 | 730 | 60 | 3 | 1.1 | 421 | 1044 | 718/600 | 47 | 614 | 766 | 2.5 | 1 | 560 | 750 |

| 630 | 780 | 69 | 4 | 1.5 | 518 | 1160 | 718/630 | 69.7 | 648 | 715 | 3.1 | 1.5 | ||

| 670 | 820 | 69 | 4 | 1.5 | 498 | 1161 | 718/670 | 77 | 688 | 802 | 3 | 1.5 | 850 | 1200 |

| 710 | 870 | 74 | 4 | 1.5 | 546 | 1467 | 718/710 | 93.5 | 725 | 855 | 3 | 1 | 800 | 1100 |

| 750 | 920 | 78 | 5 | 2 | 585 | 1620 | 718/750 | 110 | 768 | 902 | 4 | 2 | 400 | 530 |

| 850 | 1030 | 82 | 5 | 2 | 620 | 1674 | 718/850 | 140 | 868 | 1012 | 4 | 2 | 340 | 450 |

| 719 Series | ||||||||||||||

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | ra1 | Grease | Oil | ||

| 100 | 140 | 20 | 1.1 | 0.6 | 60.6 | 65.5 | 71920 | 0.8 | 106 | 134 | 1 | 1 | 8500 | 14000 |

| 110 | 150 | 20 | 1.1 | 0.6 | 62.4 | 72 | 71922 | 0.86 | 116 | 144 | 1 | 1 | 8000 | 13000 |

| 120 | 150 | 20 | 1.1 | 0.6 | 24.7 | 25.5 | 71924 | 1.15 | 116 | 144 | 1 | 1 | 10000 | 15000 |

| 130 | 180 | 24 | 1.5 | 0.6 | 92.3 | 108 | 71926 | 1.55 | 137 | 173 | 1.5 | 1.5 | 7000 | 11000 |

| 140 | 190 | 24 | 1.5 | 0.6 | 95.6 | 116 | 71928 | 1.65 | 147 | 183 | 1.5 | 1.5 | 6700 | 10000 |

| 150 | 210 | 28 | 2 | 1 | 90 | 120 | 71930 | 3 | 160 | 200 | 2 | 1 | 6300 | 9500 |

| 160 | 220 | 28 | 2 | 1 | 109 | 129 | 71932 | 3 | 170 | 210 | 2 | 1 | 6000 | 9000 |

| 170 | 230 | 28 | 2 | 1 | 110 | 140 | 71934 | 3.3 | 179 | 221 | 2 | 2 | 5600 | 8500 |

| 190 | 260 | 33 | 2 | 1 | 139 | 177 | 71938 | 4.45 | 199 | 255 | 2 | 2 | 5000 | 7500 |

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmln | Cr | Cor | da | Da | Ta | ral | Grease | Oil | ||

| 200 | 280 | 38 | 2.1 | 1.1 | 150 | 210 | 71940 | 7.1 | 212 | 268 | 2 | 1 | 4300 | 6000 |

| 220 | 300 | 38 | 2.1 | 1.1 | 200 | 250 | 71944 | 7.2 | 232 | 288 | 2 | 1 | 3800 | 5600 |

| 240 | 320 | 38 | 2.1 | 1.1 | 203 | 285 | 71948 | 8.37 | 252 | 308 | 2 | 1 | 3200 | 4800 |

| 260 | 360 | 46 | 2.1 | 1.1 | 242 | 345 | 71952 | 13.5 | 272 | 348 | 2 | 1 | 1300 | 1800 |

| 280 | 380 | 46 | 2.1 | 1.1 | 226 | 337 | 71956 | 15 | 292 | 368 | 2 | 1 | 1100 | 1600 |

| 320 | 440 | 56 | 3 | 1.1 | 350 | 550 | 71964 | 25.5 | 334 | 426 | 2.5 | 1 | 800 | 1000 |

| 340 | 460 | 56 | 3 | 1.1 | 292 | 510 | 71968 | 27.5 | 354 | 446 | 2.5 | 1 | 800 | 1000 |

| 360 | 480 | 56 | 3 | 1.1 | 350 | 600 | 71972 | 29 | 800 | 1000 | ||||

| 380 | 520 | 65 | 4 | 1.5 | 369 | 661.5 | 71976 | 40.5 | 395 | 505 | 3 | 1 | 850 | 1200 |

| 400 | 540 | 65 | 4 | 1.5 | 380.7 | 702 | 71980 | 42 | 415 | 525 | 3 | 1 | 800 | 1100 |

| Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

| mm | kN | kg | mm | r/min | ||||||||||

| d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | Ta1 | Grease | Oil | ||

| 420 | 560 | 65 | 4 | 1.5 | 327 | 603 | 71984 | 44.5 | 435 | 545 | 3 | 1 | 700 | 950 |

| 440 | 600 | 74 | 4 | 3 | 456.3 | 936 | 71988 | 61 | 455 | 585 | 3 | 1 | 750 | 1000 |

| 460 | 620 | 74 | 4 | 1.5 | 456 | 936 | 71992 | 58 | 475 | 605 | 3 | 1 | 750 | 900 |

| 530 | 670 | 78 | 5 | 2 | 498 | 1098 | 719/530 | 78 | 518 | 652 | 4 | 1 | 630 | 850 |

| 560 | 710 | 82 | 5 | 2 | 556 | 1206 | 719/560 | 92 | 558 | 692 | 4 | 1 | 1000 | 1500 |

| 600 | 750 | 85 | 5 | 2 | 533 | 1161 | 719/600 | 105 | 578 | 732 | 4 | 2 | 560 | 750 |

| 630 | 800 | 90 | 5 | 2 | 644 | 1557 | 719/630 | 125 | 618 | 782 | 4 | 2 | 900 | 1300 |

| 750 | 950 | 106 | 6 | 3 | 767 | 1980 | 719/750 | 195 | 733 | 927 | 5 | 2 | 800 | 1100 |

Over 30 years of industry experience, more than 50 invention patents, ISO9001/ISO14001 certifications, performance meeting international high standards

2.Four series including 618/619/718/719, complete precision levels, adapting to installation and operation requirements of equipment in multiple fields;

Professional team provides personalized solutions, tailored to working conditions and user needs, optimizing equipment efficiency and service life

4.Offers technical support, installation guidance and after-sales guarantee, stable supply and sufficient replacement parts;

5.Adapts to complex working conditions such as clean, high-speed, heavy-load and vibration, covering precision manufacturing and heavy industry fields.

1. Machine Tools

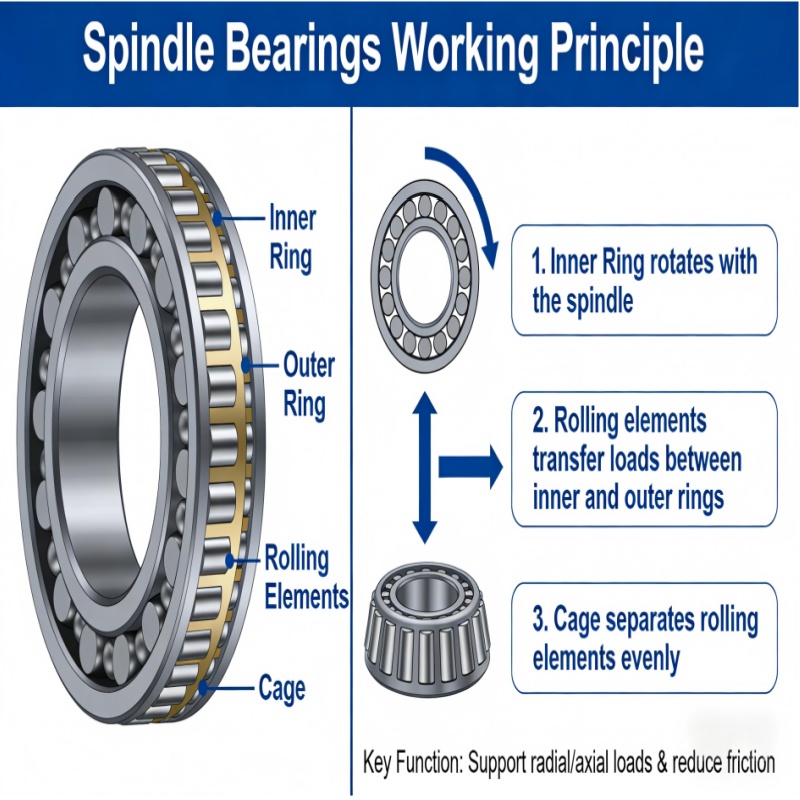

CNC Machines: Spindle bearings are critical in CNC (Computer Numerical Control) machines where high-speed rotation of the spindle is required to cut, mill, or drill materials with precision. These bearings ensure smooth and accurate rotation of the tool.

Lathe Machines: Spindle bearings are used in lathes to hold the rotating tool or workpiece with high precision.

Milling Machines: In milling operations, spindle bearings support the rotating tool, allowing for high-speed cutting with minimal vibration.

2. Electric Motors and Generators

High-Speed Motors: Spindle bearings are used in electric motors, especially in high-speed ones, such as in turbines, to ensure smooth rotation under varying loads and speeds.

Generators: Similarly, in generators, spindle bearings support the rotor, ensuring stable operation and high reliability.

3. Precision Instruments

Microscopes and Optical Instruments: Spindle bearings are used in microscopes and other optical devices, where high precision and minimal wobble are necessary for accurate imaging.

Measuring Equipment: They help maintain the precision of instruments that require rotation or movement with a high degree of accuracy, such as laser systems or measuring tables.

4. Automotive Applications

Automobile Engines: Spindle bearings are often found in engine components such as camshafts, crankshafts, and timing mechanisms where precise, high-speed rotation is required.

Electric Vehicle Motors: As electric vehicles become more common, spindle bearings play a role in the electric motor’s performance, supporting high-speed rotations without causing excess friction or heat.

5. Aerospace

Aircraft Engines: Spindle bearings are essential in aerospace applications, such as in jet engines, where high-speed rotation, low friction, and reliability are critical.

Gyroscopes and Inertial Systems: These bearings are used in gyroscopes, which are sensitive instruments used in navigation systems for aircraft and spacecraft.

6. Robotics and Automation

Robotic Arms: In industrial robots, spindle bearings are used in the joints and rotating parts of the arm, enabling precise movements and rotations with minimal wear and tear.

Conveyor Systems: Spindle bearings are used in the rotating parts of conveyor systems in factories to ensure smooth operation.

7. Dental and Medical Equipment

Dental Drills: High-speed dental drills rely on spindle bearings to rotate the tool at high RPMs without compromising precision and performance.

Surgical Instruments: In some surgical devices, particularly those requiring high-speed rotation or fine movement, spindle bearings are used to maintain accuracy.

8. Wind Turbines

Rotor Systems: In wind turbines, spindle bearings support the rotational movement of the rotor blades, ensuring efficient energy generation.

9. Spinning and Textile Machinery

Spinning Machines: Spindle bearings are widely used in textile manufacturing, particularly in spinning machines where spindles rotate at high speeds to twist and spin fibers into yarn.

Weaving Machines: They are also used in weaving machines to support the rotating components involved in weaving fabrics.

10. High-Speed Trains and Transportation

Railway Wheels: Spindle bearings are used in railway wheelsets to ensure smooth rotation and to handle the high stresses involved in high-speed train travel.

Turbines in High-Speed Transportation: They can also be found in certain types of high-speed transportation systems, like maglev trains, where rotating parts need to operate at high speeds.

NewBee Machinery provides high quality shaft, bearing, gears, CNC machines and other customized mining machinery.

NewBee Machinery has 20 years’ experience in customize machinery parts.

Professional and effective research and design team

We have advanced large CNC centner and processing equipment.

NewBee Machinery provides cost effective products for global customers.

If you are looking for customized machinery parts, precision bearings or CNC Machinery, feel free to contact us and our team will reply within 48 hours.